18

Product Code Product NamePart No Package Count Product Code Product NamePart No Package Count

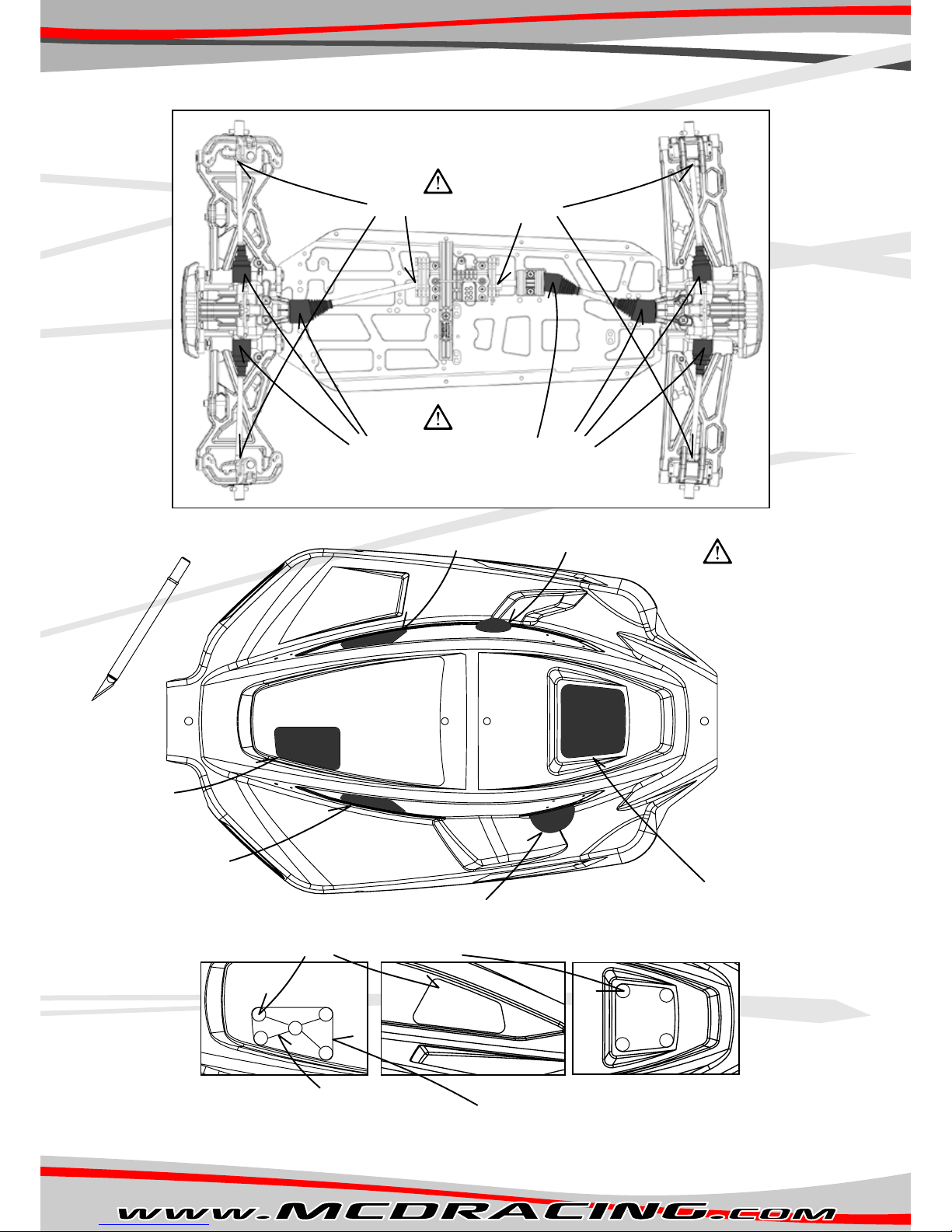

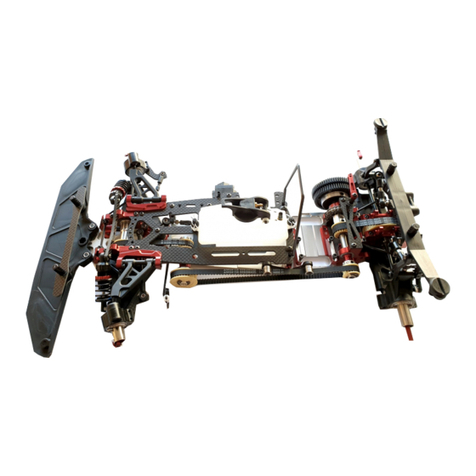

04 Chassis, Towers & Guards

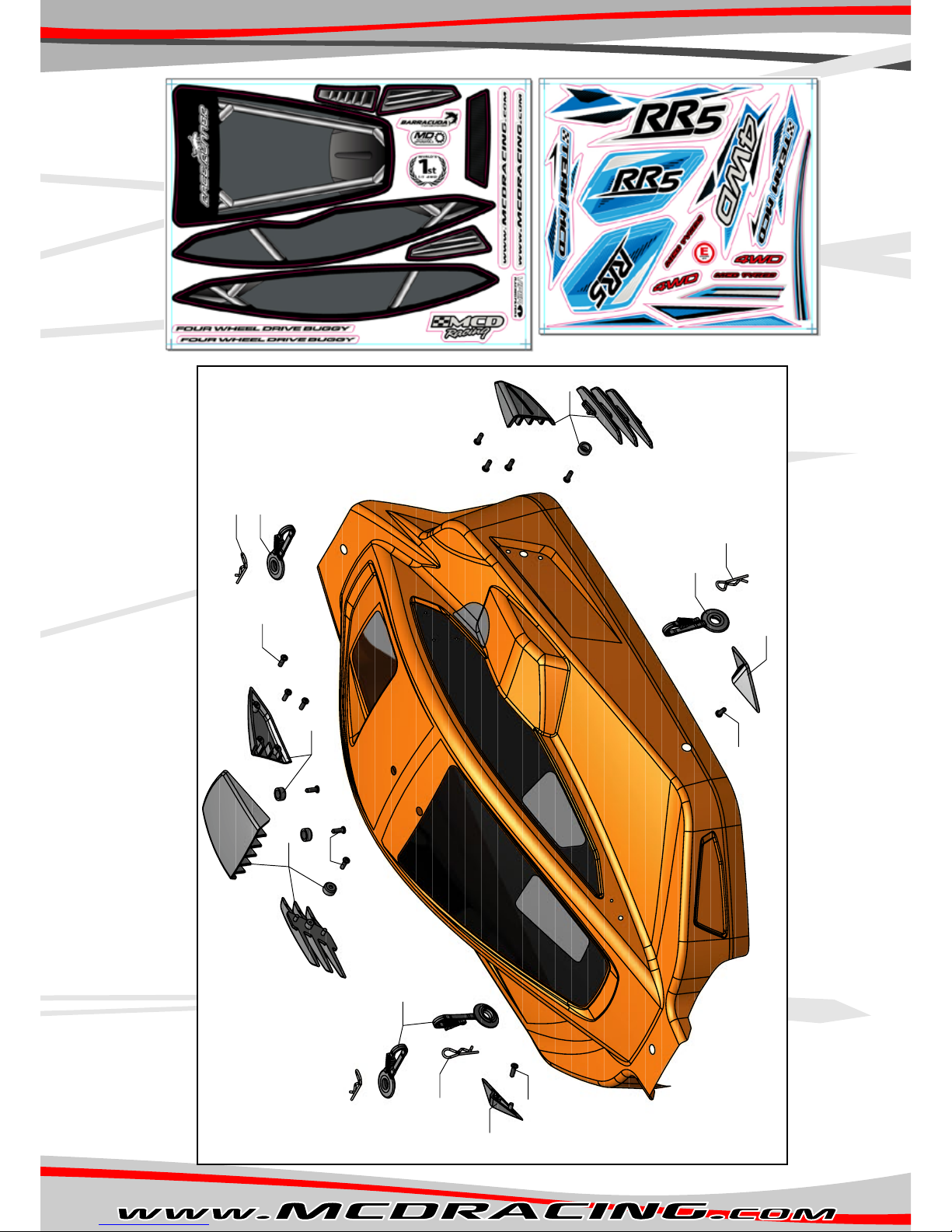

05 BodyShells & Accessories

06 Bearings,Screw and Related

340101P Rod End / Body Mount / Linkage Plastic Set3401 2

340201S Shock Joint Ball3402 4

340301S Tower Joint Ball3403 4

340401S Linkage Hub Joint Ball3404 4

340501S Steering Joint Ball3405 4

340601S Steering Servo Arm Joint Balls (2x3 2x4 )3406 4

340701S Anti-Roll Bar Upper Joint Ball3407 4

340801S Anti-Roll Bar Lower Joint Ball3408 4

340901S Shock Lower Screw Left Thread3409 2

360201A Anti-Roll Bar Shaft3602 1

360301S Anti-Roll Bar Spring 3.5 mm3603 4

380101P Composite Servo Saver Set3801 1

380201A Ackerman Plate Standard3802 1

380202A Ackerman Plate Less (Opt.)3802 1

380301A Steering Post3803 2

380401A Servo Saver Alloy Body3804 1

380501A Servo Saver Wheel Nut3805 1

380601S Servo Saver Spring3806 1

380701S Ackerman Plate Screw Hardened3807 2

380801S Ackerman Plate Thrust Washer Hardened3808 2

380901S Steering Post Thrust Washer3809 2

381001S Steering Servo Turbuckle3810 2

400101A Lightweight 7075 Chassis Anodised4001 1

400201P Chassis Composite Side Guard L/R Set4002 1

400301P Front/Rear Bumper4003 2

415101P Front/Rear Diff. House Set4151 1

415201P Center Diff. Holder Set4152 2

415301P Brake Plate & Gear Guard4153 1

415401P Lay Shaft Carrier Set4154 1

415501P Clutch Bell Carrier4155 1

415801P Clutch Bell Carrier / Brake Plate Stiffener4158 2

430101A Front Tower Lightweight 70754301 1

430201A Rear Tower Lightweight 70754302 1

445101P Front Stiffener4451 1

445201P Rear Stiffener Set4452 1

460101P Gear Mesh Selection Plate/DiffHouse-Sti ffener Spacer4601 2

460201A Engine Carrier Plate Lightweight 7075 Anodised4602 1

460301S Engine Mount Chassis Slot Insterts 2x M64603 3

460401S Engine Mount Slot Washers4604 5

460501S Gear Mesh Selection Plate Thrust Washer4605 2

475101P Radio/Servo Tray 30x60mm Futaba/Hitec Std.4751 1

475102P Radio/Servo Tray 30x66mm Savox (Opt.)4751 1

475201P Radio Tray Covers Set4752 1

475301P Standard Size Servo to 30x60 Adapter4753 3

500101P RR5 Body Shell Kit Complete5001 1

500201P RR5 Body Shell Composite Accessories5002 1

500202P RR5 Body Shell Decal Set5002 1

500301P Buggy Rear Wing5003 1

500401P Buggy Rear Wing Mounts5004 1

500601P Rear Wishbone Mudguards5006 1

500701P Body Mount Clip Holder5007 4

500801S Body/Tray Clips5008 10

600101S Ball Bearing 687 2RS (7x14x5)6001 4

600201S Ball Bearing 689 2RS (9x17x5)6002 4

600301S Ball Bearing 6900 2RS 10x22x66003 2

600401S Ball Bearing 6901 2RS 12x24x66004 2

600501S Ball Bearing 6903 ZZ 17x30x76005 2

600601S Ball Bearing 6804 2RS 20x32x76006 2

600701S Ball Bearing 6000 2RS 10x26x86007 2

605101S Roller Pin 4x20 mm6051 10

605201S Roller Pin 4x35 mm6052 5

605301S Roller Pin 5x24 mm6053 5

605401S Roller Pin 5x40 mm6054 2

610101S Fuel Tank Cap Ball Set6101 1

610201S Drive Ball 6 mm6102 25

615101S LSD Diff. Shim 10x16x0.36151 10

615201S Pinion Gear Shim 16x22x16152 5

620101S CS PZ2 Self Tap 4x25 mm6201 10

620201S CS PZ2 Self Tap 4x70 mm6202 10

620301S CS PZ2 Self Tap 5x30 mm6203 10

625101S BH PH1 Self Tap 3x9 mm6251 25

625201S BH PH1 Self Tap 3x13 mm6252 10

630101S CH Hex Screw M4x8 mm6301 10

630201S CH Hex Screw M4x12 mm6302 10

630301S CH Hex Screw M4x16 mm6303 10

630401S CH Hex Screw M4x25 mm6304 10

630501S CH Hex Screw M4x30 mm6305 10

630601S CH Hex Screw M4x35 mm6306 10

630701S CH Hex Screw M5x10 mm6307 10

630801S CH Hex Screw M5x16 mm6308 10

630901S CH Hex Screw M5x40 mm6309 10

631001S CH Hex Screw M6x20 mm6310 10

631101S CH Hex Screw M5x25 mm6311 10

631201S CH Hex Screw M3x6 mm6312 10

631301S CH Hex Screw M3x12 mm6313 10

631401S CH Hex Screw M3x20 mm6314 10

635101S CS Hex Screw M4x12 mm6351 10

635201S CS Hex Screw M5x16 mm6352 10

640101S BH Hex Screw M4x25 mm6401 10

640201S BH Hex Screw M6x30 mm6402 10

645201S Set Screw M4x4 mm6452 10

645301S Set Screw M5x6 mm6453 10

645401S Set Screw M5x12 mm6454 10

645501S Set Screw M6x6 mm6455 10

645601S Set Screw M6x20 mm6456 10

650101S Self Lock Nut M36501 20

650201S Self Lock Nut M46502 20

650301S Self Lock Nut M56503 20

650401S Self Lock Nut M66504 10

655101S Plain Washer 4 mm6551 20

655201S Plain Washer 5 mm6552 20

655301S Plain Washer 6 mm6553 10

665101S Snap Ring 1x10 mm6651 10

670101R LSD Diff. O-Ring 1.5x10 mm6701 20