Page iii SE Series - Service & Parts Manual

March 2020

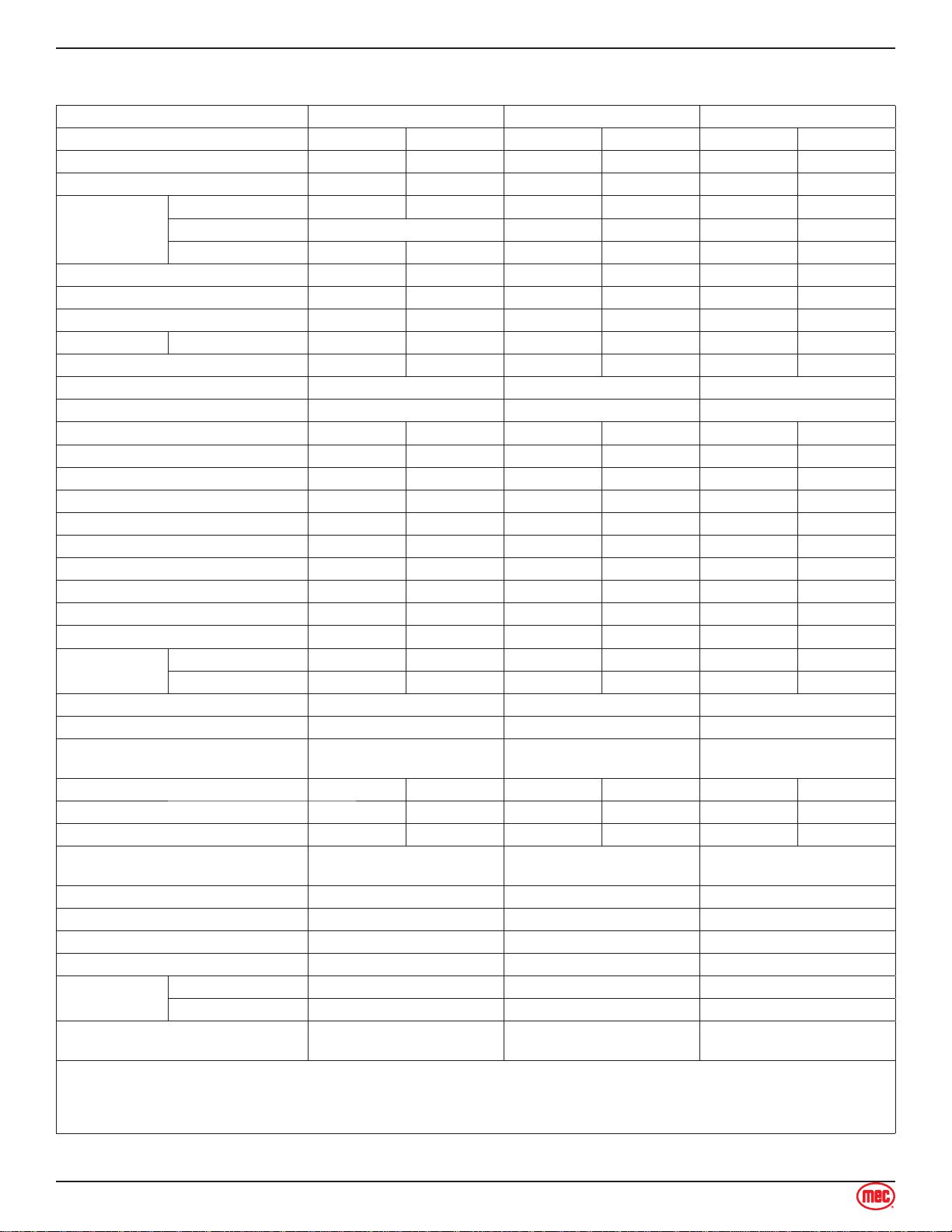

Section 13 - Parameter Adjustment . . . . . . . . . . . . 37

Parameter Adjustment. . . . . . . . . . . . . . . . . . . 37

Section 14 - Schematics . . . . . . . . . . . . . . . 40

Hydraulic Schematic - 1930SE . . . . . . . . . . . . . . . . 40

Hydraulic Components - 1930SE . . . . . . . . . . . . . . . . 41

Hydraulic Schematic - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . . 42

Hydraulic Components - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . 43

Function Valves . . . . . . . . . . . . . . . . . . . . 44

Electrical Schematic - 1930SE . . . . . . . . . . . . . . . . 45

Harness Control Circuit - 1930SE . . . . . . . . . . . . . . . . 46

Electrical Schematic - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . . 47

Harness Control Circuit - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . 48

WiringDiagram....................49

Chapter 2 - Parts . . . . . . . . . . . . . . 50

Parts Introduction ................50

Section 15 - Chassis ................51

Chassis Assembly - 1930SE . . . . . . . . . . . . . . . . . 51

Chassis Assembly - 2632SE . . . . . . . . . . . . . . . . . 53

Chassis Assembly - 3346SE, 4046SE. . . . . . . . . . . . . . . 55

Chassis Assembly - 4555SE . . . . . . . . . . . . . . . . . 57

Steering Wheel Assembly - 1930SE . . . . . . . . . . . . . . . 59

Steering Wheel Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . 61

Rear Wheel Assembly - 1930SE . . . . . . . . . . . . . . . . 63

Rear Wheel Assembly - 2632SE, 3346SE, 4046SE, 4555SE. . . . . . . . . 65

Pothole Protection Assembly - 1930SE . . . . . . . . . . . . . . 67

Pothole Protection Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . 69

Battery Module Assembly - 1930SE . . . . . . . . . . . . . . . 71

Battery Module Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . 73

Control Module Assembly - 1930SE . . . . . . . . . . . . . . . 75

Control Module Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . 77

Hydraulic Tank Assembly - 1930SE . . . . . . . . . . . . . . . 79

Hydraulic Tank Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . . 81

Motor Controller Assembly - 1930SE . . . . . . . . . . . . . . . 83

Motor Controller Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . 85

Limit Switch Assembly. . . . . . . . . . . . . . . . . . . 87

Pipe Bracket Assembly . . . . . . . . . . . . . . . . . . 89

Ground Controls Assembly - 1930SE . . . . . . . . . . . . . . . 91

Ground Controls Assembly - 2632SE, 3346SE, 4046SE, 4555SE . . . . . . . 93

Section 16 - Scissor . . . . . . . . . . . . . . . . 95

Scissor Installation. . . . . . . . . . . . . . . . . . . . 95

Scissor Assembly - 1930SE . . . . . . . . . . . . . . . . . 97

Scissor Assembly - 2632SE . . . . . . . . . . . . . . . . . 99

Scissor Assembly - 3346SE . . . . . . . . . . . . . . . . 101

Scissor Assembly - 4046SE, 4555SE . . . . . . . . . . . . . . 103