SPECS&MAINTENANCE

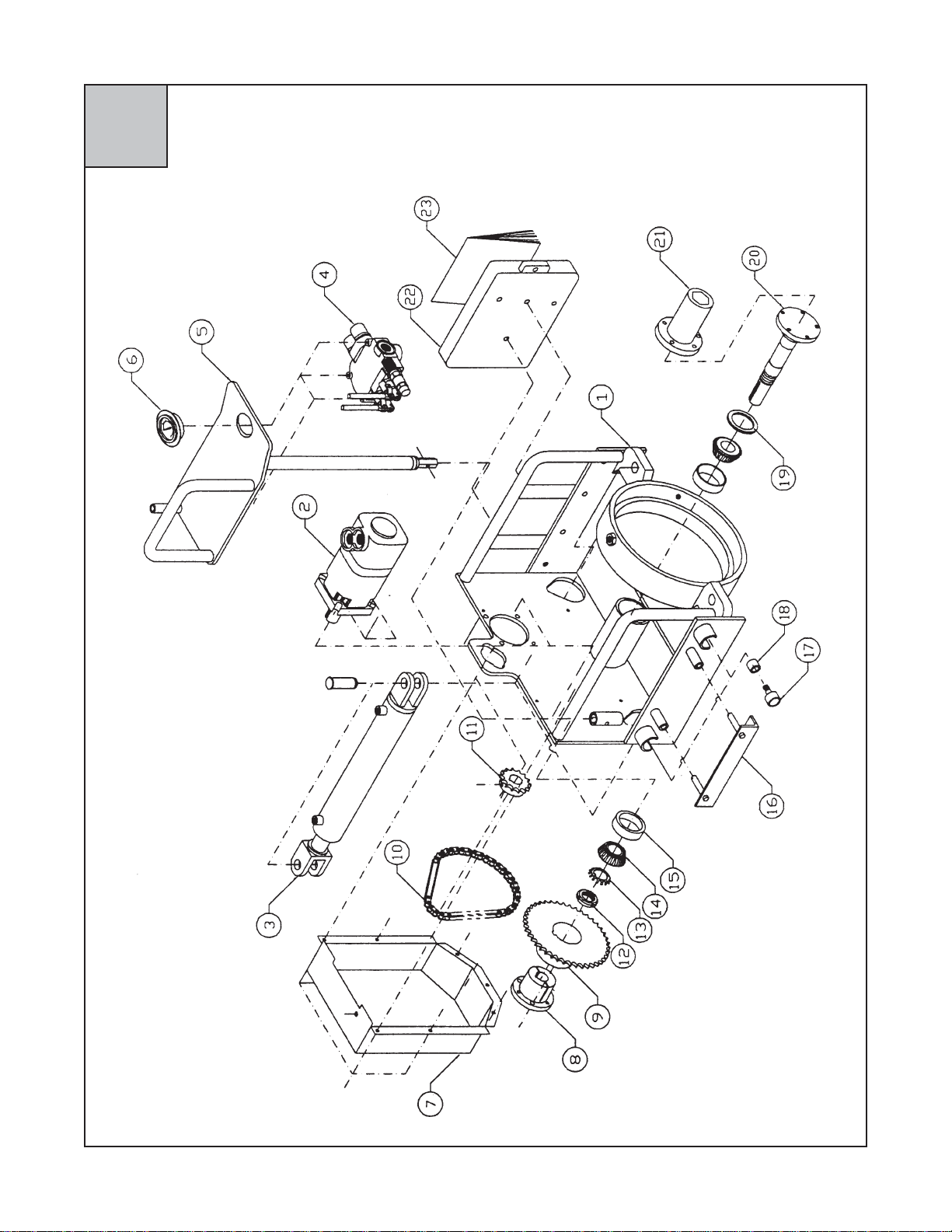

McL-12HB ZIPPER

SPECIFICATIONS OF McL-12HB

EARTH BORING MACHINE

Tunnel Diameter

Free or Cased Bore 3”-12” (8-30 cm)

Chain Final Drive

Hex Size 13/16” (2.06 cm)

(customer to specify) 1-1/8” (2.85 cm)

1-3/8” (3.50 cm)

1-5/8” (4.12 cm)

Dimensions

Carriage and Pusher

Centerline Height 9-1/2” (24.1 cm)

Width 26” (66.0 cm)

Height 44” (111.8 cm)

Weight (Less Dog Plate) 320 lbs. (145 kg)

Weight (Dog Plate) 40 lbs. (18 kg)

Master Track

For 4’Augers

Length 7’ (213 cm)

For 3’Augers

Length 6’ (183 cm)

Weight 85 lbs. (39 kg)

Extension Track

Length 6’ (183 cm)

Weight 75 lbs. (34 kg)

Performance

Advance Thrust

@ 2500 PSI 24,500 lbs. (109 kN)

Drive Chuck Speed

@ 20 GPM (Forward & Reverse) 120 RPM

Drive Chuck Torque

@ 2500 PSI

(Forward & Reverse) 1030 ft.* lbs. (1340 Nm)

Quick Disconnects

Parker NS-752-12FP and NS-751-12FP

Female disconnect ON MACHINE is the high pressure

side of system.

Specifications are subject to change without notice. All

weights and dimensions given are approximate. Exact

measurements should be verified if required.

MAINTENANCE INSTRUCTIONS

Review the Engine and Operation Manuals supplied

with the power source before starting and operating the

machine. Follow manufacturers recommendations for

operation and maintenance to maintain your engine

warranty.

REPAIRAND MAINTENANCE/GENERAL

Carriage/Tightness of Nuts & Bolts

Check four (4) bolts that mount chuck to the drive shaft

flange of the McL-12HB initially, then check each week

when in continuous use. Each bolt should have lock

washer. Tighten as needed.

Check four (4) bolts that mount hydraulic motor to the

McL-12HB carriage initially, then check each week

when in continuous use. Tighten as needed.

Check nine (9) bolts that hold sprocket cover to the

back of the McL-12HB initially, then once each month

when in continuous use. Tighten as needed.

Check all hydraulic fittings initially, then check each

week when in continuous use. Tighten as needed,

taking care not to twist hoses from original positions.

Check nuts (4) on cam rollers initially, then once each

month when in continuous use. Tighten as needed.

Carriage/Lubrication

Approximately every 50 hours of operation, lubricate

the chain drive of the McL-12HB. To do so, use the

grease fitting on the top of the chain guard. Use about

5-10 pumps with spindle rotating slowly. Do not over

lubricate the chain. Also, periodically grease the cam

rollers with all purpose bearing grease.

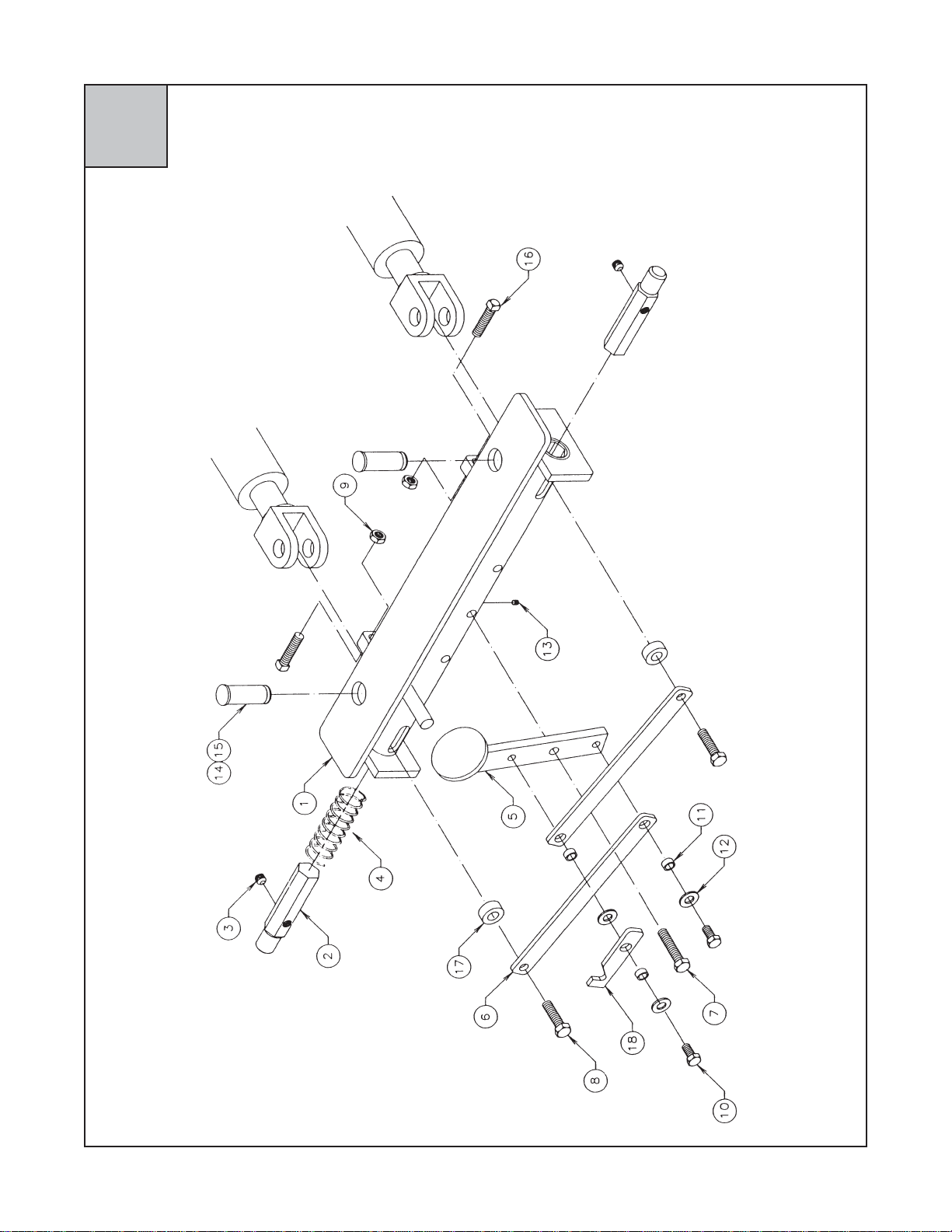

Carriage/Quick Disconnects

Wipe each Quick Disconnect with a clean rag to

remove excess oil and dirt. Always return covers to

Quick Disconnects when machine is not in use.

Carriage/Miscellaneous

Once a month, inspect the two (2) hitch pins (also

called Auger Pins, R-Clips, R-Pins) that hold the clevis

pins in place. Replace if worn or damaged.

Also, check hitch pins that hold machine hold downs in

place. Replace if worn or damaged.

After each boring operation is completed, clean the

carriage to remove dirt and mud. Use water if avail-

able. Always clean the unit before storage.

1.1.0