www.measumax.com

INSTRUCTIONS FOR IP67 CALIPER WITH ABSOLUTE

ENCODING SYSTEM

31-1851, 31-1861, 31-1871

Thank you for purchasing this product. This product has the same reliability as a vernier caliper but with a high protec-

tive level. It can be used in conditions where the instrument is , exposed to coolant, water, dust or oil. The IP67 rating

allows for the digital caliper to be used in water for a short period of time.

The Measumax Absolute encoding measuring system is designed to avoid the loss of the measurement origin when

the slider is moved very fast or is interfered. The need for setting the origin each time before measuring is also re-

moved. After replacing the battery the origin is retained.

In order to maintain the eciency of this product, please carefully read and keep the instructions for future reference

FEATURES

• New patented electromagnetic induction displacement measuring system with absolute en

• Waterproof, oil proof, anti-electromagnetic, interference, protection Level IP67 (CEI60529)

• Two-button design, menu prompt, simple, convenient and easy to operate

• Manual/Automatic power switch, automatic shutdown after 5 minutes without being used

(Note: Some models will automatically reboot after a 16 hour shutdown when the slider is moved)

• Low-voltage alarm, high and low temperature, and other error alarm

• Innite response speed, no speed error

• ABS/INC mode and metric/inch units conversion

Technical Data

• Measuring Range 0-150mm/6in, 0-200mm/8in, 0-300mm/12in

• Resolution: 0.01mm/0.0005in

• Repeatability: 0.01mm/0.0005in

•Operating Temperature: 0°C-40°C

•Storage Temperature: 10°C-60°C

• Relative Humidity: 100%

• Protective level: IP67(CEI60529)

• Battery Type: 3V Lithium Battery (CR2032)

• Battery Life: Approximately 2000 hours

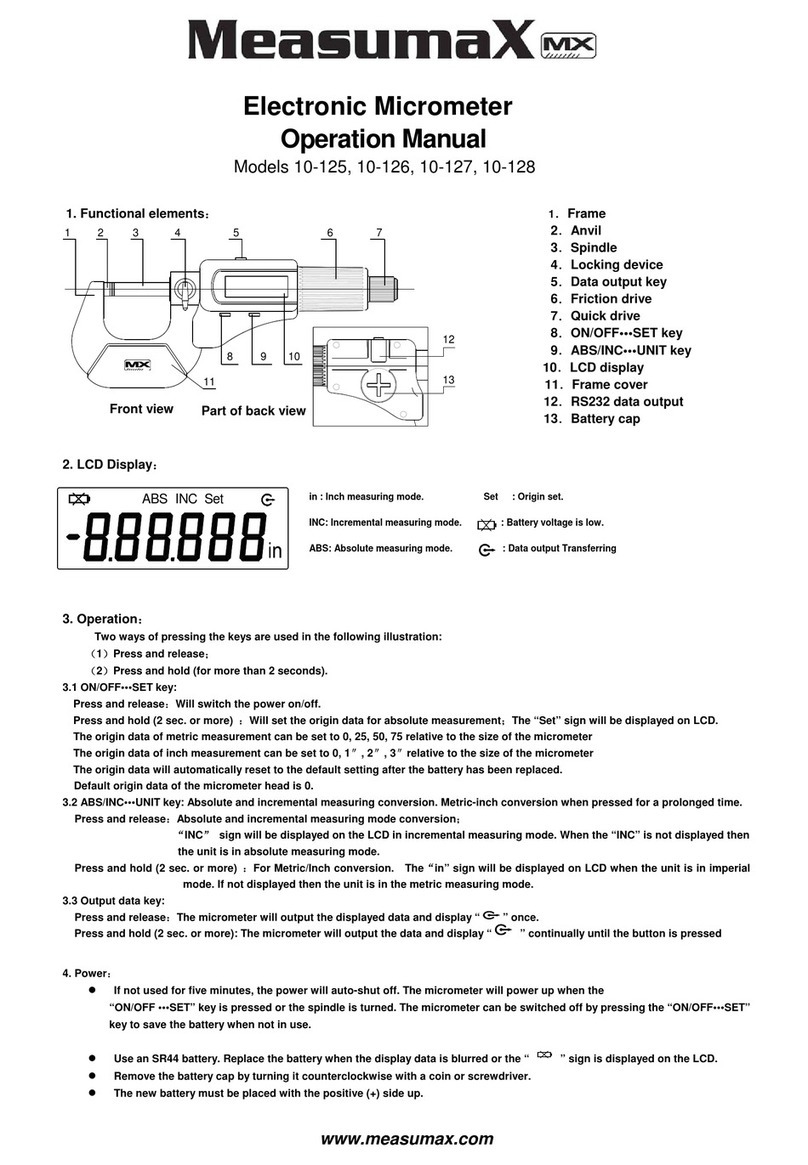

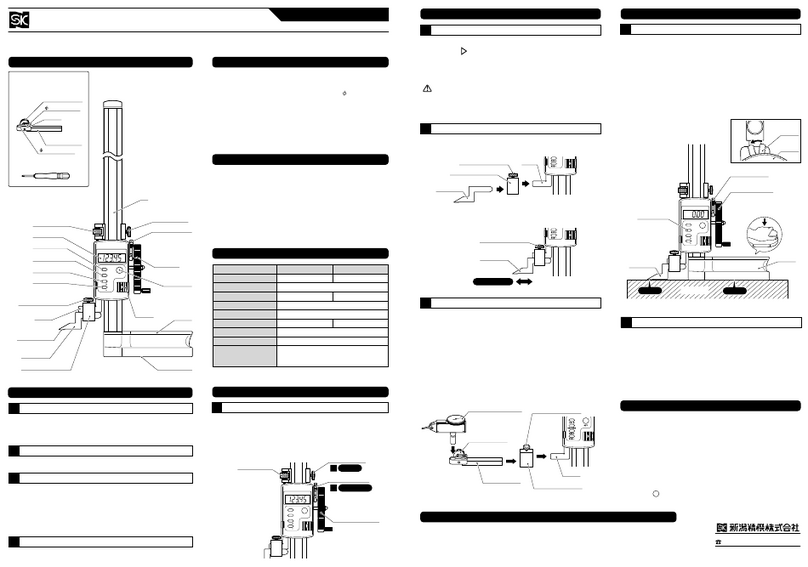

Structure Diagram and the name of the main components

Changing The Battery

To load the new battery undo the 3 screws on the

battery cover and remove the at battery.

Place the new battery into the battery seat with “+”

sign facing up, then replace the battery cover and

tighten the screws (Note: Replace the battery in a

dry environment and as quickly as possible so as to

avoid water vapor entering the electronic components)

When replacing the battery, replace the sealing O-ring

in the case if deformed or damaged

ABS/INC Conversion

In the ABS mode, when the lower jaws is closed, “0.00” is displayed, namely the absolute origin position of the digital

caliper and ABS is displayed on LCD screen. For relative measurements at any position, just press the button “0-ON”

and INC is displayed on the LCD screen and 0.00 is displayed in the INC mode (relative measurement mode). To con-

vert to ABS mode, just press the button “0/ON” until ABS is displayed on the LCD screen and then release the button.

The absolute position value is then displayed.

MM/IN Conversion

Press the button “MM/IN” to switch to change between mm or inch mode.

Manual shutdown

To manually shutdown the instrument press the button “0/ON” until OFF is displayed and then release the button.

(Note: Keep pressing the button 0/ON, INC→ABS→ OFF→ INC will be displayed on the LCD screen periodically.

When the needed function menu appears, release the button,

• Button & coin batteries (new or used) are hazardous and are to be kept away

from children

•If a lithium button/coin battery is swallowed or placed inside the body can cause

fatal injuries in 2 hours or less

•If a non-lithium button /coin battery is swallowed or placed inside the body can

cause serious injuries

•Medical attention should be sought immediately if suspected the battery has

been swallowed or placed inside the body

•Phone 13 11 26 Australian Poisons Information Centre for 24/7 fast,

expert advice

WARNING!