MAYTONI TRX001-111B User manual

www.maytoni.demaytoni technical

SINGLEPHASE TRACK

SYSTEM

UNITY

www.maytoni.demaytoni technical

SINGLEPHASE LIGHTING

TRACK SYSTEM

The track is the basis for the construction of track lighting systems and is intended

for installation and supply of power lines to track lighting fixtures in AC networks

with a rated voltage of 230V and a frequency of 50Hz. The track may be used

indoors only in the absence of an aggressive environment and foreign aerosol

particles at a temperature from 0 °C to +50 °C and a max. relative humidity of

80%. Options may be installed on walls and ceilings, in grooves, in specially

prepared recesses made of normally flammable materials. There is also another

installation option using rope suspensions. The track is supplied in segments with

a length of 1 and 2 meters. It is allowed to cut off segments and build structures of

various shapes using connectors.

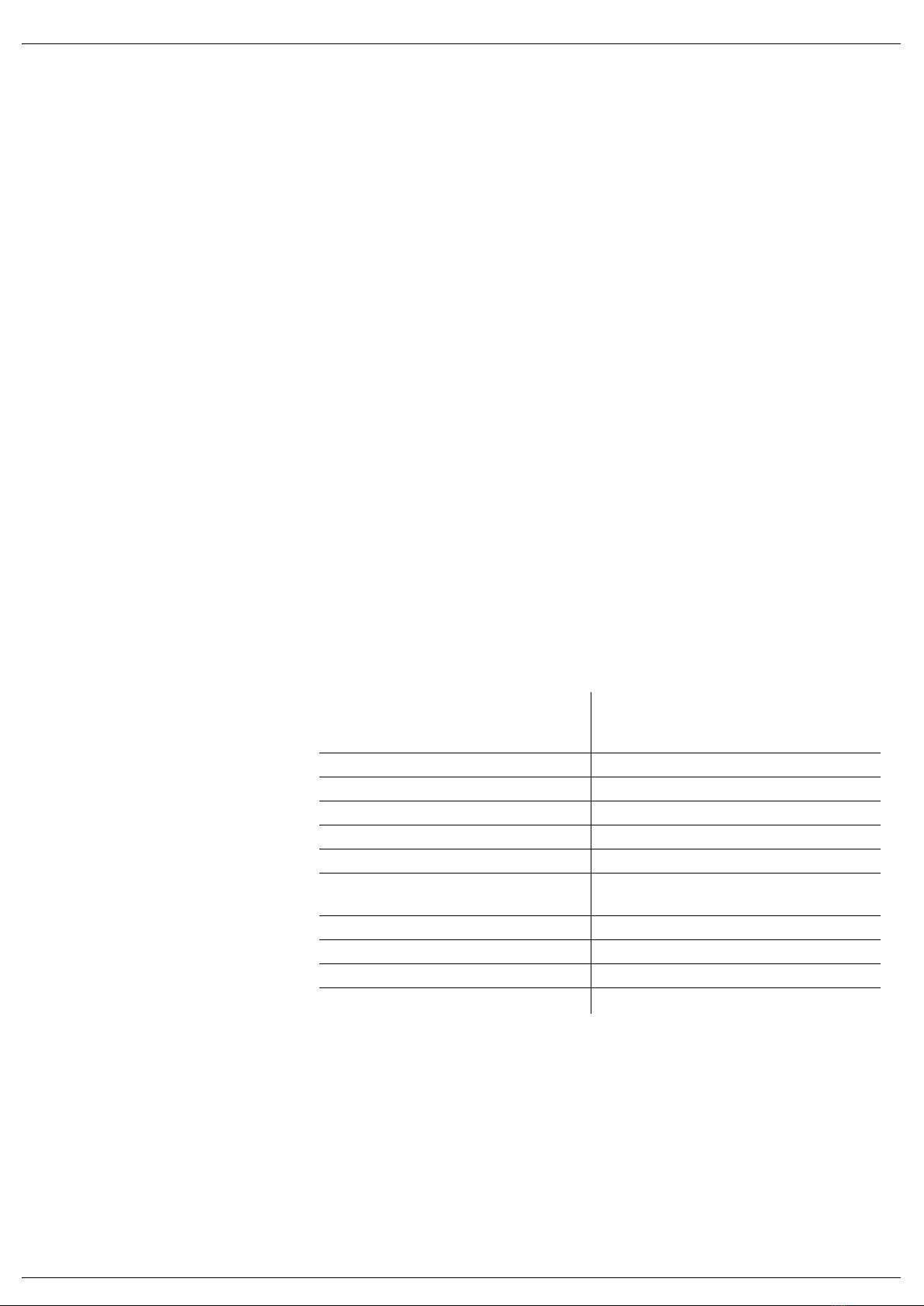

Article

Supply voltage and frequency ~230V 50Hz

Electrical shock protection class III

Mounting method Surface-mounted/suspended/built-in

Ingress Protection Code IP20

Climatic version

Operating temperature 0° - +50°

Material Aluminium

Colour Black

Track length 1m 2m

TECHNICAL DATA

Boreal climate()

Rated current

TRX00B

TRX00W

TRX00B

TRX00W

TRX00B

TRX00W

TRX00B

TRX00W

0A

www.maytoni.demaytoni technical

1

7

2

8

3

9

654

9

5

2

10

6

7

4

8

1

3

track

TRX001 -111B

TRX001 -111W

TRX001 -112B

TRX001 -112W

power input

TRA00BB

TRA00BW

straight connector

TRA00CB

TRA00CW

L-shaped

connector

TRA00CLB

TRA00CLW

flexible connector

TRA00CFB

TRA00CFW

plug

TRA00ECB

TRA00ECW

T-shaped connector

TRA00CTB

TRA00CTW

X-shaped connector

TRA00CXB

TRA00CXW

cable suspension

TRA00CWB

TRA00CWW

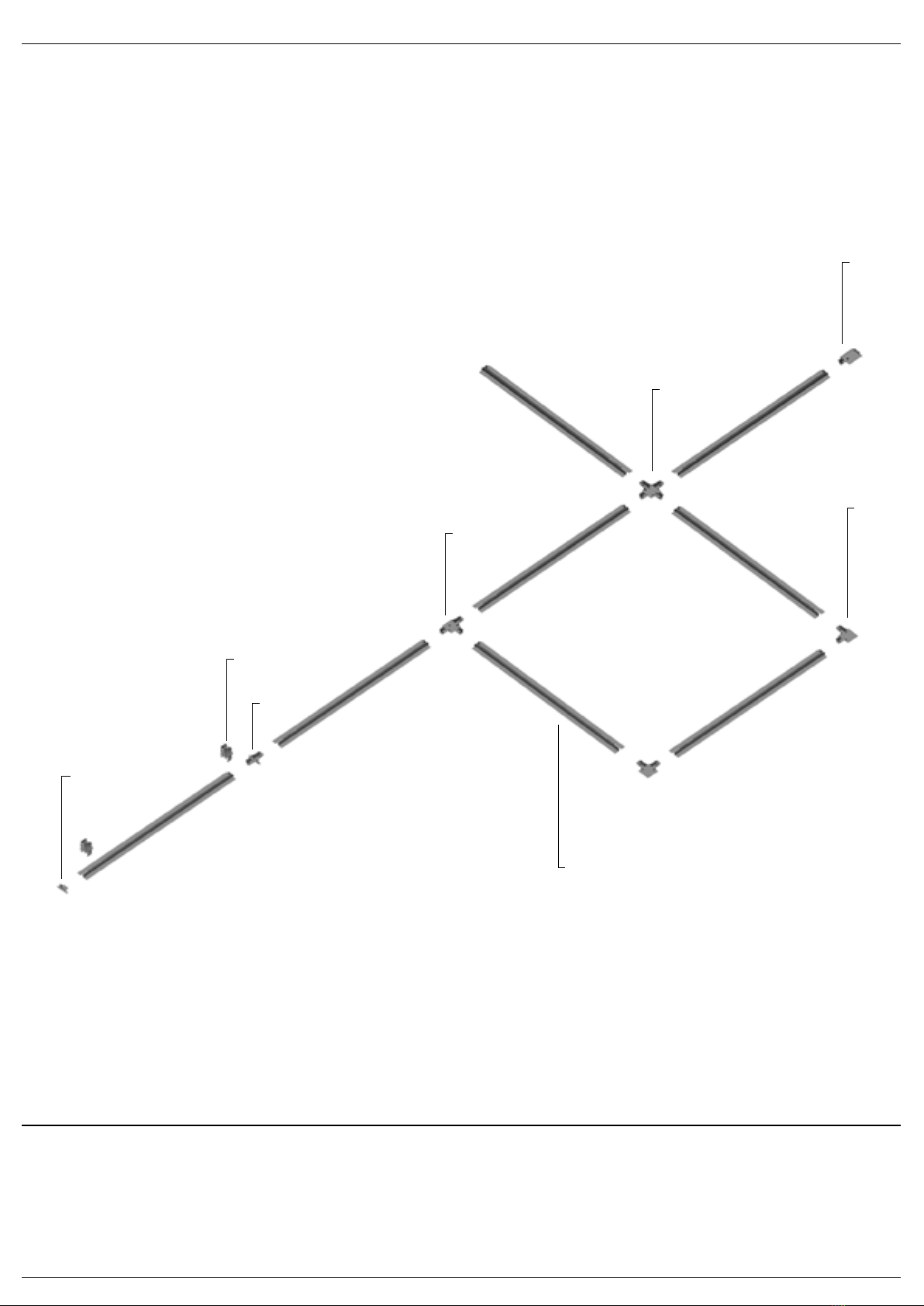

SINGLEPHASE UNITY

TRACK SYSTEM

DIAGRAM OF SURFACE AND SUSPENDED MOUNTING

SINGLE-PHASE TRACK SYSTEM

www.maytoni.demaytoni technical

single-phase track

20 × 33 × 1000 mm

TRX001-111B

TRX001-111W

single-phase track

20 × 33 × 2000 mm

TRX001-112B

TRX001-112W

single-phase

track/track adapter

17,5 x 100 x 100

mm

TRA010-1-BS-B

TRA010-1-BS-W

power input

TRA00BB

TRA00BW

straight

connector

TRA00CB

TRA00CW

plug

TRA00ECB

TRA00ECW

flexible

connector

TRA00CFB

TRA00CFW

Lshaped

connector

TRA00CLB

TRA00CLW

Tshaped

connector

TRA00CTB

TRA00CTW

Xshaped

connector

TRA00CXB

TRA00CXW

cable suspension

TRA00CWB

TRA00CWW

connectors for pendant mounting

of lamps in a track

TRA011-1-A-B

TRA011-1-A-W

ELEMENTS OF A SINGLEPHASE TRACK

SYSTEM UNITY FOR SURFACE AND

SUSPENDED MOUNTING

SURFACE AND SUSPENDED MOUNTING SINGLE-PHASE TRACK

ACCESSORIES FOR SURFACE AND SUSPENDED MOUNTING SINGLE-PHASE TRACK

www.maytoni.demaytoni technical

T-shaped connector

R2CT-11

R2T-11W

track

TRX004 -111B

TRX004 -111W

TRX004 -112B

TRX004 -112W

spring holder

TRA002HR-11B

1 2 3 4 5 6

7 8

5

1

3

6

4

2

8

7

SINGLEPHASE UNITY

TRACK SYSTEM

DIAGRAM OF BUILT-IN

SINGLE-PHASE TRACK

power input

TRA00BB

TRA00BW

straight connector

TRA00CB

TRA00CW

L-shaped connector

TRA00CLB

TRA00CLW

plug

TRA00ECB

TRA00ECW

X-shaped

connector

TRA00CXB

TRA00CXW

www.maytoni.demaytoni technical

single-phase track

20 × 60 × 1000 mm

TRX004-111B

TRX004-111W

single-phase track

20 × 60 × 2000 mm

TRX004-112B

TRX004-112W

SINGLEPHASE UNITY

TRACK SYSTEM

BUILTIN MOUNTING SINGLEPHASE TRACK

ACCESSORIES FOR BUILT-IN MOUNTING SINGLE-PHASE TRACK

X-shaped connector

20 × 130 × 130 mm

R002CX-11

R002X-11W

spring holder

37 45 32 mm

TRA002HR-11B

sealing plug

20 × 60 × 37 mm

TRA002EC-11B

TRA002EC-11W

power input

TRA00BB

TRA00BW

straight

connector

TRA00CB

TRA00CW

Lshaped connector

TRA00CLB

TRA00CLW

Tshaped connector

RCT

RTW

connectors for suspended mounting

of lamps in a track

TRA0AB

TRA0AW

www.maytoni.demaytoni technical

GENERAL RECOMMENDATIONS AND

PRECAUTIONS

All installation and mounting services must be rendered by persons having

the appropriate permits and qualifications. Please contact a qualified

electrician, where necessary.

All installation and dismantling work should be performed in a powered

down state only.

The track may not be used without a protective grounding wire.

When building a tracking system, make sure not to exceed the total load of

electric consumers of 10A (total power of lighting fixtures is not more than

2300 W).

Do not install the track at a height below 2.5 meters, or in places where

people may accidentally touch the track.

Do not use the product with a damaged housing and damaged insulation of

the supply cable.

The product is intended for indoor use only.

Do not use the product in rooms with high humidity and with a high content

of dust or aerosol particles in the air.

Make sure to install lighting fixtures on a 1m track segment with a spacing

of no more than 25 cm.

Use a soft, dry cloth to clean the product with the power switched off. Do

not use chemically aggressive cleaning agents.

!

www.maytoni.demaytoni technical

GENERAL RECOMMENDATIONS AND

PRECAUTIONS

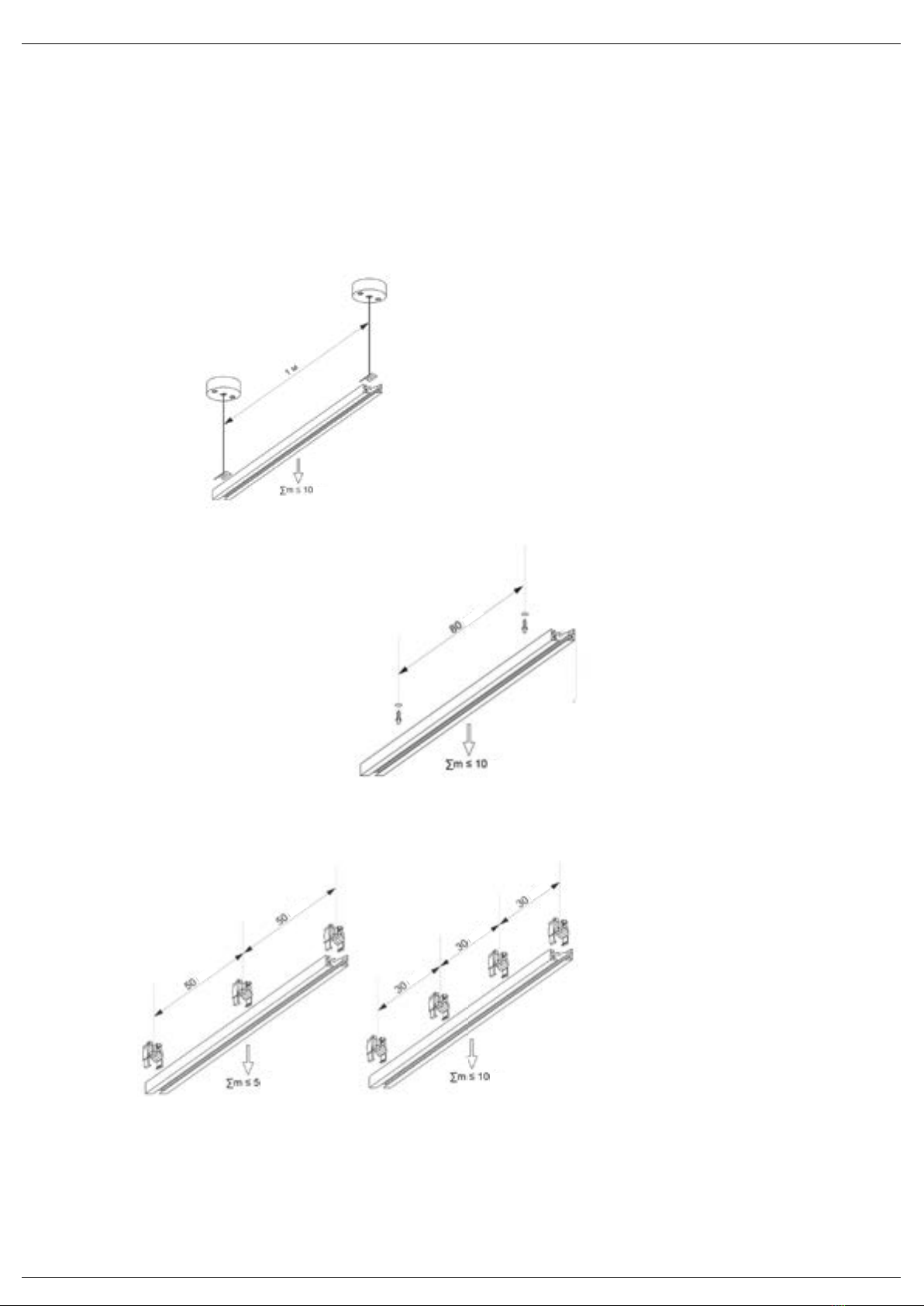

PERMISSIBLE LOADS AND POSITIONS

OF FASTENING ELEMENTS

The max. distance between suspension mounts is

1 m. The recommended distance between lamps

is 25 cm. The maximum permissible load on the

surface-mounted track installed using suspension

fasteners is 10 kg per 1 meter.

The max. distance between fasteners to

the surface is 80 cm. The recommended

distance between lamps is 25 cm.

The maximum permissible load on the

surface-mounted track installed on

a rough surface is 10 kg per 1 meter.

In order to create closed continuous

contours, please use TRA001CF-11

and arrange power input through them.

The distance between the holders is

selected based on the weight of installed

lamps. The lamp weight at 1 meter ≤ 5 kg

- the distance between holders is 50 cm.

The lamp weight at 1 meter ≤ 10 kg — the

distance between holders is 30 cm. The

recommended distance between lamps

is 25 cm. The max. permissible load on

the built-in track installed using holders is

10 kg per 1 meter.

SURFACE MOUNTING

BUILT-IN INSTALLATION

USING SPRING HOLDERS

kg

cm

cm cm

cm

cm

cm

kg

kg kg

kg

SUSPENDED MOUNTING

www.maytoni.demaytoni technical

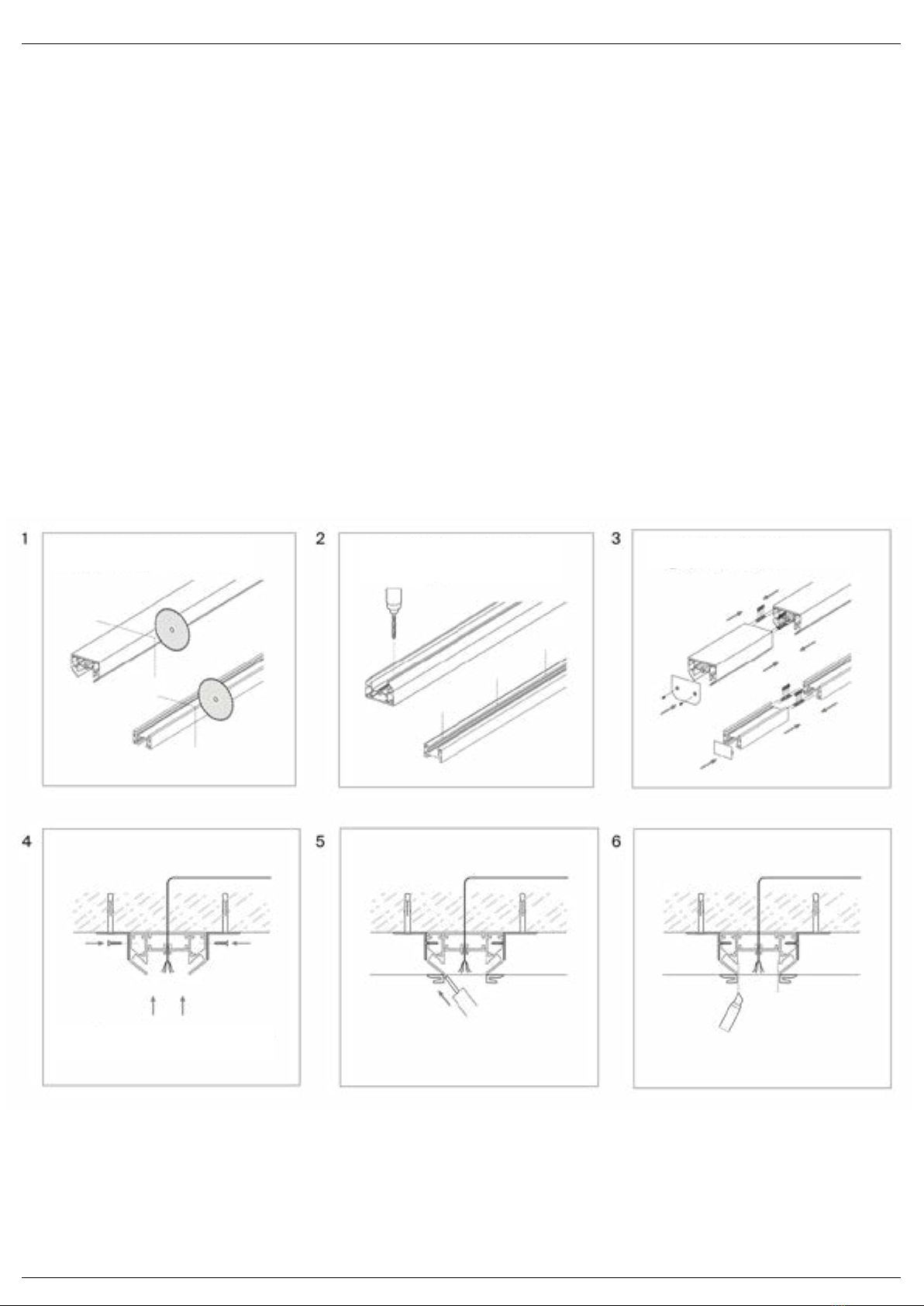

CONNECTION OF A SINGLEPHASE

TRACK TO POWER SUPPLY

1. Before connecting the track, make sure to de-energize the supply cable. Remove the track from the

packaging, make sure that the housing and current-carrying parts are not damaged. Disconnect the power

lead-in from the track.

2. Remove the screw on the front side of the power lead-in using a screwdriver and remove the plastic cover.

3. Lay the three-core cable to the track installation site. Connect the protective ground wire to the yellow-green

wire on the power lead-in housing. Pull the phase and neutral wires through the hole in the back side of the

power lead-in.

4. Fasten the phase and neutral conductors on the contact plates using clamping screws.

5. Close the power lead-in by taking steps stated in clause 2 in a reverse order.

6. Insert the connected power lead-in into the track. Install the track in the most relevant way.

A single-phase track of all types is connected to a 230V 50Hz AC mains through a power lead-in. The relevant

end power lead-in is included with delivery of each track segment.

1

4

2

5

3

6

www.maytoni.demaytoni technical

INSTALLATION PLAN FOR SURFACE

MOUNTED SINGLEPHASE TRACK

CAUTION

Do not tighten the screws at high screwdriver speed and do not tighten until it stops to avoid deformation of the track.

The rules for installation of fasteners are given in the section "General recommendations and precautions".

34.00

34.00

19.50

TRACK INSTALLED ON

A CONCRETE CEILING

TRACK INSTALLED ON A GYPSUM

BOARD CEILING

19.50

The surface-mounted single-phase track may be installed on any hard surface made

of normally flammable materials. During the installation, carefully prepare and correctly

mark the mounting surface to avoid bending moments that may cause deformation of

the track.

When installing the surface-mounted track, select the appropriate fasteners based on

the material of the mounting surface.

www.maytoni.demaytoni technical

INSTALLATION PLAN FOR SURFACE

MOUNTED SINGLEPHASE TRACK IN

SUSPENDED WAY

The surface-mounted single-phase track can be installed in a suspended way

on a concrete ceiling and plasterboard suspended ceiling as well as other types

of ceiling provided that necessary embedded parts are available and sufficient

firmness of construction materials is secured.

When suspending the surface-mounted track, select fasteners that suit to the

ceiling material.

For the suspended mounting of the track, use special suspension kits

TRA001CW-11B/TRA001CW-11W, consisting of a rope with an end locking element

to adjust its length, the bracket and ceiling bowl.

1. Unpack the track and visually check for possible defects.

2. Mark the installation locations and prepare the mounting brackets for their

subsequent fixation on the track.

3. Fix the ceiling bowl on the ceiling.

4. Insert the rope into the collet on the mounting bracket and adjust the length.

5. Cut off the unnecessary part of the rope.

6. Fix the bracket on the track with the screws located on top.

7. Use the carpenter level to check the levelness, if necessary, adjust the length

of the ropes.

CAUTION

When mounting several connected track segments in a suspended way, place them strictly horizontally, avoid skewness and

uneven tension of ropes.

prepare the mounting surface

mark and drill the holes

insert the dowels into the holes

attach the ceiling bowl

fix it with screws

adjust the installation height

using the collet fixtures

push the plate into the groove on

the back side of the track

fix the plate with screws

INSTALLATION OF SUSPENDED

MOUNTED SINGLE-PHASE TRACK

USING A SUSPENSION MOUNT

www.maytoni.demaytoni technical

INSTALLATION DIAGRAM FOR SURFACE

MOUNTED SINGLEPHASE TRACK WITH A

PROFILE FOR STRETCHED CEILING

In order to implement this option, you need to purchase the profile not in the assortment,

sold separately in addition to the surface-mounted track and perform installation as

follows:

1. Cut the profile and track in the required length.

2. Drill the mounting holes and cable entry holes.

3. Assemble all parts of the profile and track if required, and insert the plugs.

4. Fix the profile to the surface using the mounting angles.

5. Stretch the ceiling cloth and glue the edges of the harpoons along the entire profile

length.

6. Leave a slot between the harpoons.

INSTALLATION OF SURFACE-

MOUNTED SINGLE-PHASE TRACK

WITH A PROFILE FOR STRETCHED

CEILING

CAUTION

Installation of track with this profile is only possible using PVC cloths for a stretched ceiling.

maytoni technical www.maytoni.ru

СХЕМА УСТАНОВКИ НАКЛАДНОГО

ОДНОФАЗНОГО ШИНОПРОВОДА

С ПРОФИЛЕМ ДЛЯ НАТЯЖНОГО

ПОТОЛКА

Для осуществления данного варианта в дополнение к накладному шинопроводу

приобретается профиль TRA004MP-21S и монтаж проводится следующим

образом:

1. Нарежьте профиль и шинопровод необходимой длины.

2. Просверлите монтажные отверстия и отверстия для ввода кабеля.

3. Соберите все части профиля и шинопровода если это требуется,

4. установите заглушки.

5. Заркепитепрофиль на поверхности спомощью монтажныхуголков.

6. Натяните полотнопотолкаи проклейте краягарпунов по всей длине

7. профиля.

МОНТАЖ НАКЛАДНОГО

ОДНОФАЗНОГО ШИНОПРОВОДА

С ИСПОЛЬЗОВАНИЕМ ПРОФИЛЯ

ДЛЯ НАТЯЖНОГО ПОТОЛКА

ВНИМАНИЕ!

Монтаж шинопровода с использованием данного профиля возможно только с применением ПВХ полотен

для натяжного потолка.

www.maytoni.demaytoni technical

7. Put the harpoons into the profile grooves and glue the end faces.

8. Install the track and fix it inside the profile.

9. The track is ready for operation and installation of lamps on it.

maytoni technical www.maytoni.ru

СХЕМА УСТАНОВКИ НАКЛАДНОГО

ОДНОФАЗНОГО ШИНОПРОВОДА

С ПРОФИЛЕМ ДЛЯ НАТЯЖНОГО

ПОТОЛКА

МОНТАЖ НАКЛАДНОГО

ОДНОФАЗНОГО ШИНОПРОВОДА

С ИСПОЛЬЗОВАНИЕМ ПРОФИЛЯ

ДЛЯ НАТЯЖНОГО ПОТОЛКА

8. Сделайте прорезь между гарпунами.

9. Заправьте гарпуны в пазы профиля и проклейте торцы.

10. Установите шинопровод и закрепите его в профиле.

11. Шинопровод готов к эксплуатации и монтажу светильников на нем.

INSTALLATION DIAGRAM FOR SURFACE

MOUNTED SINGLEPHASE TRACK WITH A

PROFILE FOR STRETCHED CEILING

INSTALLATION OF SURFACE-

MOUNTED SINGLE-PHASE TRACK

WITH A PROFILE FOR STRETCHED

CEILING

www.maytoni.demaytoni technical

CAUTION

If you wish to install a built-in track in the gypsum board ceiling, use an additional accessory — holder TRA002HR-11B. The rules

for installation of fasteners are given in the section "General recommendations and precautions".

The built-in single-phase track may be installed in a groove or a specially prepared

recess and in a suspended ceiling made of gypsum boards.

When installing a built-in track, select fasteners with due regard for the ceiling

design.

TRACK INSTALLED IN A GROOVE OR

RECESS

TRUCK INSTALLED IN A GYPSUM

BOARD CEILING

INSTALLATION DIAGRAM FOR BUILTIN

SINGLEPHASE TRACK

60.00

60.00

34.00

40.00

34.00

40.00

1.00

19.00

19.00

www.maytoni.demaytoni technical

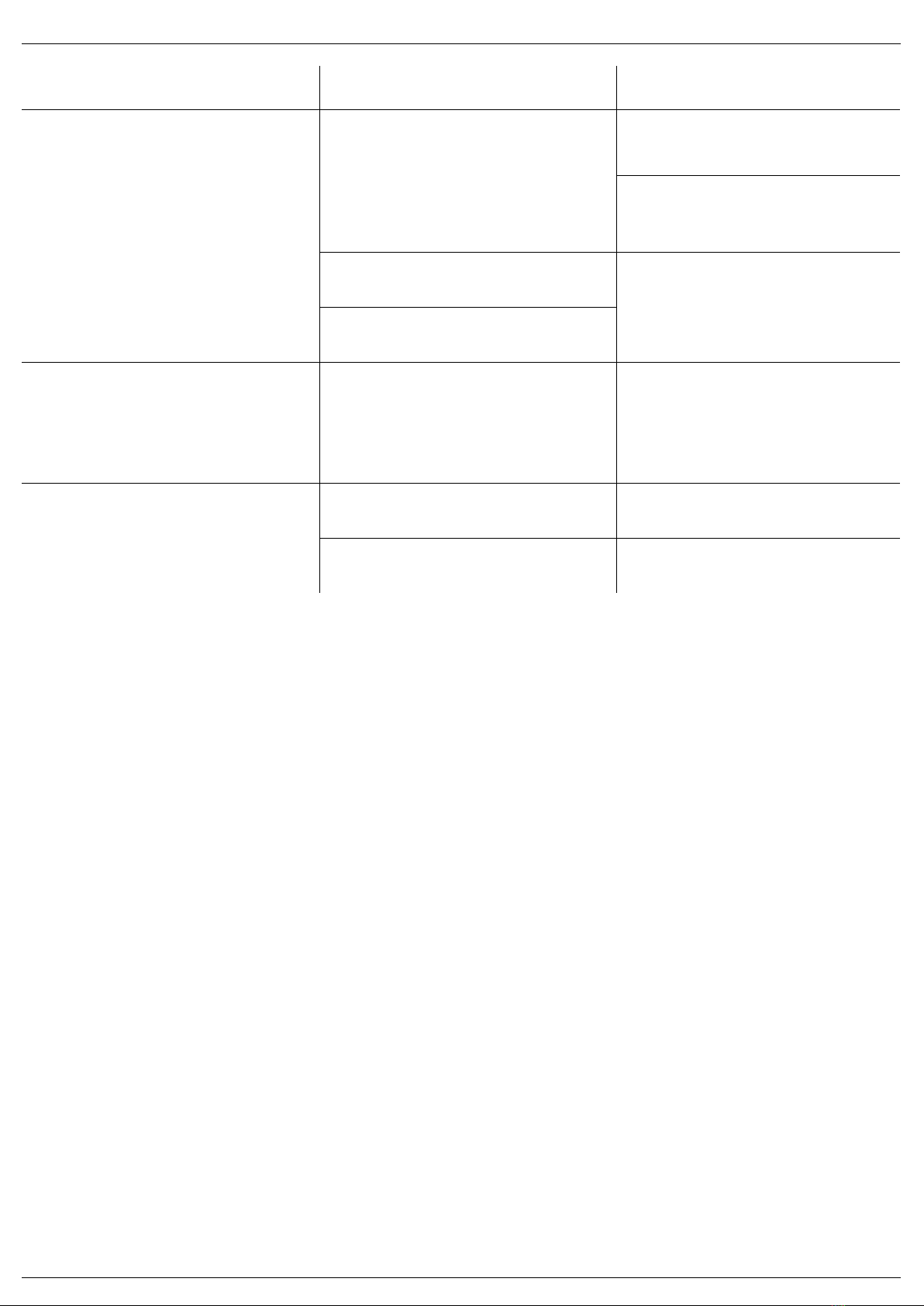

Fault description Cause Remedy

The lighting fixture does not operate Loose connection of current-carrying

parts

Install the lighting fixture on the track

until full contact between the adapter

and current-carrying wires is reached

Check the contacts of the lead-in

cable, connection of the lead-in

contacts to the track, and other

connections.

Contact the seller

to replace it under a warranty

Contact the seller for a warranty

replacement

Malfunction of lighting fixture

The lighting fixture flashes or glows

dimly in switched-off state

A switch with illuminated keys is

installed, or a motion (light) sensor is

used to control the lighting circuit

Replace the switch with a model

without backlit keys, or with auxiliary

incorporated resistor. Use the motion

(light) sensor with a relay output only

Unstable glowing, flickering, unusual

sound

Brightness control (dimmer switch) is

installed in the power supply circuit

Remove the brightness control from

the circuit, replace it with a switch

Defective power supply source / lamp

driver

Contact the seller for a warranty

maintenance or replacement

Store the product indoors, in the original packaging in a place protected from

aggressive environment. Store at a temperature in the range from -20 °C to +70°

C and relative humidity not exceeding 95%. Direct exposure to moisture is not

allowed.

The product is shipped in a package which is suitable for transportation by sea,

rail, road and air.

STORAGE

TRANSPORTATION

DISPOSAL Do not dispose the product with the regular household waste!

Products must be disposed according to the directive on electrical and

electronic devices at local collection points for such

devices!

www.maytoni.demaytoni technical

WARRANTY

Maytoni GmbH, Feldstiege 98, Münster, Germany, 48161

Maytoni GmbH, Feldstiege 98, Münster, Germany, 48161

Developed in Germany.

Made in China.

Shelf life is not limited.

MANUFACTURER

IMPORTER

The warranty is granted for a period of 24 months from the date of sale which is

determined on the basis of documents serving as proof of purchase.

This warranty covers defects in workmanship provided that all rules of operation,

transportation and storage given in this manual are complied with.

The warranty is not valid in following cases: if the product has been used for

the purposes other than it is intended for; the malfunction occurred after the

handover of goods to the consumer and was caused by improper or negligent

handling, failure to observe the requirements set forth in these instructions. And

in force majeure circumstances as well, in particular in the following events: fire,

flood, high-voltage discharges, and other natural disasters, accidents and wilful

acts of third parties that caused the product to malfunction.

This manual suits for next models

7

Table of contents