Mecon mag-flux M1 User manual

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 1 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

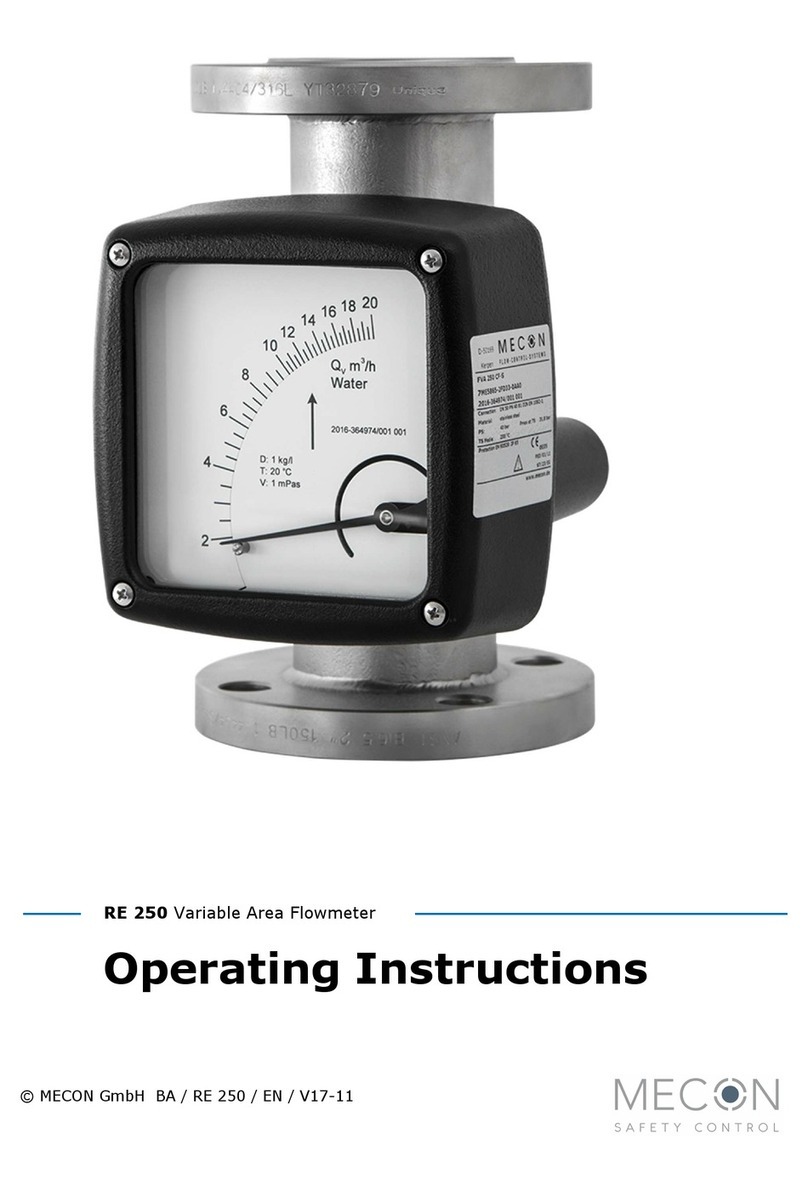

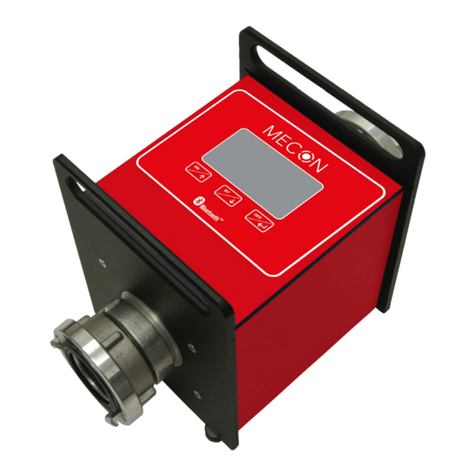

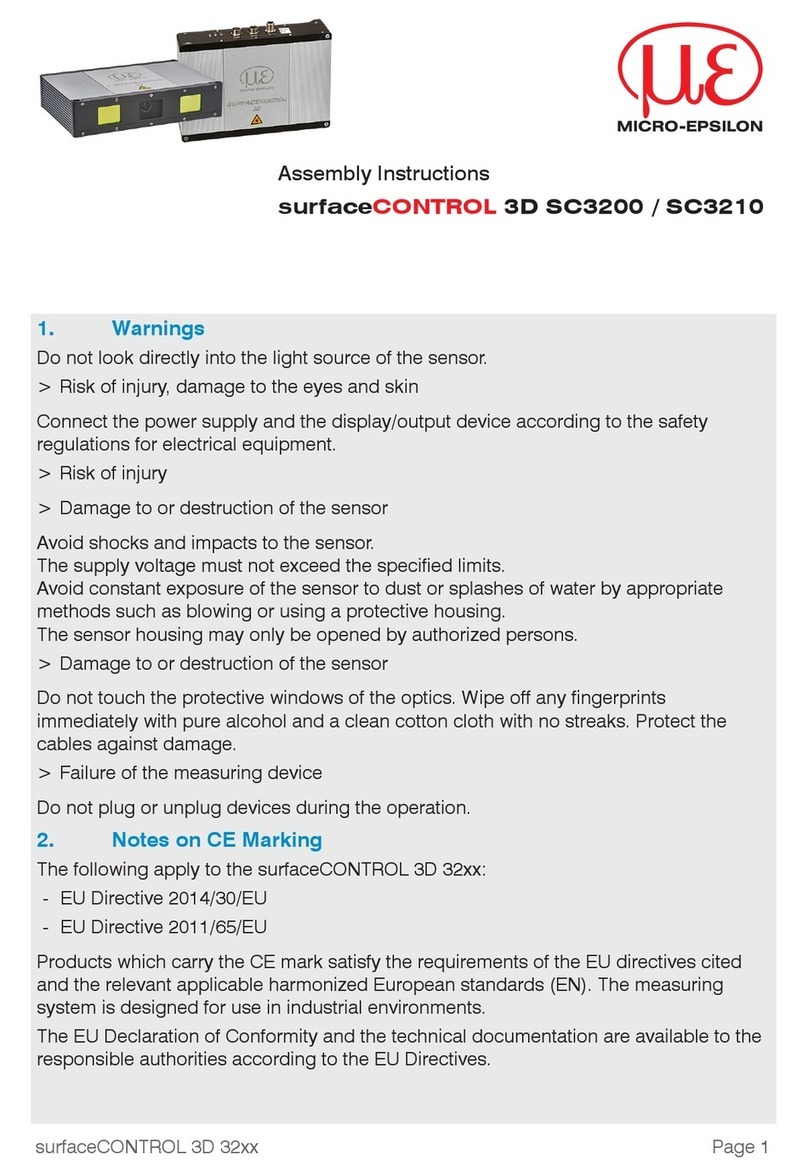

Transmitter mag-flux M1

Fig 1 Transmitter max-flux M1

__ Application domain

The mag-flux M1 is a microprocessor controlled and program-

mable transmitter that can be customized using control unit.

Although basic configuration settings such as transmitter

calibration are realized at the factory, other settings such as

those for measurement data processing, analysis, display and

output are user definable.

Measurement data from sensors of series mag-flux are processed

by the transmitter (hereinafter referred to as mag-flux M1). t

can be installed directly on the sensor (compact version) or be

mounted separately (remote version) and it is designed for flow

velocities up to 10 m/s.

A remote version is available for sensor mag-flux A, mag-flux S,

mag-flux F5 and also for probes mag-flux M S 1/D and mag-flux

M S 2/15.

A compact version is only available for sensor mag-flux A and

mag-flux S.

The transmitter mag-flux M1 is communication enabled and

supports optional the HART® protocol.

__ Special features

•High-speed signal processing by 16-bit Microcontroller

•Easy multilingual menu navigation with a two-line display

•Self-monitoring system

•nternal simulation for all output values

•Analog output (0/4-20 mA)

•Digital outputs (pulse, frequency, alarm, forward and

reverse flow, M N / MAX flow rate)

•User settings protected by user definable password

__ Introduction

I. Shipping, storage and product inspection

Shipping and storage

The device is to be safeguarded against dampness, dirt, impact

and damage.

Product inspection

Upon receipt of the product, check the contents of the box and

the product particulars against the information on the delivery

slip and order form so as to ensure that all ordered components

have been supplied. Notify us of any shipping damage

immediately upon receipt of the product. Any damage claim

received at a later time will not be honored.

II. Warranty

Your flowmeter was manufactured in accordance with the highest

quality standards and was thoroughly tested prior to shipment.

However, in the event any problem arises with your device, we

will be happy to resolve the problem for you as quickly as

possible under the terms of the warranty which can be found in

the terms and conditions of delivery. Your warranty will only be

honored if the device was installed and operated in accordance

with the instructions for your device. Any mounting,

commissioning and/or maintenance work is to be carried out by

qualified and authorized technicians only.

III. Repair

t is important that you do the following before shipping your

flowmeter to MECON GmbH for repair:

•Enclose a description of the problem with your device.

Describe in as much detail as possible the application and

the physical and chemical properties of the fluid.

•Remove any residues from the device and be sure to clean

the seal grooves and recesses thoroughly. This is

particularly important if the fluid is corrosive, toxic,

carcinogenic, radioactive or otherwise hazardous.

•The operator is liable for any substance removal or personal

damage costs arising from inadequate cleaning of a device

that is sent for repair.

IV. Using HART® hand-held terminal

For information regarding operation of the transmitter using the

HART hand-held terminal, see “Operation of the mag-flux M1

transmitter using the HART hand-held terminal.”

__ Steps prior to operation

t is essential that these operating instruc-

tions have been read before installing and

operating the device. The device has to be in-

stalled and serviced by a qualified technician

only. The mag-flux M1 transmitter is solely

suitable to measure volume flow of liquids in

conjunction with a sensor of series mag-flux.

Downloading of the present document from our web site

www.mecon.de and printing out this document is allowed only for

purposes of using our flowmeters. All rights reserved. No instruc-

tions, wiring diagrams, and/or supplied software, or any portion

thereof, may be produced, stored, in a retrieval system or

transmitted by any means, electronic, mechanical, photocopying

or otherwise, without the prior written permission of MECON

GmbH.

Although the materials in the present document were prepared

with extreme care, errors cannot be ruled out. Hence, neither the

WWW.TEESING.COM | +31 70 413 07 50

Page 2 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

company, the programmer nor the author can be held legally or

otherwise responsible for any erroneous information and/or any

loss or damage arising from the use of the information enclosed.

MECON GmbH extends no express or implied warranty in regard

to the applicability of the present document for any purpose

other than that described.

We try hard to optimize and improve the products and parti-

cularly we appreciate any suggestions for improvement made by

our customers. f you have any recommendation for improving

our products please send your suggestions to the following

address:

Mecon GmbH

Dept. Development

Headword: mag-flux M1

R ntgenstraße 105

D-50169 Kerpen

or:

via fax: +49 (0)2237 – 600 06 – 40

via email: customerservice@mecon.de

We reserve the right to change the technical data in this manual

in the light of any technical progress that might be made.

For actual updates regarding this product, visit our website at

www.mecon.de, where you will also find contact information for

the MECON distributor nearest to you.

For information regarding our own sales operations, contact us at

customerserv[email protected].

Installation and servicing

The devices described in this manual are to be installed and

serviced only by qualified technical personnel such as a qualified

MECON GmbH electronics engineer or service technician.

Warning!

Before servicing the device, it must be completely

switched off, and disconnected from all peripheral

devices. The technician must ensure that the

device is completely off-circuit. Only original re-

placement parts have to be used.

MECON GmbH accepts no liability for any loss or damage of

any kind arising from improper operation of any product,

improper handling or use of any replacement part, or from

external electrical or mechanical effects, overvoltage or

lightning. Any such improper operation, use or handling shall

automatically invalidate the warranty for the product

concerned.

n the case of a problem with your device, please contact us

using one of the following numbers:

Phone: +49 (0)2237 - 60006 - 0

Fax: +49 (0)2237 - 60006 - 40

Contact our customer service department if your device needs

repair or if you need assistance in diagnosing a problem with

your device.

Safety advisory for the user

The present document includes all information you need for

proper operation of the product. The document is intended for

use by qualified personnel. This means personnel who are

qualified to operate the device described herein safely, including

•electronics engineers,

•electrical engineers

•service technicians

who are conversant with the safety regulations pertaining to the

use of electrical and automated technical devices and with the

applicable laws and regulations in their own country. The

personnel must be authorized by the facility operator to install,

commission and service the product described herein, and are to

read and understand the contents of the present operating

instructions before working with the device.

Hazard warnings

The purpose of the hazard warnings listed below is to ensure that

device operators and maintenance personnel are not injured and

that the flowmeter and any devices connected to it are not

damaged.

The safety advisories and hazard warnings in the present docu-

ment to avoid injury of placing operators and maintenance

personnel and to avoid material damage are prioritized using the

terms listed below, which are defined as follows

Danger

means that failure to take the prescribed precautions will result

in death, severe bodily injury, or substantial material damage!

Warning

means that failure to take the prescribed precautions could

result in death, severe bodily injury, or substantial material

damage!

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 3 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Caution

means that failure to take the prescribed precautions could result

light severe bodily injury or material damage!

Note

means that the accompanying text includes important

information about the product, handling the product or about a

section of the documentation that is of particular importance.

Proper use of the device

Warning!

The operator is responsible for ensuring that the

material used in the sensor and housing is suitable

and that such material meets the requirements for

the fluid being used and the ambient site conditions.

The manufacturer accepts no responsibility in regard

to such material and housing.

Note!

n order for the device to perform correctly and

safely, it must be shipped, stored, set up, mounted

operated and maintained properly.

Return for servicing or calibration

Before returning your flowmeter for servicing or calibration,

make sure it is completely clean. Any residues of substances that

could be hazardous to the environment or human health are to

be removed from all crevices, recesses, gaskets, and cavities of

the housing before the device is shipped!

Warning!

The operator is liable for any loss or damage of any

kind, including personal injury, decontamination

measures, removal operations and the like that are

attributable to inadequate cleaning of the device.

Any device returned for servicing is to be ac-

companied by a certificate as specified in

„Product return form”!

The device is to be accompanied by a document describing the

problem. Please also quote the name of a contact person. This

will help to repair your device as expeditiously as possible and

therefore minimize the cost of repairing it.

Replacement of the terminal board

Before replacing the terminal board, please read the safety

instructions in Section „ Replacement of the terminal board” on

page 12.

Caution!

Make sure that you obey the applicable standards

and regulations pertaining to electrical devices,

device installation and process technology when

replacing the transmitter electronics. The highly

integrated electronic components of the device are

ESD sensitive.

Caution!

The complete unit has to be replaced with all of its

printed boards (except for the memory chip (DSM)).

The specified precision and interchangeability of the

electronics are only guaranteed if the complete insert

is replaced.

__ Identifikation

Manufacturer Mecon GmbH

Röntgenstraße 105

D-50169 Kerpen

Phone: +49 (0)2237 6 00 06 – 0

Fax: +49 (0)2237 6 00 06 – 40

nternet: http://www.mecon.de

Email: customerservice@mecon.de

Product type Transmitter for magnetic-inductive flowmeters

series mag-flux

Product name Transmitter Type mag-flux M1

Version-No. 10/2014 dated from 2014-10-06

__ Commissioning

Installation of magnetic-inductive flowmeters

At the installation of the magnetic-inductive flow sensor the

instructions and notes of the assembly instructions and operating

manuals have to be followed. Also, abserve the regulations of

grounding, potential equalization and company-internal groun-

ding guidelines.

Potentials

All outputs are electrically isolated from the auxiliary power, the

sensor circuit and from each other. The housing and the inter-

ference suppression filters of the power supply are connected to

PE.

The electrodes and measuring electronics are related to the

potential of the function earth FE of the sensor. FE is not

connected to PE, but may be connected with each other in the

sensor junction box. f the sensor is grounded by using ground

disks (earthing rings), these must in connected with the function

earth FE.

At a separate assembly of sensor and transmitter the outer

screen of the connecting cable is connected to the transmitter

housing and has PE potential. The inner screens of the electrode

line are connected to FE inside the junction box of the sensor and

to the mass (GND) of the transmitters electronic.

Details of all wirings, terminals and drawing can be found in the

chaper „Wiring diagrams” starting at page 9.

Cathodic protective units

Using a cathodic protective unit to avoid corosion, which put a

voltage to the tube wall, it must be connected to terminal FE.

The transmitter boards, control panal and internal switches are

on the same potential as FE.

WWW.TEESING.COM | +31 70 413 07 50

Page 4 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Warning!

According to EN 50178:1997 all electrical circuits

with „protectiv safety isolation without any

protection against contacts” must observe the

following maximum voltages:

•Maximum AC voltage (Veff) 25 V

•Maximum DC voltage 60 V

It is strictly forbidden to connect FE to any

higher voltage!

Startup conditions

The device is not subject to specific startup conditions. However,

pressure surges should be avoided.

Commisioning the mag-flux flow probes

n order to be able to calculate the volume flow when using the

mag-flux flow probes correctly from the measured flow velocity,

the installation requirements must be kept regarding position and

mounting depth correctly.

Transmitter settings must be made as specified in

chapter „Operating the mag-flux flow probes with

the mag-flux M1” on page 6 to ensure the correct

operation!

Particularly for existing installations after replace-

ments or modifications e.g. tubing diameter.

__ Operating principle and system design

Measuring principle

t was back in 1832 that Faraday suggested utilizing the principle

of electrodynamic induction for measuring flow velocities. His

experiments in the Thames, though unsuccessful due to

superimposed polarization effects, are nonetheless regarded as

the first experiment in the field of magnetic-inductive flow

measurement. According to Faraday’s law of electromagnetic

induction, an electrical field E is generated in a conductive liquid

moving through a magnetic field B at a velocity v in accordance

with the vector product E = [v x B].

Fig 2 Principle of the magnetic-inductive flow measurement

Through a meter tube provided with an insulating lining a liquid

flows at velocity v and a flow rate Q, producing a measuring-

circuit voltage Um at the two electrodes at right angles to the di-

rection of flow. The size of this measuring-circuit voltage is pro-

portional to the mean flow velocity and the volume flow rate.

System design

The complete meter consists of a mag-flux M1 transmitter and a

sensor e.g. mag-flux series. The device is qualified to measure

any liquid, conductive media, providing that the sensor’s material

is suitable for the fluid.

The mag-flux M1 transmitter generates the inductive current

necessary for the magnetic field and preprocesses the induced

voltage at the electrodes.

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 5 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Basic version mag-flux M1

An analog 0/4...20 mA current output (active), a pulse or fre-

quency output and a status output are standard features of the

device.

Additionally the mag-flux M1 has a LCD display with backlight.

Customers are able to configure the transmitter with 6 keypads

without any further external tool.

Fig 3 Basic version of the transmitter mag-flux M1

HART®-interface (Option)

An analog 0/4−20 mA output is a standard feature and digital

data transmission via HART® protocol as an optional feature of

the device.

A retrofit by customer is not possible.

Empty pipe detection

The transmitter has the ability for an empty pipe detection. The

operating reliability depends on the conductivity of the liquid and

the cleanliness of the electrodes. As higher the conductivity is, as

more reliable operates the empty pipe detection.

nsulation coatings on the electrodes surface worse the empty

pipe detection.

Data memory chip (DSM)

The replaceable data memory chip (DSM) is an EEPROM device in

D L-8 housing, located in a socket on the power supply board. t

includes all characteristic data of the sensor e.g. sensor constant,

version or serial number. Consequently, the memory module is

linked to the sensor and in case of a transmitter replacement it

has to remain by the sensor!

After replacing the transmitter or its electronics, the DSM will be

installed in the new transmitter. After the measuring system has

been started, the measuring point will continue working with the

characteristic values stored in the DSM. Thus, the DSM offers

maximum safety and high comfort when exchanging device

components.

Fig 4 Electronic, Power supply board mag-flux M1

At any exchange observe the polarity of the memory chip. Pin 1

is signed by a dot or a notch.

Safety of operation

A comprehensive self-monitoring system ensures maximum

safety of operation.

•Potential errors can be reported immediately via the

configurable status output. The corresponding error messages

will also be displayed on the transmitter display. A failure of

the auxiliary power can also be detected via the status output.

•When the auxiliary power fails, all data of the measuring

system will remain in the DSM (without back-up battery).

•All outputs are electrically isolated from the auxiliary power,

the sensor circuit and from each other.

Slot DSM

WWW.TEESING.COM | +31 70 413 07 50

Page 6 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

__ Input

Measurand

The measurand is an induced voltage which is typical for the

actual flow velocity inside the flow tube.

Measuring range

The measuring range, which varies according to which sensor is

used, can be found on the relevant data sheet or rating plate.

Operating the mag-flux flow probes with the mag-flux M1

The flow probes mag-flux M S 1/D und mag-flux M S 2/15 are

calibrated for flow velocity. n order to display the measured

value in volume flow units, it must be calculated using the flow

velocity and the inside diameter of the tube. The following

parameters must be set at the mag-flux M1:

1. At the functional level SENSORSETTINGS +M1 set the sensor

type mag-flux MIS. The dimension of the sensor constants will

be automatically adapted.

2. Setting of the sensor constant.

3. Set the nside diameter of the tube in xxx mm.

Note!

The effective diameter has to be set, not the

nominal diameter of the tube!

4. At the functional class FLOW, set the desired unit of volume

flow.

5. Using the function VOLUME FLOW UPPER-RANGE VALUE set the

upper-range value.

__ Output

Output signal

All signal outputs

Electrically isolated from each other and from ground (PE).

Analog output

•0/4-mA current output, electrically isolated, optional with

HART®

•Volume flow or flow velocity

(Using the HART®-protocol the current output has to be

assigned to volume flow in the mode of 4-20mA)

Pulse-/Frequency output

•Pulse duration adjustable range is 0,1 ... 2000 ms

(default value 50 ms)

(Mark-to-space ratio is 1:1, if the set pulse duration is not

reached.)

Note!

When programming the pulse duration, a plau-

sibility check is carried out. f the selected pulse

duration is too long for the set upper range value,

an error message will be displayed.

•Frequency output max. 1 kHz

•Passive via optocoupler

UN = 24V

Umax = 30 V

max = 60 mA

Pmax = 1,8 W

Pulse value

The pulse value is referred to the selected pulse unit (e.g. m³)

and can be set between 0.001 - 999.999.

Default: 1 pulse/unit

Status output

•for: - forward and reverse flow

-M N flow rate

-MAX flow rate

-alarm

•passive via optocoupler

UN = 24 V

Umax = 30 V

max = 60 mA

Pmax = 1,8 W

Failure signal

A failure in the meter can be indicated via the current output or

the status output. The current output ca be set to a failure signal

(alarm) of < 3.8 mA or > 22 mA.

The status output can be configured as N/O or N/C contact.

Load for the current output

Standard version: ≤ 600 Ohm

HART® (minimum load) > 250 Ohm

Damping

Programmable from 0 to 60 seconds.

Low flow cut-off

The low-flow cut-off can be set to values between 0 and 20%

and it refers to the upper range value.

f the measured value is lower than the set value, the flow rate

will set to 0.0 (l/h). This results in the analog output being set to

0/4 mA, and the pulse output will stop generating pulses.

The configurable hysteresis takes effect only one side while

exceeding this limit.

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 7 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

__ Technical data

Reference conditions

n conformity with EC 770:

Temperature: T = 20°C

Relative humidity: rH = 65%,

Air pressure: p = 101,3 kPa

Measuring tolerance

See characteristic values of the corresponding sensor.

Repeatability

See characteristic values of the corresponding sensor.

Influence of ambient temperature

•For the pulse output: ± 0.05 % per 10 K.

•For the current output: ± 0.1 % per 10 K.

__ Operating conditions

Installation conditions

Caution!

Additional cable glands (not contained):

The operator is responsible for that fact that

according to the enclosure and ignition enclosure

certified cable glands or screws are used. The kind of

threads is stamped on the rating plate.

At the connection between sensor and transmitter a

metalized cable gland must be used for the screen.

(See chapter „Connection of the magnetic current

and electrode line on page 10).

Compact version

For the compact version the transmitter housing is mounted on

the sensor. Therefore no cable is necessary between sensor and

transmitter.

Remote version

The transmitter has to be mounted separately from the sensor in

the following cases:

•Difficult access to the mounting area

•Lack of space

•Medium and ambient temperatures are extremely high

•Strong vibrations are expected.

Fig 5 Proper installation of cables at high humidity and wet conditions

The mag-flux M1 transmitter has to be mounted free of vibra-

tions!

Warning!

For the separate version, the minimum permissible

conductivity of the medium is determined by the

distance between the sensor and the transmitter. The

maximum cable length to ensure accuracy is 200 m.

For the cable type see chapter „cable specification” on

page 9.

Fig 6 Cable length for remote version

Note!

•The electrode cable must be fixed. f the

conductivity of the medium is low, cable move-

ments may change the capacity considerably and

thus disturb the measuring signal.

•Do not lay the cables close to electrical machines

and switching elements.

•Equipotential bonding must be ensured between

sensor and transmitter.

Caution!

Do not connect or disconnect the field coil cable

before the primary power of the meter has been

disconnected!

Environmental conditions

Ambient temperature range

- 20 °C to + 60 °C (-4°F to 140°F).

Below 0 °C the readability of the LCD display will be limited.

n the case of an outdoor installation, the device must be

protected against direct solar irradiation with a weather shield.

Storage temperature

- 25 °C to + 60 °C (-13 °F to 140 °F)

Degree of protection

P67.

WWW.TEESING.COM | +31 70 413 07 50

Page 8 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Caution!

ngress protection P67 is only achieved if suitable

and firmly tightened cable glands are used. f the

cable glands are only tightened manually water may

leak into the terminal compartment in the housing.

Danger!

Particular care must be taken if the front window of

the housing gets fogged or discolored because of

moisture. nherently water might seep into the

housing through the wire sheath!

Note!

Electromagnetic compatibility is only achieved if the

electronics housing is closed. Leaving the enclosure

open can lead to electromagnetic disturbances.

Process conditions

Fluid temperature

The data sheet/rating plate of the connected transmitter is

binding. With directly mounted transmitter on the sensor

(compact version) the heat entry from the process to the

transmitter must be considered.

Phase of Medium

Liquid.

Viscosity

No restrictions.

The data sheet/rating plate of the connected sensor is binding.

Fluid temperature limit

The data sheet/rating plate of the connected sensor is binding.

Flow rate limit

The data sheet/rating plate of the connected sensor is binding.

Pressure drop

The data sheet/rating plate of the connected sensor is binding.

Empty pipe detection

All transmitters mag-flux M1 have a selectable empty pipe detec-

tion. The operating reliability depends on the conductivity of the

liquid and the cleanliness of the electrodes.

__ Construction details

Type of construction / dimensions

Fig 7 Transmitter mag-flux M1 (remote version with wall mounting)

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 9 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Technical data mag-flux M1

Weight: 2,4 kg

Material: aluminum die-cast housing,

powder-coated

Process connection: Directly mounted on the sensor

(compact version) or connected via

cable (remote version).

Electrical connection: Mains

230 V AC, -15%/+10%, 50/60 Hz

115 V AC; -15%/+10%, 50/60 Hz

or

24 V DC; ±15 %

Power consumption: 10 VA

Mains fuse: 5 x 20mm (acc. D N 41571-3)

Rated voltage: 250V AC

Braking capacity: 80A@250V AC

Mains Rated current

250 V AC 100 mA (T)

115 V AC 100 mA (T)

24 V DC 1 A (T)

Electrical terminals

Fig 8 Electrical connections of the transmitter mag-flux M1

Fig 9 Electrical connection of the mag-flux M1

(Remote version only)

Cable specification

f the transmitter is mounted separately from the sensor, the

following cables must be used:

Electrode cable and field coil cable

Shielded twisted pair. n order to protect the cable from external

interference, the twisted-pair wires are covered by an additional,

overall shield.

Cable

length

wire

cross section

Example

≤ 10 m ≥ 0,25 mm² L YCY-CY TP 2 x 2 x 0,25 mm².

> 10 m ≥ 0,75 mm² L Y-TPC-Y 2 x 2 x 0,75 mm².

The outer shield is grounded by means of special EMC-compliant

cable glands at both ends of the cable.

Wiring diagrams

Connection of the signal cables

•Lay the signal cables separately from cables with voltages >

60 V.

•Only use signal cables as specified in chapter „Electrode cable

and field coil cable“.

•Avoid laying signal cables close to large electrical installations

or use – if possible – only shielded cables.

•A load at least 250 Ω must exist in the signal circuit for error

free communication via the HART® protocol.

Fig 10 Mains and signal terminals of the transmitter

mag-flux M1

Terminal

Label

Function

115

V

/

230

V

AC

24

V

DC

1

PE

Protective conductor

2

N /

-

Mains

0 V

3

L / +

Mains

+24 V

4

Pulse

-

Pulse output (passive)

5

Pulse +

6

Status

-

Status output (passive)

7

Status +

8

Current

-

Current output (active)

9

Current +

Power supply

Signal line

WWW.TEESING.COM | +31 70 413 07 50

Page 10 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Connection of the magnetic current and electrode line

(Remote version only)

Fig 11 Connection diagram for sensor cable of the mag-flux M1

Terminal

Function

5

Magnetic field current 1

6

Magnetic field current 2

7

Potential equilization / PE

22

Measuring ground

23

Electrode 1

24

Electrode 2

For cable specifications see chapter „Electrode cable and field coil

cable" on page 9.

The outer shield is grounded by means of special EMC-compliant

cable glands at both ends of the cable, the inner shields are

connected to terminal 7 and 22 respectively.

For terminal assignments see „Electrical terminals" on page 9.

Caution!

Do not connect or disconnect the field coil cable

before the primary power of the meter has been

disconnected!

Please observe also the advices in chapter „Cable

specification” on page 9 and „Cable specification” on

page 7.

Connection of the sensor mag-flux A

The remote version of the sensor mag-flux A has a terminal box

as shown in Figure 12.

Feed the electrode line through the left gland and the magnetic

current line through the right gland and connect the cables as

shown in Figure 12.

Fig 12 Electrical connections of the mag-flux A sensor

Connection of the sensor mag-flux F5

Feed the electrode line through the lower gland as shown in

Figure 13 and the magnetic current line through the upper gland

(see Fig 14) and connect the cables.

Fig 13 Electrical connections of the mag-flux F5 sensor (bottom)

Fig 14 Electrical connections of the mag-flux F5 sensor (top)

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 11 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Connection of the sensor mag-flux S and the flow probes

mag-flux MIS

These sensors are equipped with a pre-assembled cable ex-

factory. This cable is permanently connected to the sensor at one

end. The end leading to the transmitter is fitted with a cable

gland and pre-prepared cable ends for connection. The attached

wire numbers serve for orientation.

Fig 15 Connections of the sensor mag-flux S and the probes

Connection for HART® Communication

A number of options are available for HART® communication.

However, for all these options loop resistance must be less than

the maximum load specified in Chapter „Outputs“ (see page 6).

The HART®- nterface is connected via terminals 8 and 9 of the

(active) current output.

The minimum load impedance is 250Ω.

.

Fig 16 Electrical connection for HART® communication, schematic diagram

Changing the direction of the transmitter housing (only

compact version)

For the compact version the transmitter housing isn't rigid inter-

linked with the sensor housing but it can be turned by ± 180°.

The factory set orientation for the transmitter housing is such

that it is in the correct position for a horizontal piping and a flow

direction from left to right.

For changing the orientation of the transmitter housing the

following steps are neccessary (refer also Fig. 17):

1. Unloose the two setscrews.

2. Turn the transmitter housing in the desired position.

3. Retighten the two setscrews.

Fig 17 Position of the setscrews for changing the orientation of the

transmitter housing (mag-flux A compact)

Setscrews

WWW.TEESING.COM | +31 70 413 07 50

Page 12 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Maintenance and repair

The transmitter mag-flux M1 is designed for maintenance-free

performance. t contains no parts, which have to be replaced or

adjusted cyclically.

While commissioning or maintenance, mains power must be

switched off. Do not connect or disconnect the wiring between

sensor and transmitter while power is on!

Mains fuse

The mains fuse is located in the terminal compartment. Before

replacing the fuse, the power has to be switched off. Check

carefully that the transmitter is voltage free. The fuse may only

be replaced by the exactly same type of fuse! (See also chapter

„Technical data mag-flux M1“on page 9).

Replacement of terminal board

The terminal board is located in the terminal compartment.

Before replacing the board, the power has to be switched off.

Check carefully that the transmitter is voltage free. The board

may only be replaced by the exactly same type of board.

First the rear housing cover has to be removed.

n the next step all pluggable connectors have to be released

(refer Fig 17).

The board can be removed after loosening the 3 fixing screws

(refer Fig 17).

Fig 18 Terminal board of the mag-flux M1

For the assembly of the new board ensure, that the screws are

secured again by toothed washers. Only after all connectors are

plugged in, the power should be switched on again

Replacement of transmitter electronic

The transmitter electronic may be replaced only as complete

module. Therefor numerous steps are necessary which can't be

accomplished by the customer.

Please contact your distributor or the MECON customer service

for replacing the transmitter electronic.

__ mag-flux M1 control unit

Introduction

The transmitter mag-flux M1 can be operated depending on con-

figuration by using a control unit or via a HART® interface.

Below the operation and parameterization of the transmitter is

described using the control unit. t is located in the electronic

compartment and covered by an inspection window.

Fig 19 Transmitter mag-flux M1 with control unit

Display

The control unit in the mag-flux M1 has an integrated back

lighted, alphanumeric display with two 16-character lines (format

16 x 60 mm). Measurement data and settings can be read direct-

ly from this display.

The LCD display is designed to be operated at temperatures

ranging from − 20 °C to + 60 °C (-4° F to 140 °F) without being

damaged. However, near-freezing temperatures the display be-

comes slow and the readability of the measured values is re-

duced. At temperatures below − 10 C° (14 °F), only static values

(parameter settings) can be displayed. At temperatures

exceeding 60 C° (140 °F), contrast decreases substantially on

the LCD and the liquid crystals can dry out.

Fixi

ng

screws

Connectors

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 13 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Keys and their functions

On the control unit are six keys to change the settings.

Note!

Do not press these keys with sharp or sharp-edged

objects such as pencils or screwdrivers!

Fig 20 Keypad of the mag-flux M1

Cursor keys:

These keys are used for:

•change numerical values

•give YES/NO answers

•select parameters

Each key is assigned a symbol in the following

table:

Description Symbol

Cursor key, right arrow 4

Cursor key, left arrow 3

Cursor key, up arrow 5

Cursor key, down arrow 6

Enter-key:

The ↵-key is used for entering the parameter

level from the menu level.

All entries are confirmed with the ↵ key.

ESC-key:

The Esc-key is used to cancel the current

action and leads to the next higher level.

This is used for rollback.

Pressing Esc twice moves you directly to the

MEASURED VALUES functional class.

Operating modes

The transmitter mag-flux M1 can be operated in the following

modes:

Mode 1: Display

n display mode, measured values can be displayed in various

combinations and the same applies to the mag-flux M1 settings.

Parameter settings cannot be changed in this mode.

Display mode is the standard (default) operating mode when the

device is switched on.

Mode 2: Programming

The programming mode of the transmitter mag-flux M1 is pro-

tected by password.

The scope of the parameters, which is permissible for the custo-

mer is alterable after entering the customer password.

The complete parameter set can only be altered after entering

the service password for technicians.

Operation

User interface

The user interface is hierarchically structured.

At the top level you can find the Functional classes which are

displayed as headings. t represents a kind of logical groups for

values and parameters.

The second level is the menu level and it includes either para-

meters or further submenues.

The third and lowest level is the parameter level, which only

includes parameters.

All functional classes are interlinked horizontally, while all sub-

items of a functional class are interconnected vertically.

Fig 21 Structure of the mag-flux M1 user interface

Functional classes, functions and parameters

Functional classes are strictly written in upper case letters (head-

ings). For the functions and parameters at the next levels upper

und lower case is used.

WWW.TEESING.COM | +31 70 413 07 50

Page 14 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

The various functional classes and functions are described in

chapter „Transmitter functions of the mag-flux M1” starting on

page 15.

The control unit of the transmitter mag-flux M1 has an alphanu-

meric display with two lines.

For the menue level always the first line of the LCD displays the

corresponding heading for the menue item and the contents of

second line is context-sensitive:

•information,

•YES/NO answers,

•Alternative values,

•Numerical values (with dimensions, if applicable),

•Error messages.

f the user attempts to modify values for any of these

parameters without entering the required password, the message

“Access denied” will be displayed (see also „Operating

modes” on page 13.

The various categories for sumenu-items are described below.

Selection window / make a selection

For the selection window, the first line of the LCD always displays

the heading, while the second line displays the current setting.

This setting is shown in square brackets if the system is in pro-

gramming mode (see chapter „Operating modes” on page

13).

Function name

[se

lection]

n Programming mode, i.e. after a password has been entered

the operator can navigate to the desired setting by using the

5key or the 6key. The actual selection will be confirmed by

pressing ↵ (ENTER key). Pressing the Esc-key will discard chan-

gings.

Input window / modify a value

For the input window, the first line of the LCD always shows the

heading, while the second line shows the current setting.

Example:

Function name

-

4,567 Unit

These modifications can only be made in Programming mode

(see chapter „Operating modes” on page 13).

To move the cursor from one decimal place to another, use the

3 or 4keys.

To in-/decrease the value of the decimal place, which is high-

lighted, by 1, use the 5 or 6key.

To change the minus and plus sign, place the cursor in front of

the first digit.

To confirm and apply the change, press the ↵ key.

To discard the changes, press Esc.

Passwords

Programming mode is password protected.

A two level protection is implemented for the mag-flux M1.

Entering the customer password will allow all changes that are

permissible for customers. This password can be changed when

the device is first put into operation. Therefor changes should be

kept in a safe place.

The factory setting for the mag-flux M1 customer password is

0002.

The service password allows modification of all functions and

parameters. This password is not given to customers.

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 15 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Fig 22 Main menu mag-flux M1 (functional classes)

__ mag-flux M1 transmitter functions

The software functions of the mag-flux M1 transmitter are

separated into functional classes which are arranged in a circle.

Navigation is carried out by using the 3 or 4cursor keys. To

return to your starting point (the MEASURED VALUES functional

class) press Esc.

n the following, all software functions are described which are

selectable using the customer password. Functions which are

only accessible to the vendor (service functions) are not

described in this manual.

WWW.TEESING.COM | +31 70 413 07 50

Page 16 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Functional class: MEASURED VALUES

The MEASURED VALUES functional class includes all functions for

displaying the measured values.

Fig 23 Funktional class MEASURED VALUES incl. all submenu items

Volume flow rate

f you select the function volume flow the current value for the

volume flow will be displayed:

Example:

Volume flow

100.0 l/h

The displayed unit is defined in the functional class FLOW using

the function volume flow unit.

Totalizer forward 1

Totalizer for ard 1 and Totalizer for ard 2 are independent tota-

lizers that can also be reset separately. With totalizer 1, for

example, you can measure the yearly or monthly volume. f you

select the function totalizer forward 1, the following will be

displayed:

Example:

Totalizer 1 fwd.

+000001.0 l

The displayed unit is defined in the functional class TOTAL ZER

using the function totalizer unit.

Totalizer forward 2

The function is identical with totalizer 1. For example, totalizer 2

can be used as a daily counter.

f you select the function totalizer forward 2, the following

will be displayed:

Example:

Totalizer 2 fwd.

+000001.0 l

The displayed unit is defined in the functional class TOTAL ZER

using the function totalizer unit.

Totalizer reverse

f you select the function totalizer reverse the following will

be displayed:

Example:

Totalizer rev.

000000.0 l

The displayed unit is defined in the functional class TOTAL ZER

using the function totalizer unit.

Flow velocity

f you select the function flow velocity the LCD shows the

current value of the average flow velocity of the medium.

Example:

flow velocity

1,5 m/s

The display unit is always meters per second (m/s).

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 17 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

The average velocity is calculated from the measured volume

flow and the cross section of the meter tube. For the calculation

of the cross section, the inside diameter of the meter tube is

needed. t will be defined by the function inside diameter in

the functional class SETT NGS SENSOR + M1.

Relative flow rate

The relative flow rate Qrel is the percentage ratio of the (current)

volume flow Qabs and the upper range value of the volume flow.

The upper range value is defined in the functional class FLOW

using the function volume flow QV URV.

The calculation of the relative flow rate is based on the following

formula:

%100

limit rangelower limit rangeupper

limit rangelower

abs

Q

rel

Q⋅

−

−

=

f you select the function relative flow, the following will be

displayed.

Example:

Relative flow

95.3 %

QV + forward totalizer 1

f the function QV + forward totalizer 1 is selected, in the

first line the value of the forward totalizer 1 and in the second

line the the current value of the volume flow will be displayed.

Example:

XXXX.X l

T1 XXXX.XX l/h

The displayed unit for the volume flow is defined in the functional

class FLOW using the function volume flow unit and the unit of

the totalizer is defined in the functional class TOTAL ZER using

the function totalizer unit.

QV + forward totalizer 2

This function is basically similar to the function QV + forward

totalizer 1, but the only difference is, that in the first line the

value of the forward totalizer 2 is displayed.

Example:

XXXX.X l

T2 XXXX.XX l/h

QV + flow velocity

f the function QV + flow velocity is selected, in the first line

current value of the volume flow and in the second line the the

current flow velocity will be displayed.

Example:

XXX.X l/h

XXX.X m/s

The displayed volume flow unit is defined in the functional class

FLOW using the function volume flow unit, the unit of the flow

velocity is always m/s.

Display mode during startup

By choosing the function display mode during startup the

operator can define the default display.

This selected parameter will be displayed after switching on the

device and when no keystroke occurs for a long period of time.

Example:

Display mode

[ QV ]

One of the following default parameters can be selected:

QV (volume flow rate)

Totalizer 1 forward flow

Totalizer 2 forward flow

Totalizer 1 reverse flow

Velocity

QVabs + QVrel

QV + totalizer 1

QV + totalizer 2

QV + velocity

Raw values.

Raw values

The raw value display supports fault diagnostics and trouble

shooting. Please inform our service department about the clear

text error messages and contens of the raw value display.

Example:

xxx.xxx ggooo

iiii gguuu

The displayed values are decimals and have the folling meaning:

xxx.xxx:

s a numeric value for the measured eletrode

voltage.

iiii:

s a numeric value for the current to generate

the field coil’s magnetic field.

ggooo:

s a numeric value for the upper value of the

reference calibration.

gguuu:

s a numeric value for the lower value of the

reference calibration.

WWW.TEESING.COM | +31 70 413 07 50

Page 18 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Functional class: PASSWORD

The PASSWORD functional class includes the functions for ente-

ring and changing the customer password and entering the ser-

vice password.

Fig 24 Functional class PASSWORD incl. all submenu items

Customer-password

The customer password is intended to prevent changes for soft-

ware parameters by the control unit without permission.

f the operator does not enter a valid password, all settings can

be displayed but not changed.

Note!

Parameter changes via HART® may be carried out

at any time without entering password.

For selecting the desired function please use the key 5 or 6.

After selecting the Customer password function and pressing ↵,

the following will be displayed:

Password?

0

000

According to the description in Section „Input window /

modify a value“, the password can be changed.

After entering a valid password, the following message will be

displayed:

Password

Valid

f the entered password is not correct, the following message will

be displayed:

Password

invalid

Note!

The factory set for the customer password is 0002.

A valid customer password allows changes for all software para-

meters that are permissible for customers.

After the operator switched off the device or no keystroke occurs

for about 15 minutes, the authorization for changes are canceled

and the password must be entered again.

Change customer password

After entering a valid customer password, you may change the

existing password and enter a new one.

For selecting the desired function please use the key 5 or 6.

After selecting the function Change customer password and

pressing ↵, the operator enters the parameter level for changing

the customer password and the following will be displayed:

New password?

0

000

According to the description in Section „Input window /

modify a value“ the changes can be done.

Press ↵ to confirm and save the new password.

Note!

A copy of the password should be kept in a safe

place. Reactivation of a transmitter at the vendor’s

site due to a lost password is not part of our

warranty!

Service password

The service password is not required for parameter settings

which are relevant for operation.

The service password is reserved for service technicians and not

provided to customers.

WWW.TEESING.COM | +31 70 413 07 50

Mecon GmbH Phone +49(0)2237 600 06 - 0

Fax +49(0)2237 600 06 - 40 Page 19 / 35

R ntgenstraße 105 www.mecon.de

D-50169 Kerpen

Mecon 10/2014

Transmitter mag-flux M1

Functional class: TOTALIZER

The TOTAL ZER functional class includes the following functions:

Fig 25 Functional class TOTAL ZER incl. all submenu items

For changing the current settings and parameters the customer

password is needed. Otherwise, the settings only can be read but

not be changed.

The Esc-key is used for discarding changes.

Totalizer unit

For selecting the desired function please use the key 5 or 6.

After choosing the function Totalizer unit and pressing ↵, the

current forward and reverse totalizer unit will be displayed:

Example:

totalizer unit

[

l

]

How to change the parameter please refer to Section „Selection

window / make a selection”.

The following units are available:

Volume units

m3

Cubic meter

l

Liter

USG

Gallon (US)

UKG

Gallon (brit.)

ft3

Cubic feet

Mass units* kg Kilogram

t

Ton

* When selecting a mass unit the liquid density is certainly required

(refer to functional class FLOW).

The changes will be confirmed by pressing the ↵-key and the

new unit will be active as well for the forward totalizers and the

reverse totalizers.

Note!

When the unit is changed, the totalizers will be

reset to 0.00 automatically!

Totalizer reset

The transmitter mag-flux M1 has three independent totalizers.

Each of them can be reset individually to the initial value 0.00.

n the first step the required totalizer has to be choosen by using

the 5 or 6 key. After the confirmation with the ↵-key, the func-

tion Reset totalizer must be selected the following will be dis-

played:

Reset total?

[yes]

To reset one of the totalizers, you need to toggle to [yes]

explicitly.

By pressing Esc or toggling to [no] the current action will be

aborted the menu item is quitted without changing the totalizer.

WWW.TEESING.COM | +31 70 413 07 50

Page 20 / 35 Mecon GmbH

Phone +49(0)2237 600 06 - 0 Fax +49(0)2237 600 06 - 40

R ntgenstraße 105

Mecon 10/2014 D-50169 Kerpen

Transmitter mag-flux M1

Functional class: MEASUREMENT PROCESSING

The MEASUREMENT PROCESS NG functional class includes all

functions that affect the processing of the measured values.

Fig 26 Functional class MEASUREMENT PROCESS NG incl. all submenu-

items

Before changing the current settings, the customer password has

to be entered. Otherwise, the settings only can be watched but

not changed.

Damping

The damping value τ is intended to attenuate abrupt changes of

the flow rate or disturbances. t affects as well the display of the

measured value as the current output and pulse output of the

mag-flux M1.

For selecting the desired function please use the key 5 or 6.

By choosing the function Damping value and pressing ↵, the

parameter level is entered and the current value for the damping

is displayed:

Example:

Damping

0

3 s

The damping value can be varied within an interval from 1 to 60s

(see also chpater „Input window / modify a value“).

Note!

After a jump in the measuring variable the output

measured value reaches about 99% of the new

setpoint after 5τ.

The factory setting for τ is 3 seconds.

Low flow cut

The lo flo cut is a threshold for flow rate (percentage the

upper-range value).

f the volume drops below this value (e.g. leakage), the dis-

played value and the current outputs will be set to “ZERO.”

For selecting the desired function please use the key 5 or 6.

After choosing the function Low flow cut and pressing ↵, the

following selection field will be displayed:

Example:

Low flow cut

0

0 %

The value for low flow cut can be set from 0 to 20 % in 1-percent

increments.

Hysteresis for the low flow cut

The value for hysteresis for the lo flo cut is given as a percen-

tage of the upper-range value. t is the flow rate, the low flow

cut has to exceed, to activate the display and the outputs of the

mag-flux M1.

For selecting the desired function please use the key 5 or 6.

After selecting the function Low flow cut hysteresis and

pressing ↵, the following selection field will be displayed:

Example:

Low flow cut

hysteresis

0

0%

The hysteresis for the lo flo cut can be set from 0 to 10 %.

Zero point calibration

The function Zero point calibration is intended for recalibra-

ting the zero point of the measuring system.

Zero point calibration is mandatory after any installation proce-

dure or after modification of piping near the sensor. Refer also to

section „zero point adjustment“ on page 11.

Caution!

This function may only be carried out if it is certain

that

•The fluid in the sensor is not flowing.

Otherwise, the flow rates measured sub-

sequently will be incorrect.

•The sensor may be completely filled with fluid. A

partially filled sensor or air bubbles will lead to an

incorrect zero point calibration

For selecting the desired function please use the key 5 or 6.

After choosing the function Zero point calibration and

pressing ↵, the current remaining flow rate will be displayed:

Example:

0.00 l/h

cal.? [no]

By pressing Esc or toggling to [no] the recalibration will be can-

celed the action will be aborted without changing the zero point.

By Toggeling to [yes] explicitly and confirming with pressing the

↵–key, the zero point will be recalibrated.

WWW.TEESING.COM | +31 70 413 07 50

Other manuals for mag-flux M1

1

Table of contents

Other Mecon Measuring Instrument manuals