Medem SafeSpace M User manual

27/04/2017

SafeSpace M

Please read this sheet as it contains

important information

Before commencing installation please familiarise yourself to the

equipment by reading the comprehensive installation instructions. If

in doubt then please call 01 1 233 0 00.

It is a statutory requirement that this safety system is installed and

commissioned to the satisfaction of the manufacturer.

A commissioning certificate must be issued to the end user along

with instructions for the operation of the equipment.

As the Manufacturer Medem UK should commission this safety

system whereupon a commissioning report will be forwarded to the

installing agent who should provide a copy to the end user.

27/04/2017

SafeSpace M

Four Channel

Gas Monitoring System

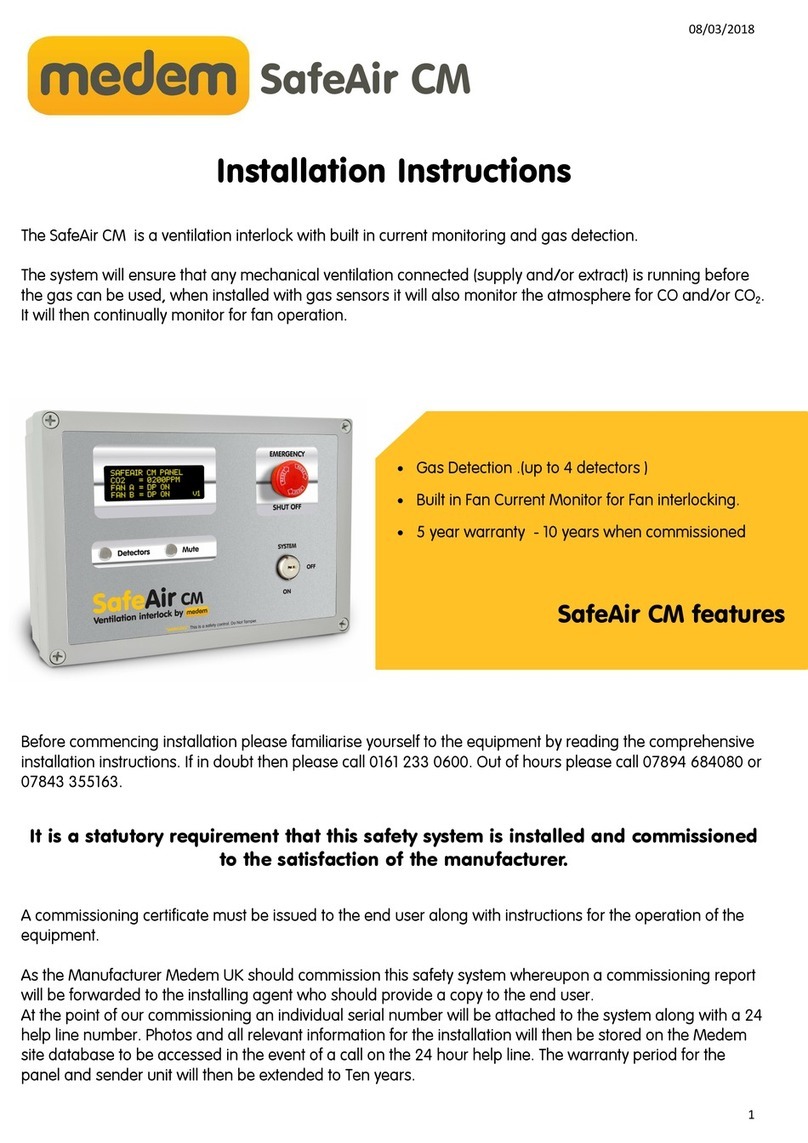

The SafeSpace M is a gas detection system, it can monitor the atmosphere for

natural gas (CH4 & LPG), CO, CO2 and Oxygen Depletion when fitted with the

appropriate Medem detectors.

In the event of a high alarm from one of the sensors the system will alarm. Any

connected remote beacons and sounders would then be activated..

The system will automatically restart after a power failure.

The system comprises of a mains powered panel capable of monitoring up to four

sensors. The sensors, purchased separately are pre-calibrated by Medem (UK) Ltd

such that they only require to be addressed then connected to the panel and

functionally tested.

27/04/2017

SafeSpace M

Technical data sheet

The model SafeSpace M consists of a mains powered panel capable of operating up to four detectors.

The system will automatically restart after a power failure.

The detectors are connected by low voltage 4 core cable (typically beldon cable) back to the control panel.

The detectors may be mounted up to 100mtrs from the control unit.

The complete system is designed to comply with the latest CE directives including the low voltage directive.

This is housed in an IP 5 rated ABS enclosure measuring 180mm high x 129mm wide x 70mm deep.

Relay outputs:

SELV relay rated at 48volts to activate a remote sounder/beacon or signal a BMS system.

The aux relay function depends on the setting of the “Aux RLY” DIP Switches - this is a dynamic (non-latching) relay.

This can advise a BMS of any one of the following conditions.

AX1 - AX2

Off - Off = High Alarm

On - Off = Unused

Off - On = Unused

On - On = Detector Fault

Gas Detector Types

AD-MED-CO Carbon Monoxide Detector (CO)

AD-MED-CO2 Carbon Dioxide Detector (CO2)

AD-MED-M Natural Gas Detector (Methane) (CH4)

AD-MED-LPG Natural Gas Detector (Propane) (LPG)

AD-MED–OXY Oxygen Depletion Detector (O2)

Detector Alarm levels

Type Pre-Alarm High Alarm

CO: 80ppm 100ppm

CO2: 2800ppm 5000ppm

CH4/LPG 5% 10%

OXY-DEP 19.5% 18%

All current wiring regulations must be followed with reference to running low and mains voltage cables together.

The maximum cable length between a detector and the control panel should not exceed 100 metres, if the distance between

the main panel and the detectors is greater than 20metres a 1mm screened cable must be used on the +VE, 0v terminals

Gas detectors, require a four core screened Belden type security cable or 00v rated BMS cable (max cable length of

100meters.)

Remote emergency stops and thermal links require a two core screened cable.

Warranty will be void if Fire Protection Cable or cable over 1mm dia. is used on the SELV side.

27/04/2017

SafeSpace M

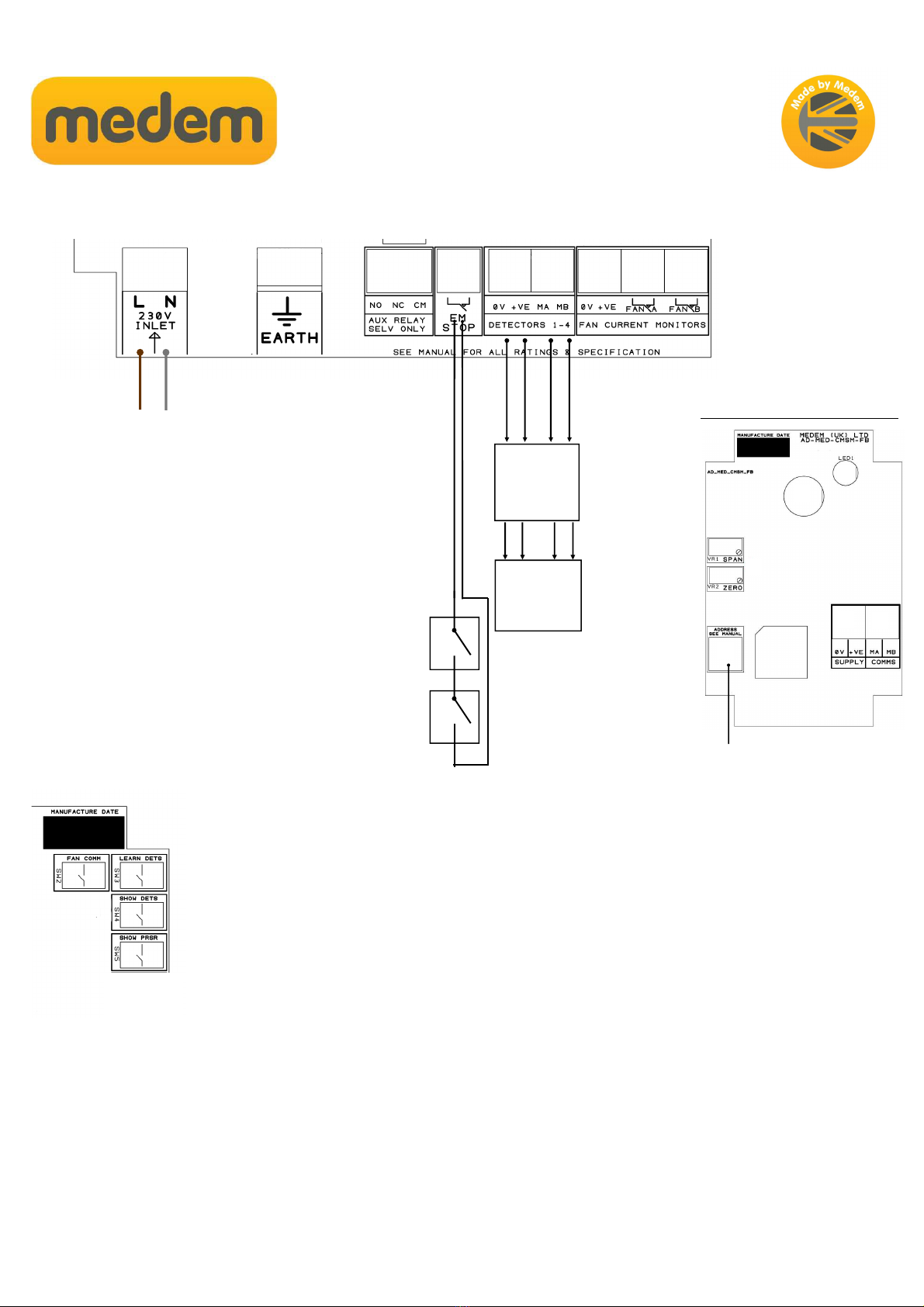

1 2

12 11

1

17

13

14

3 4 5 7 8 9 10

18

19

20

Connections to panel: marked on board.

1. Live & Neutral 230 volts supply from 3amp switched fuse spur

2. 230 volts out to gas solenoid valve

3. Earth connection terminals

4. BMS to indicate, high alarm, gas on, EM stop, low alarm. (Using No13 AX1 & 2 )

00 = EM Stop & High Alarm

10 = Unused

01 = Gas On

11 = Detector Fault

5. Remote emergency stop buttons SELV, connect in series multiple buttons (requires a N/C circuit) - Thermal links and Fire

Alarm can also be connected in series

. Power connections for detectors, Methane, LPG, CO, CO2, Oxygen, Temperature

7. Comms connections for detectors, Methane, LPG, CO, CO2, Oxygen, Temperature

8. 12 volt power for current monitor (CM2M-K)

9. Fan A interlock for current monitor (CM2M-K) or PD switches.

10.Fan B interlock for current monitor (CM2M-K) or PD switches.

11. Jumper link to disable audible alarm sounder.

12. Header socket for front panel key switch.

13. AUX relay settings (see No4).

14. Header socket for front panel Mute button.

1 . Learn detectors button, press once only when all detectors are connected and powered

17. View detectors

18. Display gas pressures on the LCD screen

27/04/2017

SafeSpace M

Installing gas detectors

Gas detectors are wired via a four core low voltage cable into terminals marked & 7. The detectors must

have their “address id selector switch” set to the addresses 1-4.

CO detectors must be number addressed before natural gas detectors.

Once connected and addressed the system must be “taught” which detector types are on which address.

This is done by pressing button marked 1 ‘Learn Dets’. The system will beep to confirm the action.

Pressing No 17 will display detector addresses 1 &2, pressing 17 & 18 together will display addresses 3 & 4.

Detector Fault DXX Lost Comms

If the system displays a message “Detector Fault DXX Lost Comms” the system is informing you that a

detector which has been previously “learnt” to address DXX is no longer communicating. This could be

because the detector has had its address changed or has been removed. In which case “re-learning” using

button 17 will correct the addressing.

If the detector is present, but not being seen by the system on its address channel, then check the wiring

between the main control panel and detector.

1

17

1 3 4 5 7 8 9 10

18

Connect in

parallel

3 amp fused spur

230v

EM Stop Buttons,

TT-70c heat detectors &

Fire Alarm Input

Series connected

Addressable

Gas

Detectors

2

Example Medem Gas Detector

Address selector switch: use 1 to 4 only

27/04/2017

SafeSpace M

It is essential that the installation of the system is carried out in the order given

below to ensure the correct operation of the system.

This guide, when completed, should be posted to Medem UK in order that the

warranty period can be activated.

Site Name

Installing ompany

Engineers Name

Date ompleted

Tick as each step is completed

1: All wiring checked tight and connected

as per the installation instructions.

2: Each detector has an individual number

from adjusting the rotary switch before the

“learn” button was pressed.

3: All detectors have a solid green LED

Illuminated when not in alarm.

4: Each detector has been recognised by

the panel.

5: On applying test gas to the

detectors the LED turns red

and the panel alarms and closes the

gas valve.

With the panel fitted to the wall the following steps should be

followed.

1. Connect BMS, beacons, sounders etc to the

relay outputs.

2. Connect any additional EM stop buttons and

thermal links in series to the terminals marked

“EM STOP”.

3. Each detector has a rotary address switch and

each switch should be set to a different number

starting with “1”. Then connect the gas detectors

to terminals marked “detectors” on the panel.

Detectors can be wired “Daisy chain”.

4. Connect the 3 amp fused spur 240 volt supply to

marked terminals and switch on.

5. Press the “learn dets button” this is on the main

circuit board in the top right corner. Pressing this

once allows the panel to learn how many and

which type of detectors are fitted.

6. Once power is connected to the panel the

detectors will flash the green LED’s for 90

seconds after which the LED’s will be on

continuously.

Return one copy of this sheet to the address below:

Manufactured by:

Medem (UK) Limited

Project House, 19 Dallimore Road, Roundthorn Industrial Estate,

Manchester, M23 9NX

Tel: +44 (0) 6 233 0600

Fax:+44 (0) 6 233 060

Please do not hesitate to call for advice on the

following numbers:

0161 233 0600 office hours

Detector type Methane CO LPG

Number fitted

Other Medem Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

red lion

red lion CUB5R manual

Electronics International Inc

Electronics International Inc M-1 Operating and installation instructions

Midwest

Midwest Delta Meter 142 Installation and operating instructions

POTOMAC INSTRUMENTS INC.

POTOMAC INSTRUMENTS INC. PI 4100 user guide

Electronics International Inc

Electronics International Inc SR-8A Operating and installation instructions

Flocorp

Flocorp UltraFlo UFD3 user manual