1

Table of Contents

ABOUT THIS MANUAL ................................................................................................... 1

Purpose..........................................................................................................................................1

SAFETY INSTRUCTIONS .............................................................................................. 1

INTRODUCTION ........................................................................................................... 3

Features.........................................................................................................................................3

Basic System Architecture............................................................................................................3

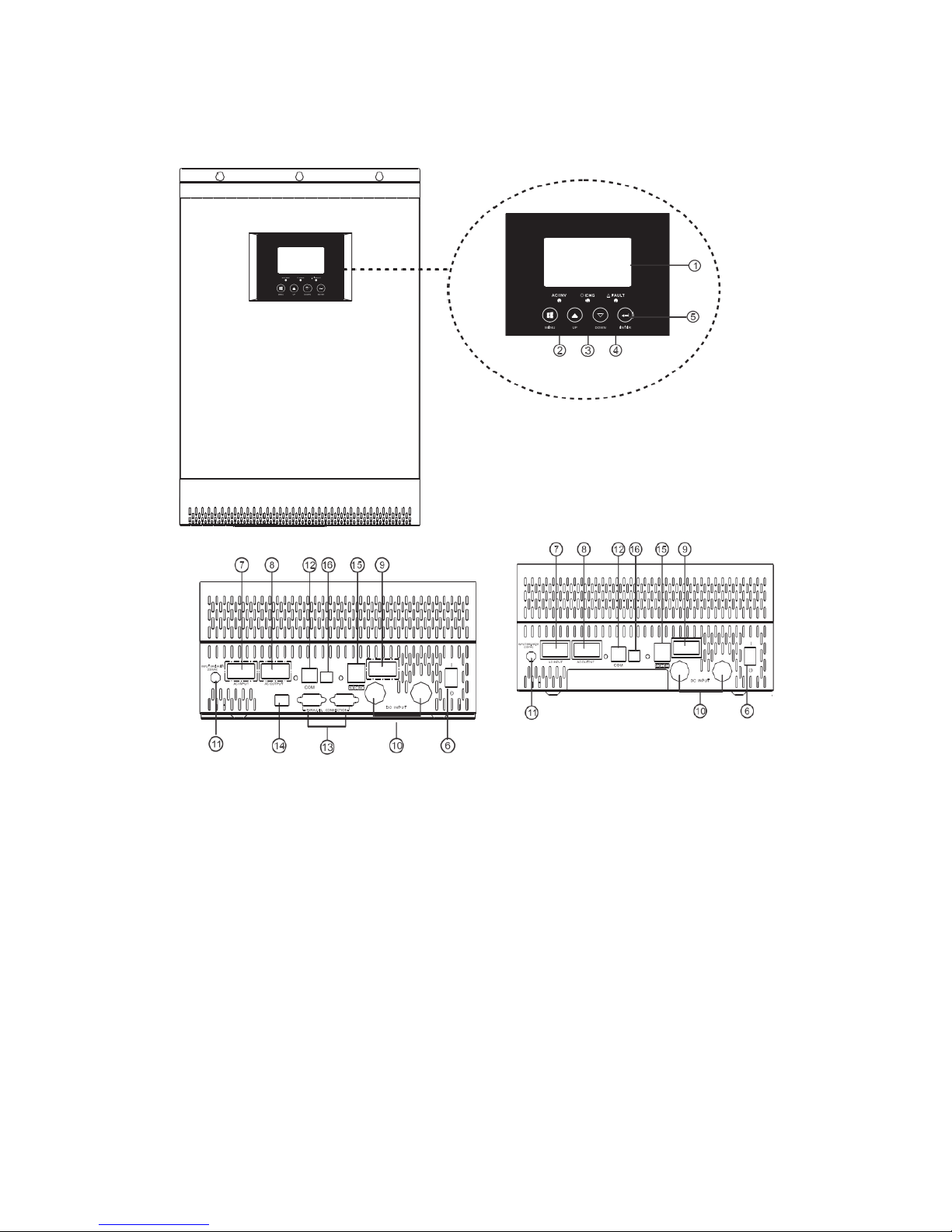

Product Overview .........................................................................................................................4

INSTALLATION ............................................................................................................ 5

Unpacking and Inspection.............................................................................................................5

Preparation....................................................................................................................................5

Mounting the Unit.........................................................................................................................5

Battery Connection .......................................................................................................................6

AC Input/ Output Connection.......................................................................................................8

PV Connection............................................................................................................................10

Communication Connection .......................................................................................................11

Dry Contact Signal......................................................................................................................11

Connecting the CAN Cable ........................................................................................................11

OPERATION ................................................................................................................ 12

Power ON/OFF...........................................................................................................................12

Operation and Display Panel ......................................................................................................12

LCD Display Icons .....................................................................................................................13

LCD Setting................................................................................................................................15

Fault Reference Code..................................................................................................................20

Warning Indicator.......................................................................................................................22

Operating Mode Description.......................................................................................................23

Display Setting............................................................................................................................25

SPECIFICATIONS .....................................................................................................................26

Table 1 Line Mode Specifications..............................................................................................26

Table 2 Inverter Mode Specifications.........................................................................................27

Table 3 Charge Mode Specifications..........................................................................................28

Table 4 General Specifications...................................................................................................29

TROUBLE SHOOTING ................................................................................................. 29

Appendix: Approximate Back-up Time Table .......................................................... 30