Page 3

Step 5 –Check that the ON/OFF/DISARM toggle switch on the grey control box

in the OFF position. Connect the terminals from the wire harness to the battery,

(a fully charged, good quality, deep cycle marine battery is recommended.) It is

imperative that the “RED” wire go to the Positive Post and the “BLACK” wire go

to the Negative Post. Never hammer the terminals onto the posts of the battery,

or over tighten the terminals.

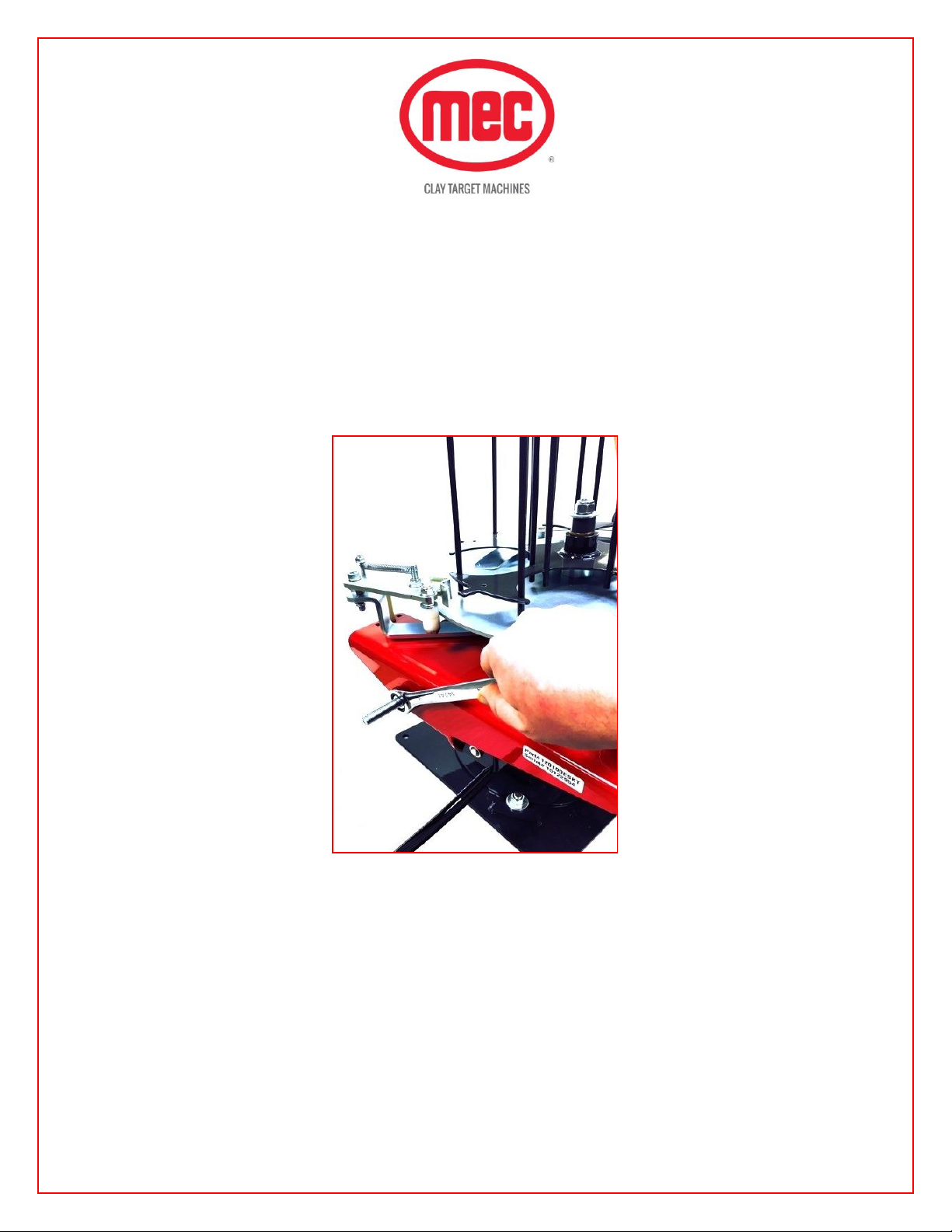

Step 6 –Visually check, from the rear of the machine, that the motion of the

Throwing Arm is not restricted or blocked in any way.

CAUTION: ALWAYS OPERATE THE MACHINE FROM BEHIND,

NEVER FROM THE FRONT OR THE SIDES OF THE MACHINE.

KEEP HANDS AND BODY PARTS AWAY FROM THE MACHINE

WHEN ARMING, RELEASING AND DISARMING.

Step 7 –Standing at arm’s length behind the machine and making sure that all

body parts are clear of the machine, push the ON/OFF/DISARM toggle switch

into the DISARM position and then release it as soon as the throwing arm fires.

The toggle switch is spring loaded and will return to the off position as soon as

the switch is released stopping the machine from re-arming itself. If done

correctly the arm will be pointing away from the left side of the machine when

viewed from behind (right handed machines only). On left handed machines the

arm will point away from the right side of the machine. The machine will now be

in a safe condition.

Disconnect the terminals from the battery to ensure that the machine is not

accidentally armed while adjusting and loading the machine.