Mechanical Safety Equipment 2005 User manual

Operating Instructions for MSE Three-Way Recovery Winch

Model 2005

Personal Fall Arrest Device, Self Retracting Lifeline with retrieval winch.

This instruction manual covers the

installation, operation, inspection and

maintenance procedures for the product

listed above.

WARNING

!

You must read and fully understand all

instructions, or have all instructions explained to you,

before attempting to use this device. Equipment must

not be installed, operated or inspected by anyone who

does not understand this Owner’s Manual. Failure to

observe these instructions could result in serious

injury or death. Careless or improper use of this

equipment can result in serious injury or

death.

Training and instructions review should be repeated

at regular intervals. If you have any questions

regarding these instructions or need additional

copies,

please call Mechanical Safety Equipment Corp. at

215-676-7828

General

THREE-WAY RECOVERY WINCH is designed for use in confined spaces such as manholes, tanks, and other confined areas, where fall-

arrest and retrieval rescue are important. The winch operates as a retractable as well, to raise and lower a worker.

In the situation where a ladder or other means of descent and ascent is in place, a worker should be attached to a Three-Way Recovery

Winch.

Functions:

•Fall Arrest – a braking action if a worker falls

•Retrieval – a means for a topside worker to raise another worker

•Reverse direction - a means for the topside worker to reverse directions, if for any reason the worker becomes wedged while

retrieval is in progress

Note: A Three-Way Recovery Winch, when used in conjunction with anchors such as (Tripod, Quadpod, Monopod or Davit) with optional

Personnel or Work Winch is called a Three-Way Recovery System.

Mechanical Safety Equipment Corp.

WARNING: This unit is NOT meant to hold or

suspend a worker. The capability to raise a

worker (retrieval) should only be used for rescue

operations; NOT for routine lifting. If suspension

or non-rescue retrieval capabilities are required,

use the Personnel Winch Model no. 142. All

material will be lowered and raised with a

material handling winch Model no.140

Suspension Retrieval

2

Three-Way Recovery Winch Installed on Tripod

INSTALLATION PROCEDURES

Attach the Three-Way Recovery Winch to inside of one Tripod leg making

sure the unit’s bracket is aligned so that both locking pins can be fully pushed-

in through the leg to secure the unit. Unit may be easily attached by lifting with

winch handle and resting unit on one knee while inserting two locking pins.

Attach a carabiner (narrow end up) to the center eye bolt of Tripod head.

Release cable from unit and pull out enough cable to extend past carabiner.

Place cable through a pulley (pulley halves will slide apart to accommodate

cable) and attach pulley to carabiner. Make sure both halves of the pulley are

attached to the carabiner and that the cable extends and retracts freely through

the pulley.

Label For Three-Way

Recovery Winch attachment

Tripod System

Three-Way

Recovery Winch

Model 2005

Personnel Winch

Model 142

For 3 WAY Unit

Model 2005

3

Three-Way Recovery Winch Installed on Quadpod\Davit

Label For Three-Way

Recovery Winch attachment

INSTALLATION PROCEDURES

Three-Way Recovery Winch attaches to a boom with two locking pins

(see picture above). Attach the Three-Way Recovery Winch to the

boom (the attachment point is marked with a label). Align the holes in

the bracket with the holes provided on the Quadpod/Davit Boom and

insert the push pins completely through the bracket and secure them

with a cotter pin. Take out the pin from the pulley at the top of the

boom. Pull the cable out from the unit (in retractable mode) to extend

past the pulley. Place cable through a pulley and put the pin back

through the top of the boom. Make sure the cable extends and retracts

freely through the pulley.

For 3 WAY Unit

Model 2005

Quadpod System

Davit System

Boom

Three-Way

Recovery Winch

Model 2005 Personnel Winch

Model 142

Three-Way

Recovery Winch

Model 2005

Personnel Winch

Model 142

4

Monopod System

Personnel Winch

Model 142

Three-Way Recovery Unit Installed on Monopod

Rescue and

Recovery Winch

Model 2005

INSTALLATION PROCEDURES

Three-Way Recovery Winch attaches to a monopod with two locking pins (see

picture above). Attach the Three-Way Recovery Winch to the monopod (the

attachment point is marked with a label). Align the holes in the bracket with the

holes provided on the monopod and insert the push pins completely through the

bracket and secure them with a cotter pin. Take out the pin from the pulley at the

top of the boom. Pull the cable out from the unit (in retractable mode) to extend

past the pulley. Make sure the cable extends and retracts freely through the pulley.

Label For Three-Way

Recovery Winch attachment

For 3 WAY Unit

Model 2005

5

INSPECTION PROCEDURES

WARNING Never use the winch without thorough inspection before each use

.

Inspect the work area for debris and other material that could cause injury or interfere with the operation of the unit.

Be sure that the Tripod, Quadpod, Davit and Monopod are positioned on a stable, hard ground before setting it up.

The leg chains (for Tripod) and all locking pins should be checked to assure correct securing of the equipment.

Caution: Gloves should be worn when inspecting and handling cable.

Check the cable to insure it moves freely and retracts correctly. If the cable doesn’t pull out smoothly – pull the

cable out of the housing and allow it to retract slowly under light tension. Check the cable for cuts, kinks, broken

strands, excessive wear or other damage. The cable shall be check regularly for the signs of wear. Schedule

regular safety inspections based on the amount of use and working conditions.

Checking cable retraction: Test the cable retraction by pulling out at least 4 ft. (1.2 meters) of the cable and

allowing it to retract slowly back into the housing, while keeping tension on the cable.

Checking Fall-Arrest Mode: To test the locking mechanism (fall arrest/suspension) of the winch - pull out

approximately 2 ft. (.6 meters) of the cable from the housing and give it a quick, hard downward tug. The cable

should stop and lock.

Checking Retrieval Mode: Test the rescue (retrieval) capability of the unit by pulling out approximately 2 ft. (.6

meters) of the cable from the housing and giving it a quick tug to lock it. While maintaining the downward pressure

on the cable, push the selection knob (4) in and turn it clockwise ¼ turn and lock the unit into the rescue (retrieval)

mode. Rotate the crank handle (2) clockwise to wind about 1 ft. of the cable back into the housing.

Inspect the snap hook and connecting hardware for any damages or cracks. Make sure that the hook keepers and

free of burrs and clean.

Three-Way Recovery Winch should be removed from service immediately and returned to MSE Corp. 2070

Bennett Road, Philadelphia, PA 19116 if:

•Winch has been subjected to a free fall

•Winch or winch components/part have not passed above described inspection

MSE Corp. recommends annual or more frequent inspections depending of the use of the equipment.

6

Operation Procedures

Read and complete all instructions listed in the “Inspection Procedures” section.

Unscrew the handle from the mounting bracket and slide it outward.

After successful testing, a worker can now be attached to the winch via attaching the swivel snap hook at the end of

the cable to the back center “D” Ring of a Full Body Harness that meets government standards. Visual Check:

Swivel Snap Hook freely engages “D” Ring of the Harness. Keep the snap hook completely closed during each

use. Do NOT rely solely of the feel or sound of a snap hook engaging.

Warning: Attach the locking snap hook on the fall-arrest unit only onto the back “D” Ring of a

harness that meets government standards for the intended use.

Fall Arrest Operation (Lowering)

1. Unscrew the crank handle (2) from the mounting bracket (3) and slide outward. Push the selection knob (4) in

and turn it clockwise ¼ turn to lock unit into the rescue (lowering) mode.

2. Rotate the crank handle (2) clockwise until the worker is lifted approximately 1 ft., and then start to lower him by

rotating the handle counterclockwise.

Under normal working conditions the cable is released in and out of the unit as required. The centrifugal brake will

engage only when the unit is under load. In this condition a worker may experience slight restraint while working. In the

event of a fall, however, the braking system brings the worker to a decelerated stop and holds him in place. While this

action helps prevent injury, it may be necessary to use the unit’s rescue (retrieval) capability to raise a worker safely to

the surface

.

Rescue Operation (Retrieval)

1. Unscrew crank handle (2) from the mounting bracket (3) and slide it outward.

Push the selection knob (4) in and turn it clockwise ¼ turn and lock the unit into the rescue (retrieval) mode.

2. Rotate the crank handle (2) clockwise to raise worker to the surface

.

If for any reason a worker becomes wedged while the retrieval is in progress, the topside worker can reverse direction

by cranking counterclockwise, thus allowing the worker to be lowered and repositioned before continuing with the

retrieval.

To change to fall arrest mode, the load must be removed from the cable. Then, follow instructions under “Fall Arrest

Operation”.

7

Storage and Maintenance

A written log of all servicing and inspection date for this Three-Way Recovery

Winch should be maintained by the company safety officer.

Always store and transport the unit in an area free of corrosive elements and

excessive heat. andle should be secured to the mounting bracket to avoid

undue stress on the handle.

DO NOT leave this unit for extended periods of time in an environment where

corrosion may take place (such as sewage and fertilizer plants). Additionally,

avoid use in areas that contain high concentrations of ammonia. When used

near sea or other similar environments, more frequent inspections may be

necessary to monitor potential corrosive damage. Avoid use with acids,

alkaloids or other caustic chemicals, especially at elevated temperatures.

Clean the exterior of the winch and cable with water and mild soap detergent,

rinse, and thoroughly air dry. DO NOT use harsh chemicals. Clean labels are

required.

Never attempt to lubricate, adjust, repair or modify any part of the winch.

Repair and recertification MUST BE performed by Mechanical Safety Equipment Corp. annually,

or more frequently, depending of the use and operating conditions, or whenever subjected to a

severe free fall. Check label on the winch for next inspection date.

ANSI Z359.1 E6.1.1… The frequency of periodic inspections by a competent person should be

established by the user’s organization based upon careful consideration of relevant factors.

Such factors include the nature and severity of workplace conditions affecting the equipment

and modes of use and exposure time of the equipment.

OS A 1926.502 (d)(21) Personal Fall Arrest systems shall be inspected prior to each use for

wear, damaged and other deterioration, and defective components shall be removed from

service”.

Return the winch to Mechanical Safety Equipment Corp. 2070 Bennett Road,

Philadelphia, PA 19116 for inspection, repair and recertification.

8

Technical Information

Principles of Design Combination of Fall Arrest/Retrieval Device and Self Retracting

Lifeline.

Body Construction Casted Aluminum

Cable Length 50 – 100 ft.

Cable Material Galvanized Steel, Stainless Steel, Synthetic Rope

Cable Diameter 3/16” (4.8 mm)

Cable Breaking Strength 4,200 lbs. (1,890 kg), 3,800 lbs (1,727 kg), 5,500 lbs (2,500 kg)

Max. Working Load/ Min. Working Load 300 lbs (136 kg) / 75 lbs (34 kg)

Cable Locking Speed 4-5 ft./second

Stopping Distance 2 ft. (.6 m) or less

Max. Arresting Force 1200 lbs (544 kg)

Speed 20 ft. per minute in rescue mode (approx.)

Gear Ratio 5.5 : 1

Mechanical Advantage 22 : 1

Weight 50 ft. Galvanized or Stainless Steel – 43 lbs (20 kg)

50 ft. Synthetic Rope – 38 lbs. (17 kg)

65 ft. Galvanized or Stainless Steel – 46 lbs (21 kg)

65 ft. Synthetic Rope – 39 lbs (18 kg)

100 ft. Galvanized or Stainless Steel – 62 lbs (28 kg)

100 ft. Synthetic Rope – 50 lbs (23kg)

Suitable for Material No

Raise & Lower Ability Raise (yes) Lower (yes)

Specifications of products are subject to change without notice.

WARRANTY

The MSE Corp. product (s) listed in this instruction manual, manufactured and sold for commercial or industrial uses are warranted to be free from

defects in materials and workmanship for one year. THERE ARE NO IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS. At its option,

MSE Corp. will repair or replace, or refund the purchase price of, any product which fails to conform to this warranty under normal use and service. In

no event shall MSE Corp. be liable for incidental or consequential damage.

9

WARNINGS

Read, understand and follow all instructions and warnings, attached to and/or packed with this unit before each use. Do

NOT use winch if any instruction or warning is not fully understood. Telephone MSE Corp. at 215-676-7828 for clarification.

For use by properly trained personnel only.

Inspect Before Each Use. All occupational protective equipment must be inspected and thoroughly tested before each

use. If any part or component shows damage, excessive wear or does not functions properly, the entire system should be

removed from service.

Never use any occupational protective equipment for anything other than its intended use.

DO NOT use the Three-Way Recovery Winch if the total working load exceeds 300 lbs. (136 kg).

Avoid prolonged use in caustic or corrosive environments.

DO NOT use winch if the brake does not function upon testing. DO NOT use winch if the cable does not retract.

When using the tripod, always insure that the leg chains securing the tripod legs are attached.

Before each use, make sure all locking pins are inserted completely through the attachment point on the anchor.

Be sure

Tripod, Quadpod, Davit and Monopod

are positioned on a hard, stable surface before each use.

Always work directly under the anchorage point. Workers must be vertically in line with

Tripod, Quadpod, Davit and

Monopod

to avoid swing-fall injuries (pendulum effect).

Make sure the anchorage and connective device are compatible before each use. Always use locking type connectors for

attachment to anchorage.

Use only locking carabiner, pulley and swivel snap hook supplied with the winch.

Attach the swivel snap hook on the winch only onto the rear center “D” ring of a full-body harness meeting governmental

standards for the intended use.

Always Visually Check that: Swivel Snap Hook freely engages “D” Ring of the Harness. Keep the snap hook completely

closed during each use. Never rely solely of the feel or sound of a snap hook engaging.

All cables must be clean and free of foreign matter.

Never allow cable to retract uncontrollably. Always use a tag line to allow slow return of the cable to housing. Never allow

cable to pass under or get wrapped around the legs, arms, neck or torso.

Never allow cable to pass under or get wrapped around the legs, arms, neck or torso of the worker.

Never clamp off or stand on the cable nor allow the cable to become slack when in use.

Never extend cable length by attaching extensions. Use correct length for a job. Never alter or add additional cable to

winches.

To insure compatibility, use only MSE Corp. components of this system.

Winch must be attached to a fall-arrest anchorage capable of supporting 5,000 lbs (22.2 kN) per attached worker and be

independent of worker support.

For use with one person only. Never use winch to support multiple workers. Winch is for personal use only. Not for towing

or lifting.

The buddy system (two workers) must always be used when operating a

Tripod, Quadpod, Davit or Monopod

systems.

Three-Way Recovery Winch is NOT to be used as a material handling device or for routine lowering and raising personnel.

Do NOT use personnel and material winch at the same time. Use only one device per pulley assembly. Use only one

pulley per eye bolt. Never use Three-Way Recovery Winch for positioning or suspension.

DO NOT disconnect Three Way Winch swivel snap hook form “D” ring any time while working in an enclosed or confined

space.

The braking action of the Three-Way Recovery Winch requires a minimum speed to engage. Fall-arrest function will not

operate if footing is on loose or sliding material such as sand or grain.

10

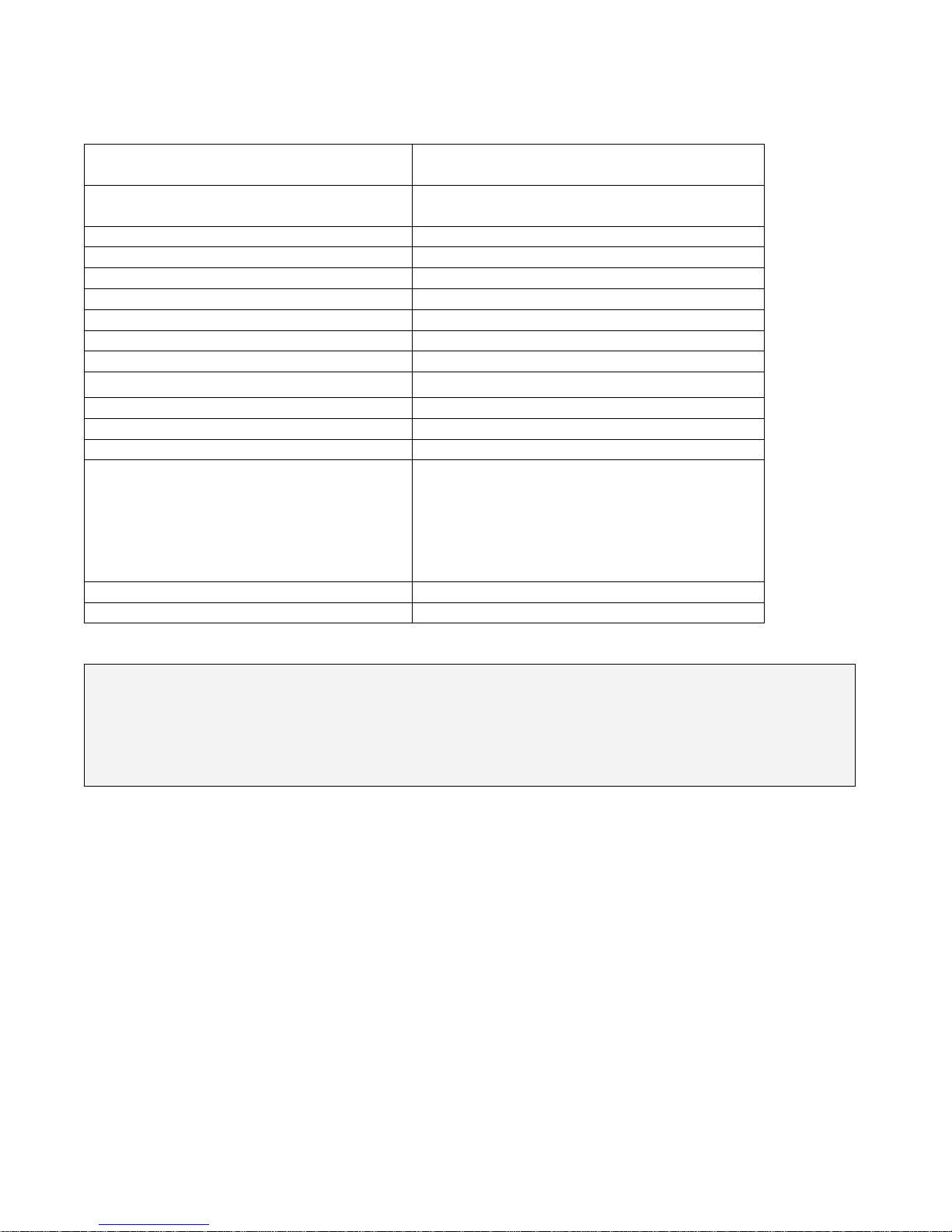

Inspection and Maintenance Log

SERIAL NO. MODEL NO. DATE PURCHASED:

Inspection

Date Inspection Items Noted Corrective Action Taken Maintenance Performed

Approved by:

Approved by:

Approved by:

Approved by:

Approved by:

Approved by:

Approved by:

Approved by:

Approved by:

11

12

Mechanical Safety Equipment Corp.

2070 Bennett Rd

Philadelphia PA, 19116

Phone: 215-676-7828 Fax: 215-676-5199

www.msecorporation.com

Table of contents