Mecon mag-flux T4 User manual

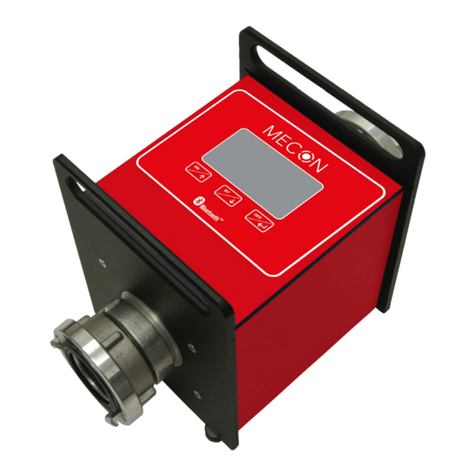

mag-ux T4

Magnetic ow meter

compact and separated

OPERATING INSTRUCTIONS

© MECON GmbH BA / mag-flux T4 / EN / 19-04

2© MECON GmbH BA / mag-ux T4 / EN / 19-04

IMPRINT

All rights reserved. Any reproduction or usage without written authorisation of MECON

GmbH - even partial content - is strictly prohibited.

Subject to change without notice.

Copyright 2019 by MECON GmbH - Röntgenstr. 105 - 50169 Kerpen - Germany

3

© MECON GmbH BA / mag-ux T4 / EN / 19-04

Contents

..............................................................................................

1.1 Intended use.......................................................................................................................4

......................................................................................................................5

1.3 Manufacturer’s safety instructions ...............................................................................5

.................................................................................................

2.1 Scope of delivery ...............................................................................................................7

2.2 Nameplate...........................................................................................................................8

.............................................................

3.1 Measuring principle...........................................................................................................9

3.2 System design....................................................................................................................9

3.3 Installation notes...............................................................................................................10

3.4 Installation instructions ...................................................................................................10

3.5 Assembly.............................................................................................................................13

3.6 Electrical connection........................................................................................................16

......................................................................................................................

.........................................................................................................

5.1 Reference conditions........................................................................................................20

5.2 Flow sensor / transducer.................................................................................................20

...............................................................................................................21

5.4 Transducer M1.....................................................................................................................21

5.5 Dimensions coupling connection compact design....................................................22

5.6 Dimensions coupling connection separate design....................................................23

........................................................24

........................................................25

5.9 Dimensions thread connection compact design........................................................26

5.10 Dimensions thread connection separate design........................................................27

........................................................................28

....................................................................................................

.........................................................................................................................

7.1 Storage ................................................................................................................................34

7.2 Maintenance .......................................................................................................................34

7.3 Returning the equipment to the manufacturer..........................................................34

7.4 Disposal ...............................................................................................................................34

........................................................................................................

4© MECON GmbH BA / mag-ux T4 / EN / 19-04

SAFETY INSTRUCTIONS

1

1.1 Intended use

-

-

Warning!

The operator of these measuring devices is solely responsible for the suit-

ability, intended use and corrosion resistance of the selected materials. In

particular. it must be ensured that the materials selected for the wetted

parts of the ow meter are suitable for the process media to be measured.

The meter must not be exposed to external loads. These ow meters are

primarily designed for static applications.

Hot process media can lead to hot surfaces! There is a risk of burns where

the surface temperatures are above +70 °C.

Suitable protective measures should be taken, e.g. protection to prevent

contact.

The contact protection must be designed such that the maximum ambient

temperature around the equipment is not exceeded.

The equipment may only be operated within the pressure and voltage limits stated on the

free of hazardous media and pressure.

5

© MECON GmbH BA / mag-ux T4 / EN / 19-04

SAFETY INSTRUCTIONS

"Return equipment Form" which can be found on the Internet at www.mecon.de/en/

MECON GmbH.

1.2

-

»

»Low Voltage Directive 2014/35/EU

»

»G419006

1.3

-

damages.

relevant product documentation and the valid terms and conditions.

such changes.

The responsibility that the instruments are suitable for the particular application rests solely

-

6© MECON GmbH BA / mag-ux T4 / EN / 19-04

SAFETY INSTRUCTIONS

In case of a complaint the contested elements must be cleaned of hazardous substances

operating instructions carefully before starting to use the equipment.

-

nance of the equipment.

Special designs for special applications and custom models are not covered by this

documentation.

7

© MECON GmbH BA / mag-ux T4 / EN / 19-04

DEVICE DESCRIPTION

2

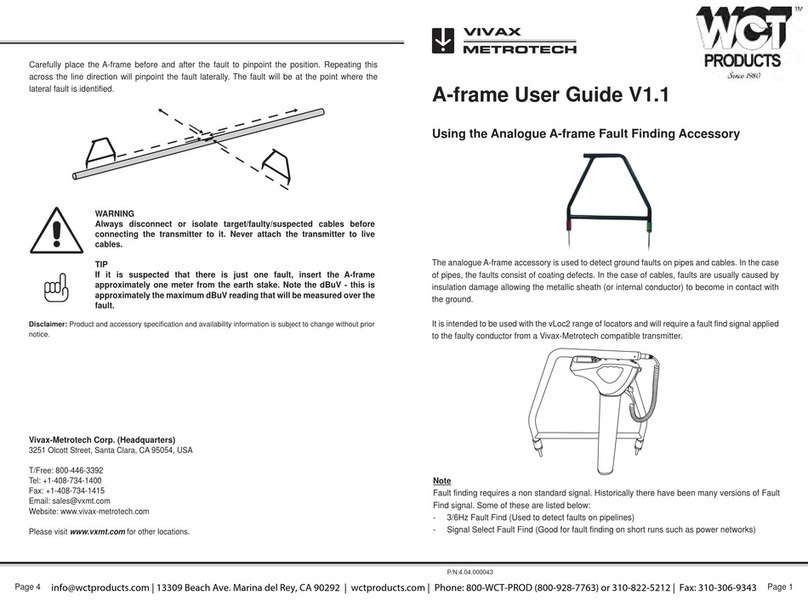

2.1

Operating Instruction

Fig. 1 Scope of delivery

8© MECON GmbH BA / mag-ux T4 / EN / 19-04

DEVICE DESCRIPTION

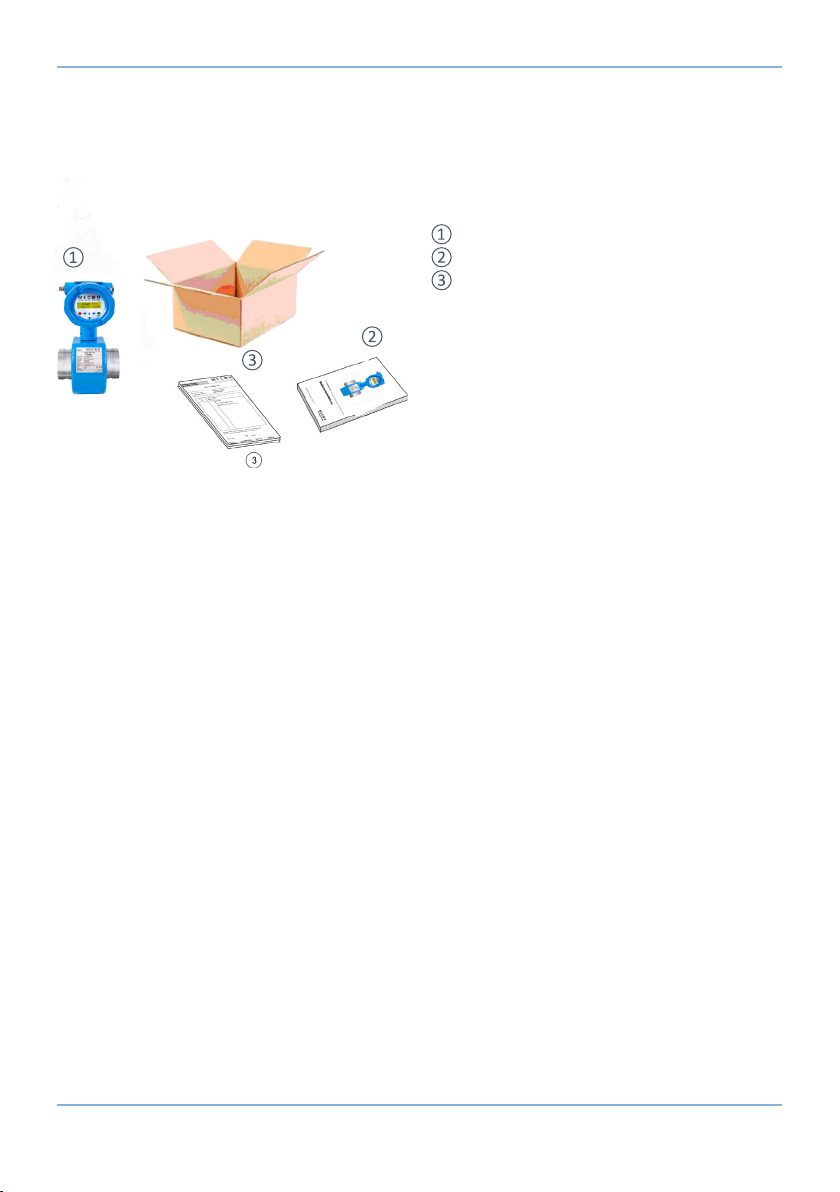

Fig. 2 Nameplate mag-ux M1 transducer

2.2

Fig. 3 Nameplate mag-ux T4 sensor

The operating pressure and temperature de-

from the operating instructions.

9

© MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

3

-

3.1

of the principle of electrodynamic induc-

-

iments in the Thames were not successful

-

the vector product E = [v x B].

an electrically insulating lining and where

-

at the two electrodes. The magnitude of this measurement voltage is proportional to the

3.2

creates the conditions for the induced voltage applied to the electrodes.

-

Fig. 4 Principle of magnetic inductive ow measure-

ment

10 © MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

3.3

Information!

All instruments are carefully checked for proper function before shipment.

On receipt, immediately check the outer packing carefully for damage or

signs of improper handling.

Report damage to the carrier and your local sales sta. In such cases, a

description of the defect, the type and the serial number of the device is

indicated.

Unpack the unit carefully to avoid damage.

Check the delivery against the packing list for completeness. Check the

name plate, if the delivered ow meter according to your order. Check that

the correct voltage supply is specied.

Special requirements VdS: The version with rolled grooved ends may only

be used in combination with VdS-approved pipe couplings manufactured

by Anvil (all Gruvlok mechanical grooved couplings), Jinan Meide (cast-

ing couplings type 1G), Minimax, Modgal, Tyco (Grinnell Mechanical and

G-Fire steel IPS couplings) and Victaulic (except pipe couplings of the type

"Style77").

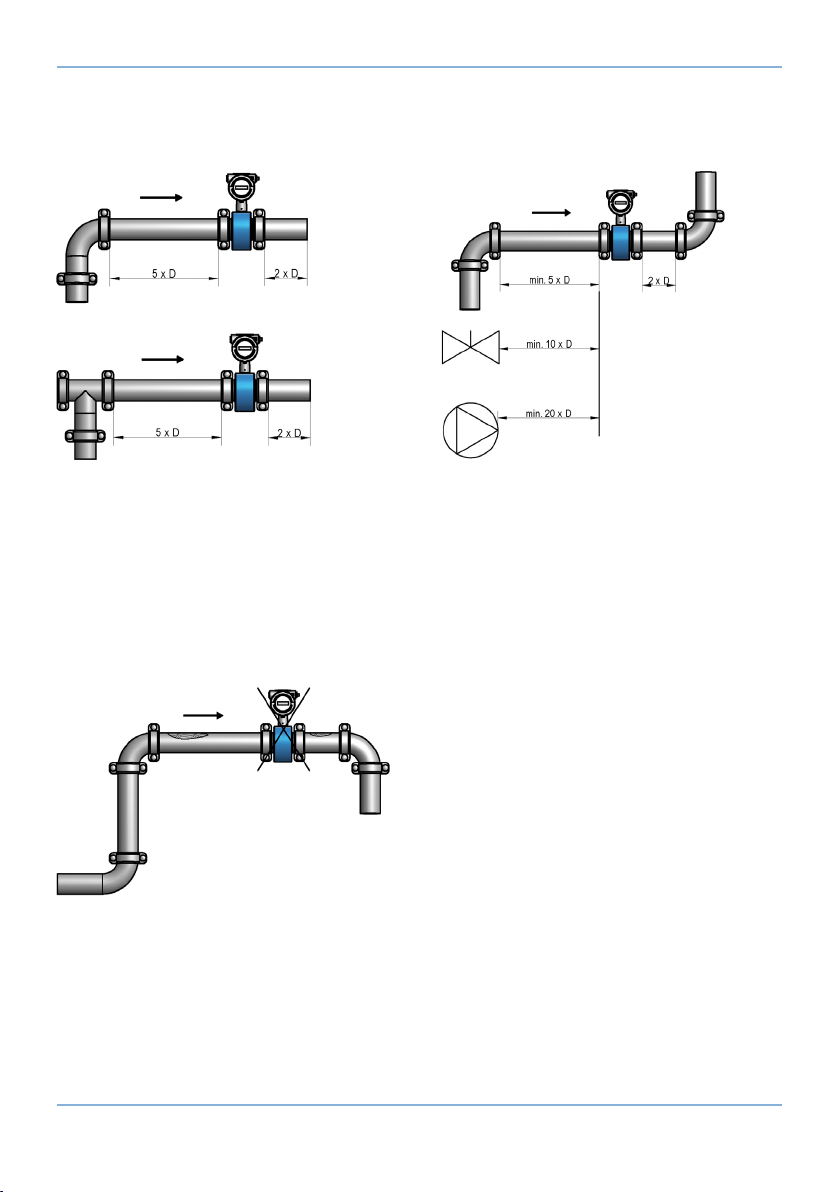

front of and behind the measuring point. An inlet of min. 5 x DN and an outlet of min. 2 x DN

»Enlarging the inlet and outlet sections

»

»Reduction of the pipe cross section

11

© MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

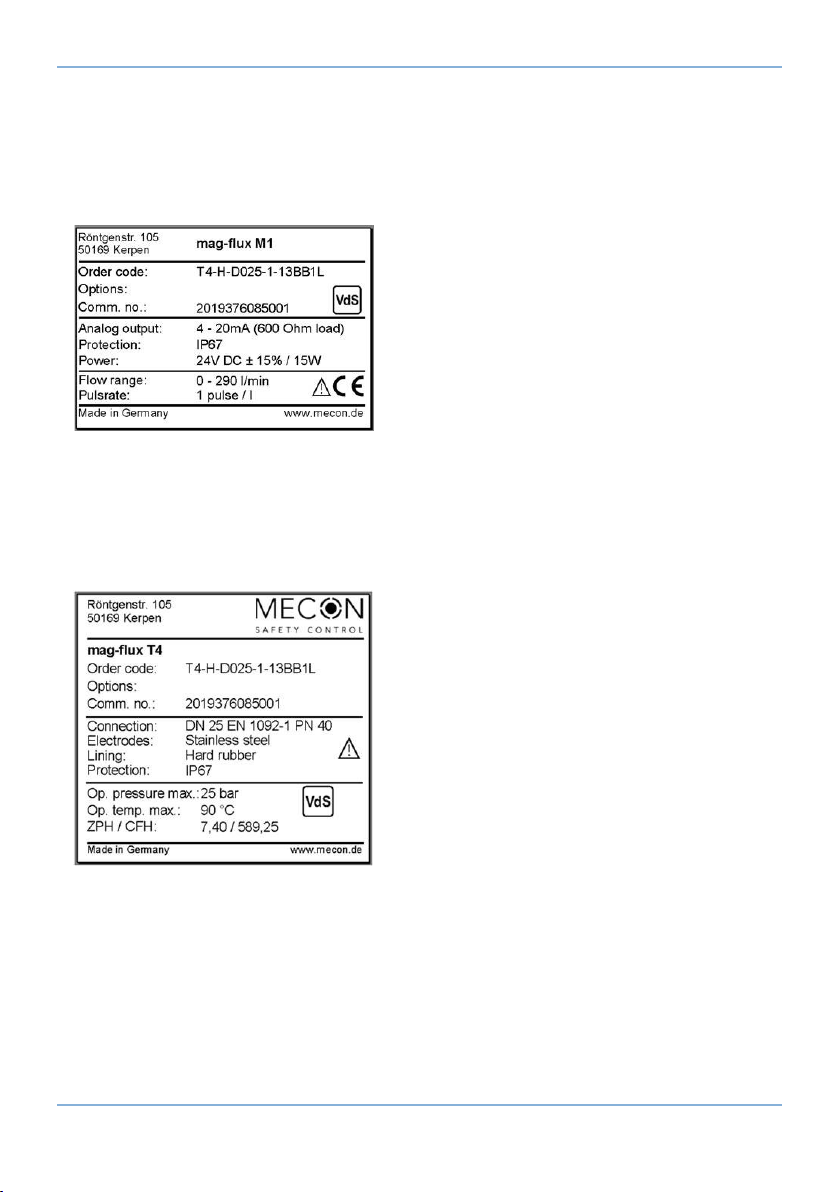

Fig. 5 Installation in horizontal and vertical pipelines

Fig. 6 Installation in rising and falling pipes

The sensor must be installed so that the measuring tube can not run empty and is always

Fig. 7 Installation with piping that is always lled

12 © MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

straighteners must be used or alternatively the measuring cross-section must be reduced.

Fig. 8 Installation between elbows, valves and pumps (D = DN)

minimum distance is 1 m.

Fig. 9 Installation at the highest point

13

© MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

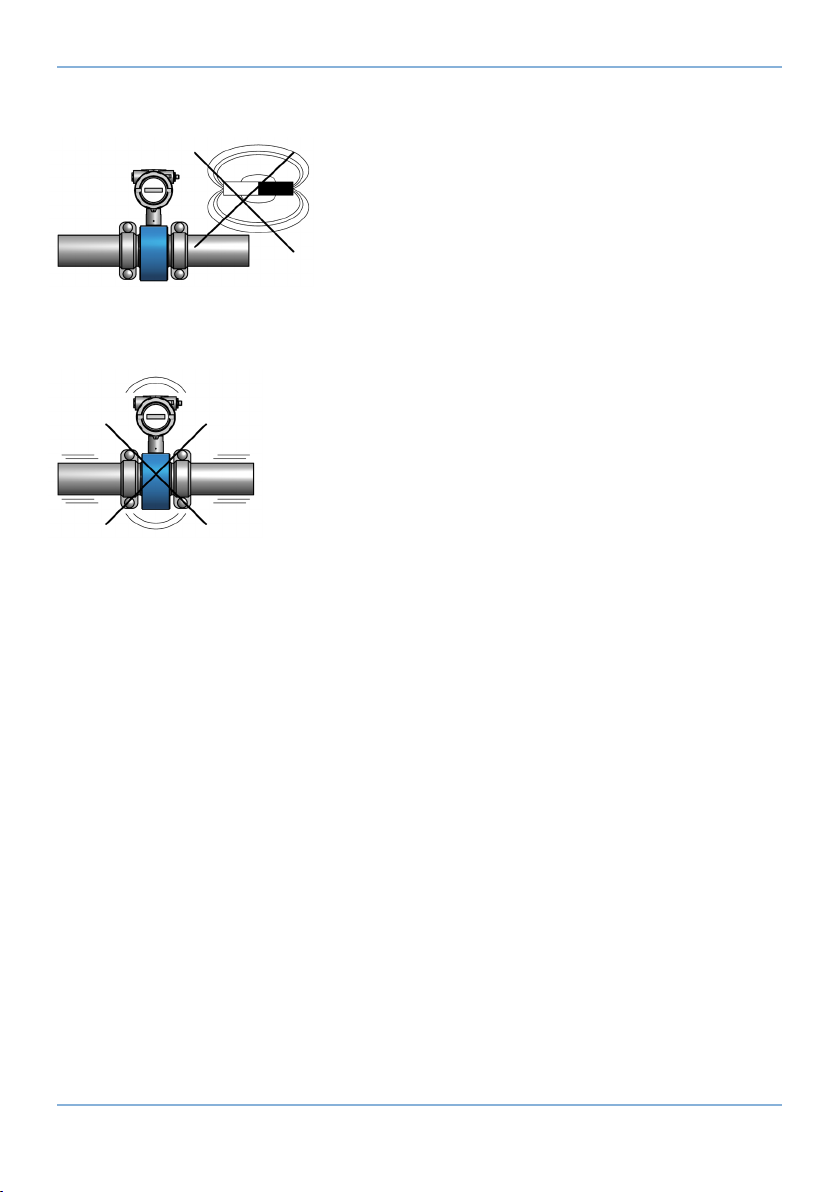

Fig. 10 Avoid magnetic elds

Fig. 11 Avoid shocks

3.5

are galvanically insulated from each other and from the measuring circuit. The housing

the measuring electronics are based on the potential of the functional earth FE of the

to the functional earth FE.

When using cathode protection devices which apply a voltage to the pipe wall to prevent

14 © MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

The measuring electronics and all operating elements within the transducer now have this

potential too.

electronics technicians or service technicians from MECON GmbH.

Warning!

Before such interventions, the equipment must be completely switched

o, all external devices be disconnected and it must be veried that the

system is no longer live! Only original parts may be used for repair.

accepted for any resulting consequential damages.

Our customer service is at your disposal to provide coordination and assistance with any

necessary diagnostic and repair measures required

This documentation contains the information required for the intended use of the product

-

persons who

»either as an electronics technician or

»a member of maintenance personnel

are familiar with the safety regulations that apply to electrical and automation engineering

and the regulations applicable in your country. They must be authorized by the plant oper-

15

© MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

and obey the instructions in them!

The following instructions are for your personal safety and also for avoiding damage to the

described product or any connected devices.

Safety instructions and warnings to prevent danger to the life and health of users or main-

-

Danger!

This means that death, serious injury or signicant damage to property will

occur if the appropriate precautions are not taken!

Warning!

This means that death, serious injury or signicant damage to property

can occur if the appropriate precautions are not taken!

Attention!

This means that slight physical injuries or damage to property may occur if

the appropriate precautions are not taken!

Information!

This is important information about the product, the handling of the

product or the relevant part of the documentation, to which particular

attention should be given.

16 © MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

3.6

Tab. 1 Terminal connection diagram

Tab. 2 Pin assignment Power supply 230 V / 115 V

Tab. 3 Connector assignment, Analogue output

1 PN Protective conductor

2 N Mains

3 L Mains (phase)

4Impulse - Pulse output (passive)

5Impulse + Pulse output (passive)

6Status - Status output (passive)

7Status + Status output (passive)

8Power - Power output (active)

9Power + Power output (active)

Pin

(Connection cable)

1brown L / phase

2white PE

3blue N / neutral conductor

4black not used

Pin

(Connection cable)

1brown not used

2white not used

3blue Earth / 0 V

4black not used

5grey Analogue output 4 - 20 mA

17

© MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

Tab. 4 Connector assignment Analogue output

Tab. 5 Cable connections with separate design

Fig. 12 Sensor connection of the mag-ux M1 sensor

Pin

(Connection cable)

1brown +24 V

2white not used

3blue Earth / 0 V

4black not used

5grey Analogue output 4 - 20 mA

Pin

(Connection cable)

5brown Magnetic current 1

6white Magnetic current 2

7green yellow Potential equalisation / PE

22 red Measuring earth

23 brown Electrode 1

24 white Electrode 2

* The green-yellow and blue wires are not connected

Fig. 11 Electr. connections of the sensor

mag-ux T4

18 © MECON GmbH BA / mag-ux T4 / EN / 19-04

INSTALLATION AND MODE OF OPERATION

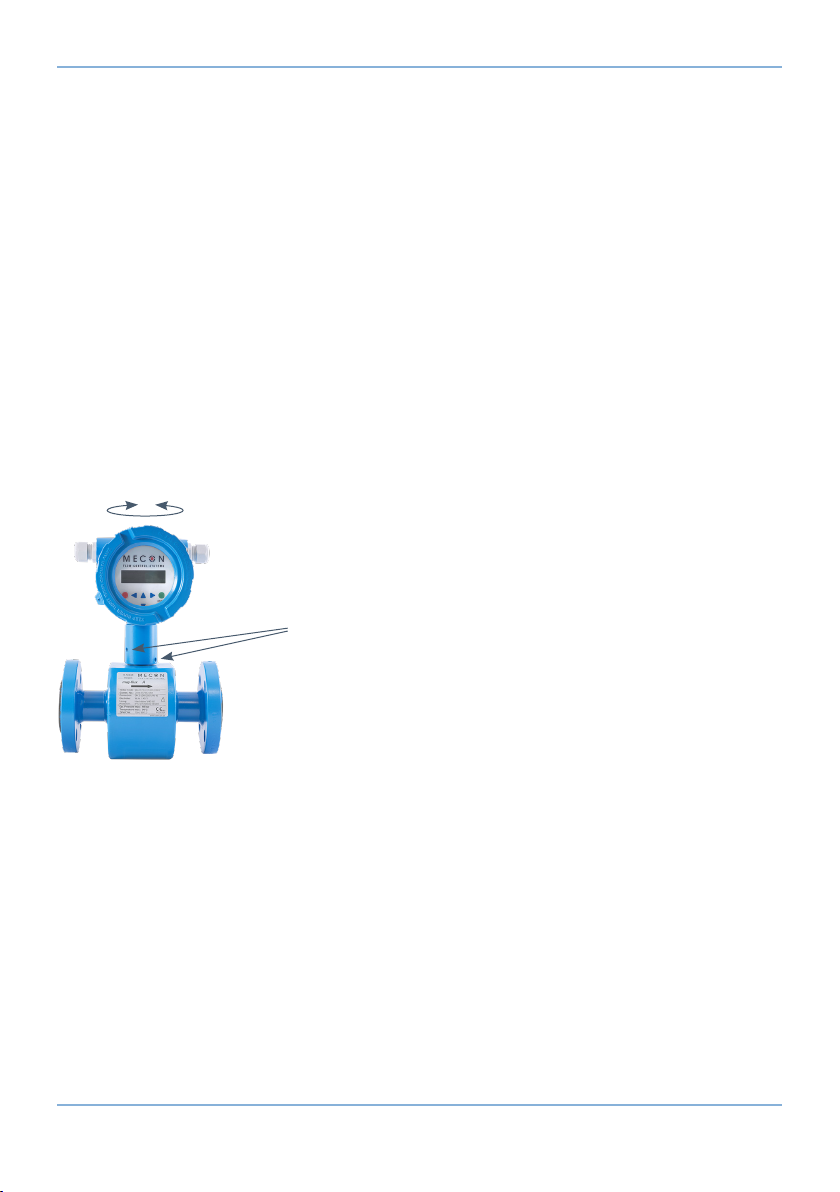

can be extended by max. ± 180°.

display can be read in the correct position with a horizontal installation position and a

1. Loosen the two set screws.

2. The transducer housing must be placed in the desired position.

3. Re-tighten the two set screws.

Fig. 14 Position of the set screws for turning the transducer housing (mag-ux A compact)

19

© MECON GmbH BA / mag-ux T4 / EN / 19-04

The operating instructions are to be read completely before installation and start-up. Only

transducer described in these operating instructions may only be used to measure the

Downloading this document from the homepage www.mecon.de and printing it out for use

with one of our MIDs is permitted. No part of this manual may be reproduced or transmit-

-

ducted by any other means without the prior written consent of MECON GmbH.

-

consequences.

other than as described in this manual.

We reserve the right to change technical data as a result of developmental progress.

The latest information about this product can be found on the Internet at the homepage

20 © MECON GmbH BA / mag-ux T4 / EN / 19-04

TECHNICAL DATA

5

5.1

5.2

30 min.

Inlet section 5 x DN

Outlet section 2 x DN

properly centred

properly earthed

»Process connection /

nominal diameter

Thread connection G½"- G2"

Coupling connection 50/2 "- 300/12"

Flange connection EN 1092-1 DN 15 - DN 300

»Measurement error

»Repeatability

± 0.5% of the measured value from 1 m/s to 10 m/s

± 0.15 % of the measured value from 0.5 m/s to 10 m/s

»Inlet section

»Outlet section

5 x D

2 x D

DN 65 - DN 300

DN 200 - DN 300

DN 15 - DN 150

IP 67

Other manuals for mag-flux T4

1

Table of contents

Other Mecon Measuring Instrument manuals