characters and changing the selected character’s value. Arrow icons above and below the selected digit

indicate which of the two modes are active.

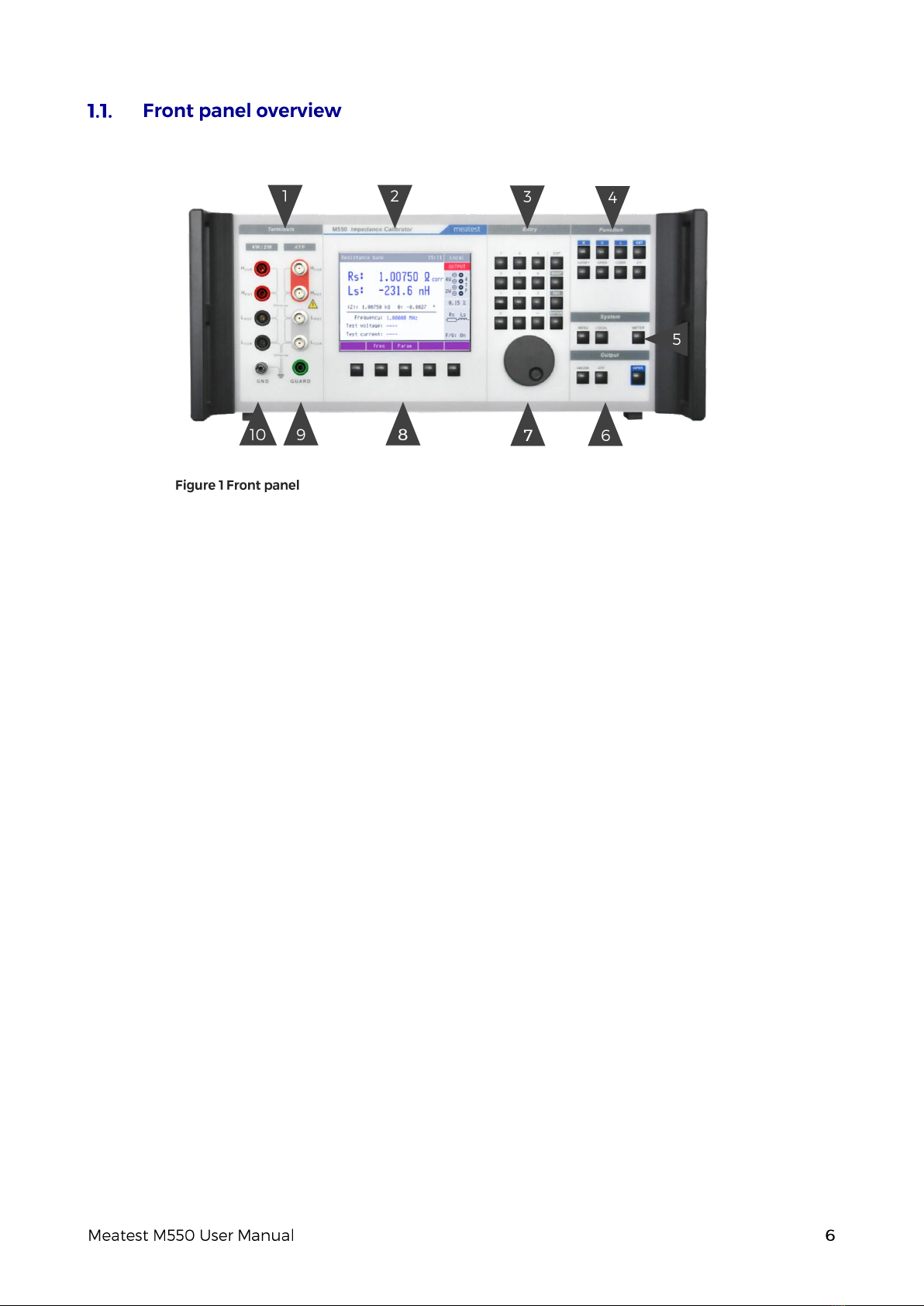

8. Soft keys - There are five buttons below the display, which meaning changes depending on the content

of the display. These buttons usually call up local menu with parameters setting, modes, etc. or enable

to close currently opened function or menu.

9. Guarding terminal –Guarding terminal. It is connected to shielding of the 4TP coaxial output

connectors. It has no function in 4W or 2W mode.

10. Grounding terminal –Grounding post is joined to metal parts of housing and to protective earth in

power line socket.

Display is divided into several sections with following meaning:

1. Information line from left to right:

-Type of selected bank Resistance, Capacitance, Inductance

-Current date/time. Displaying of the date and time can set to be hidden in setup menu.

-Local/remote mode status indication tooltip. Shows additional information about selected

parameter or main value. Information may include uncertainty, range, description, limits (burden

current, compliance voltage), etc. Tooltip is hidden when no parameter is selected.

2. Auxiliary parameter field from top to bottom:

-Status of output terminals ON or OFF

-Selected output terminals and basic mode 4TP or 4W/2W indication

-Calibration uncertainty of the selected standard at selected frequency

-Parallel or serial equivalent circuit of the displayed calibration values

-Working mode of built-in test signal level meter ON/OFF

3. Soft button line:

-Soft buttons description. If there is no description above soft button, the button is not active in

selected function.

4. Meter reading. Main parameter field from top to bottom:

-Both main complex parameters of selected standard in selected frequency point including type of

displayed values. In the upper line primary parameter, in the bottom line secondary parameter is

always displayed.

-Indication of function CORRECTION ON or OFF. Symbol “corr” is displayed beside the main

parameter if Correction is ON.

-Z/θ normalized polar format calibration values of the selected standard