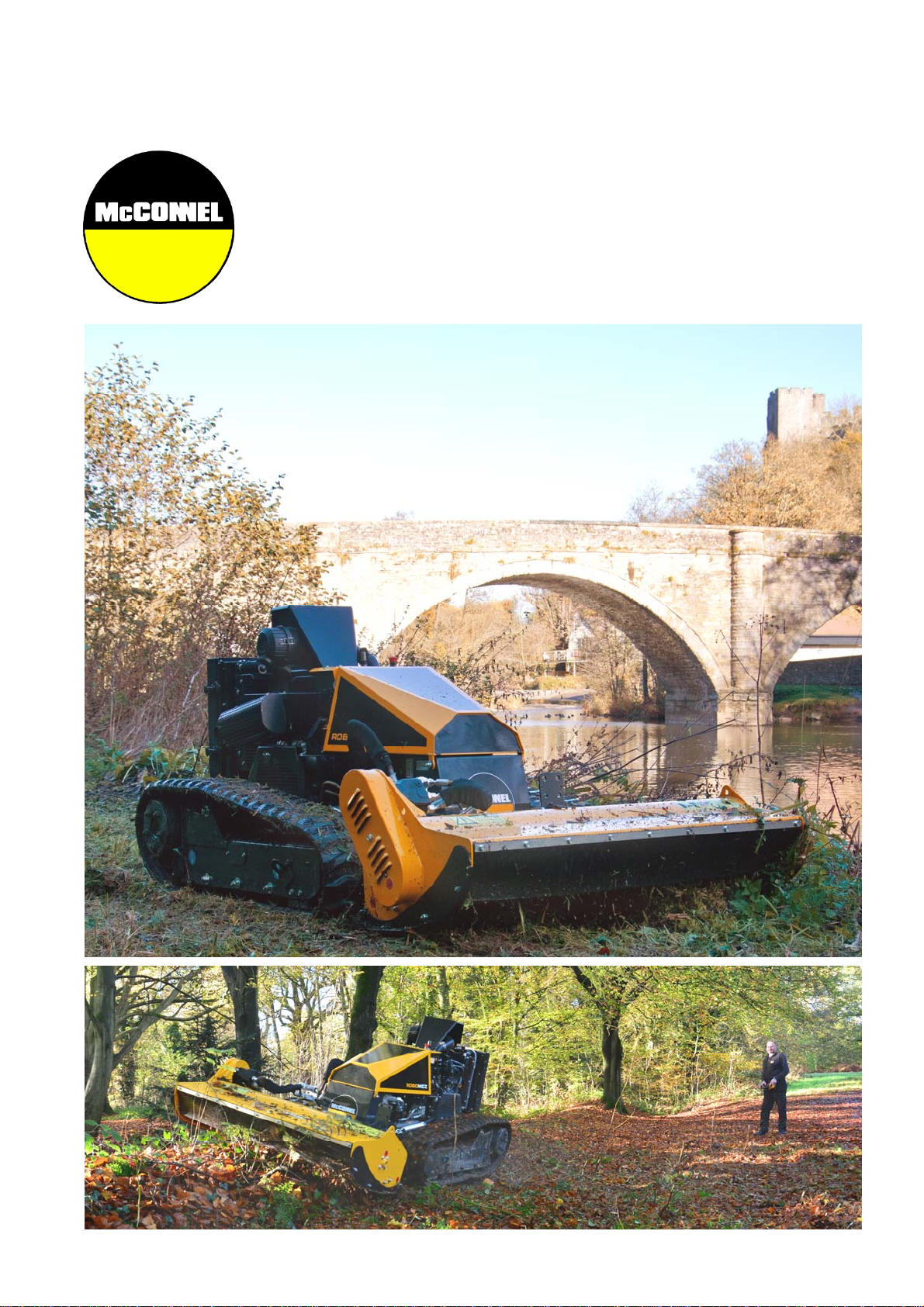

McConnel ROBOMOZ User manual

Publication 816

October 2015

Part No. 23671.16

Revision: 24.11.15

McCONNEL

ROBOMOZ

REMOTE CONTROLLED MOWER

Operator Manual

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user – failure to do so may affect the validity of the machine warranty.

To register machines go to the McConnel Limited web site at www.mcconnel.com, log

onto ‘Dealer Inside’ and select the ‘Machine Registration button’which can be found in

the Service Section of the site. Confirm to the customer that the machine has been

registered in the section below.

Should you experience any problems registering a machine in this manner please contact

the McConnel Service Department on 01584 875848.

Registration Verification

Dealer Name:

……………………..…………………………………………………………….

Dealer Address:

…….………………………………………………………………………….

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below.The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines general maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

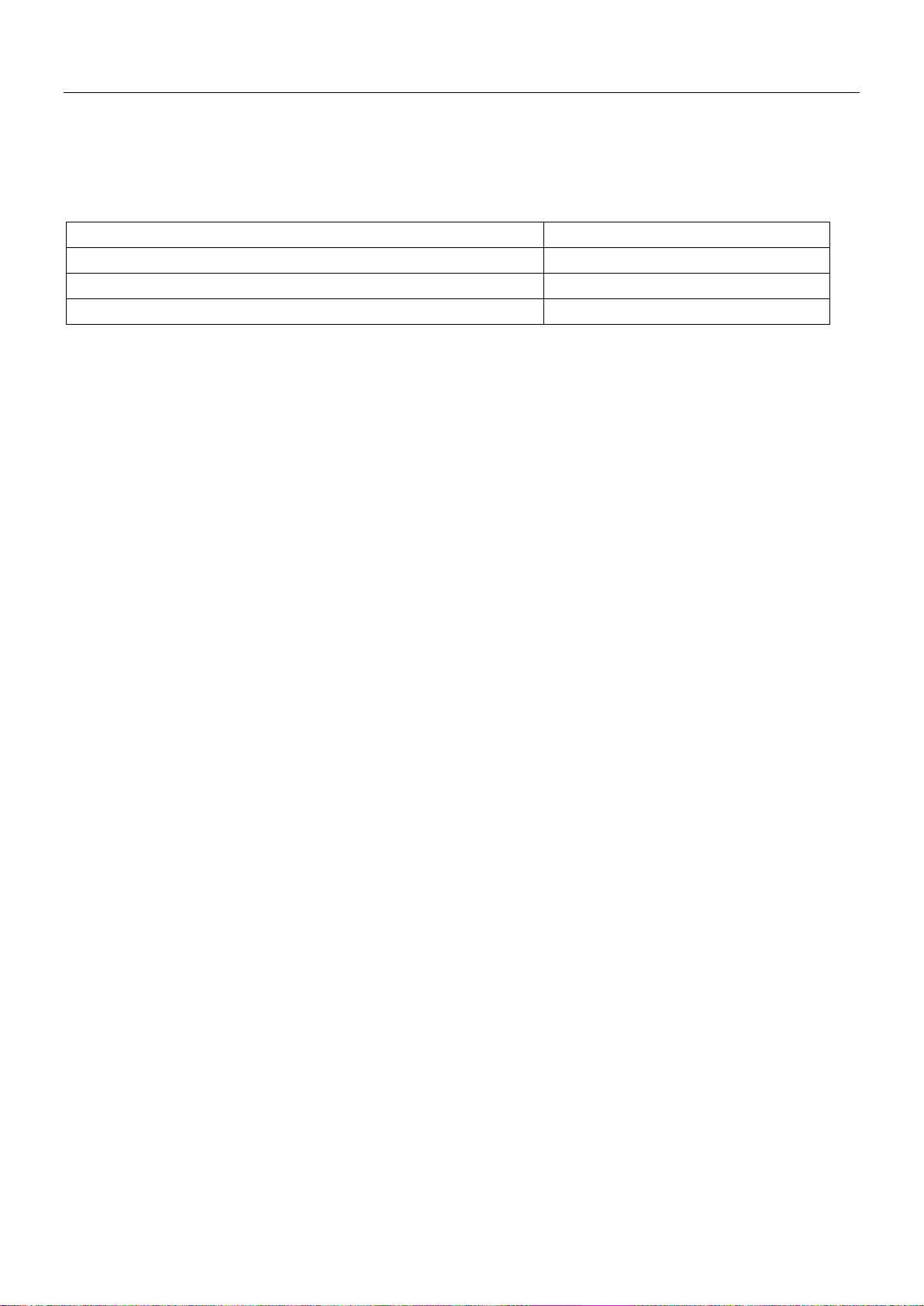

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP

Setting

Metric

BSP

Setting

Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm

19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm

22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm

27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm

30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm

32 mm

1” 125 Nm 41 mm 1” 203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm

55 mm

2” 420 Nm 70 mm 2” 400 Nm

70 mm

Warranty Policy (page 1 of 3)

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the end user.

On receipt of the goods it is the buyer’s responsibility to check that the Verification of Warranty

Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All mounted machines supplied by McConnel Ltd are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

All Self Propelled Machines supplied by McConnel Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12 months

or 1500 hours. Engine warranty will be specific to the Manufacturer of that unit.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be free from

defects in material and workmanship from the date of sale to the original purchaser for a period of 6

months. All parts warranty claims must be supported by a copy of the failed part invoice to the end

user. We cannot consider claims for which sales invoices are not available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement for the

purchaser any part or parts found, upon examination at its factory, to be defective under normal use

and service due to defects in material or workmanship. Returned parts must be complete and

unexamined. Pack the component(s) carefully so that any transit damage is avoided. All ports on

hydraulic items should be drained of oil and securely plugged to prevent seepage and foreign body

ingress. Certain other components, electrical items for example, may require particular care when

packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate has

been removed or altered.

1.05. The warranty policy is valid for machines registered in line with the terms and conditions detailed and

on the basis that the machines do not extend a period of 24 months or greater since their original

purchase date, that is the original invoice date from McConnel Limited.

Machines that are held in stock for more than 24 months cannot be registered for warranty.

1.06. This warranty does not apply to any part of the goods, which has been subjected to improper or

abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident damage,

or damage resulting from contact with overhead power lines, damage caused by foreign objects (e.g.

stones, iron, material other than vegetation), failure due to lack of maintenance, use of incorrect oil or

lubricants, contamination of the oil, or which has served its normal life. This warranty does not apply

to any expendable items such as blades, belts, clutch linings, filter elements, flails, flap kits, skids, soil

engaging parts, shields, guards, wear pads, pneumatic tyres or tracks.

1.07. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.08. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired

will be rejected.

1.09. Machines must be repaired immediately a problem arises. Continued use of the machine after a

problem has occurred can result in further component failures, for which McConnel Ltd cannot be held

liable, and may have safety implications.

1.10. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine part.

Warranty Policy (page 2 of 3)

1.11. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of McConnel Ltd.

1.12. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.12.1. Hoses, exposed pipes and hydraulic tank breathers.

1.12.2. Filters.

1.12.3. Rubber mountings.

1.12.4. External electric wiring.

1.12.5. Bearings and seals

1.12.6. External Cables, Linkages

1.12.7. Loose/Corroded Connections, Light Units, LED’s

1.12.8. Comfort items such as Operator Seat, Ventilation, Audio Equipment

1.13. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

1.14. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair work

are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be held

responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the McConnel web

site and confirms the registration to the purchaser by completing the confirmation form in the

operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs. Continued use

of a machine, after a fault has occurred, can result in further component failure for which McConnel

Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be

rejected, unless the delay has been authorised by McConnel Ltd. Please note that failure by the

customer to release the machine for repair will not be accepted as a reason for delay in repair or

submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days of the

date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for any valid

claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate labour and mileage

allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd. is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with respect to

the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for

damages incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may

be brought more than one (1) year after the cause of the action has occurred.

Warranty Policy (page 3 of 3)

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

McConnel Limited

DECLARATION OF CONFORMITY

Conforming to EU Machinery Directive 2006/42/EC

We,

McCONNEL LIMITED, Temeside Works, Ludlow, Shropshire SY8 1JL, UK

Hereby declare that:

The Product; Radio Controlled Tracked Mower

Product Code; RMOW

Serial No. & Date ………………………………… Type …………………………

Manufactured in; Italy

Complies with the required provisions of the Machinery Directive 2006/42/EC

The machinery directive is supported by the following harmonized standards;

■BS EN ISO 12100 (2010) Safety of machinery –General principles for design –Risk

assessment and risk reduction.

■BS EN 349 (1993) + A1 (2008) Safety of machinery - Minimum distances to avoid the

entrapment with human body parts.

■BS EN ISO 14120 (2015) Safety of machinery - Guards general requirements for the

design and construction of fixed and movable guards.

■BS EN 4413 (2010) Hydraulic fluid power. Safety requirements for systems and their

components.

McCONNEL LIMITED operates an ISO 9001:2008 quality management system,

certificate number: FM25970.

This system is continually assessed by the;

British Standards Institution (BSI), Beech House, Milton Keynes, MK14 6ES, UK

BSI is accredited by UK Accreditation Service, accreditation number: UKAS 003.

The EC declaration only applies if the machine stated above is used in

accordance with the operating instructions.

Signed …………………................ Responsible Person

CHRISTIAN DAVIES on behalf of McCONNEL LIMITED

Status: General Manager Date: January 2018

For Safety and Performance…

ALWAYS READ THE BOOK FIRST

Operating, servicing and maintaining this equipment can

expose you to chemicals including gasoline, diesel fuel,

lubricants, petroleum products, engine exhaust, carbon

monoxide, and phthalates, which are known to the State of

California to cause cancer and birth defects or other

reproductive harm. To minimize exposure, avoid breathing exhaust, do not idle the engine except as

necessary, service your vehicle in a well-ventilated area and wear gloves or wash your hands

frequently when servicing your vehicle. Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the state of California to cause cancer, birth defects or

other reproductive harm. For more information go to www.P65Warnings.ca.gov. This website,

operated by California's Office of Environmental Health Hazard Assessment, provides information

about these chemicals and how individuals may be exposed to them.

McCONNEL LIMITED

Temeside Works

Ludlow

Shropshire

England

Telephone: +44 (0)1584 873131

www.mcconnel.com

LIST OF CONTENTS

Page No.

General Information

1

Features & Specifications

2

Technical Data

3

Safety Information

4

Safety Decals & Warnings

7

Safety Devices & Emergency Stop

9

Machine Delivery

10

Machine Overview

11

Radio Control Unit

14

Starting the Engine

15

Driving & Manoeuvring

16

LCD Display

20

Emergency Manual Control Unit

23

Pre-Operation Checks

25

Operation

26

Maintenance

28

Electrical System Fuses & Relays

39

Troubleshooting

42

Parts Section

Chassis Assembly

42

Rubber Tracks

44

Equipment Mounting Assembly

46

Engine Cover Assembly

48

Machine Cover Assembly

50

Diesel Engine Assembly

52

Diesel Engine Components

56

Pumps Assembly

58

Actuator Assembly

60

Reversible Fan System

62

Diesel Fuel Circuit

64

Oil Tank Assembly

66

Electrical Components

68

Electrical Wiring

72

Control Transmitting / Receiving Units

74

Intake & Drain Pumps

76

Change Over Valve Circuit

80

Tracks Hydraulic Circuit

82

Hydraulic Rams Circuit

86

Hydraulic Equipment Circuit

88

Flailhead Assembly

90

Rotors & Flails

94

1

GENERAL INFORMATION

Always read this manual before attempting to operate the machine –whenever any doubt exists

contact your dealer or the McConnel Service Department for advice and assistance.

Use only McConnel Genuine Service Parts on McConnel Equipment and Machines

DEFINITIONS –The following definitions apply throughout this manual:

WARNING

An operating procedure, technique etc., which –

can result in personal injury or loss of life if not observed carefully.

CAUTION

An operating procedure, technique etc., which –

can result in damage to either machine or equipment if not observed carefully.

NOTE

An operating procedure, technique etc., which is –

considered essential to emphasis.

LEFT AND RIGHT HAND

These terms are applicable to the machine when it is viewed from the rear facing forwards.

Note: The illustrations in this manual are for instructional purposes only and may on occasion not show

some components in their entirety. In some instances an illustration may appear slightly different to that of

your particular model but the general procedure will be the same.

MACHINE & DEALER INFORMATION

Record the Serial Number of your machine on this page and always quote this number when

ordering parts. Whenever information concerning the machine is requested remember also

to state the make and model of tractor to which the machine is fitted.

Machine Serial Number:

Installation Date:

Machine Model details:

Dealer Name:

Dealer Address:

Dealer Telephone No:

Dealer Email Address:

2

FEATURES & SPECIFICATIONS

ROBOMOZ

○33HP (24kW) Yanmar 3 Cylinder Diesel Engine

○Tracked Carriage Hydraulically Driven via Piston Pumps

○Grease System Track Tensioning

○Remote Controlled Operation (up to 150m range)

○Rubber Tracks

○Independent Cooling System for Hydraulic Circuits

○Electronically Controlled, Hydraulically Powered Flail Head

○0-7 km/h Forward / Reverse Speed with Slow / Medium / Fast Settings

○25 Litre Fuel Tank Capacity

○1.3m Flail Head

○Machine Weight 940kg

3

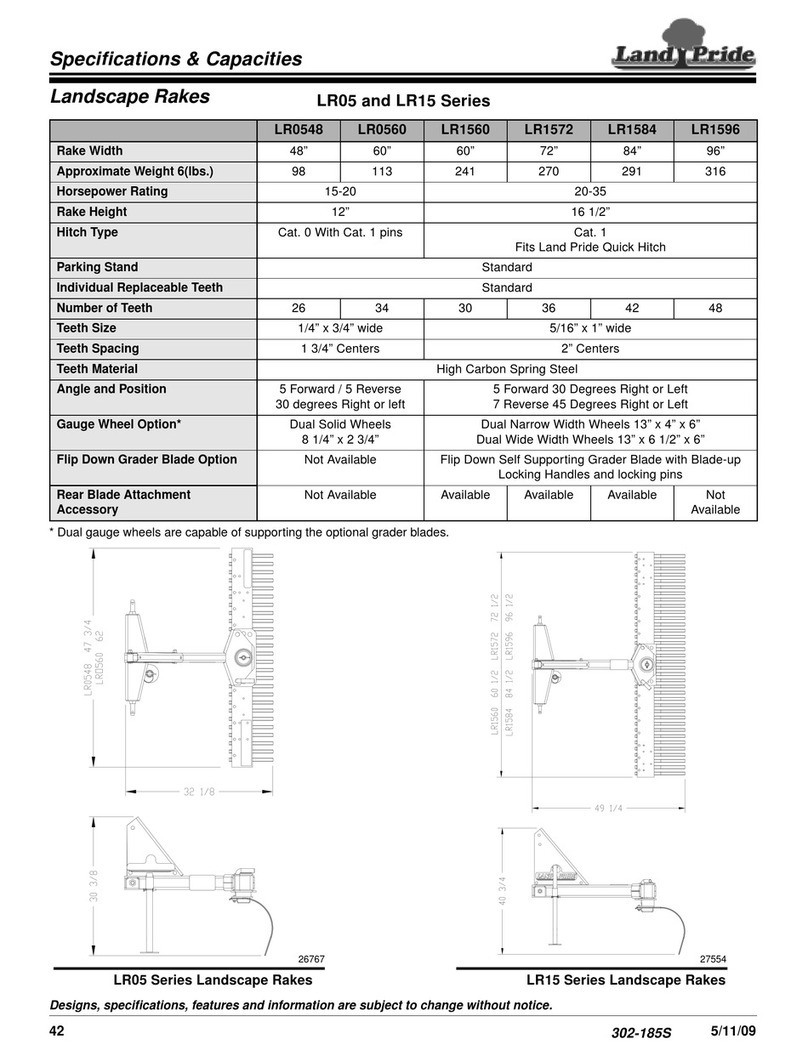

TECHNICAL DATA

Engine

Make: YANMAR

Model: 3TNV82A-BDYED

Cylinders: 3

Displacement: 1331cc

Power: 24Kw / 33HP

Torque (Max.) 86Nm @ 1800 RPM

Cooling: Liquid

Air Filter Type: Cartridge

Electrical System

Voltage: 12v (DC)

Alternator: 40 Amp.

Battery: 18Ah

Hydraulic System

Transmission: Tandem Piston Pump (closed circuit) max flow 57L@250 bar.

Mower Unit: Piston Pump (closed circuit) max flow 55L@290 bar.

Utility: Gear Pump max flow 12L@180 bar.

Transport Speed (@3000 RPM)

Slow Gear: 4 Km/h (Forwards or Backwards)

Fast Gear: 7 Km/h (Forwards or Backwards)

Machine Weights

Machine weight without equipment 940kg

Machine weight with 250mm rubber tracks and 1.3m mower head 1100kg

Machine weight with 280mm rubber tracks and 1.3m mower head 1190kg

Machine weight with 250mm tracks with spikes and 1.3m mower head 1210kg

Noise

The machine produces the following noise level: Acoustic Power Level = 105dB (A) LWA

4

SAFETY INFORMATION

This machine has the potential to be extremely dangerous - in the wrong hands it can kill or

maim; It is therefore imperative that both owner and operator of the machine reads and

understands the following section to ensure they are fully aware of the dangers that do, or may

exist, and their responsibilities surrounding the use and operation of the machine.

The operator of this machine is responsible not only for their own safety but equally for the

safety of others who may come into the close proximity of the machine, as the owner you are

responsible for both.

When the machine is not in use it should be parked on a firm level site with the cutting head

resting on the ground and the starting key removed.

In the event of any fault being detected with the machine’s operation it must be stopped

immediately and not used again until the fault has been corrected by a qualified technician.

Before starting the machine the operator must read and understand all aspects of use and

maintenance of the machine as stated in this manual.

The machine must only be used by a responsible adult who is familiar with all aspects

relating to safe operation.

The machine must not be operated by children or non-authorised persons.

Operators must know the meaning of all operation and safety decals on both the machine

and the remote control unit.

Operators must know the procedure for switching the machine off normally and the correct

procedure for using the Emergency Stop.

Do not attempt to use the machine if the Emergency Stop switch is damaged or

malfunctioning.

Never use the machine with safety guarding removed or defective.

5

Operators should practice operation on flat open ground to familiarise themselves with

driving and manoeuvring the machine before attempting to use it on sloping ground.

Operators should practice manoeuvring the machine around obstacles without the flail head

running before using the machine for work purposes.

Never operate the machine when your vision is blocked by obstacles such as vehicles,

buildings, hedges etc.; move to a position where you have an un-interrupted view of the

machine.

Never operate the machine standing directly in the line of travel.

Do not use the machine on sand piles, gravel, or similar materials.

Only operate the machine in good light conditions.

Never run the machine in an enclosed area or building.

Keep the machine clean to avoid build ups of dry materials that could ignite on hot

components.

Never stand directly below a machine that is operating or parked on a slope.

Always operate the joystick control slowly; rapid or jerky movements can cause the machine

to rear up causing loss of control.

When operating the machine with the flail head running the operator must remain at least 5

metres away from the machine; always switch the flail head off before approaching it.

When using the machine the operator should place themselves in a position that provides

optimum visibility over the work area.

Never leave a running machine unattended; always switch the engine off and remove the

ignition key.

Always stop and switch the machine off if persons or animals enter the work area, do not

restart the machine until they are at a safe distance.

Never use the machine to perform tasks it was not designed for.

Never ride, or allow others to ride on the machine.

Always inspect the work area prior to operation and remove stones, glass, metal, wire or any

other foreign objects that are hazardous. Immovable hazards should be ‘marked’so they

can be avoided.

Take extra care when operating the machine on slopes or uneven ground, there is increased

risk of objects being thrown from the flail head when working in these conditions.

The machine can be used on slopes of up to 50° (maximum) providing the surface is dry and

firm.

6

Should a machine overturn, a suitable crane or winch should be used to recover it, keep all

persons at a safe distance before and during recovery.

Do not operate the machine in foggy or frosty conditions as there is increased risk of

accidents.

Take extra care when working in close proximity to electrical cables; in some circumstances,

operating the machine under overhead power lines can result in loss of radio signal causing

the engine to deactivate.

Do not operate the machine close to vehicles or properties where there is risk of damage by

objects accidentally thrown from the flail head.

It is the user’s responsibility to protect persons in or near the work zone.

When servicing or maintaining the machine no one should be allowed beneath it when it is

raised unless it is securely supported on suitable ramps or stands.

Never attempt to service or maintain the machine whilst it is running; always switch off the

engine and remove the starting key.

When transporting the machine on another vehicle or trailer the engine must be switched off

and the machine chocked and secured using suitable ropes or chains.

Check the condition of the flails and fixings on a regular basis; never use the machine with

damaged/missing flails or loose fixings.

Always clean the machine after use; care must be taken if the machine is hot. Never use

solvent based chemicals for cleaning.

When operating in excessively dusty conditions work may need to be interrupted on a

regular basis to remove any build ups of dust on components that could cause overheating.

Always press the Emergency Stop switch before refuelling.

Wherever possible refuel the machine before work when the engine is cold. If refuelling

during work, switch off the engine and allow it to cool before adding fuel.

Test the Emergency Stop switch before each period of work to ensure it functions correctly.

Never leave the machine, ignition key and control unit unattended where it could be started

and used by un-authorised persons.

Any inspection, service or maintenance of the flail head must only be performed with

machine switched off and the starting key removed.

Always wear safety gloves and glasses when performing service or maintenance on the flail

head.

Flail head must always be switched off when manoeuvring outside of the work zone.

7

1. 2. 3. 4. 5. 6.

7. 8. 9. 10. 11.

12. 13.

SAFETY & WARNING DECALS

1. WARNING: Read the manual first.

2. DANGER: Risk of thrown objects, keep your distance.

3. DANGER: Electrical voltage and harmful substances.

4. DANGER: Rotating components, keep clear.

5. DANGER: Acid, read the user and maintenance manual.

6. DANGER: Hot components, risk of burns.

7. WARNING: Do not lubricate or service moving components, stop the machine first.

8. WARNING: Do not lift machine by the roll bar (if applicable) use hooks on machine frame.

9. WARNING: Do not use high pressure washer on or near machines electrical components.

10. ADVISORY: Machine lifting point.

11. ADVISORY: Emergency Stop button

12. ADVISORY: Always wear safety footwear when using the machine.

13. ADVISORY: Always wear ear defenders and safety glasses when using the machine.

8

Decal Locations

9

SAFETY DEVICES & EMERGENCY STOP

Automatic Emergency Safety Features

As the RoboCut is operated by remote control and the user is not directly operating the driving

elements of the machine specific safety features have been built in to protect the user, third

party persons and the machine itself; these are as follows

Danger / Risk Situation

Automatic Safety Feature

Machine beyond signal reception area or radio signal blocked.

EMERGENCY STOP will activate.

Radio signal failure.

EMERGENCY STOP will activate.

Another machine on same frequency operating in the area.

EMERGENCY STOP will activate.

Manual Emergency Safety Feature

In addition to the automatic safety features stated above the operator can immediately stop

machine movements / operations either by pressing the Emergency Stop button located on the

remote control unit or by pressing the Emergency Stop button located on the top panel of the

machine itself.

In all instances stated above, emergency stopping of the machine will take a maximum of 0.2

seconds from execution of the automatic or manual command and the following actions will

occur;

Machines to June 2015;

Machine movement / operations and functions will be halted.

Electrical voltage will be deactivated.

Entire electrical system will be disabled.

Engine will be switched off

Ignition will be turned off.

Machines June 2015 onward;

Machine movement / operations and functions will be halted.

Engine will remain running (Engine RPM is automatically reduced to idle speed).

Note; after using Emergency Stop the machine will cease to function completely, to regain

functions and continue operating the Connection/Horn button on the Remote Control Unit must

be operated or the engine manually switched off and a normal restart performed.

In the unlikely event of movement malfunction

If machine movements perform in an unexpected or incorrect manner follow the instructions

below;

1) Release the forwards/backwards movement joystick –the control is equipped with automatic

zero position; on release it will automatically return to the central (stop) position, this action

activates the track brakes.

2) Press the Emergency Stop button on the control unit.

DANGER! Do not approach the machine if it is moving.

3) Press the machine’s Emergency Stop button.

4) Turn the ignition key into the off position (anti-clockwise) and remove the key.

Contact your Authorised Dealer or McConnel Service –do not attempt to operate the

machine until advice has been sought.

Table of contents

Other McConnel Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

New England Arbors

New England Arbors Cambridge Raised Planter Extension Kit Assembly instructions

MO-EL

MO-EL MO-STICK INOX 372 Use and maintenance

Troy-Bilt

Troy-Bilt OEM-290-257 Operator's manual

Zhejiang Longyard Trade Industrial

Zhejiang Longyard Trade Industrial NE-0608 Owner's manual and assembly instructions

PROZIS

PROZIS HABITAT user manual

TURFCO

TURFCO TurnAer 6 Operator's manual