USE OF ACCESSORIES

Remove the required accessories from the accessory

compartment.

FITTING THE ACCESSORIES

Your inflator is supplied with the standard tapered nozzles and

the needle inflator nozzle, these are located on the bottom of

the unit.

• To use the universal valve adaptor, make sure that the lever

is in the up position.

• Place the valve adapter over the stem of the inflation needle

or tapered nozzle.

• Press the lever on the valve adapter down to lock it in place.

• Place the inflation needle or tapered nozzle into the item to

be inflated.

POWER THE LCD DISPLAY

WARNING: Do not operate the inflator when the car

engine is running.

Note: Make sure that your 12 Volt accessory socket is live. On

some vehicles the accessory socket may only become live

when the ignition key is in the accessory position.

To power the display from the 12Vdc adapter, just plug the 12

Vdc vehicle connector⑨into the vehicle 12V accessory socket

QUICK START

WARNING: Never leave inflator running unattended in

this mode. In can burst car tyres and other items.

To use your inflator immediately you can do so without setting

the automatic shut-off feature.

•Before use, check the manufacturers recommended tyre

pressures for the vehicle.

•Plug the 12Vdc vehicle connector into the vehicle accessory

socket. The LCD will be powered.

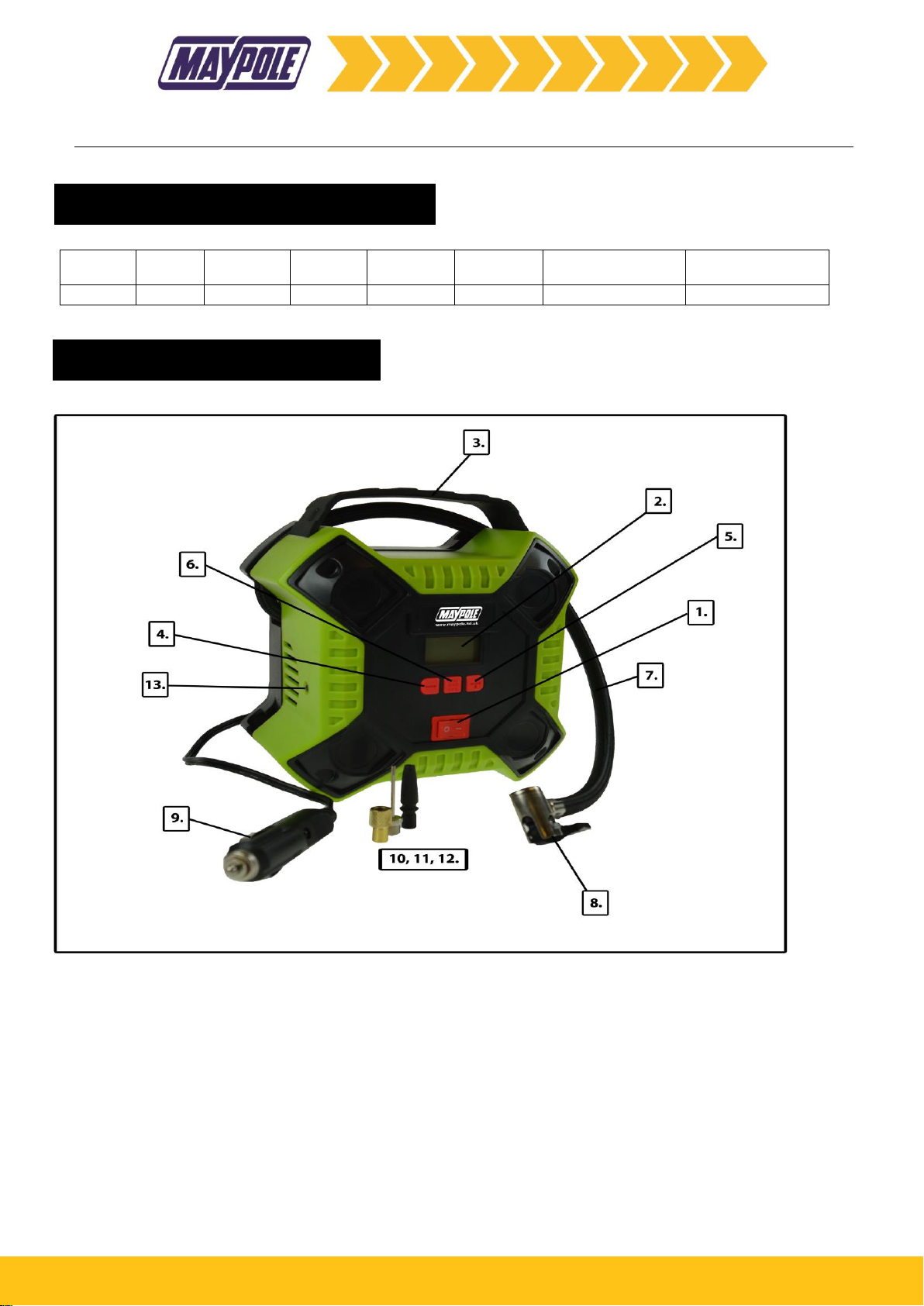

• To switch between the different units (PSI, BAR or KPA) press

the unit shift button (6) until the required units are displayed.

• Connect the quick coupler (8) and an accessory, if required,

to the item to be inflated, making sure that the lever of the

coupler is in the down position to lock it in place.

Note: Make sure that the Quick Coupler is correctly fitted

to the item to be inflated.

• To start the inflator press the main switch (1) to the on

position.

• When the item is inflated as required or to stop the

inflator at any time press the main switch (1) to the off

position.

SETTING THE AUTOMATIC SHUT-OFF PRESSURE

Note: The LCD will only show inflation pressures when

the inflator is being used.

• To switch between the different units (psi, bar or kPa),

press the unit shift button (6) until the required units are

displayed.

• Press and hold either buttons - & + (4, 5) for 3 seconds,

the value will increase or decrease until get the reqired

value.

• After 3 seconds the display will flash and return to a

reading of "0.0". This is normal.

• Connect the Quick Coupler (8) and accessories, if

required, to the item to be inflated, making sure that the

lever of the quick coupler is in the down position to lock

it in place.

• To start the inflator press the main switch (1) to the on

position.

• When the item to be inflated has reached the preset

value the unit will automatically turn off.

Note: You may notice the actual pressure reading may

drop after a couple of seconds, this is normal.

• To stop the inflator at any time press the main switch

(1) to the off position.

• Remove the quick coupler and/or accessory from the

inflated item and the 12 Volt connector (9) from your

vehicle's 12 Volt accessory socket.

Note: If the main power switch is turned off, all settings

will be lost and will need to be re-entered following the

instructions under the heading 'Setting the automatic

shut-off pressure'. This is a safety feature to prevent the

risk of items OVER INFLATING.

USING THE INFLATOR AS A PRESSURE GAUGE

• Plug the 12Vdc vehicle connector into the vehicle

accessory socket. The LCD will be powered.

• Connect the quick coupler (8) to the item to be

checked.

• The LCD will display the items pressure.

• After checking, return the air hose to the storage

location.