Contents

I. EPNC Installation ................................................................................................................................................5

Program Installation...........................................................................................................................................5

II. Description of EPNC .........................................................................................................................................6

2.1 Initialization window ...................................................................................................................................6

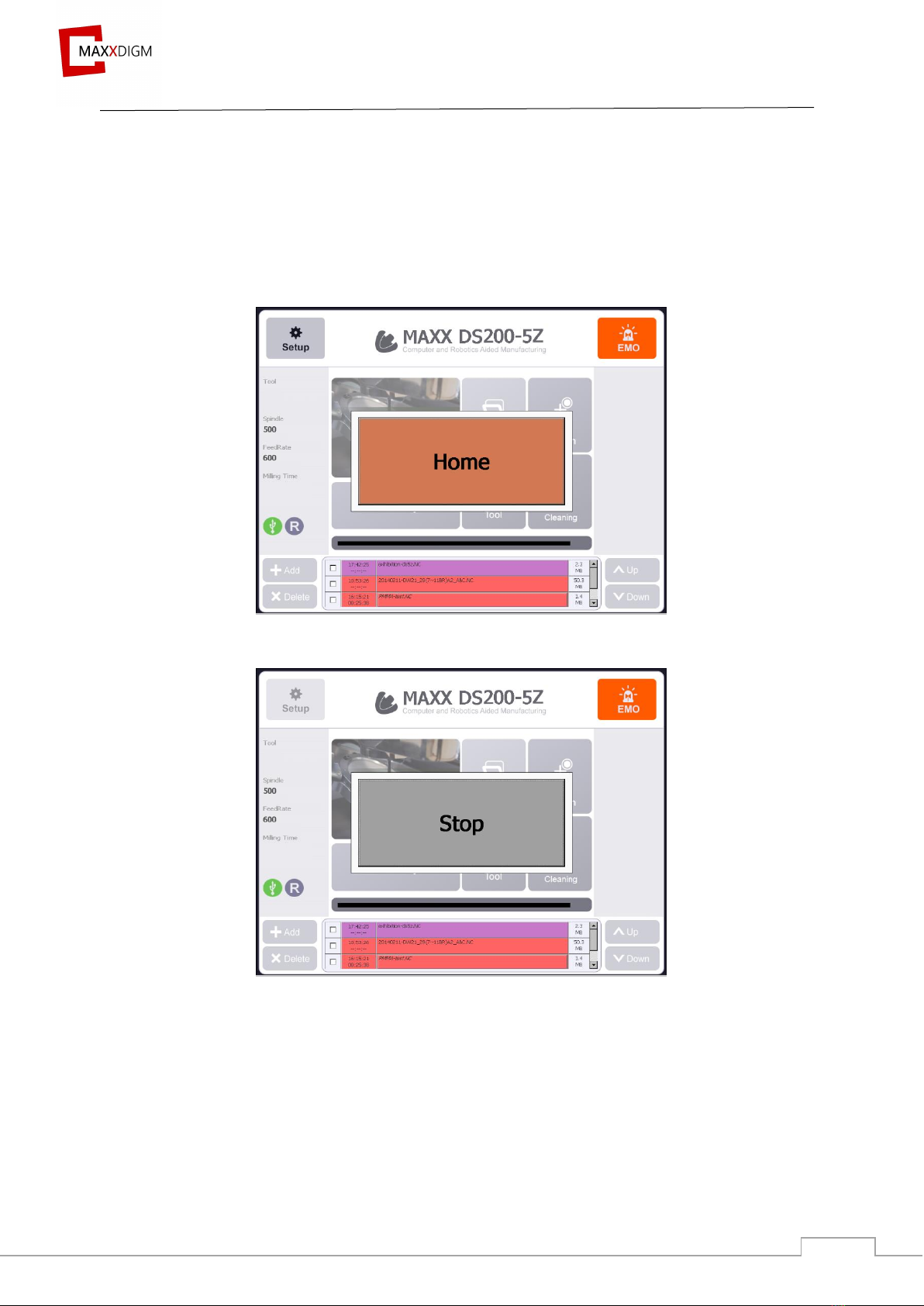

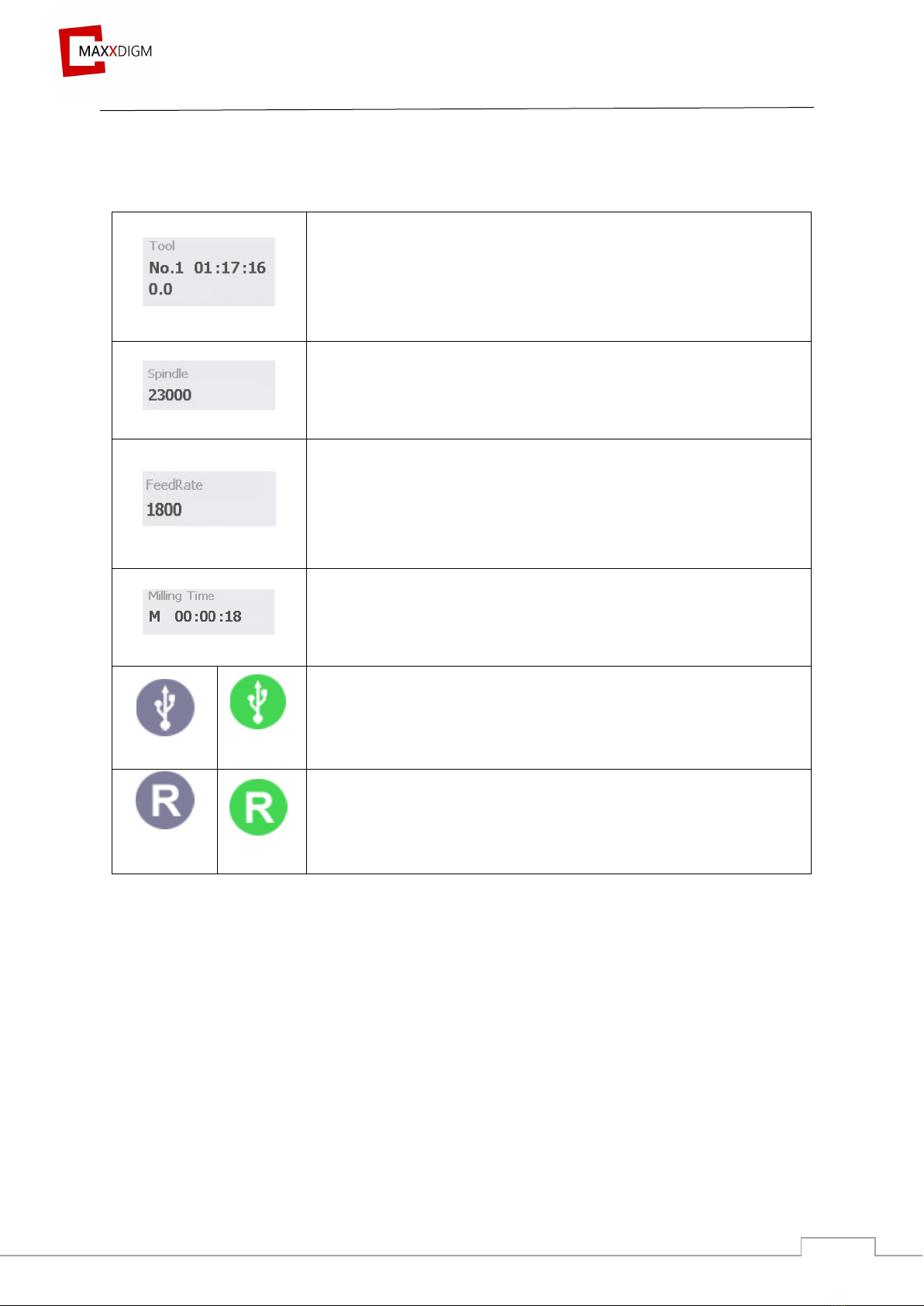

2.2 Main window..................................................................................................................................................7

2.2.1 Functions of main window.................................................................................................................7

2.3 Setup............................................................................................................................................................... 14

2.3.1 Entering setup..................................................................................................................................... 14

2.3.3 Tool......................................................................................................................................................... 23

2.3.4 Term....................................................................................................................................................... 25

2.3.5 Option.................................................................................................................................................... 26

2.3.6 I/O ........................................................................................................................................................... 28

2.3.7 Log .......................................................................................................................................................... 29

2.3.8 System.................................................................................................................................................... 30

III. Milling................................................................................................................................................................ 31

3.1 Machine power............................................................................................................................................ 31

3.2 Milling preparation................................................................................................................................... 31

3.2.1 Mounting workpiece ......................................................................................................................... 31

3.2.2 Tool......................................................................................................................................................... 35

3.2.3 NC file.................................................................................................................................................... 41

3.2.4 Maxxlink............................................................................................................................................... 41

IV. Maintenance..................................................................................................................................................... 45

4.1 Maintenance precautions......................................................................................................................... 45

4.2 Daily maintenance...................................................................................................................................... 45

4.2.1 Cleaning ................................................................................................................................................ 45

4.2.2 Dummy tool.......................................................................................................................................... 46