Contents

1. Rules and general warnings ................................................................................ 4

1.1 Introduction....................................................................................................... 4

1.2 Terms of the warranty....................................................................................... 5

1.3 Service.............................................................................................................. 5

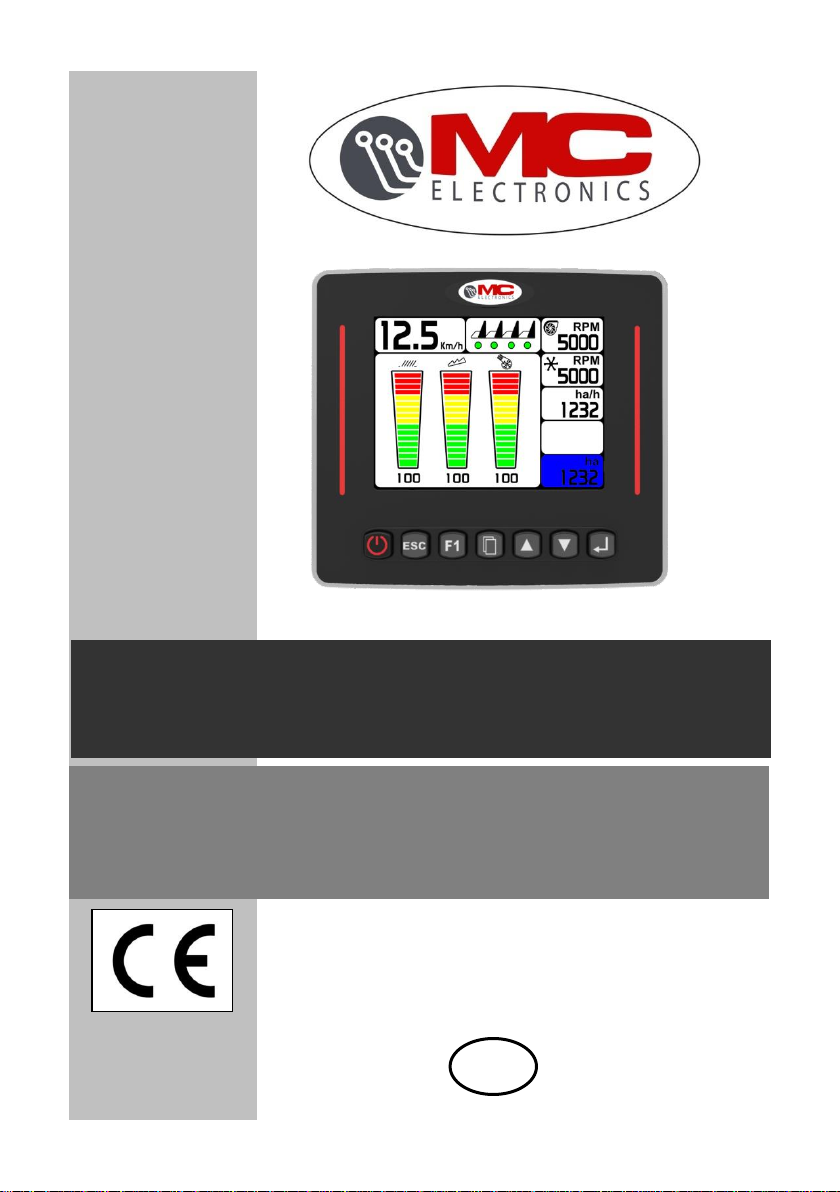

2. General description .............................................................................................. 6

3. System installation............................................................................................... 7

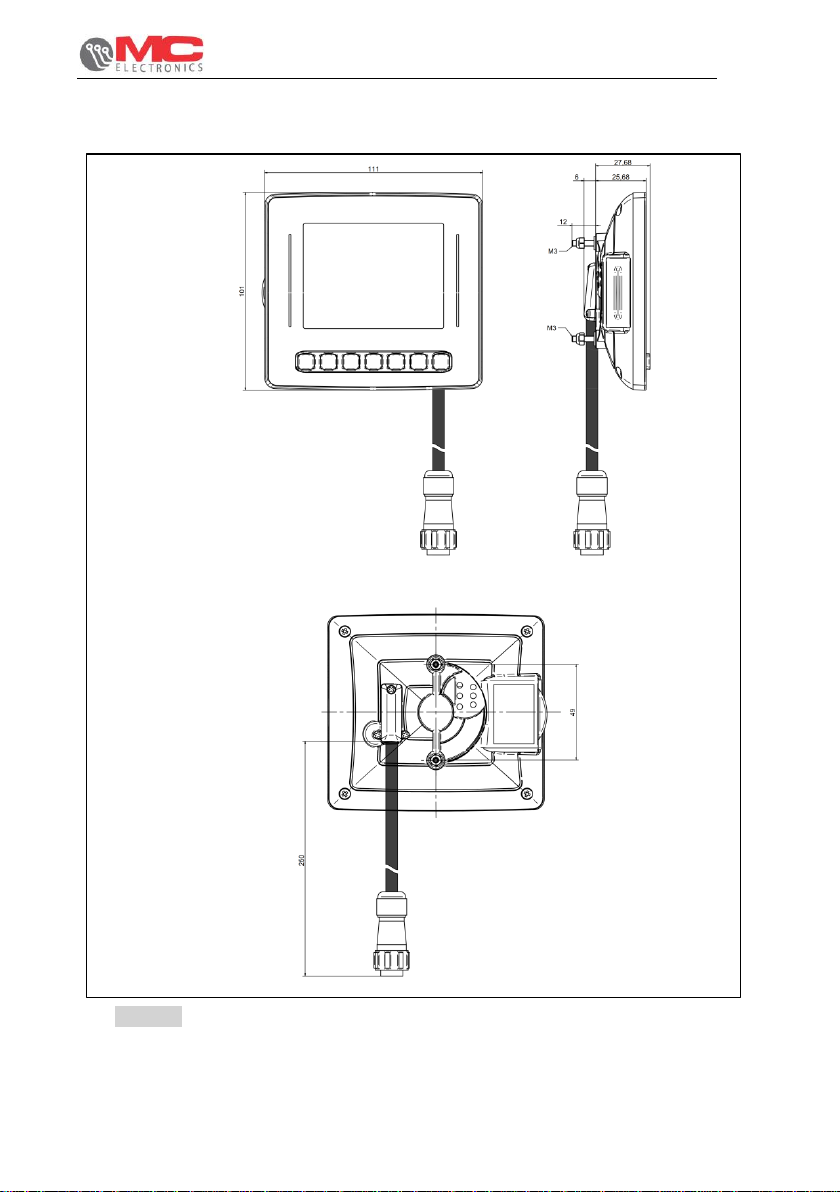

3.1 Virtual Terminal assembly................................................................................. 9

3.2 Sensor installation........................................................................................... 10

3.2.1 Speed sensor installation......................................................................... 10

3.2.2 "RPM" sensor installation......................................................................... 11

3.3 Keyboard operation......................................................................................... 12

3.3.1 Home screen............................................................................................ 12

3.3.2 Main screen ............................................................................................. 13

3.3.3 Screen of sensor sensitivity ..................................................................... 14

3.4 Graphic interface description .......................................................................... 15

3.4.1 Home screen............................................................................................ 15

3.5 Work screen.................................................................................................... 16

3.6 Screen of sensor sensitivity ............................................................................ 17

4. Programming....................................................................................................... 18

5. User settings....................................................................................................... 19

5.1 Speed sensor calibration................................................................................. 21

6. Machine settings................................................................................................. 22

6.1 How to access the machine menu .................................................................. 22

6.2 Machine setup screens................................................................................... 23

7. Diagnostics.......................................................................................................... 25

8. Programmable parameters................................................................................. 26

9. Virtual Terminal software update ...................................................................... 27

10. ECU software update........................................................................................ 29

11. Technical data................................................................................................... 30

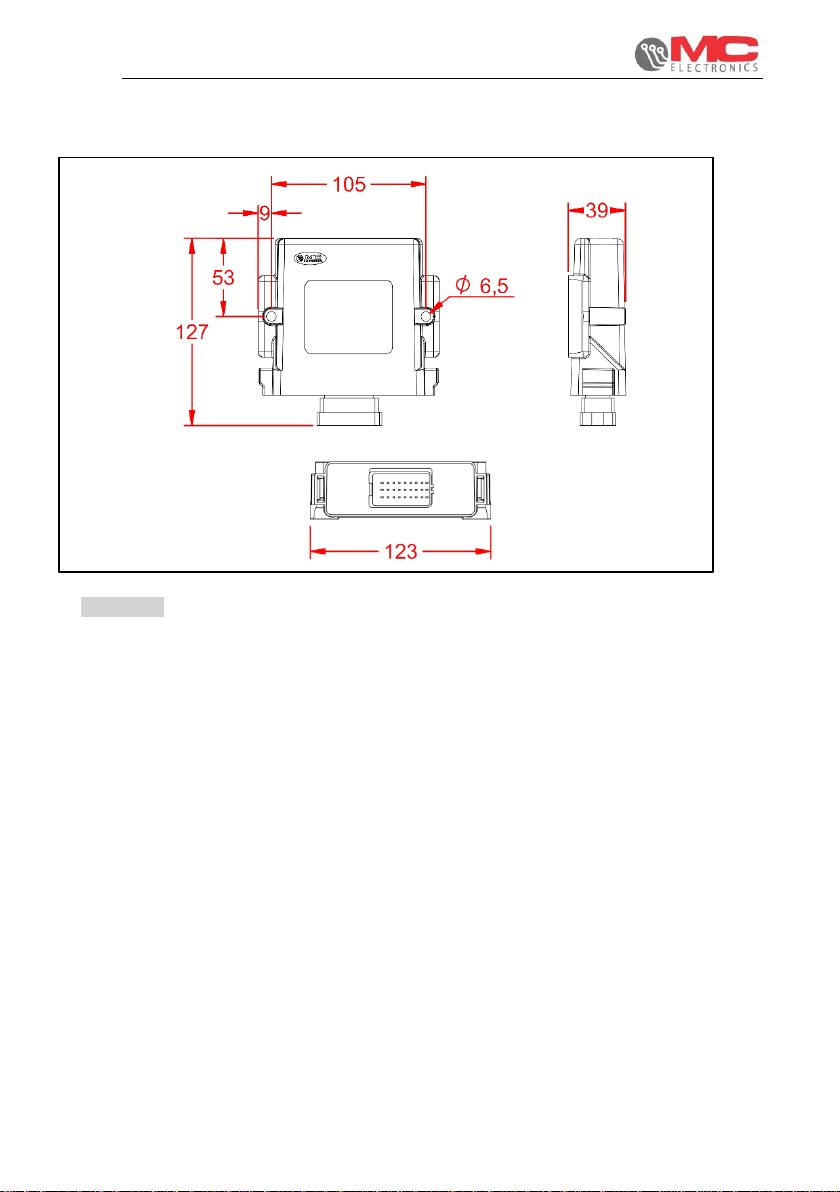

11.1 3.5” Virtual Terminal...................................................................................... 30

11.2 ECU GLM...................................................................................................... 30

11.3 Accessories................................................................................................... 31

11.3.1 Proximity inductive sensor ..................................................................... 31

11.3.2 Capacitive sensor .................................................................................. 31

11.3.3 Sieves / straw walker / recovery sensors............................................... 31