HM500 DISPLAY PANEL OF GENERATOR CONTROLLER USER MANUAL

9

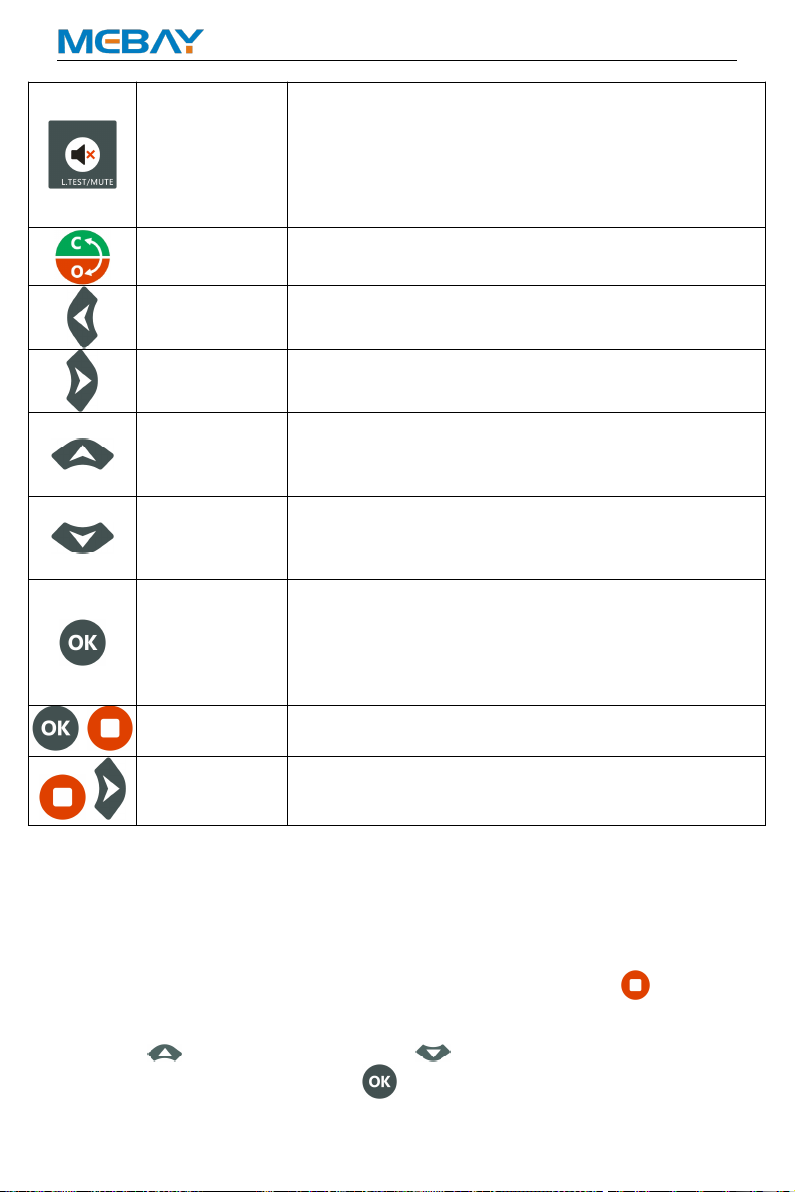

Test if all LED lights are ok, pressing this key to test if all

lighted, all off when loosen it.

Under warning, pressing this key can clear warning and

controller will re-check warning.

Under alarm, pressing this key can clear the buzzer call.

Pressing this key in 3 seconds can clear the buzzer call,

pressing it again in 3 seconds can recover the buzzer call.

Under manual mode, pressing this key can transfer load

to genset/mains.

Under display mode, pressing this key to turn left page.

Under edition mode, pressing this key to move the digit.

Under display mode, pressing this key to turn right page.

Under edition mode, pressing this key to move the digit.

Under display mode, parts of the page can move up.

Under edition mode, pressing this key to move the digit

or increase the numbers.

Under records mode, pressing this key to move the digit.

Under display mode, parts of the page can move down.

Under edition mode, pressing this key to move the digit

or decrease the numbers.

Under records mode, pressing this key to move the digit.

Confirm the change under edition mode.

Page exited under records checking mode.

In the display mode, press to return to the display

homepage;

In standby state, press for 3 seconds to enter the

parameter setting mode.

Pressing OK and STOP simultaneously to come into

setting mode

Pressing STOP and RIGHT to check the records and

any buttons pressed to exit from the page.

Alarm records checking

HM500 controller can save 14 group of alarm records which contains the alarm

record data includes detailed data such as alarm time, generator parameters, engine

parameters, etc.

How to check the alarm records:

1)Enter alarm record page: In the standby state, press and hold the for more

than 3 seconds to enter the historical alarm recording interface;

2)Press to turn upper digit and press to turn lower digit in order to

choose the record you need. Press to confirm the record and come into

history records checking page.