McConnel PA4745 Series User manual

Publication 734

February 2013

Part No. 22675.34

Revised: 17.05.16 McCO

N

NEL

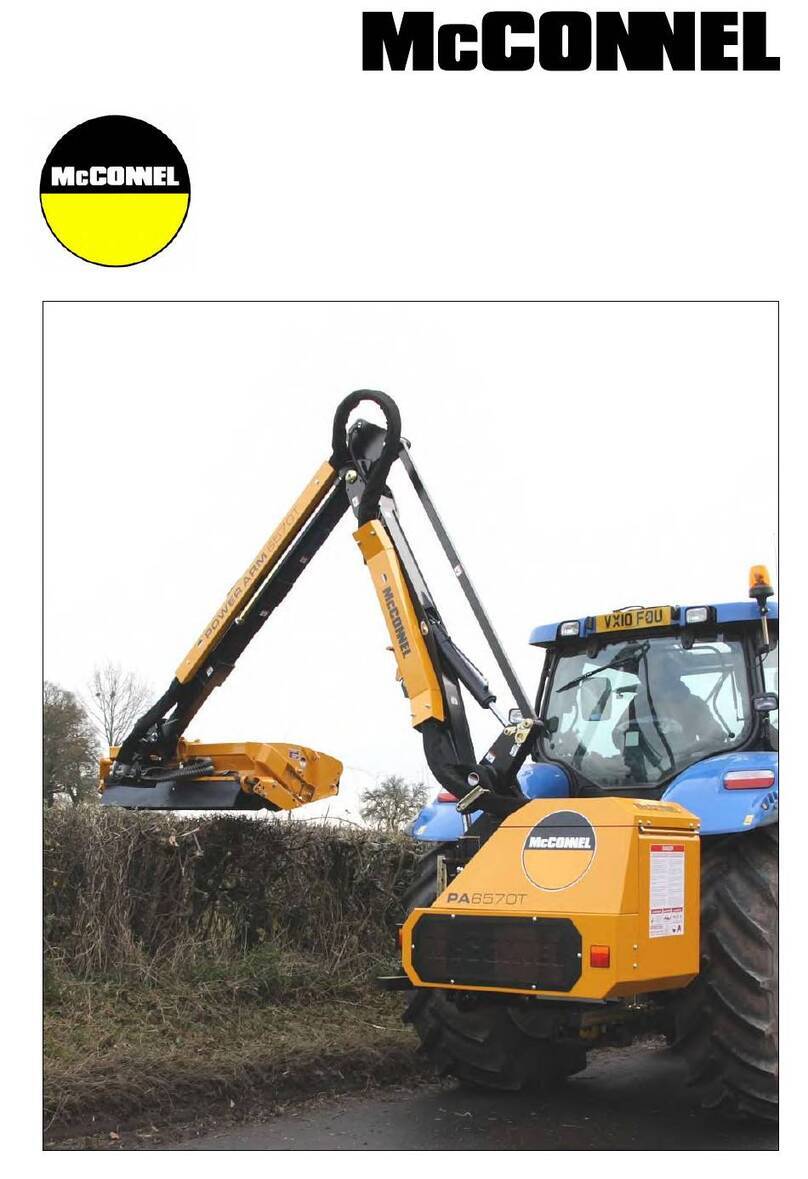

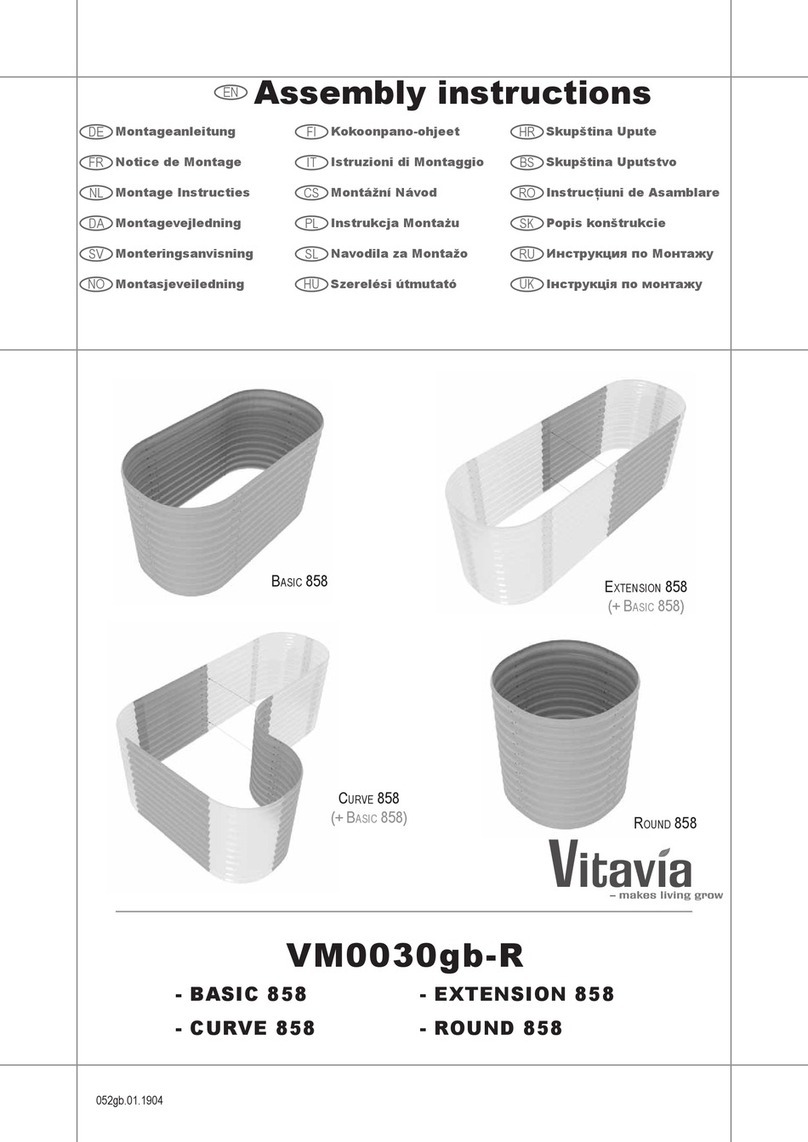

PA4745 / PA5045 Series

45HP AGRICULTURAL RANGE HEDGECUTTERS

North American Builds

Operator Manual

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user – failure to do so may affect the validity of the machine warranty.

To register machines go to the McConnel Limited web site at www.mcconnel.com, log

onto ‘Dealer Inside’ and select the ‘Machine Registration button’ which can be found in

the Service Section of the site. Confirm to the customer that the machine has been

registered in the section below.

Should you experience any problems registering a machine in this manner please contact

the McConnel Service Department on 01584 875848.

Registration Verification

Dealer Name:

……………………..…………………………………………………………….

Dealer Address:

…….………………………………………………………………………….

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below.The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines general maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP

Setting

Metric

BSP

Setting

Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm

19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm

22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm

27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm

30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm

32 mm

1” 125 Nm 41 mm 1” 203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm

55 mm

2” 420 Nm 70 mm 2” 400 Nm

70 mm

Warranty Policy (page 1 of 3)

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the end user.

On receipt of the goods it is the buyer’s responsibility to check that the Verification of Warranty

Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All mounted machines supplied by McConnel Ltd are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

All Self Propelled Machines supplied by McConnel Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12 months

or 1500 hours. Engine warranty will be specific to the Manufacturer of that unit.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be free from

defects in material and workmanship from the date of sale to the original purchaser for a period of 6

months. All parts warranty claims must be supported by a copy of the failed part invoice to the end

user. We cannot consider claims for which sales invoices are not available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement for the

purchaser any part or parts found, upon examination at its factory, to be defective under normal use

and service due to defects in material or workmanship. Returned parts must be complete and

unexamined. Pack the component(s) carefully so that any transit damage is avoided. All ports on

hydraulic items should be drained of oil and securely plugged to prevent seepage and foreign body

ingress. Certain other components, electrical items for example, may require particular care when

packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate has

been removed or altered.

1.05. The warranty policy is valid for machines registered in line with the terms and conditions detailed and

on the basis that the machines do not extend a period of 24 months or greater since their original

purchase date, that is the original invoice date from McConnel Limited.

Machines that are held in stock for more than 24 months cannot be registered for warranty.

1.06. This warranty does not apply to any part of the goods, which has been subjected to improper or

abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident damage,

or damage resulting from contact with overhead power lines, damage caused by foreign objects (e.g.

stones, iron, material other than vegetation), failure due to lack of maintenance, use of incorrect oil or

lubricants, contamination of the oil, or which has served its normal life. This warranty does not apply

to any expendable items such as blades, belts, clutch linings, filter elements, flails, flap kits, skids, soil

engaging parts, shields, guards, wear pads, pneumatic tyres or tracks.

1.07. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.08. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired

will be rejected.

1.09. Machines must be repaired immediately a problem arises. Continued use of the machine after a

problem has occurred can result in further component failures, for which McConnel Ltd cannot be held

liable, and may have safety implications.

1.10. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine part.

Warranty Policy (page 2 of 3)

1.11. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of McConnel Ltd.

1.12. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.12.1. Hoses, exposed pipes and hydraulic tank breathers.

1.12.2. Filters.

1.12.3. Rubber mountings.

1.12.4. External electric wiring.

1.12.5. Bearings and seals

1.12.6. External Cables, Linkages

1.12.7. Loose/Corroded Connections, Light Units, LED’s

1.12.8. Comfort items such as Operator Seat, Ventilation, Audio Equipment

1.13. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

1.14. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair work

are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be held

responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the McConnel web

site and confirms the registration to the purchaser by completing the confirmation form in the

operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs. Continued use

of a machine, after a fault has occurred, can result in further component failure for which McConnel

Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be

rejected, unless the delay has been authorised by McConnel Ltd. Please note that failure by the

customer to release the machine for repair will not be accepted as a reason for delay in repair or

submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days of the

date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for any valid

claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate labour and mileage

allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd. is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with respect to

the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for

damages incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may

be brought more than one (1) year after the cause of the action has occurred.

Warranty Policy (page 3 of 3)

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

McConnel Limited

DECLARATION OF CONFORMITY

Conforming to EU Machinery Directive 2006/42/EC

We,

McCONNEL LIMITED, Temeside Works, Ludlow, Shropshire SY8 1JL, UK

Hereby declare that:

The Product; Tractor Mounted Hedgecutter / Grass Mower

Product Code; P470

Serial No. & Date ………………………………… Type …………………………

Manufactured in; United Kingdom

Complies with the required provisions of the Machinery Directive 2006/42/EC

The machinery directive is supported by the following harmonized standards;

■BS EN ISO 12100 (2010) Safety of machinery –General principles for design –Risk

assessment and risk reduction.

■BS EN 349 (1993) + A1 (2008) Safety of machinery - Minimum distances to avoid the

entrapment with human body parts.

■BS EN ISO 14120 (2015) Safety of machinery - Guards general requirements for the

design and construction of fixed and movable guards.

■BS EN 4413 (2010) Hydraulic fluid power. Safety requirements for systems and their

components.

McCONNEL LIMITED operates an ISO 9001:2008 quality management system,

certificate number: FM25970.

This system is continually assessed by the;

British Standards Institution (BSI), Beech House, Milton Keynes, MK14 6ES, UK

BSI is accredited by UK Accreditation Service, accreditation number: UKAS 003.

The EC declaration only applies if the machine stated above is used in

accordance with the operating instructions.

Signed …………………................ Responsible Person

CHRISTIAN DAVIES on behalf of McCONNEL LIMITED

Status: General Manager Date: January 2018

POWER ARM INSPECTION AND MAINTENANCE

A daily equipment inspection of the tractor and mower should be conducted before the

equipment is used. You may use the inspection sheets to assist with these daily

inspections. Any damaged or missing guards should be repaired or replaced before

operating the mower. Failure to repair the damaged shield can result in objects being

thrown from the mower and possibly hitting the operator or bystander.

Inspect the Mower for Safe Operating Condition

Make sure the driveline guards and shielding are in place and in good repair.

Inspect the flexible thrown object shielding to assure that they are in place on the

front and rear of the mower head and in good repair. Repair or replace any

damaged or missing thrown object shields.

Ensure the mower cutting height is set high enough to reduce the possibility of the

mower blades contacting the ground. Actual height will be dependent on the ground

conditions. Increase the height when working in rough or undulating conditions.

Inspect for broken, chipped, bent, missing, or severely worn blades. Replace

damaged blades before operating the mower. Ensure the blade retaining bolts and

fasteners are secure and tight.

Ensure all head bolts and nuts are tight.

Lubricate the driveline universal joints and telescoping members daily.

Grease the rotor and roller bearings and inspect their condition.

Inspect for any oil leaks or damaged hoses

Inspect for worn or damaged decals and safety instructions. Replace unreadable,

damaged or missing safety decals.

Follow the operator’s manual(s) inspection and maintenance instructions for

lubricating parts, and keeping thrown object shielding, driveline guards, rotating

parts shields, mower blades and decals in good repair.

Inspect the Tractor for Safe Operating Condition:

Inspect the controls, lights, SMVs (Slow Moving Vehicle sign), seat belts, and

ROPS to assure that they are in place and in good working order.

Be sure the tires, wheels, lug bolts/nuts are in good condition.

Make sure the tractor brakes and steering are in proper operating condition.

Follow the operator’s manual(s) inspection and maintenance procedures for

keeping the tractor in good and safe condition before operating.

The inspection sheet on the following page should be kept in this book as a record. A

second sheet is included for you to cut out and photocopy or the inspection sheets can be

downloaded from our website at;

http://www.mcconnel.com/support/aftersales/default.aspx?nav=After Sales

POWER ARM PRE-OPERATION Inspection

Power Arm ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key removed, all

rotation has stopped and the tractor is in park with the parking brake engaged. Make sure

the mower head is resting on the ground or is securely blocked up and supported and all

hydraulic pressure has been relieved.

Item Condition at

start of shift Specific Comments if not O.K.

The Operator’s Manual is in the Canister on the mower

All Warning Decals are in place, clean and legible

All Lights are clean and working

The Mounting frame bolts are in place and tight

The Arm pivot pins are tight and correctly secured

There are no cracks in the arms

The Hyd. Cylinder pins are tight and correctly secured

The Hyd Cylinder hose connections are tight

The Hyd. Pump hose connections are tight

The Hyd. Valve hose connections are tight

The Hyd. Valve controls function properly

There are no damaged hoses

The Oil level is to the green mark on the tank sight glass

There is no evidence of Hydraulic oil leaks

Flails are not missing, chipped, broken or excessively worn

The Flail bolts are tight

The Front & Rear Flaps are fittrd and in good condition

The Front hood is in place and in good condition

The Wire Trap is in good condition

The Skid shoes are in good condition & tight

There are no cracks or holes in flail casing

The Hyd. motor mounting bolts are tight

All Flail Head Nuts and Bolts are tight

The Rotor Bearings are in good condition and greased

The Roller bearings are in good condition and greased

The drive line Shaft guard is in good condition

The drive line shaft guard is correctly secured

Controls are securely mounted in the cab

With engine running check arm operation

Have a spare pack of flails, bushes, bolts and nuts

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION Inspection

Power Arm ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key is removed

all rotation has stopped and the tractor is in park with the parking brake engaged. Any

implement attached to the tractor is firmly on the ground.

Item Condition at

start of shift Specific Comments if not O.K.

The flashing lights function properly.

All lights are clean and working correctly

All cab windows are clean and wipers working correctly

The SMV sign, where required, is clean and visible.

The tyres are in good condition with correct pressure.

The wheel nuts are tight.

The tractor brakes are in good condition.

The steering linkage is in good condition.

There are no visible oil leaks.

The hydraulic controls function properly.

The ROPS or ROPS cab is in good condition.

The seatbelt is in place and in good condition.

The 3-point hitch is in good condition.

The drawbar/pick up hook is secure & in good condition

The PTO master shield is in place.

The engine oil level is full.

The brake fluid level is full.

The power steering fluid level is full.

The fuel level is adequate.

The engine coolant fluid level is full.

The radiator & oil cooler are free of debris.

The air filter is in good condition

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

POWER ARM PRE-OPERATION Inspection

Power Arm ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key removed, all

rotation has stopped and the tractor is in park with the parking brake engaged. Make sure

the mower head is resting on the ground or is securely blocked up and supported and all

hydraulic pressure has been relieved.

Item Condition at

start of shift Specific Comments if not O.K.

The Operator’s Manual is in the Canister on the mower

All Warning Decals are in place, clean and legible

All Lights are clean and working

The Mounting frame bolts are in place and tight

The Arm pivot pins are tight and correctly secured

There are no cracks in the arms

The Hyd. Cylinder pins are tight and correctly secured

The Hyd Cylinder hose connections are tight

The Hyd. Pump hose connections are tight

The Hyd. Valve hose connections are tight

The Hyd. Valve controls function properly

There are no damaged hoses

The Oil level is to the green mark on the tank sight glass

There is no evidence of Hydraulic oil leaks

Flails are not missing, chipped, broken or excessively worn

The Flail bolts are tight

The Front & Rear Flaps are fittrd and in good condition

The Front hood is in place and in good condition

The Wire Trap is in good condition

The Skid shoes are in good condition & tight

There are no cracks or holes in flail casing

The Hyd. motor mounting bolts are tight

All Flail Head Nuts and Bolts are tight

The Rotor Bearings are in good condition and greased

The Roller bearings are in good condition and greased

The drive line Shaft guard is in good condition

The drive line shaft guard is correctly secured

Controls are securely mounted in the cab

With engine running check arm operation

Have a spare pack of flails, bushes, bolts and nuts

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

TRACTOR PRE-OPERATION Inspection

Power Arm ID ________________ Date: _______________ Shift: _______________

WARNING Before conducting the inspection, make sure the tractor engine is off, the key is removed

all rotation has stopped and the tractor is in park with the parking brake engaged. Any

implement attached to the tractor is firmly on the ground.

Item Condition at

start of shift Specific Comments if not O.K.

The flashing lights function properly.

All lights are clean and working correctly

All cab windows are clean and wipers working correctly

The SMV sign, where required, is clean and visible.

The tyres are in good condition with correct pressure.

The wheel nuts are tight.

The tractor brakes are in good condition.

The steering linkage is in good condition.

There are no visible oil leaks.

The hydraulic controls function properly.

The ROPS or ROPS cab is in good condition.

The seatbelt is in place and in good condition.

The 3-point hitch is in good condition.

The drawbar/pick up hook is secure & in good condition

The PTO master shield is in place.

The engine oil level is full.

The brake fluid level is full.

The power steering fluid level is full.

The fuel level is adequate.

The engine coolant fluid level is full.

The radiator & oil cooler are free of debris.

The air filter is in good condition

Operators Signature: ___________________________________________

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

For Safety and Performance…

ALWAYS READ THE BOOK FIRST

- NOISE STATEMENT -

The equivalent daily personal noise exposure from this machine measured at the operators’ ear is

within the range 78 –85 dB, these figures apply to a normal distribution of use where the noise

fluctuates between zero and maximum. The figures assume that the machine is fitted to a tractor with

a ‘quiet’ cab with the windows closed in a generally open environment. We recommend that the

windows are kept closed. With the cab rear window open the equivalent daily personal noise

exposure will increase to a figure within the range 82 –88 dB. At an equivalent daily noise exposure

level of 85 –90 dB ear protection is recommended and must always be used if any window is left

open.

Operating, servicing and maintaining this equipment can

expose you to chemicals including gasoline, diesel fuel,

lubricants, petroleum products, engine exhaust, carbon

monoxide, and phthalates, which are known to the State of

California to cause cancer and birth defects or other

reproductive harm. To minimize exposure, avoid breathing exhaust, do not idle the engine except as

necessary, service your vehicle in a well-ventilated area and wear gloves or wash your hands

frequently when servicing your vehicle. Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the state of California to cause cancer, birth defects or

other reproductive harm. For more information go to www.P65Warnings.ca.gov. This website,

operated by California's Office of Environmental Health Hazard Assessment, provides information

about these chemicals and how individuals may be exposed to them.

McCONNEL LIMITED

Temeside Works

Ludlow

Shropshire

England

Telephone: +44 (0)1584 873131

www.mcconnel.com

0

CONTENTS

General Information 1

Features 2

Safety Information 3

Tractor Requirements 8

Tractor Preparation 9

Pre-Attachment 10

Hydraulic Oil 11

Attachment to Tractor 12

PTO Driveshaft Installation 14

Fitting Operator Control Units 15

Flailhead Attachment 16

Running Up Procedure 17

Pre-Operational Checks 18

Operation 19

Cable Controls 20

Electric Switchbox Controls 24

Electric Monolever Controls 28

XTC Mk2 Proportional Switchbox Controls 32

XTC Mk3 Proportional Switchbox Controls 36

Mini Proportional Controls 42

Rotor Operation 45

Breakaway Protection Systems 46

Transport 48

Emergency Stopping 48

Machine Removal & Storage 49

General Working Practices 50

Overhead Power Lines 52

Lift Float Kits (Optional Extras) 54

Maintenance 55

Troubleshooting Chart 63

1

GENERAL INFORMATION

Read this manual before fitting or operating the machine. Whenever any doubt exists

contact your dealer or the McConnel Service Department for assistance.

Use only McConnel Genuine Parts on McConnel equipment and machines.

DEFINITIONS; The following definitions apply throughout this manual:

WARNING:

An operating procedure, technique etc., which can result in personal injury or loss of life if

not observed carefully.

CAUTION:

An operating procedure, technique etc., which can result in the damage of either machine

or equipment if not observed carefully.

NOTE:

An operating procedure, technique etc., which is considered essential to emphasise.

LEFT AND RIGHT HAND:

This term is applicable to the machine when fitted to the tractor and viewed from the rear.

This also applies to tractor references.

Note: The illustrations in this manual are for instructional purposes onl y and ma y on occasion not

show some components in their entirety . In s ome instances an illustration ma y a ppear slightl y

different to that of your particular model but the general procedure will be the same. E&OE.

MACHINE & DEALER INFORMATION

Record the Serial Number of your machine on this page and always quote this number when

ordering parts. Whenever information concerning the machine is requested remember also

to state the make and model of tractor to which the machine is fitted.

Machine Serial Number:

Installation Date:

Machine Model details:

Dealer Name:

Dealer Address:

Dealer Telephone No:

Dealer Email Address:

2

FEATURES

PA4745 Models

4.7m (15’ 5”) Reach

Fully Independent or Semi-independent Hydraulic System

Cable or Electric Rotor Control

Three-point Linkage Mounting System

Parallel Arm Geometry

Mechanical Safety Breakaway

Left or Right Hand Build

Operator Guard

45HP High Performance Hydraulic System

180 Litre Hydraulic Reservoir

Choice of Operator Controls – Cable, Electric or Proportional

Choice of Flailheads

PA5045 Models

5.0m (16’ 5”) Reach

Fully Independent or Semi-independent Hydraulic System

Cable or Electric Rotor Control

Three-point Linkage Mounting System

Parallel Arm Geometry

Mechanical Safety Breakaway

Left or Right Hand Build

Operator Guard

45HP High Performance Hydraulic System

150 Litre Hydraulic Reservoir

Choice of Operator Controls – Cable, Electric or Proportional

Choice of Flailheads

Optional Extras

Lift Float Kit – Manual or Electric

Angle Float – Electric Models Only

Debris Blower Mounting Kit

Lighting Kit

Cooler Kit

3

SAFETY

This machine has the potential to be extremely dangerous, in the wrong hands it can kill or

maim. It is therefore imperative that both owner, and operator of this machine, read and

understand the following section to ensure that they are fully aware of the dangers that do,

or may exist, and their responsibilities surrounding the use and operation of the machine.

The operator of this machine is responsible not only for their own safety but equally for the

safety of others who may come into the close proximity of the machine, as the owner you

are responsible for both.

When the machine is not in use the cutting head should be lowered to rest on the ground.

In the event of a fault being detected with the machine’s operation it should be stopped

immediately and not used again until the fault has been corrected by a qualified technician.

POTENTIAL SIGNIFICANT DANGERS ASSOCIATED WITH THE USE OF THIS MACHINE:

▲Being hit by debris thrown by rotating components.

▲Being hit by machine parts ejected through damage during use.

▲Being caught on a rotating power take-off (PTO) shaft.

▲Being caught in other moving parts i.e.: belts, pulleys and cutting heads.

▲Electrocution from Overhead Power Lines (by contact with or ‘flashover’ from).

▲Being hit by cutting heads or machine arms as they move.

▲Becoming trapped between tractor and machine when hitching or unhitching.

▲Tractor overbalancing when machine arm is extended.

▲Injection of high-pressure oil from hydraulic hoses or couplings.

▲Machine overbalancing when freestanding (out of use).

▲Road traffic accidents due to collision or debris on the road.

4

BEFORE USING THIS MACHINE YOU MUST:

▲Ensure you read all sections of the operator handbook.

▲Ensure the operator is, or has been, properly trained to use the machine.

▲Ensure the operator has been issued with and reads the operator handbook.

▲Ensure the operator understands and follows the instructions in operator handbook.

▲Ensure that all machine guards are in position, are undamaged, and are kept

maintained in accordance with the manufacturer’s recommendations.

▲Ensure flails and their fixings are of a type recommended by the manufacturer, are

securely attached and that none are missing or damaged.

▲Ensure hydraulic pipes are carefully and correctly routed to avoid damage by chaffing,

stretching or pinching and that they are held in place with the correct fittings.

▲Always follow the manufacturer’s instructions for attachment and removal of the

machine from the tractor.

▲Check that the machine fittings and couplings are in good condition.

▲Ensure the tractor meets the minimum weight recommendations of the machine’s

manufacturer and that ballast is used as necessary.

▲Always inspect the work area thoroughly before starting to note obstacles and remove

wire, bottles, cans and other debris.

▲Use clear suitably sized warning signs to alert others to the nature of the machine

working within that area. Signs should be placed at both ends of the work site. (It is

recommended that signs used are of a size and type specified by the Department of

Transport and positioned in accordance with their, and the Local Highways Authority,

guidelines).

▲Ensure the operator is protected from noise. Ear defenders should be worn and tractor

cab doors and windows must be kept closed. Machine controls should be routed

through proprietary openings in the cab to enable all windows to be shut fully.

▲Always work at a safe speed taking account of the conditions i.e.: terrain, highway

proximity and obstacles around and above the machine. Extra special attention should

be applied to Overhead Power Lines. Some of our machines are capable of reach in

excess of 8 metres (26 feet) this means they have the potential to well exceed, by

possibly 3 metres (9’ 9”), the lowest legal minimum height of 5.2 metres from the

ground for 11,000 and 33,000 volt power lines. It cannot be stressed enough the

dangers that surround this capability, it is therefore vital that the operator is fully aware

of the maximum height and reach of the machine, and that they are fully conversant

with all aspects regarding the safe minimum distances that apply when working with

machines in close proximity to Power Lines. (Further information on this subject can be

obtained from the Health & Safety Executive or your Local Power Company).

▲Always disengage the machine, kill the tractor engine, remove and pocket the key

before dismounting for any reason.

▲Always clear up all debris left at the work area, it may cause hazard to others.

▲Always ensure when you remove your machine from the tractor that it is left in a safe

and stable position using the stands and props provided and secured if necessary.

This manual suits for next models

1

Table of contents

Other McConnel Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Bosch

Bosch MSGP3L user manual

Scheppach

Scheppach MFH380-20Li Dual Translation from the original instruction manual

EasyPro

EasyPro PA10 Installation, Operation, Maintenance Guidelines

Garden Oasis

Garden Oasis Garden Oasis UA38338 owner's manual

VITO GARDEN

VITO GARDEN VIE54 instruction manual

AQUAvalve

AQUAvalve 24Pot system Simple care guidelines