TABLE OF CONTENTS

What You Can Do With This Machine .................................................. 9

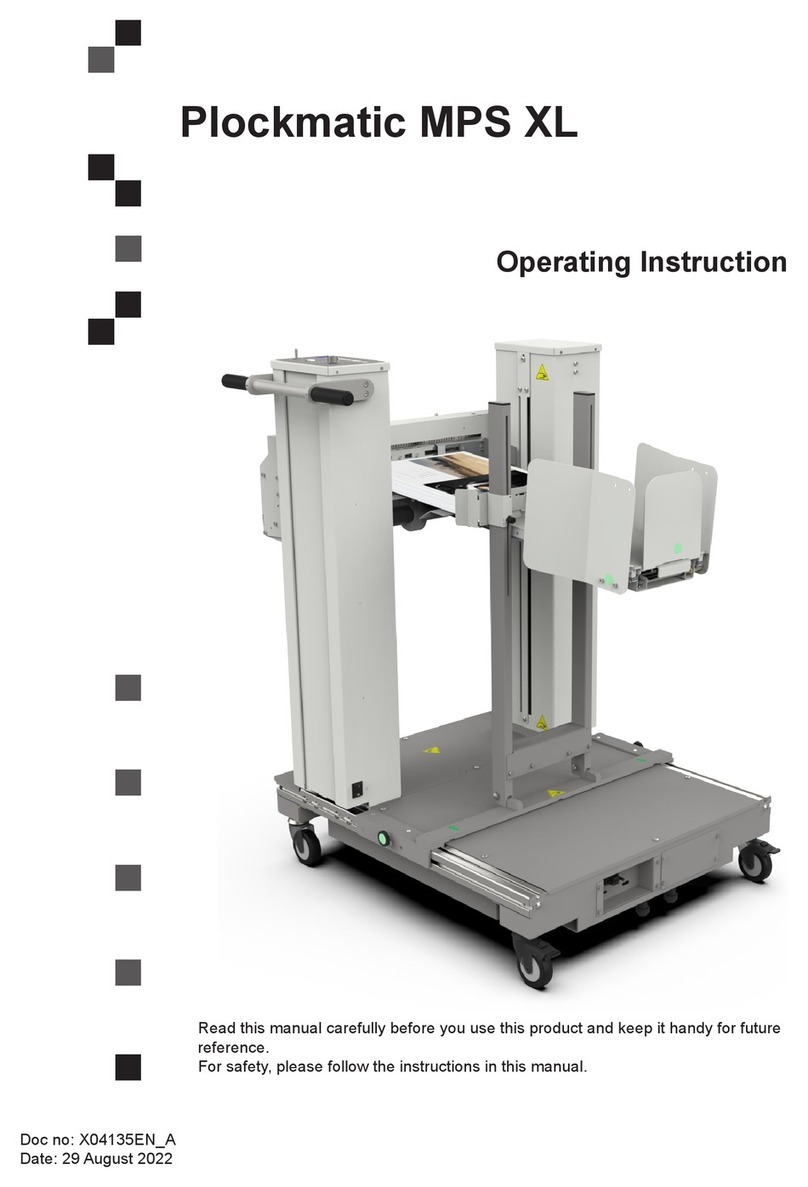

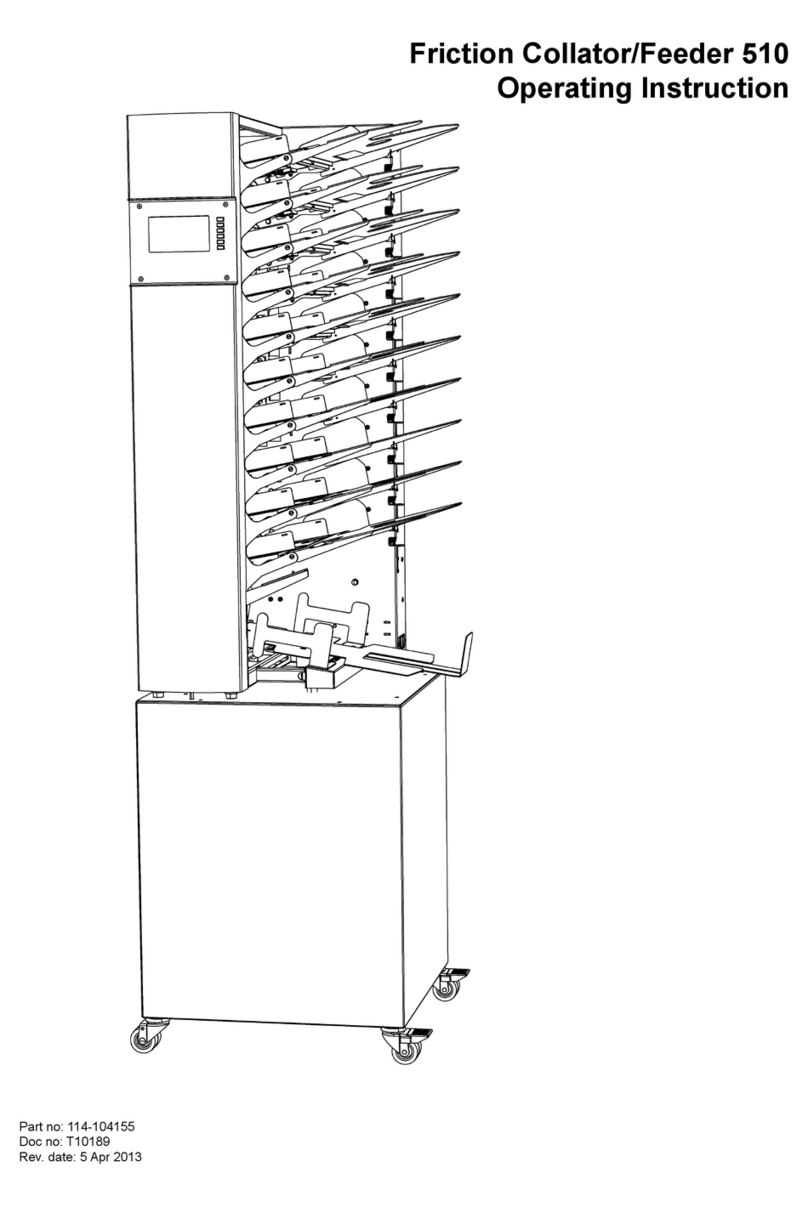

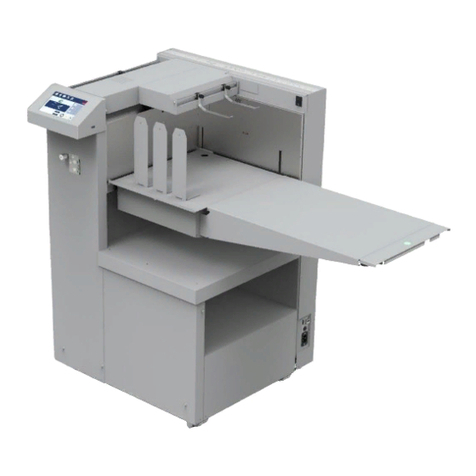

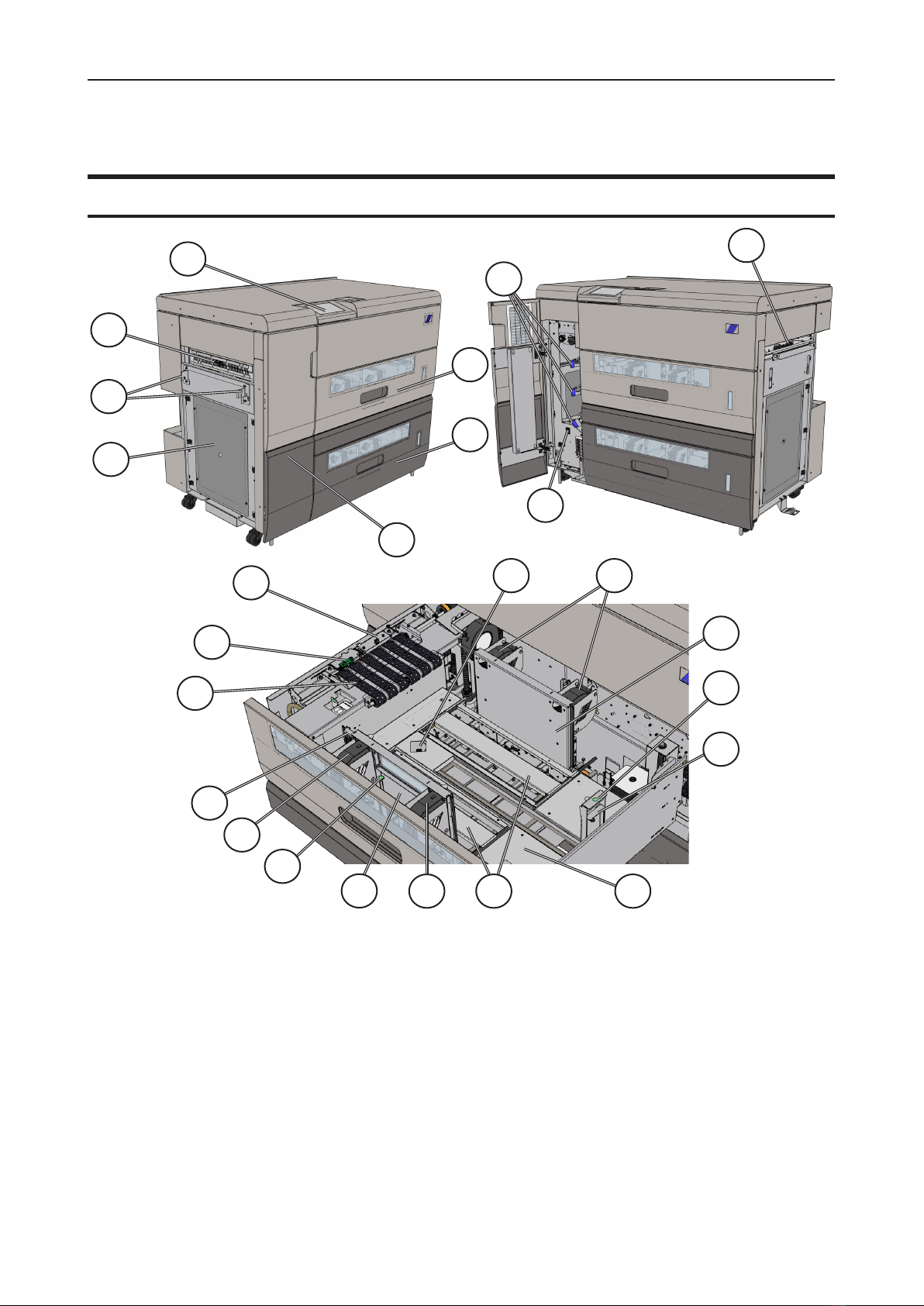

Guide To Components ..................................................................................................... 11

HCI3500...................................................................................................................................... 11

User Interface ............................................................................................................................. 14

1. Basics............................................................................................... 17

Turning On / Off the Power .............................................................................................. 17

Calibration......................................................................................................................... 18

Job Preparation ................................................................................................................ 19

Paper stack preparation.............................................................................................................. 19

Measuring the paper curl ............................................................................................................ 21

Loading Paper ............................................................................................................................ 22

2. Setting Up a Job .............................................................................. 25

Settings Sub-Menus......................................................................................................... 25

Settings....................................................................................................................................... 25

Tray A/B ...................................................................................................................................... 25

Auto Fans / Manual Fans............................................................................................................ 26

Paper Curl................................................................................................................................... 26

DSD Sensors .............................................................................................................................. 27

Advanced.................................................................................................................................... 28

Manual Fans Adjustment ............................................................................................................ 28

Process Position ......................................................................................................................... 31

Saving changes .......................................................................................................................... 32

3. Tools ................................................................................................. 33

The Tools Menu ................................................................................................................ 33

Units............................................................................................................................................ 33

Language.................................................................................................................................... 33

Test ............................................................................................................................................. 34

Calibrate DSD and Ultrasonic DSD ............................................................................................ 34

Service Mode.............................................................................................................................. 34

Software version ......................................................................................................................... 35

4. Jobs .................................................................................................. 37

Handling jobs.................................................................................................................... 37

Loading a Job ............................................................................................................................. 37

Saving a Job ............................................................................................................................... 38

Saving a New Job....................................................................................................................... 38

Deleting a Job............................................................................................................................. 38

5. Clearing Misfeed(s) ......................................................................... 39

Clearing Misfeed(s) .......................................................................................................... 39

Misfeed / Jam in Feeder Tray ..................................................................................................... 39

Misfeed / Jam in Paper Transport Area ...................................................................................... 39

Misfeed / Jam in Infeed / Bypass Area ...................................................................................... 39