Measuring The Coolant Concentration: it is best to clean

the instrument test area, both the daylight plate and the top of

the main prism assembly by using a soft damp cloth.

Then once the scale has been calibrated place 1 to 2 drops

of cutting uid onto the prism glass and close the plate cover

(Fig.4). If you are measuring the current concentration of a

sump it is recommended to ll a paper cup with the your used

cutting uid and let it sit for 10 minutes. Then poke a small

hole in the middle of the cup and use the stream of coolant to

take your sample. When you look through the refractometer

your reading is measured at the intersection of where the two

blue & white colours meet - example 3 Brix. (Fig.5)

Note! It is important to note that each coolant has its own

unique concentration readings. Coolant can have a different

refractometer reading of 9.2°Bx at 10% concentration (10:1)

while another coolant may have reading of 3.3°Bx at 10%

concentration (10:1)

Example: Coolant with a Refractometer Index of 2. Therefore

if the scale measures 3 on the Brix scale then we multiply this

gure by the index (2 x 3 Brix = 6) concentration ratio is 6:1

The advantage of checking coolant with a refractometer is

that it can also indicate when the coolant is dirty and old. This

is displayed as a fuzzy or blurred line where the top colour

meets the white bottom of the scale. Clean coolant will display

a sharp line. (Fig.6)

Automatic Temperature Compensation (ATC) System:

The Measumax 70-670 unit has an Automatic Temperature

Compensation system (ATC). Please note for best results the

ambient working temperature of the room should be 20°C

Warnings: Accurate measurements depends on properly

calibrating the refractometer and the temperature of the prism

should be the same as the test piece.

Do not immerse the instrument into liquids.

Clean the instrument after using

Fig.5

Fig.6

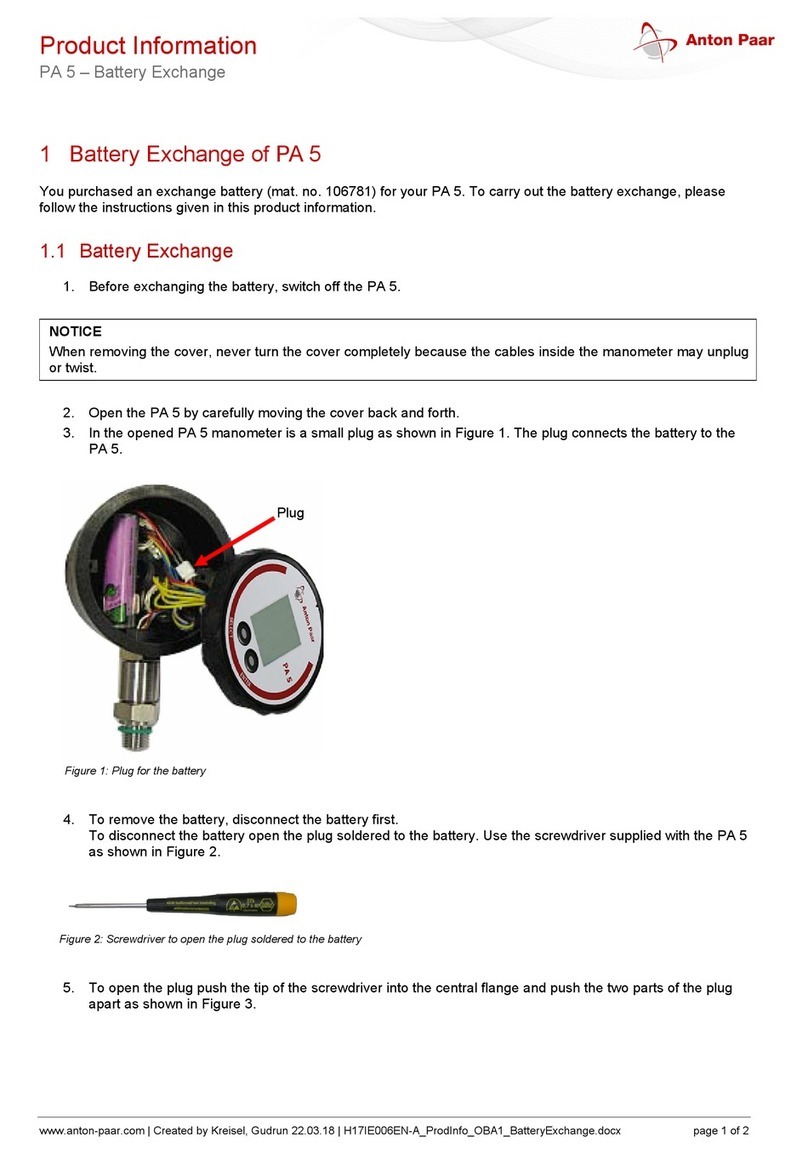

Fig.4