Mecon FO N4 User manual

© MECON GmbH 04/2013 OI_FO_N4_EN

FO N4 Orifice flowmeter

Operating Instructions

Pa e 2 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Imprint

All ri hts reserved. It is prohibited to reproduce this document, or any parts thereof, withoutprior written

authorization of MECON Flow Control Systems GmbH.

Subject to chan e without notice.

Copyri ht 2013 by

MECON Flow Control Systems GmbH - Rönt enstraße 105 - 50169 Kerpen

Operatin Instructions F O N4 www.mecon.de Pa e 3 / 20

04/2013 OI_FO_N4_EN

Contents

Contents

1 Safety instructions _________________________________________________________ 4

1.1 Intended use .............................................................................................................. 4

1.2 Certifications .............................................................................................................. 4

1.3 Safety instructions for the operator ............................................................................... 5

2 Start-up ................................................................................................................................. 6

3 Installation ............................................................................................................................ 7

3.1 Installation instructions ................................................................................................ 7

3.2 Installation ................................................................................................................. 7

4 Ser ice __________________________________________________________________ 8

4.1 Stora e ...................................................................................................................... 8

4.2 Maintenance and cleanin ............................................................................................ 8

4.3 Returnin the device to the manufacturer ...................................................................... 8

5 De ice description _________________________________________________________ 9

5.1 Scope of delivery ........................................................................................................ 9

5.2 Versions ..................................................................................................................... 9

5.3 Nameplate ................................................................................................................ 10

6 Description code _________________________________________________________ 11

7 Measuring ranges for liquids ________________________________________________ 13

8 Measuring ranges for gases _________________________________________________ 14

9 Technical Data ___________________________________________________________ 15

9.1 Dimensions and wei hts ............................................................................................. 16

10 Contacts _______________________________________________________________ 17

Pa e 4 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Safety Instructions

1 Safety Instructions

1.1 Intended use

The FO N4 orifice flowmeter is used to measure the flow of transparent liquids and ases in closed

pipes. The flowmeter is suitable for any mountin location, position and flow direction.

The flowmeter can also be used for flow monitorin if equipped with limit contacts.

Warning!

The operator of these measuring devices is solely responsible for the suitability,

intended use and corrosion resistance of the selected materials. It must be particularly

ensured that the materials selected for the etted parts of the flo meter are suitable

for the process media to be measured.

The manufacturer is not liable for any damage resulting from improper or unintended

use of these devices.

The FO N4 may only be operated within the pressure and volta e limits specified on the name

plate.

No external loads may act upon the meter. The flowmeters are primarly desi ned for static

applications.

1.2 Certifications

Classification by

• Pressure equipment directive 97/23/EC

The meter meets the requirements of Article 3, para raph 3 (sound en ineerin practice SEP).

The most hazardous permissable media are

-for liquids and gases: fluids of group 2

Operatin Instructions F O N4 www.mecon.de Pa e 5 / 20

04/2013 OI_FO_N4_EN

Safety Instructions

1.3 Safety instructions from the manufacturer

Disclaimer

The manufacturer will not be liable for any dama e resultin from the use of its product, includin ,

but not limited to direct, indirect , incidental, punitive and consequential dama es

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the ri ht to revise the content of its documents, includin this

disclaimer, without prior notifica, and will not be liable in any way for possible consequences of

such chan es.

Product liability and warranty

Mecon GmbH assumes no uarantee for repair work carried out by the customer without prior

notification and consulation. Any instruments or parts rejected by a customer must be returned to

us, if no other arran ement has been made.

General information

This manual is intended for the correct installation as well as operation and maintenance of the

devices. Read this instructions carefully before installin the device and placin into operation.

Specially desi ned or customised models and specialised applications are not included in this

manual.

Pa e 6 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Start-up

2 Start-up

When starting up the unit, the following points must be obser ed:

• Make sure that the actual operatin conditions (pressure and temperature) do not exceed the

limits specified on the nameplate.

• The calibration is carried out for defined conditions. It is essential to ensure compliance with the

calibration conditions. Deviations of the density, pressure or temperature of ases, as well as

density and viscosity of liquids, result in errors.

• Bends, valves and the like must be installed in such a distance of the orifice unit that

disturbances have subsided. Orifice units with lar e diameters are hi hly sensitive to

disturbance.

• When floats with ma nets and contact switches are used, it is recommended durin

commissionin to ensure the correct position of the bistable contact by movin the float alon

the contact in flow direction.

Exceptions for the measurements of gases:

• Provide valves downstream the flowmeter if pabs > 1,013 bar and usually upstream the flow-

meter if pabs = 1,013 bar (no overpressure).

• Install a flow control valve close to the flowmeter (downstream), to prevent oscillations durin

the measurement.

• Adjust the operatin pressure exactly to the reference pressure (durin calibration) to prevent

measurement errors.

Operatin Instructions F O N4 www.mecon.de Pa e 7 / 20

04/2013 OI_FO_N4_EN

Installation

3 Installation

3.1 Installation instructions

Information !

All instruments are carefully checked for proper function before shipment. Check

immediately on receipt, the outer packing carefully for damage or signs of impro

handling.

Report damage to t

he carrier and your competent sales staff. In such cases, a description

of the defect, the type and the serial number of the device is indicated.

Information !

Unpack the unit carefully to avoid damage.

Information !

Check the completeness of the delivery by using the packing list. Check the

name plate, if

the delivered flo meter is according to your order. Especially c

heck units ith electrical

components for the correct supply voltage.

3.2 Installation

The measurin re ulations for the flow DIN EN ISO 5167 not only include the version of orifice

units but also require an installation conformin to standards so that the indicated uncertainty in

measurement can be kept.

The standard installation must already be considered durin the projectin of the pipeline. The

orifice unit must be installed in a strai ht pipeline which is lon enou h.

• Ali n orifice with the sharp ed e (+ markin ) to the entry side

• Insert differential pressure sensor with askets concentrically between the flan es of the

pipeline and ti hten uniformly

• Loosen the union nut, ali n the indicatin part vertically downwards and then ti hten union nut

(Fi .4,

1

)

• In eneral, an inlet pipe of 10 x D and an outlet section of 5 x D is sufficient.

Pa e 8 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Service

4 Ser ice

4.1 Storage

Keep the device in a dry and dust-free place.

Keep away from direct sun and heat.

Avoid external load to the device

The stora e temperature ran e for standard devices with electrical components is about

-40 … +70 °C (– 40 °F … 158 °F)

4.2 Maintenance and cleaning

The devices were built within scope of low maintenance but periodically the flowmeters should be

inspected for si ns of corrosion, mechanical wear as well as dama e to the fittin and the display

unit.

We advice to carry out inspections at least once a year.

F3,or a detailed inspection and cleanin the device must be removed from the pipin .

Contamination, especially around the bypass orifice, may lead to faults in the measurement. The

bypass orifice plate can be dismounted and cleaned without interruptin the main flow it the ball

valves are closed first.

Caution!

Appropriate safety precautions have to be taken hen removing the device. Al ays use

ne gaskets hen reinstalling the device in the pipng.

4.3 Returning the de ice to the manufacturer

This device has been carefully manufactured and tested. Should you nevertheless need to return a

device to MECON GmbH please observe the followin points:

Caution!

Accordin to the actual waste disposal directives, the owner/customer is responsible for

the waste mana ement of hazardous and toxic waste. For reasons of environmental

protection and safe uardin the health and safety of our personnel all de ices sent to

MECON GmbH to be repaired must be free of toxic and hazardous substances.

This also applies to ca ities of the de ices before returning them to MECON.

The customer has to confirm this by filling in an appropriate form hich is available for

do nload on the MECON ebsite:

.mecon.de/en/declaration/contamination pdf

Caution!

In case of returnin devices which contain hazardous and toxic substances, Mecon

GmbH is entitled to dispose of these substances at cost to the customer without any

further notice.

Operatin Instructions F O N4 www.mecon.de Pa e 9 / 20

04/2013 OI_FO_N4_EN

Device Description

5 De ice Description

5.1 Scope of deli ery

1 Orifice flowmeter FO N4

2 Operatin instructions

3 Certificates (optional)

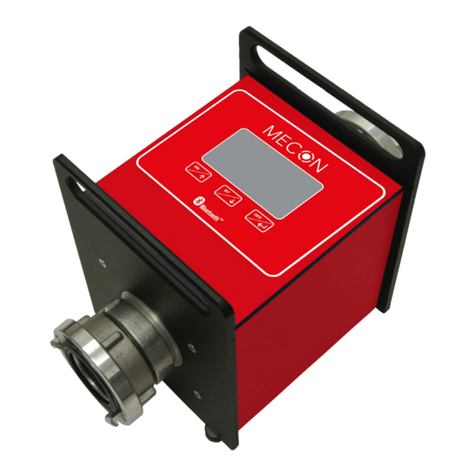

Fig. 1 Scope of devlivery

Information !

Please check the delivery for completeness using the packing list.

5.2 Versions

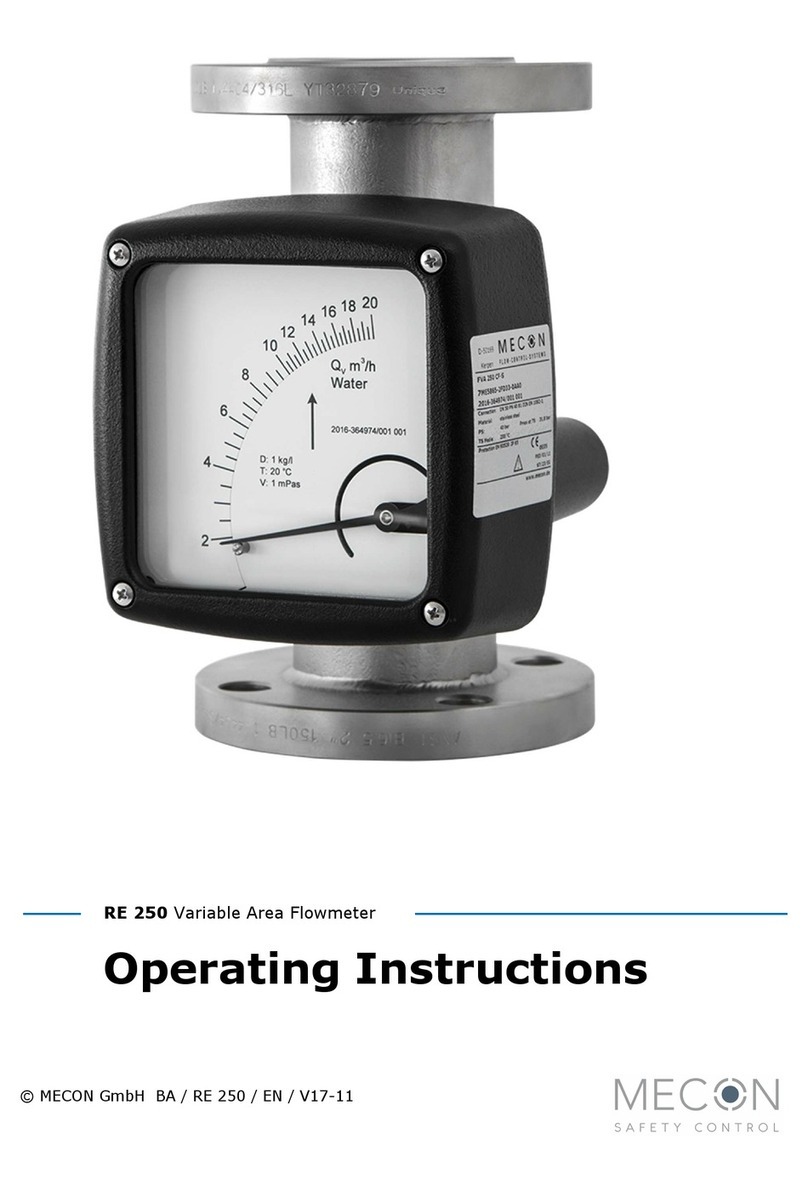

Fig. 2 Standard device with bypass

and orrifce made of PVC

The FO N4 orifice flowmeter primarly consists of an orifice plate as the sensor and a float as the

display element. A differential pressure is produced across the orifice plate which is fitted in the

main stream between two flan es in the pipin . In a bypass, this differential pressure produces a

volume flow in a variable area meter. The hei ht of the float indicates the flow rate.

The flow is read at the position of the float´s widest diameter.

Pa e 10 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Device Description

Special features:

• Complies with requirements for treatment and disinfection of swimmin / bathin pools

(DIN 19 643)

• Simple installation

• Direct visualitzation of flow rate in bypass

• Suitable for any mountin positions without reduction in accuracy

5.3 Nameplate

Important!

Please refer to the device nameplate to ensure that the device is built

according to your order.

Check particularly for the corect supply voltage

Fig. Nameplate of the FO N4

1 Code number Device specific code number

2 Year / Serial number Device specific serial number and the year it was built

3 Cate ory Cate ory acc. To Pressure Equipment directive (PED)

4 TS Medium Maximum temperature of the medium

5 PS Maximum pressure of the medium

6 Pmax bei TS Maximum pressure of the medium at temperature TS

Operatin Instructions F O N4 www.mecon.de Pa e 11 / 20

04/2013 OI_FO_N4_EN

Description code

7 Description Code

The description code consists of the followin elements:

1

Flow tube

0 Tro amid

1 Polysulfone

2 Nominal diameter

P DN 25 (1")

Q DN 32 (1 ¼")

A DN 40 (1 ½" )

B DN 50 (2")

C DN 65 (2 ½")

D DN 80 (3")

E DN 100 (4")

F DN 125 (5")

G DN 150 (6")

H DN 200 (8")

J DN 250 (10")

K DN 300 (12")

L DN 350 (14")

M DN 400 (16")

3

Measuring ranges (for water in [m³/h] (refer to the following table))

A Standard ran e A

B Standard ran e B

C Standard ran e C

D Standard ran e D

E Standard ran e E

Z Special ran e (with additional Y01)

Nominal size A B C D E

DN Inch

25 1" 0.6 – 3.0 0.9 – 4.5 1.2 – 6.0 -- --

32 1 ¼" 0.8 – 4.0 1.5 – 7.5 2.0 – 10.0 -- --

40 1 ½" 1.2 – 6.0 2.0 – 10.0 3.2 – 16.0 -- --

50 2" 2.0 – 10.0 3.0 – 15.0 5.0 – 25.0 -- --

65 2 ½" 3.2 – 16.0 6.0 – 30.0 8.0 – 40.0 9.0 – 45.0 16.0 – 80.0

80 3" 5.0 – 25.0 10.0 – 50.0 13.0 – 65.0 15.0 – 75.0 20.0 – 100

100 4" 10.0 – 50.0 16.0 – 80.0 20.0 – 100 24.0 – 120 40.0 – 200

125 5" 13.0 – 65.0 24.0 – 120 32.0 – 160 39.0 – 195 40.0 – 200

150 6" 20.0 – 100 32.0 – 160 50.0 – 250 54.0 – 270 70.0 – 350

200 8" 34.0 – 170 60.0 – 300 80.0 – 400 99.0 – 495 130 – 640

250 10" 50.0 – 250 80.0 – 400 130.0 – 650 150 – 750 160 – 800

300 12" 80.0 – 400 120 – 600 200 – 1,000 -- 180 – 900

350 14" 100 – 500 200 – 1,000 270 – 1,300 -- --

400 16" 140 - 700 240 – 1,200 320 – 1,600 -- --

Pa e 12 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Description code

4 Float material

0 Mat.No.. 1.4305

1 Mat.No. 1.4571

2 Mat. No..1.4571 with Ma net

3 PVC wei hted

4 PVC weit hted with Ma net

5 Connection standard

0 DIN 2501

1 ASME B16.5 150 RF

6 Contacts (only with magnetic float)

0 without

1 Contact K18/A (closes when limit is fallen below)

2 Contact K18/B (closes when limits exceeded)

3 2 Contacts K18/A

4 2 Contactc K18/B

5 1 each Contact 18/A und K18/B

7 Bypass pipe / Orifice

AW PVC / PVC

PW PP / PP

Bx PVC / stainless steel mat. No.1.4571

Qx PP / stainless steel mat. No. 1.4571

xP DN 25 (1")

xQ DN 32 (1 ¼")

xA DN 40 (1 ½")

xB DN 50 (2")

xC DN 65 (2 ½")

xD DN 80 (3")

xE DN 100 (4")

xF DN 125 (5")

xG DN 150 (6")

xH DN 200 (8")

xJ DN 250 (10")

xK DN 300 (12")

xL DN 350 (14")

xM DN 400 (16")

8 Calibration certificate

0 Without calibration ceritficate

1 With calibration certificate

9 Further designs

Y01 Measured medium: specify in plein text: medium always required measurin ran e with

dimension, sensity with viscosity with dimension, operatin temperature, operatin

Y04 Silicone-free-version

Y99 Special version in plain text

Operatin Instructions F O N4 www.mecon.de Pa e 13 / 20

04/2013 OI_FO_N4_EN

Measuring ranges for liquids

7 Measuring ranges for liquids

Standard measuring ranges for liquids (p= 1k /l (62,43 lb/cu.ft), viscosity 1mPa.s (1cP))

Nominal

diameter

o erpressure ≥ 0,5bar

Minimum measuring range Maximum measuring range

DN Inch

[m³/h] [Usgpm]

∆p*

[m³/h] [Usgpm]

∆p*

[mbar]

[psi] [mbar]

[psi]

25 1 0,6 … 3,0 2,64 … 13,2 335 4,86 1,2 … 6,0 5,28 … 26,4 205 2,97

32 1 ¼

0,8 … 4,0 3,52 … 17,6 335 4,86 2,0 … 10,0 8,8 … 44,0 205 2,97

40 1 ½

1,2 … 6,0 5,28 … 26,4 335 4,86 3,2 … 16,0 14,1 … 70,0 200 2,90

50 2 2,0 … 10,0 8,8 … 44,0 330 4,79 5,0 … 25,0 22,0 … 110 200 2,90

65 2 ½

3,2 … 16,0 14,1 … 70,0 330 4,79 16,0 … 80,0 39,6 … 198 200 2,90

80 3 5,0 … 25,0 22,0 … 110 330 4,79 20,0 … 100 66,0 … 330 190 2,76

100 4 10,0 … 50,0

44,0 … 220 300 4,79 40,0 … 200 106 … 528 190 2,76

125 5 13,0 … 65,0

57,0 … 286 325 4,71 40,0 … 200 172 … 858 190 2,76

150 6 20,0 … 100 88,0 … 440 315 4,57 70,0 … 350 238 … 1188 175 2,54

200 8 34,0 … 170 150 … 749 320 4,64 130 … 640 436 … 2179 185 2,68

250 10 50,0 … 250 220 … 1100 250 3,63 160 … 800 661 … 3301 190 2,76

300 12 80,0 … 400 352 … 1761 315 4,57 200 … 1000 881 … 4403 180 2,61

350 14 100 … 500 440 … 2202 325 4,71 270 … 1300 1189 … 5724 190 2,76

400 16 140 … 700 616 … 3082 320 4,64 320 … 1600 1409 … 7045 200 2,90

* Pressure drop

Pa e 14 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Measuring ranges for gases

8 Measuring ranges for gases

Standard measuring ranges for gases (Pe=0 bar , T=0 °C, ρ=1,293 k /m³, v=0,0181 mPa⋅s)

Nominal

diameter

0,1 bar ≤ o erpressure ≤ 0,5 bar o erpressure > 0,5 bar

Minimum measuring range

Maximum measuring range Maximum measuring range

DN Inch

[m³/h]

∆p*

[mbar]

[m³/h]

∆p*

[mbar]

[m³/h]

∆p*

[mbar]

25 1 -- -- -- -- -- --

32 1 ¼

-- -- -- -- -- --

40 1 ½

12.0 … 60.0 40 36.0 … 180 24 100 … 500 125

50 2 20.0 … 100 36 50.0 … 250 22 160 … 800 130

65 2 ½

20.0 … 100 42 130 … 650 22 280 … 1,400 138

80 3 50.0 … 250 38 130 … 650 23 400 … 2,000 125

100 4 100 … 500 38 200 … 1,000 22 600 … 3,000 115

125 5 130 … 650 35 360 … 1,800 22 1,000 … 5,000 130

150 6 200 … 1,000 34 500 … 2,500 22 1,500 … 7,500 140

200 8 250 … 1,250 38 500 … 2,500 20 2,600 … 13,000 135

250 10 500 … 2,500 36 1,300 … 6,500 18 4,000 … 20,000 130

300 12 600 … 3,000 37 2,000 … 10,000 20 6,000 … 30,000 140

350 14 1,000 … 5,000 40 2,800 … 14,000 23 8,000 … 40,000 135

400 16 1,400 … 7,000 35 3,600 … 18,000 23 10,000 … 50,000 125

* Pressure drop

Operatin Instructions F O N4 www.mecon.de Pa e 15 / 20

04/2013 OI_FO_N4_EN

Technical data

9 Technical Data

General Data

Application Flow measurement of transparent liquids and ases

Measurin principle Orifice plate as differential pressure sensor with

variable areas meter in bypass

Accuracy ± 2 % of full scale value

Dynamic ran e 1:5

Flow direction Any

Rated operating conditions

Temperature and pressure limits [°C] (°F) [bar] (psi)

Water and non-corrosive liquids ≤ 40 (104) 10 (145)

50 (122) 6.25 (91)

60 (140) 2.5 (36)

Corrosive liquids ≤ 20 (68) 10 (145)

40 (104) 4 (58)

60 (140) 1 (15)

Measurin ran e 0.6 to 1,600 m³/h (2.64 to 7,045 Us pm). Special

scale for liquids with a density other than 1 k /l

Medium conditions

Measurin unit m

3

/h

Viscosity limits for all measurin ran es 1.0 – 1.3 mPa.s

Construction design

Process connection Rin between flan es EN 1092-1 (PN 10)

DN 25 (1") to 400 (16")

Material of wetted parts

Rin PVC / PP

Orifice plate

9

(s. Fi .

4

)

PVC / PP (optional stainless steel mat.-No. 1.4571)

Flow tube

5

(s.

f

i

4

)

Tro amid (up to 50 °C (122 °F)),

Polysulfone (up to 60 °C (140 °F))

Ball valve PVC / PP

Connectin tube PVC / PP

Float

7

(s.Fi .

4

)

Stainless steel mat.-No. 1.4571, PVC

Limits

4

(s. Fi .

4

)

Polysulfone

Gasket

2

(

s.Fi .

4

)

Perbunan (NBR)

Bypass orifice plate

3

(s.Fi .

4

)

Stainless steel mat.-No. 1.4571 (optional PVC)

Pa e 16 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Technical data

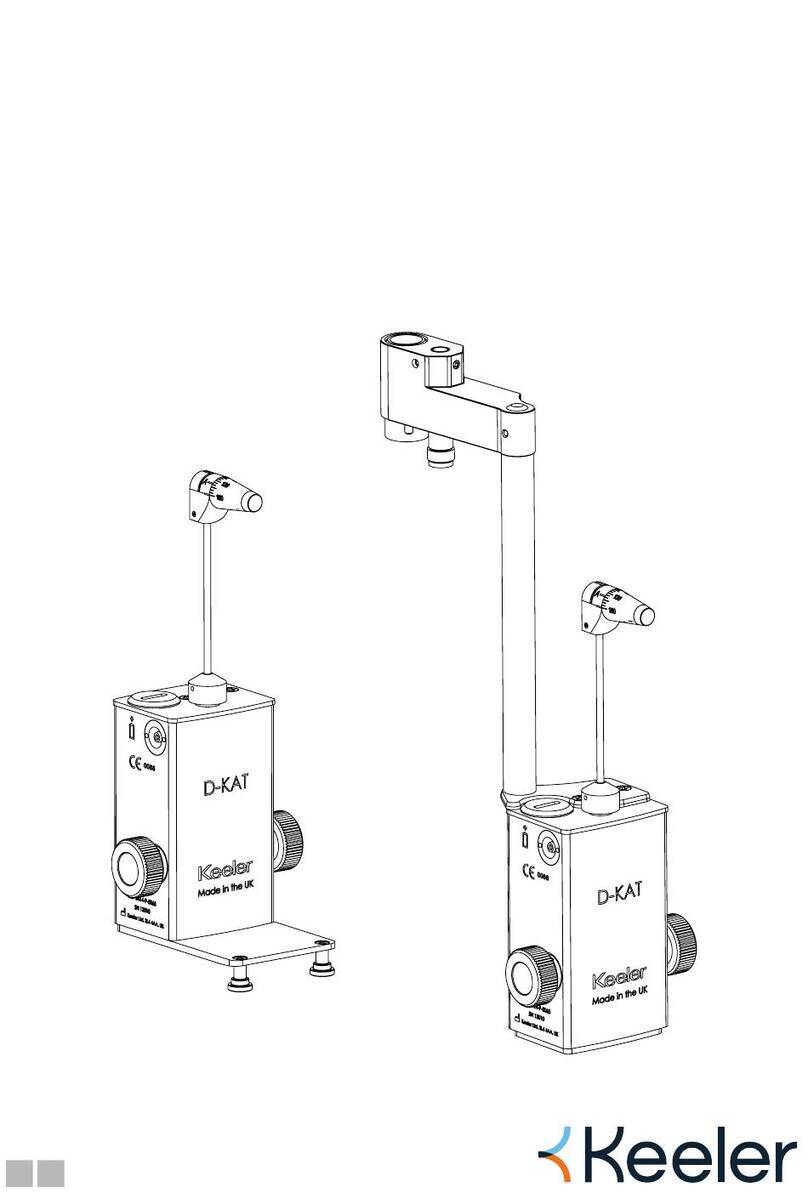

9.1 Dimensions and weights

1 Union nut

2 O-Rin

3 Bypass orifice

4 Limit

5 Flow tube

6 Setpoint indicator

7 Float

8 Stopper

9 Orifice plate

Fig. 4 FO N4, Dimensions in mm

Nominal diameter L

[mm] (inch)

Ø D

[mm] (inch)

Weight

[kg]

DN Inch

25 1" 259 (10.2) 68 (2.68) 1,4

32 1 ¼" 264 (10.39) 78 (3.07) 1,4

40 1 ½" 269 (10.59) 88 (3.46) 1,5

50 2" 276 (10.87) 102 (4.02) 1,6

65 2½" 286 (11.26) 122 (4.80) 1,8

80 3" 294 (11.57) 138 (5.43) 1,9

100 4" 304 (11.97) 158 (6.22) 2,0

125 5" 319 (12.56) 188 (7.40) 2,3

150 6" 331 (13.03) 212 (8.35) 2,5

200 8" 359 (14.13) 268 (10.55) 3,1

250 10" 385 (15.16) 320 (12.60) 3,5

300 12" 410 (16.14) 370 (14.57) 4,1

350 14" 444 (17.48) 430 (16.93) 5,1

400 16" 466 (18.35) 482 (18.98) 5,8

Operatin Instructions F O N4 www.mecon.de Pa e 17 / 20

04/2013 OI_FO_N4_EN

Contacts

10 Contacts

The bistable contact K18 is intended for si nalin of limit values and for controllin purposes.

Special features

•bistable function

•hi h vibration resistance

• no interaction between contacts

• low cost plastic version

• easy to use elelctrical connection

Mode of operation

A bistable reed contact consists of a sprin contact which is covered by a lass tube filled with inert as. It

is operated by a ma netic field. This ma netic field is enerated by a permanent ma net inside the float of

a MECON flowmeter.

There are two versions availabe:

Fig. 5 Contact K 18 A Fig. 6 Contact K 18 B

K 18 A: contact closes on fallin below the limit

K 18 B: contact closes on exceedin the limit

Electrical loadability

The sprin contacts of the K18 are sensitive to current overload (max. 500 mA). A hi h current could lead

to a weldin effect and this will dama e the contact blades – this specifically applies to inductive loads e. .

relais (hi h self-induction).

Protecti e circuits

At reat cable len ths (cable capacity) it is recomended to connect a protectice resitor in series to contact

K18 A(B) for current limitation.

Fig. 7 Protective circuit for current limitation

Pa e 18 / 20 www.mecon.de Operatin Instructions F O N4

04/2013 OI_FO_N4_EN

Contacts

When usin a DC power supply in combination with an inductive load it is recomended to connect a diode

in parallel to the load.

Fig. 8 Protective circuit for inductive loads and DC power supply

Technical data

Contact material Rhodium (with inert as)

max. switchin capacity 5 W / 10 VA

Max. switchin volta e 250 V DC/AC

Contact resistance 0,1 Ω

Isolation resistance 10

11

Ω

Contact closin time 2 ms

Contact openin time 0,07 ms

Frequency of operation 2000 Hz

Duration of bounce 0,5 ms

Temperature ran e -40 °C to +80 °C

Material of housin Plastics

Electrical connection Rectan ular connector acc. to DIN EN 175301-803

(previously DIN 43 650)

Protection class IP 65

Max. startin current (peek) 0,5 A

Max. switchin current 230 V DC : 21 mA

115 V DC : 43 mA

24 V DC : 0,2 A

10 V

DC : 0,5 A

Warning !

Observe in any case the max. s itching capacity and the max. starting current –

other ise a

elding effect ill damage the contact blades.

Operatin Instructions F O N4 www.mecon.de Pa e 19 / 20

04/2013 OI_FO_N4_EN

Contacts

Installation of the connection cable to the connector:

1. Remove the cable land (9) and take out the

asket kit (8, 7, 6).

2. Remove the lockin screw (5) and pull of the

housin (4) from the insert connector (3).

3. Insert the connection cable throu h the cable

land (9), the asket kit (6, 7, 8) and the

housin .

4. Connect the wires to terminal 1 and 2 of the

insert connector.

5. Assamble the rectan ular connector in reverse

order as described above. Please note, that

the cable outlet can be varied by rotatin the

insert connector (4) throu h 90°.

Fig. 9 Explosion drawin contact K 18

Commissioning:

When commissionin the contact K18 we recommend to ensure the correct position of the bistable

contact by movin the float alon the K18 in flow direction.

OI_FO_N4_EN

Subject to chan e without notice

Copyri ht

Mecon GmbH

Rönt enstraße 105

D 50169 Kerpen

Phone: +49 (0)2237 600 06 – 0

Fax.: +49 (0)2237 600 06 – 20

Email: [email protected]

www.mecon.de

Table of contents

Other Mecon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Kanomax

Kanomax 2212 user manual

MICRO-EPSILON

MICRO-EPSILON optoControl 1200 operating instructions

FCI

FCI ST100 series Configuration software manual

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Thermo Scientific

Thermo Scientific RadEye SPRD operating instructions

QUNDIS

QUNDIS Q heat 5.5 US Operating and installation instructions