Mecon RE 250 User manual

© MECON GmbH BA RE 250 EN 18-01

Operating Instruction

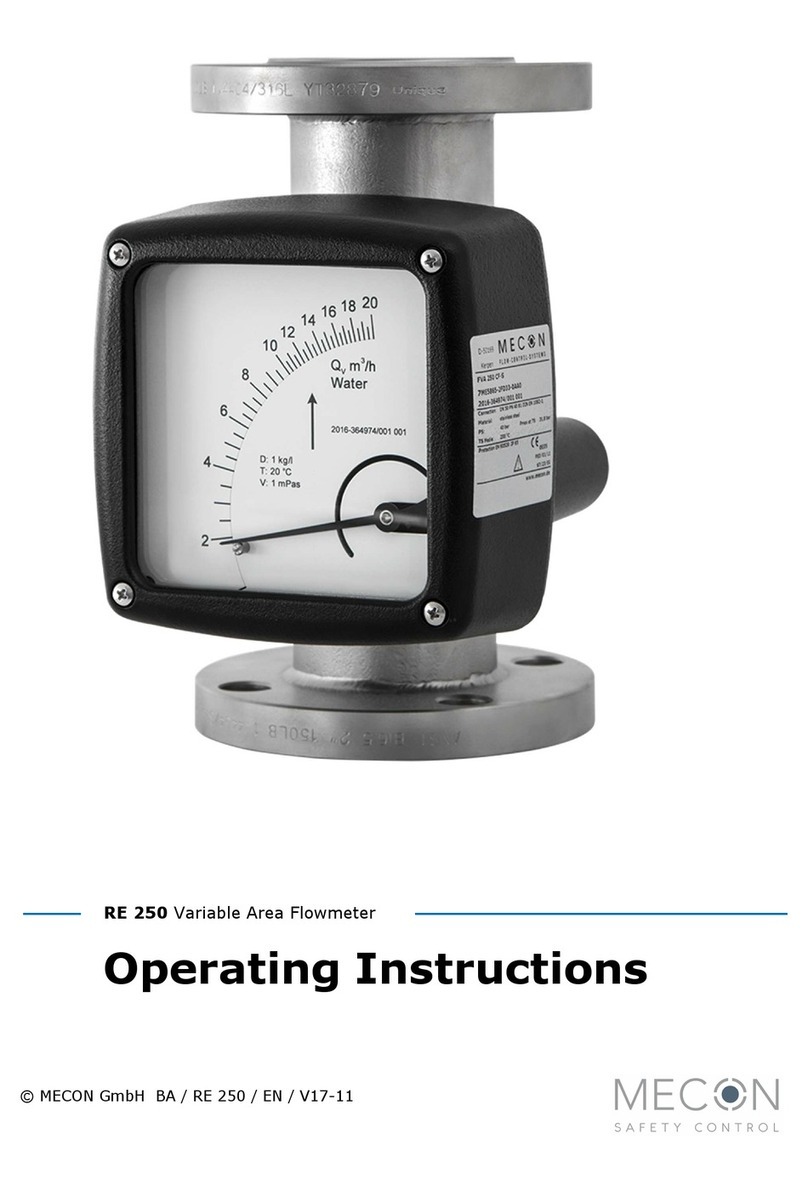

RE 250 Variable Area Flowmeter

Pa e 2 / 32 www.mecon.de BA RE 250 EN 18-01

Imprint

All ri hts reserved. It is prohibited to reproduce this document, or any parts thereof, without prior written

authorization of MECON GmbH.

Subject to chan e without notice.

Copyri ht 2018 by

MECON GmbH - Rönt enstraße 105 - 50169 Kerpen - Germany

BA RE 250 EN 18-01 www.mecon.de Pa e 3 / 32

Contents

Contents

1 Safety instructions _________________________________________________________ 4

1.1 Intended use _____________________________________________________________ 4

1.2 Certifications ______________________________________________________________ 5

1.3 Safety instructions from the manufacturer _______________________________________ 5

2 Start-up _________________________________________________________________ 6

3.1 Standard device ___________________________________________________________ 6

3.2 Device with electrical output (MEM) ____________________________________________ 7

3.3 Device with limit switches ____________________________________________________ 7

3 Installation ode of operation _______________________________________________ 8

2.1 Notes on installation ________________________________________________________ 8

2.2 Installation _______________________________________________________________ 8

2.3 Operatin principle ________________________________________________________ 10

2.4 Classification accordin the Pressure Equipment Directive 2014/68/EU ________________ 10

4 Service ________________________________________________________________ 11

4.1 Stora e _________________________________________________________________ 11

4.2 Maintenance and cleanin __________________________________________________ 11

4.3 Replacin float ___________________________________________________________ 12

4.4 Replacin float dampin ____________________________________________________ 12

4.5 Returnin the device to the manufacturer ______________________________________ 13

5 Device description _______________________________________________________ 14

5.1 Scope of delivery _________________________________________________________ 14

5.2 Device versions ___________________________________________________________ 14

5.3 Name plate ______________________________________________________________ 16

6 Description code _________________________________________________________ 17

7 Technical Data ___________________________________________________________ 21

7.1 Pressure limits vs. temperature stainless steel ___________________________________ 23

7.2 Dimensions and wei hts ____________________________________________________ 24

8 Electrical connections _____________________________________________________ 28

Pa e 4 / 32 www.mecon.de BA RE 250 EN 18-01

Safety Instructions

1 Safety Instructions

1.1 Intended use

The series RE 250 of flowmeters with a standard len th of 250 mm (9.84 inch) and a completely

metal desi n is suitable for measurin different liquids and ases in closed pipin .

The robust desi n enables the operation in rou h conditions. Different types of flan es, liners and

float materials meet the requirements of the pharmaceutical and chemical industries.

The devices are particularly suitable for the easure ent of:

• Water

• Fluids

• Corrosion protection a ents

• Lubricants

• Saturated and superheated steam

• Food and bevera es

• Industrial ases

Warning!

The operator of these measuring devices is solely responsible for the

suitability, intended use and corrosion resistance of the selected mate

rials. It must be particularly ensured that the materials selected for the

wetted parts of the flowmeter are suitable for the process media to be

measured.

The manufacturer is not liable for any damage resulting from improper or

unintended use of these devices.

No external loads may act upon the meter. The flowmeters are primarily desi ned for static

applications.

Caution!

Hot surfaces resulting from hot process media.

Danger of burns resulting from surface temperatures above 70 °C.

● Take appropriate protective measures, for example contact protection.

● The design of the contact protection must meet the maximum permissible

ambient temperature of the meter.

Caution!

For devices used in hazardous areas, additional safety notes

apply; please refer to the Ex documentation!

The flowmeter may only be operated within the pressure and volta e limits specified on the name

plate.

Before takin the flowmeter out of operations, check that the unit is free of hazardous media and

de-pressurized.

BA RE 250 EN 18-01 www.mecon.de Pa e 5 / 32

Safety Instructions

1.2 Certifications

CE arking

The anufacturer certifies for the device RE 250 eets all statutory require ents of the

following EU directives by applying the CE arking:

• Pressure equipment directive 2014/68/EU

• Low volta e directive 2014/35/EU *

• EMC-directive 2014/30/EU

• NAMUR recommandation NE21 *

• ATEX directive 2014/34/EU **

(*Devices with electrical installations)

(**Devices for use in hazardous areas)

1.3 Safety instructions fro the anufacturer

Disclai er

The manufacturer will not be liable for any dama e resultin from the use of its product, includin ,

but not limited to direct, indirect, incidental, punitive and consequential dama es.

Any product purchased from the manufacturer is warranted in accordance with the relevant product

documentation and our Terms and Conditions of Sale.

The manufacturer reserves the ri ht to revise the content of its documents, includin this disclaimer,

without prior notification, and will not be liable in any way for possible consequences of such chan es.

Product liability and warranty

MECON GmbH assumes no uarantee for repair work carried out by the customer without prior

notification and consultation. Any instruments or parts rejected by a customer must be returned to

us, if no other arran ement has been made.

General infor ation

This manual is intended for the correct installation as well as operation and maintenance of the

devices. Read the instructions carefully before installin the device and placin it into operation.

Specially desi ned or customized models and specialized applications are not included in this

manual.

Pa e 6 / 32 www.mecon.de BA RE 250 EN 18-01

Start up

2 Start-up

2.1 Standard device

When startin up the device, the followin points must be observed:

● Ensure that the actual operation conditions (pressure, temperature) do not exceed the limits

which are iven on the nameplate of the device

● Avoid float impacts!

Therefore it is recommended to start up with a closed shut-off valve to be opened slowly. The use

of solenoid valves is not recommended.

● When measurin liquids, the pipes must be vented slowly to prevent shock pressure due to as

bubbles.

● When measurin ases, the pressure must be increased slowly in order to prevent hi h shock

pressure.

● Durin start-up of new systems, residual materials may be carried in the medium and could

adhere to the float. In such cases it is recommended to clean the instrument after a relatively

short period of operation.

● When operatin the flowmeter at low flowrates, the device has to start-up with a hi h flowrate to

allow the float to level out. This will ensure measurements within the specified accuracy class.

Special issues for easuring gas flow:

● Valves have to be installed downstream of the device if p

abs

>1.013 bar and upstream of the

device if p

abs

=1.013 bar (free outflow).

● Install a throttle just downstream of the device to prevent compression oscillations durin

measurement.

● Ensure that the operatin pressure for the flowmeter corresponds to the calibration reference

pressure to avoid erroneous measurements.

Float da ping

A float dampin is recommended

● in eneral for measurin ases

● where pipin vibrations can not be avoided

It is also stron ly recommended in the case of:

● applications where air bubbles in the medium cannot be avoided

● possibility of shock pressure in the pipin , e. . due to rapid throttlin or process shut-off

● turbulence, pulsations, etc. which could lead to vibrations of the flowmeter

● rapid pressure build-up in the pipin

BA RE 250 EN 18-01 www.mecon.de Pa e 7 / 32

Start up

2.2 Device with current output (MEM)

The ma neto-electrical measurin transducer (MEM) is factory-set when it is delivered to the

customer.

After applyin the supply volta e to the device, initially the current output will be about 3.5 mA

to 4 mA for a few seconds. After that a current correspondin to the pointer deflection will flow.

Important!

Due to the influence of the float magnet, the MEM transmitter will only

output the correct current if the pointer position is caused by the float.

Turning the pointer manually will cause incorrect values, but it is suitable

for testing the unit.

2.3 Device with li it switches

The limit switches can be set over the entire measurin ran e by varyin the position of the limit

pointers.

Important!

Unless otherwise specified by the customer, the factory set value for the

switching point on versions with one limit switch is about 0% of URV

and for devices with two limit switches it is about 20% / 80% of URV.

To set the limit switches at the desired position the followin steps have to be observed:

● Unloosen the two small fixin screws (2) before movin the pointer (1).

● Move the pointer to the desired position.

● Ti hten the screws to fix the pointer.

Fig. 2 Adjustment of the switchin point (limit switch)

1 Limit pointer

2 Fixin screw

Pa e 8 / 32 www.mecon.de BA RE 250 EN 18-01

Installation

3 Installation and ode of operation

3.1 Notes on installation

Information !

All instruments are carefully checked for functional capability before

shipment. Upon receipt of the device please carry out a visual inspection

of the outer packing for damage or improper handling.

Please contact the delivery carrier if you discover any defects. In such

cases a description of the defect, the type and the serial number of the

device are needed.

Information !

Unpack the equipment with care to prevent damage.

Information !

All instruments are carefully checked for order conformity.

Please check the delivery for completeness using the packing list. Please

examine the flowmeter nameplate to verify that the device was built

according to your order. Particularly check devices with electrical

components for the correct supply voltage.

3.2 Installation

Below the essential points concerning installation are described and have to be observed:

● Remove the transport securin device from the fittin .

● Prior to the installation verify that the float slides smoothly in the fittin without cantin or

deadlockin . The pointer must follow the float movement smoothly.

● Verify that all accessories such as sprin stop, as/fluid dampin are still correctly fixed in the

fittin .

● In the zero position (no flow) the pointer must be at the marked reference point (first line on

the scale). When movin the float manually to the end position, the pointer must be above the

final value of the scale.

● The flowmeter must be installed vertically – flow direction from bottom to top. For installation

recommendations refer to uideline VDI/VDE 3513 Part 3.

● The installation in the pipin must be tension-free – therefore the pipin must be positioned

parallel and ali ned with each other.

● Avoid a corrosive atmosphere –provide ventilation where necessary.

● Ensure a sufficient distance of at least 200 mm to ma net-influencin parts such as solenoid

valves or ferroma netic components e. . steel brackets.

● Observe a lateral distance of at least 300 mm between two devices mounted next to one

another. The distance can be reduced by mountin the devices sta ered by the len th of one

device. To eliminate doubt the influence can be tested by movin the instrument up and down

BA RE 250 EN 18-01 www.mecon.de Pa e 9 / 32

Installation

ca. 200 mm at a selected distance while observin whether the position of the pointer on the

display chan es.

● Specify the installation zone re ardin a reliable readin of the displayed values and adequate

spacin for servicin .

● An inlet run upstream and an outlet run downstream the device is not necessary in case of a

linear media flow profile. In cases of hi hly asymmetrical flow profiles, however, additional

measures (e. . inlet tracks, flow rectifiers) with a len th of at least 250 mm could be

appropriate to ensure the measurin accuracy.

● Avoid the installation of unilaterally constrictin fittin s upstream of the device.

● Ensure that the pipin is installed securely to avoid vibration or oscillation of the devices.

● The nominal width of the flowmeter and the connected pipin must be identically.

● Use connectors connectin bolts suitable for the particular device version (dimension, pressure

ratin ).

● Ensure that the clearance between the flan es of the pipin corresponds to the device

dimension in addition to two askets.

● Before connectin the device, blow or flush out the pipes leadin to the device.

● The surface rou hness of the flan e sealin areas must be appropriate for the used askets.

● The askets and bolts of the prescribed dimensions must be appropriate for the operatin

pressure, the temperature and the media.

● Do not use carbon steel ounting brackets for the device!

Additionally for devices with PTFE liner:

● Use askets which conform to the inner and outer dimensions of the raised face of the

flowmeter.

● Ti hten the screws crosswise to ensure the ti htness of the process connections. For ti htenin

torques please refer to Tab. “2.2 Ti htenin torques”.

● If the instrument is absolutely calibrated for a pressure exceedin 1.013 bar any valve is

usually installed at the rear of the flowmeter, at 1.013 bar absolute (free emanation) in front

of the instrument.

Special issues for easuring gas flow:

● Valves have to be installed downstream of the device if p

abs

>1.013 bar and upstream of the

device if p

abs

=1.013 bar (free outflow).

● Install a throttle just downstream of the device to prevent compression oscillations durin

measurement.

● Ensure that the operatin pressure for the flowmeter corresponds to the calibration reference

pressure to avoid erroneous measurements.

Tightening torques

The flan e bolts for devices with PTFE liner may be ti htened with the followin torques (acc.

uideline VDI/VDE 3513):

Pa e 10 / 32 www.mecon.de BA RE 250 EN 18-01

Installation

Process connection ax. torque

EN1092-1 ANSI B16.5 N ftlbf

15 ½” 14 10

25 1” 14 10

40 1 ½” 25 18

50 2” 25 18

80 3” 35 25

100 4” 42 30

Tab 2.2 Ti htenin torques for devices with PTFE liner

Magnetic filters

To prevent a malfunction of the flowmeter caused by ferroma netic substances contained in the

medium (such as weld beads) a ma netic filter should be mounted in flow direction upstream of

the instrument.

This kind of filter is also recommended if such particles cannot be avoided in standard operation.

3.3 Operating principle

Like other devices of this series the variable area flowmeter RE 250 operates accordin to the

principle of flotation:

The measurin unit consists of a metal tube with a measurin rin in which a float can move up

and down. The media is flowin upwards throu h the tube and raises the conical float. Here the

annular ap enlar es until the equilibrium between the buoyancy force F

A

, the dra force F

S

and

the wei ht of the float F

G

is reached. The adjusted hei ht of the float is directly proportional to

the flowrate. The movement of the float is transmitted via a ma net inside the float to a

correspondin ma net inside the display unit outside of the measurin pipe.

Fig. 1 Operatin principle of the RE 250

BA RE 250 EN 18-01 www.mecon.de Pa e 11 / 32

Service

3.4 Classification

Classification in accordance with the Pressure Equipment Directive 2014/68/EU:

Process connection Ad issible edia Category

EN1092-1 ANSI B16.5

DN 15 ½ ” Gases and fluids of fluid roup 1 Art. 4.3

DN 20 ¾ ” Gases and fluids of fluid roup 1 Art. 4.3

DN 25 1 ” Gases and fluids of fluid roup 1 Art. 4.3

DN 32 1 ¼ ” Gases and fluids of fluid roup 1 III

DN 40 1 ½ ” Gases and fluids of fluid roup 1 III

DN 50 2 ” Gases and fluids of fluid roup 1 III

DN 65 2 ½ ” Gases and fluids of fluid roup 1 III

DN 80 3” Gases and fluids of fluid roup 1 III

DN 100 4” Gases and fluids of fluid roup 1 III

DN 125 5” Gases and fluids of fluid roup 1 III

DN 150 6” Gases and fluids of fluid roup 1 III

4 Service

4.1 Storage

● Store the device in a dry and dust-free place.

● Keep away from direct sun and heat.

● Avoid external loads to the device.

● The stora e temperature ran e for standard devices with electrical components is

-40 … +70 °C / -40 … +158 °F.

4.2 Maintenance and cleaning

The devices are built for low maintenance operations but periodically the flowmeters should be

inspected for si ns of corrosion, mechanical wear as well as dama e to the fittin and the display

unit.

We advise to carry out inspections at least once a year.

For a

detailed inspection and cleanin the device must be removed from the pipin .

Caution!

Appropriate safety precautions have to be taken when removing the device.

Always use new gaskets when reinstalling the device in the piping.

Pa e 12 / 32 www.mecon.de BA RE 250 EN 18-01

Service

4.3 Replacing float

Devices with measuring ring

For devices with standard measurin ran es

startin from 5 - 50 l/h ( ases: 0.15 – 1.5 m³/h)

the replacement of the float can be provided by the

customer:

● Remove the device from the pipin .

● Fix the device ideally in a horizontal position,

ensurin that the fittin will not be dama ed.

● Prevent the float

from torsion by fixin the

upper uide bracket

usin a suitable tool.

● Remove the self-lockin nut

which fixes the

lower uide bracket

and take the uide

bracket out of the fittin .

● Take the float upwards out of the measurin

unit.

● Insert the new float into the fittin from the top.

At the same time carefully uide the bottom

end of the float throu h the measurin rin .

● Slip the lower uide bracket throu h the thread at the bottom end of the float and fix it with

the self-lockin nut.

● Install the device back into the pipin .

Important!

Avoid damaging both float and measuring ring.

Important!

After float replacement a recalibration of the flowmeter is highly

recommended, otherwise the measurement accuracy cannot be ensured.

Devices with cone

● Replacin floats for devices with cone (standard measurin ran es up to 5 - 50 l/h ( ases:

0.15 – 1.5 m³/h) cannot be done by the customer. The device has to be returned to the

manufacturer. For details please refer to chapter “6.4 Returnin the device to the

manufacturer”.

Fig. Replacin floats

1 Float

2 Upper uide bracket

3 Self-lockin nut

4 Lower uide bracket

BA RE 250 EN 18-01 www.mecon.de Pa e 13 / 32

Device Description

4.4 Replacing float da ping

Devices with measuring ring

For devices with standard measurin ran es startin from

5 - 50 l/h ( ases: 0.15 – 1.5 m³/h) the float dampin can

be replaced by the customer:

● Remove the device from the pipin .

● Fix the device, ensurin that the fittin will not be

dama ed.

● The dampin cylinder is fixed by retainin clamps .

Bend up these two clamps carefully usin a suitable tool.

● Move the dampin cylinder sli htly to the bottom end of

the fittin , make a quarter turn and take the cylinder out

of the fittin .

● Insert the new dampin cylinder into the fittin from the

top, slide it over the dampin part of the float and

arran e it into the retainin clamps.

● Fix the cylinder by bendin the retainin clamps

to ether.

● Install the device back into the pipin .

4.5 Returning the device to the anufacturer

This device has been carefully manufactured and tested. Should you nevertheless need to return

a device to MECON GmbH please observe the followin points:

Caution!

According to the actual waste disposal directives, the owner/customer is

responsible for the waste management of hazardous and toxic waste.

For reasons of environmental protection and safeguarding the health and

safety of our personnel all devices sent to MECON GmbH to be

repaired must be free of toxic and hazardous substances. This also

applies to cavities of the devices. If necessary the customer is

kindly requested to neutralize or rinse the devices before returning

them to MECON.

The customer has to confirm this by filling in an appropriate form which is

available for download on the MECON website:

www.mecon.de/en/Declaration/Decontamination.pdf

Fig. 3 Replacin float dampin

1 Float with dampin

2 Upper uide bracket

3 Self-lockin nut

4 Lower uide bracket

5 Retainin clamp

6 Dampin cylinder

Pa e 14 / 32 www.mecon.de BA RE 250 EN 18-01

Device Description

5 Device Description

5.1 Scope of delivery

Fig. 5 Scope of delivery

Information!

Please check the delivery for completeness using the packing list.

5.2 Device versions

Display unit ade of alu iniu

Fig. 6 Standard device with display unit made of aluminium

The measurement ran e is indicated directly on the scale. The equipment can be supplied with

auxiliary electrical components and touch-sensitive switches for process monitorin and control.

1 Flowmeter RE 250

2 Operatin Instructions

3 Certificates (optional)

4 Software (optional)

BA RE 250 EN 18-01 www.mecon.de Pa e 15 / 32

Device Description

Display unit ade of stainless steel

Fig. 7 Standard device with display unit made of stainless steel

For applications with requirements for hi her protection cate ory or corrosion resistance the

devices are available with a display unit made of stainless steel.

Heating shield

Fig. 8 Device with heatin sheath

For installations where temperature drops are unacceptable the devices are available with an

external heatin shield.

Pa e 16 / 32 www.mecon.de BA RE 250 EN 18-01

Device Description

5.3 Na eplate

Important!

Please refer to the device nameplate to ensure that the device is built

according to your order.

Check particularly for the correct supply voltage.

Fig. 9 Nameplate of the RE 250

BA RE 250 EN 18-01 www.mecon.de Pa e 17 / 32

Description Code

6 Description code

Individual part for versions CF-S (stainless steel) and EF-H (Hastelloy

®

)

The description code consists of the followin elements:

1

Flow tube

A DN 15

B DN 25

C DN 40

D DN 50

E DN 80

F DN 100

2

Version

1 CF-S wetted parts: stainless steel

2 EF-H wetted parts: Hastelloy

®

3

Process connections

Flanges

EN1092-1 ANSI B16.5

Flow tube EN Flow tube ANSI

A

B

C

D

E

F

A

B

C

D

E

F

No inal size

Axx DN 15 ½ ”

Bxx DN 20 ¾ ”

Cxx DN 25 1 ”

Dxx DN 32 1 ¼ ”

Exx DN 40 1 ½ ”

Fxx DN 50 2 ”

Gxx DN 65 2 ½ ”

Hxx DN 80 3”

Jxx DN 100 4”

Kxx DN 125 5”

Lxx DN 150 6”

= available = reduced scale raised face

Pressure rating

xBx PN 16 (EN 1092-1) DN 65 - DN 150

xDx PN 40 (EN 1092-1) DN 15 - DN 150

xEx PN 63 (EN 1092-1) DN 50 - DN 150

xFx PN 100 (EN 1092-1) DN 15 - DN 150

xGx PN 160 (EN 1092-1) DN 15 - DN 150 (DN 20 and DN 32 not available)

xHx 150 lbs (ASME B16.5) ½ ” – 6 ”

xJx 300 lbs (ASME B16.5) ½ ” – 6 ”

xKx 600 lbs (ASME B16.5) ½ ” – 6 ”

Flange for

xxA B1 (EN 1092-1) PN 16 / PN 40

xxB B2 (EN 1092-1) PN 63 / DN 100

xxC Form D (EN 1092-1) DN 15 - DN 150

xxD Form C (EN 1092-1) DN 15 - DN 150

xxG Form RF (ASME B16.5) ½ ” – 6 ”

xxH Form FF (ASME B16.5) ½ ” – 6 ”

xxJ Form RTJ (ASME B16.5) 1 ” – 6 ”

Pa e 18 / 32 www.mecon.de BA RE 250 EN 18-01

Description Code

3

Process connections (continued)

Threaded connection

Txx Female thread Flow tube EN

xTx DIN ISO 228 1500lbs 1500lbs 1500lbs 900lbs

xNx NPT ANSI B 1.20.1 PN100 PN100 PN100 PN63

DIN ISO 228

ANSI B1.20.1

A B C D

xx7 G ¼ NPT ¼”

xx8 G ⅜ NPT ⅜”

xx1 G ½ NPT ½”

xx2 G ¾ NPT ¾”

xx3 G 1 NPT 1” max 16 m³/h

xx4 G 1 ¼ NPT 1 ¼” max 16 m³/h

xx5 G 1 ½ NPT 1 ½” max 20 m³/h

xx6 G 2 NPT 2” max 20 m³/h

4

Heating sheath

0 Without

1 With flan e connection DN 15 DIN 2501 PN 40 in stainless steel

2 With flan e connection DN 25 DIN 2501 PN 40 in stainless steel

3 With flan e connection ½ “ ANSI B16.5 150 RF in stainless steel

4 With flan e connection 1 “ ANSI B16.5 150 RF in stainless steel

5

Maxi u range values / Measuring ranges

Fluids Gases Ratio Pressure drop

[ bar]

[l/h]

[USgp ]

[ ³/h]

[scf ]

A

B

C

D

E

F

1 5 0,022

0,15

0,088

1:10 40

2 10 0,044

0,30

0,177

1:10 40

3 16 0,07

0,48

0,283

1:10 40

4 25 0,11

0,75

0,441

1:10 40

5 40 0,18

1,3 0,765

1:10 40

A 50 0,22

1,5 0,883

1:10 40

B 70 0,31

2,1 1,24 1:10 40

C 100 0,44

3,0 1,77 1:10 60

D 160 0,70

4,6 2,71 1:10 60

E 250 1,10

7,0 4,12 1:10 60

F 400 1,76

11 6,47 1:10 70

G 600 2,64

17 10,00

1:10 80

H 1000 4,40

30 17,66

1:10

60

J 1600 7,0 46 27,07

1:10

70

K 2500 11,0

70 41,20

1:10

100 50

L 4000 17,6

110

64,74

1:10

240 120 80

M 6000 26,4

170

100,0

1:10

180 90

N 10.000

44,0

290

170,7

1:10

110

P 16.000

70,0

460

270,7

1:10

230 70

Q 20.000

88,0

550

323,7

1:10

230 70

R 25.000

110,0

700

412,0

1:10

500 100

S 40.000

176,0

1.100

647,4

1:10

350 120

T 50.000

220,0

1.350

794,6

1:10

350 120

U 60.000

264,0

1.700

1.000

1:10

360

V 80.000

352,0

2.400

1.413

1:10

600

W 100.000

440,0

3.000

1.766

1:10

600

* devices for media with hi her viscosity on request = not available

6

Measured ediu

1 Water (η= 1 mPas, ρ = 1 k /l)

2 Air (T = 0 °C, pe = 0 bar, η= 0.0181 mPas, ρ = 1,293 k /m³)

3 Specify in plain text

7

Float da ping

0 Without float dampin

1 With float dampin

= available

BA RE 250 EN 18-01 www.mecon.de Pa e 19 / 32

Description Code

Individual part for version FF-P (PTFE liner)

The description code consists of the followin elements:

1

Flow tube

A DN 15

B DN 25

D DN 50

E DN 80

F DN 100

3

Process connections

EN1092-1

ANSI B16.5

Flow tube EN Flow tube ANSI

No inal Size

A

B

D

E

F

A

B

D

E

F

Axx DN 15 ¾”

Cxx DN 25 1”

Fxx DN 50 2”

Hxx DN 80 3”

Jxx DN 100 4”

Pressure

rating

xBx PN 16 B1 (EN 1092-1)

DN 100

xDx PN 40 B1 (EN 1092-1)

DN 15 - DN 100

xHx 150 lbs (ASME B16.5)

¾” – 4 ”

xJx 300 lbs (ASME B16.5)

¾” – 4 ”

Flange

for

xxA B1 (EN 1092-1)

PN 16 / PN 40

xxG Form RF

(ASME B16.5)

½ ” – 4 ”

5

Maxi u range values / Measuring ranges

Fluids Gases Ratio Viscosity

li its* Pressure drop [ bar]

[l/h]

[USgp ]

[ ³/h]

[ Pa

s]

[ Pa

s]

A

B

D

E

F

C 100 0,44 3,0 1,77 1:10 ≤ 1,0 60 60

D 160 0,70 4,6 2,71 1:10 1 … 3 60 60

E 250 1,10 7,0 4,12 1:10 1 … 3 60 60

F 400 1,76 11 6,47 1:10 1 … 3 70 70

G 600 2,64 17 10,00 1:10 1 … 5 80 80

H 1000 4,40 30 17,66 1:10 1 … 5

60

J 1600 7,0 46 27,07 1:10 1 … 5

70

K 2500 11,0 70 41,20 1:10 1 … 5

100

L 4000 17,6 110 64,74 1:10 1 … 8

80

M 6000 26,4 170 100,0 1:10 1 … 8

90

N 10.000

44,0 290 170,7 1:10 1 … 8

110

P 16.000

70,0 460 270,7 1:10 1 … 10

230

Q 20.000

88,0 550 323,7 1:10 1 … 10

230

R 25.000

110,0 700 412,0 1:10 1 … 10

100

S 40.000

176,0 1.100 647,4 1:10 1 … 15

120

* devices for media with hi her viscosity on request

= not available

6

Measured ediu

1 Water (η= 1 mPas, ρ = 1 k /l)

2 Air (T = 0 °C, pe = 0 bar, η= 0.0181 mPas, ρ = 1,293 k /m³)

3 Specify in plain text

Pa e 20 / 32 www.mecon.de BA RE 250 EN 18-01

Description Code

Description code – co on part for all versions

The description code consists of the followin elements:

9

Outputs

A A With local display

C

J With local display, 1 inductive contact SJ 3,5N

C

L With local display, 2 inductive contacts SJ 3,5N

E A With local display, electric remote sensor 4

-

20 mA

E

L With local display, electric remote sensor 4

-

20 mA, 2 inductive contacts SJ 3,5N

E

J With local display, electric remote sensor 4

-

20 mA, 1 inductive contact, 1 pulse output

F

A With HART protocol, 4 -

20mA

F

L With HART protocol, 4 -

20mA, 2 inductive contacts

F

J With HART protocol, 1 inductive contact, 1 pulse output

P

A With PROFIBUS PA interface

10

Certification of accuracy

0 Without calibration certificate

1 Certification of accuracy class (4.2.1)

2 With calibration report (5 points)

3 With calibration report incl. Electrical output (min. 5 points)

11

Leak / pressure test

0 Without leak/pressure test

1 Pressure test acc. to EN 10204 with inspection certificate 3.1

2 Leak test acc. to EN 10204 with inspection certificate 3.1

3 Pressure test + leak test (acc. to EN 10204 with inspection certificates 3.1)

12

Material certificates

A Without certificate

B Certificate of Compliance with the Order 2.1 accordin to DIN EN 10 204

C Inspection certificate 3.1 with material analysis (DIN EN 10204:2004) for wetted parts

13

Cleaning to factory standard

A Without cleanin

B Cleanin class VA – with markin : free of oil and rease

C Cleanin class VA – with markin : free of oil, rease and silicone

14

Approvals

0 Without

1 Explosion protection – mechanical approval ATEX EX II 2 GDC

2 Explosion protection – mechanical and electrical (MEM/MEM-PPA) approval ATEX EX ia IIC T6

15

Marking

0 Without markin

1 Cardboard plate with a cable tie

2 Stainless steel plate (dimensions 70 x 30mm)

3

Cardboard plate with cable tie + sta

inless steel plate (dimensions 70 x 3

0 mm)

8

Display unit / Process te perature

0 Standard (aluminium) – up to 200 °C for local display / 150 °C for electric output)

1 Standard (aluminium) – with displaced display (extension made of stainless steel)

2 Stainless steel IP66 – up to 150 °C

3 Stainless steel IP66 – with displaced display

Other manuals for RE 250

1

Table of contents

Other Mecon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

NRG Systems

NRG Systems IceFree3 user manual

Brookfield

Brookfield YR-1 operating instructions

Precision Gold

Precision Gold NO9AQ instruction manual

HP

HP 54750A quick start guide

PCE Instruments

PCE Instruments PCE-DFG NF Series user manual

WB Johnson Instruments

WB Johnson Instruments AM-801 Operation & maintenance manual