10 3210-552 3/18

Problem How To Check Solution

iQpump is on AUTO, green LED is

blinking, pump is not running.

iQpump is sleeping. System demand is low. Once the outlet pressure has fallen below

the start/draw down level, the iQpump will start the pump.

Water is leaking from around

motor/pump coupling

Turn system off. Remove motor coupling

guards. Observe mechanical seal for

leaks.

Replace mechanical seal. See Pump manual 3210-528.

Alarm light is blinking and

Digital Operator Display

indicates Alarm.

Review code and error displayed on

screen. Take appropriate actions to x

the alarm problem.

If problem still persists, call factory for alarm troubleshooting.

Alarm light is lit and Digital

Operator Display indicates Fault.

Review code and error displayed on

screen. Take appropriate actions to x

the faults.

Turn power off to the system using the disconnect. Wait 20

seconds and turn power back on. Press the RESET key, and then

press AUTO to restart the system. If the fault re-occurs, call

factory for fault troubleshooting.

Problem How To Check Solution

Pressure tank too small Pressure tank size should a minimum 25% of

total booster ow. A booster system delivering a

maximum of 240 gpm should have a minimum tank

size of 60 gallons.

Replace or add additional pressure tanks.

Incorrect air pressure in tank For discharge or bladder captive air tanks, drain the

tank of water and check the precharge air pressure.

It should be 15 psi below the pressure setpoint.

Fill precharge air pressure in tank to specied value (ensure

water pressure is zero). Replace tank if it will not hold air

pressure.

Increase Start/Draw Down

Level

Refer to Section 2.7. Sleep boost increases the

setpoint pressure before putting the system to

sleep.

Increase the (negative) valve of P1-04. The pressure tank

precharge level may need to be adjusted.

Transducer valves closed or

transducer piping blocked

Verify that pressure feedback (U1-91) on home

screen matches discharge pressure gauge. If the

two are more than 5 psi apart, ensure all test valves

on transducers are open and there is no blockage in

piping.

Open all test valves on transducer piping. Clear any

blockage. If problem still persists, replace transducer.

Problem How To Check Solution

Bypass line/valve open Locate bypass valve (if applicable) . Ensure valve is

completely in the closed position

Close valve entirely.

Pump Isolation Valves are

closed

Locate pump isolation valves located on the inlet

and outlet of each pump. Both valve handles should

in the open position

Open valves entirely (parallel with pump).

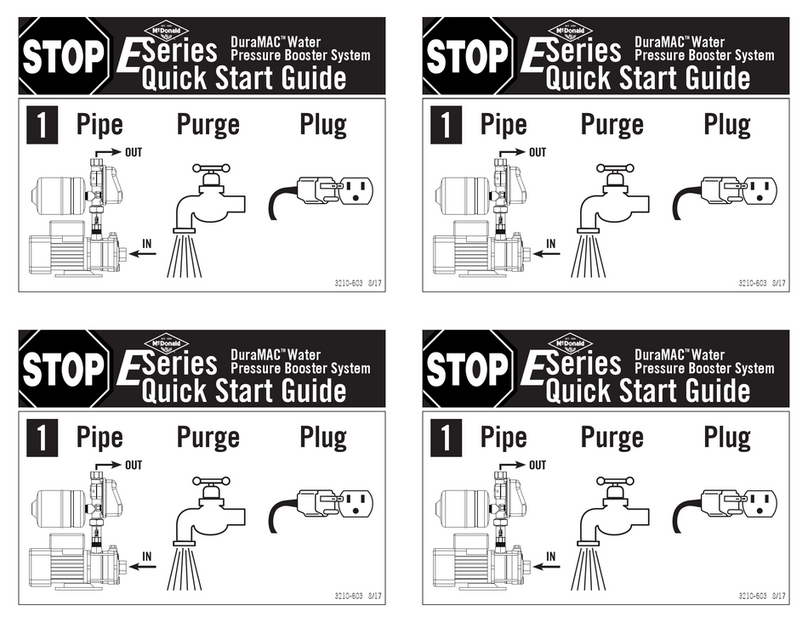

Pump may be air locked Locate the purge port located on top of the pump.

Loosen the smaller hex bolt slightly. Listen for air

escaping.

Keep purge port open until all air has been evacuated and

a steady stream of water is owing. Close purge port.

Pump may have lost Prime Check suction pipes, check valves, and foot valves

for leaks.

Ensure suction piping is pressure tight. Replace check

valves or foot valves as necessary. Re-prime as needed

using the pump ll port.

Shaft Coupling loose Turn system off and switch disconnect to “OFF”

position. Remove shaft cover and inspect motor

coupling.

If loose, refer to maintenance section of Manual 3210-528

for correct shaft coupling reassembly.

Motor operating in wrong

direction

View motor direction from top. Motor should turn in

direction of arrow on pump.

If backwards, switch any two motor leads at the drive.

Ensure drive is off, power is removed, and charge indicator

has been extinguished before removing terminal cover.

3. Troubleshooting

General Troubleshooting

Problem: Pump is running but does not deliver water

Problem: Pump short cycles or continues to run