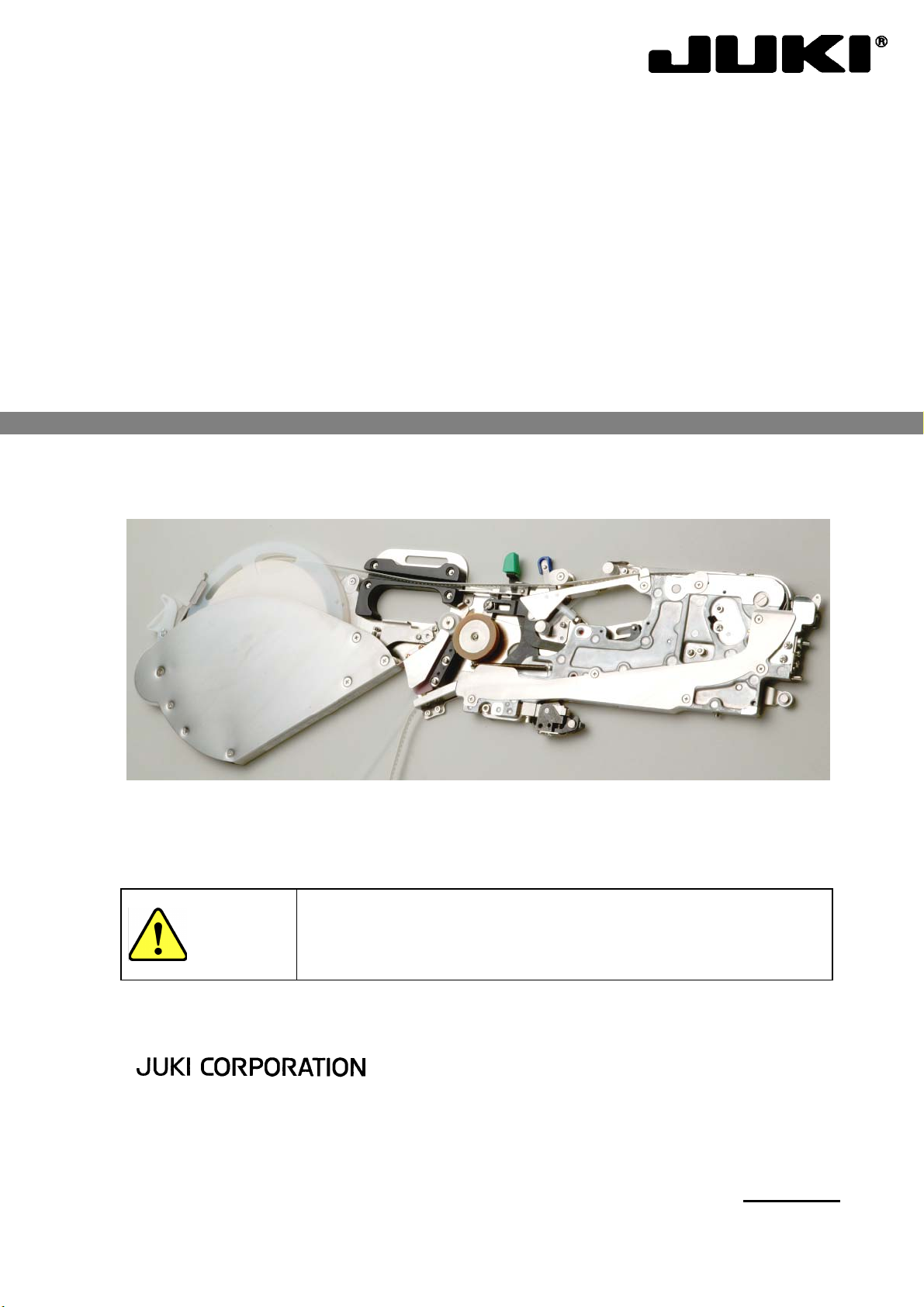

ATF Instruction Manual

Table of Contents

1. Overview .....................................................................................................1

1.1 Features ......................................................................................................................... 1

1.2 Specifications................................................................................................................. 1

1.3 Name of Each Part......................................................................................................... 2

2. How to Use..................................................................................................4

2.1 Attaching or Detaching the Tape Reel........................................................................... 4

2.1.1 How to attach the tape reel..................................................................................4

2.1.2 Removing a tape..................................................................................................8

2.2 Carrying the Tape Feeder.............................................................................................. 9

2.3 Feeding a Component (Enabling a Component To Be Picked Up)............................... 9

2.4 Splicing........................................................................................................................... 10

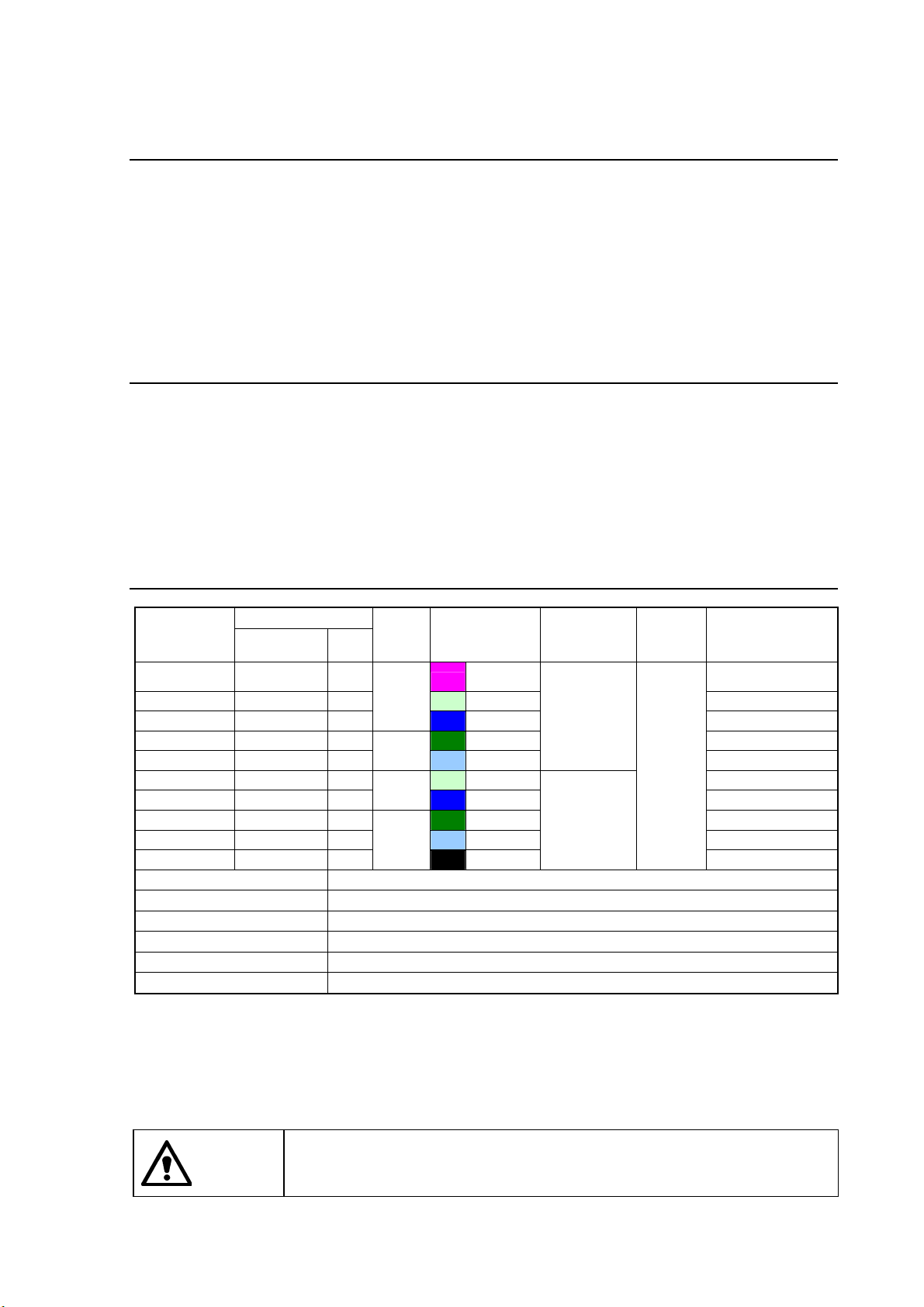

2.4.1 Specifications of a splice tape .............................................................................10

2.4.2 How to splice tapes .............................................................................................10

2.5 Attaching or Detaching the Tape Feeder onto a Mounter ............................................. 15

3. Daily Inspection..........................................................................................16

3.1 List of Daily Inspection Items ......................................................................................... 16

3.2 Where to Inspect............................................................................................................ 17

3.3 Where to Clean .............................................................................................................. 20

3.4 Where to Lubricate......................................................................................................... 23

3.5 Parts to Be Replaced Regularly..................................................................................... 24

3.5.1 List of parts to be replaced regularly ...................................................................24

3.5.2 How to replace a part that is to be replaced regularly.........................................24

4. Options........................................................................................................28

4.1 Bar Code Tag................................................................................................................. 28

4.1.1 Attaching a bar code tag......................................................................................28

4.2 Embossed Tape Spacer ................................................................................................ 29

4.2.1 Pasting an embossed tape spacer ......................................................................29

4.2.2 Combination of the embossed tape spacer thickness.........................................29

4.3 Joint tape........................................................................................................................ 30

4.4 Tape reel attaching platform .......................................................................................... 30