medical bees F-31 Series User manual

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

1 of 88

User’s Manual

F-31-XXX-XX

F-40-XXX-XX

Battery-powered tools for

large bone surgery

Orthopaedic Cordless Drill / Saw System

medical bees GmbH

Friedrich-Woehler-Strasse 13

78576 Emmingen-Liptingen

Germany

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

2 of 88

Table of Contents

Table of Contents .................................................................................................................................. 2

1Introduction and product description ........................................................................................... 6

1.1 General information ..................................................................................................................... 6

1.2 Intended use and indications...................................................................................................... 6

1.2.1 Handpieces, Battery (Power Pack) and attachments.................................................................. 6

1.2.2 Cleaning and maintenance accessories...................................................................................... 6

1.3 Contraindications......................................................................................................................... 6

1.3.1 Handpieces, Battery (Power Pack) and attachments.................................................................. 6

1.3.2 Cleaning and maintenance accessories...................................................................................... 6

1.4 Application.................................................................................................................................... 7

1.4.1 Application duration..................................................................................................................... 7

1.4.2 Patient population........................................................................................................................ 7

1.4.3 The user and the field of application ........................................................................................... 7

1.4.4 Service life................................................................................................................................... 7

1.5 Safety and warning instructions................................................................................................. 7

1.5.1 General safety instructions ................................................................................................. 7

1.5.2 Cleaning and care of the bee-system................................................................................ 7

1.5.3 Combination products and tools ........................................................................................ 8

1.5.4 The User / Application ....................................................................................................... 8

1.5.5 Users and/or patients......................................................................................................... 8

1.5.6 Operation and battery mode.............................................................................................. 8

1.6 Combination products and accessories.................................................................................... 9

1.6.1 Accessories to be used / Scope of delivery ................................................................................ 9

1.6.2 Combinability of individual beesystem components.................................................................. 10

1.6.3 Recommended cutting tool........................................................................................................ 13

1.6.4 Storage and Transport.................................................................................................. 14

1.6.5 Disposal.......................................................................................................................... 14

1.6.6 Guarantee.................................................................................................................................. 14

2Operation of the device................................................................................................................. 15

2.1 Description of the controls, indication functions and symbols ............................................ 15

2.1.1 Drilling / reaming machine (F-31-100-00).................................................................................. 15

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

3 of 88

2.1.2 Drilling machine (F-31-150-00).................................................................................................. 16

2.1.3 Oscillating saws Synthes AO connection (F-31-300-00; F-31-301-00)..................................... 17

2.1.4 Oscillating saw Stryker Sawblade connection (F-31-310-00/F-31-311-00) .............................. 18

2.1.5 Straight Oscillating saw Stryker Sawblade connection (F-40-100-00/F-40-101-00)................. 19

2.1.6 Straight Oscillating saw Synthes AO connection (F-40-110-00/F-40-111-00).......................... 20

2.1.7 Sternum saw/ reciprocating saw with keyless chuck (F-31-601-00)......................................... 21

2.1.8 Oscillating reaming machine (F-31-700-00).............................................................................. 22

2.1.9 Power Pack (F-30-900-00)........................................................................................................ 23

2.1.10 Charging unit (e.g. F-30-900-50)............................................................................................. 23

2.2 Start up........................................................................................................................................ 24

2.2.1 Power pack insertion................................................................................................................. 24

2.2.2 Power pack removal.................................................................................................................. 25

2.3 Battery capacity.......................................................................................................................... 27

2.3.1 Available battery capacity.......................................................................................................... 27

2.3.2 Power pack overheating............................................................................................................ 27

2.3.3 Energy saving function.............................................................................................................. 27

2.4 Power pack, charging, transport and storage ............................................................... 28

2.5 LED light indications.................................................................................................................. 28

2.5.1 Light indications during handpiece operation............................................................................ 28

2.5.2 The meaning of light indications................................................................................................ 29

2.6 Charging units ............................................................................................................................ 30

2.6.1 Charger start up......................................................................................................................... 30

2.6.2 Charger cleaning ....................................................................................................................... 30

2.6.3 Power pack charging................................................................................................................. 31

2.6.4 Charge new or longer unused power packs.............................................................................. 31

2.6.5 Power pack storage................................................................................................................... 31

2.6.6 Charge control indicators on the charger and on the power pack ............................................ 32

2.6.7 Indications on the power pack after removal from the charger ................................................. 32

2.6.8 Charger disconnection from the mains...................................................................................... 33

2.7 Application of drilling / reaming machines (F-31-100-00 and F-31-150-00).......................... 33

2.7.1 Start up...................................................................................................................................... 33

2.7.2 The oscillating mode on and off ................................................................................................ 33

2.7.3 Mode switching between drilling and reaming (only with F-31-100-00).................................... 33

2.7.4 Assembly / disassembly of the attachments/chucks for drilling / reaming machines (F-31-100-

00 and F-31-150-00).............................................................................................................................. 34

2.7.5 Attachment mounting................................................................................................................. 35

2.7.6 Mount cutting tools into the attachments / chucks and remove again ...................................... 35

2.7.7 Attachment removal................................................................................................................... 36

2.7.8 Rotating attachments / chucks .................................................................................................. 36

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

4 of 88

2.8 Application of oscillating saws Synthes AO saw blade connection (F-31-300-00; F-31-301-

00) 43

2.8.1 Start up of oscillating saws........................................................................................................ 43

2.8.2 Saw head positioning ................................................................................................................ 43

2.8.3 Replacement of saw blades ...................................................................................................... 43

2.8.4 Application of oscillating saws................................................................................................... 45

2.8.5 Recommendations for handling of saw blades ......................................................................... 45

2.9 Application oscillating saw Stryker saw blade connection (F-31-310-00, F-31-311-00)...... 45

2.9.1 Start-up of oscillating saw ......................................................................................................... 46

2.9.2 Saw head positioning ................................................................................................................ 46

2.9.3 Replacement of saw blades ...................................................................................................... 46

2.9.4 Application of oscillating saws................................................................................................... 48

2.9.5 Recommendations for handling of saw blades ......................................................................... 48

2.10 Application of reciprocating saw (F-31-601-00) .................................................................... 48

2.10.1 Start up of reciprocating saw................................................................................................... 49

2.10.2 Replacement of saw blades .................................................................................................... 49

2.10.3 Works with saw blades............................................................................................................ 50

2.10.4 Recommendations for handling of saw blades ....................................................................... 50

2.11 Application of sternum saws (F-31-601-00)........................................................................... 51

2.11.1 Start-up of sternum saw .......................................................................................................... 51

2.11.2 Replacement of saw blades .................................................................................................... 51

2.11.3 Works with sternum saws........................................................................................................ 51

2.11.4 Recommendations for handling of saw blades ....................................................................... 52

2.11.5 Keyless version (F-31-601-00)................................................................................................ 52

2.12 Application of oscillating reaming machine (F-31-700-00).................................................. 54

2.12.1 Start up.................................................................................................................................... 54

2.12.2 Mounting/dismounting of a tool ............................................................................................... 54

2.12.3 Cutting tool mounting............................................................................................................... 55

2.12.4 Cutting tool dismounting.......................................................................................................... 56

3Care and maintenance (after validated cleaning and sterilisation procedures)..................... 57

3.1 General information ................................................................................................................... 57

3.1.1 Extraordinary transmissible pathogens ..................................................................................... 57

3.2 Preparation to cleaning.............................................................................................................. 58

3.2.1 Dismantling................................................................................................................................ 58

3.3 Manual cleaning.......................................................................................................................... 59

3.3.1 Machine / handpiece ................................................................................................................. 59

3.3.2 Attachments............................................................................................................................... 60

3.4 Mechanical cleaning after manual pre-cleaning ..................................................................... 61

3.4.1 Manual pre-cleaning of the machine/handpiece ....................................................................... 61

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

5 of 88

3.4.2 Manual pre-cleaning of the attachments / chucks..................................................................... 62

3.4.3 Mechanical cleaning.................................................................................................................. 63

3.5 Oiling / maintenance .................................................................................................................. 65

3.6 Packaging.................................................................................................................................... 65

3.7 Sterilisation................................................................................................................................. 65

3.8 Repairs and Technical Service ................................................................................................. 66

4Troubleshooting ............................................................................................................................ 67

4.1 Device/handpiece and lid........................................................................................................... 67

4.2 Power pack.................................................................................................................................. 69

4.3 Attachments/chucks and tools ................................................................................................. 71

4.4 Charging unit .............................................................................................................................. 72

5Technical data................................................................................................................................ 73

5.1 Operating cycle........................................................................................................................... 73

5.2 Device specification................................................................................................................... 74

5.3 Environmental conditions ......................................................................................................... 78

5.4 Applicable standards ................................................................................................................. 78

5.5 Electromagnetic compliance..................................................................................................... 79

6Order information............................................................................................................ 83

6.1 Handpieces ................................................................................................................................. 83

6.2 Power Pack (battery, motor, electric)....................................................................................... 83

6.3 Attachments................................................................................................................................ 84

6.4 Cleaning and care of the bee-system....................................................................................... 84

7Used symbols ................................................................................................................................ 85

8Address / Report............................................................................................................................ 88

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

6 of 88

1 Introduction and product description

1.1 General information

Before any product use, read carefully this User’s Manual, while keeping it easily available

for the Operator or for appropriate service personnel.

Read carefully all the symbol-marked caution and warning texts. Incorrect use of

the products may lead to serious injuries of the patient, the user or other persons.

This is a User’s Manual for individual machines, including accessories. These machines can be used

either as one system or as separate units.

1.2 Intended use and indications

1.2.1 Handpieces, Battery (Power Pack) and attachments

The basic features of the beesystem serve the purpose of the medullary cavity expansion (medullary

canal; Cavitas medullaris) in preparation for implant setting by drilling, reaming, bolting, sawing and

severing of bones (or bone material). The system may be used both for resection of distal femur and

tibial condyles and for iliac bone preparation.

The system consists of battery-operated drive units with a range of attachments and accessories for

drilling, reaming and bolting operations, for mounting of pins and wires, as well as for cutting of bones

or hard tissues in general traumatic and endoprosthetic surgery.

Sternum saws, being part of the system, are intended for thorax surgery procedures and used for

sternum separation.

1.2.2 Cleaning and maintenance accessories

The cleaning and maintenance accessories are used for cleaning and processing of the beesystem

during transport and storage, culminating during surgical applications. The maintenance kit is also

used for storage and repairs of appropriate components.

A sterile funnel is a special component, intended to protect any direct contact between the non-sterile

power pack and the sterile handpiece body, after the latter is set up and sterilised for surgical use.

1.3 Contraindications

1.3.1 Handpieces, Battery (Power Pack) and attachments

No contraindication has been identified, which would speak against the use of the drive units and the

accessories.

With regards to cutting, drilling and reaming tools to be used in patients with the Creutzfeldt-Jakob

disease (CJD), who - because of associated infection hazards - are regarded to be risk patients - the

procedures shall always be undertaken with the use of disposable instruments.

Any applications of the system, other than those, specified above, are neither intended by design nor

tested and shall thus be forbidden.

1.3.2 Cleaning and maintenance accessories

The cleaning kit shall exclusively be used for the purpose for which it has been intended in the medical

fields and operated by educated and qualified personnel. The attending physician or an appropriate

medical staff member shall be responsible for cleaning kit selection with accessories for defined

applications, as well as for adequate training and correct management.

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

7 of 88

1.4 Application

1.4.1 Application duration

The products are intended for short application periods (< 60 min.)

1.4.2 Patient population

Apart from the contraindicated applications, specified both before and in this User’s Manual. there are

no limitations with regards to patient population.

1.4.3 The user and the field of application

The bee-system (including the cleaning and maintenance accessories) shall be used exclusively by

properly educated and qualified personnel. The products are intended exclusively for the medical field

and shall, therefore, be used at suitable theatre environment. It is an essential requirement that the

user, as well as the appropriate medical staff, get familiar with the instruments before their practical

handling.

1.4.4 Service life

The medical bees GmbH Company provides one-year inspection and maintenance by authorised

service stations (e.g., the Medical bees GmbH). The medical bees GmbH shall assume no

responsibility for any defects / failures, arising either from improper handling of the devices or from

their unauthorised maintenance. Assuming proper handling and authorised maintenance of the device,

its service life shall be, at least, 3 years (except wear & tear parts).

Since the products are subject to normal wear, they shall regularly be inspected or maintained,

Appropriate recommendations are specified in particular parts of the User’s Manual.

The date of manufacturing can be retrieved from the Manfacturing date number.

1.5 Safety and warning instructions

General safety and warning instructions are listed below. They will individually be added and specified

in particular parts of the present User’s Manual.

1.5.1 General safety instructions

•It is recommended to have a spare system ready at all times for immediate use, since

technical problems can never be entirely excluded. The same recommendation applies to

lengthy and long lasting procedures.

•Components with visible defects (for example, after being dropped) shall not be used.

•The system shall not be used in the presence of oxygen, nitrous oxide or of flammable

mixtures of volatile anaesthetic gases and the air.

•With regard to electromagnetic compatibility (EMV), it is imperative to learn the contents of the

appropriate chapter of this User’s Manual.

1.5.2 Cleaning and care of the bee-system

•Both before the first and all subsequent applications, the driving units, the attachments and

the accessories shall undergo a complete reprocessing procedure.

•Protective covers and films shall fully be removed before sterilisation.

•In order to assure proper performance of the system, the medical bees Company

recommends its cleaning and care after every use to be performed according to the

instructions provided in the chapter “Care and Maintenance” of this User’s Manual.

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

8 of 88

•Moving parts shall be maintained for their smooth operation with a special lubrication oil;

recommended by the bee-system GmbH is a spray oil agent (F-30-900-60) or a paraffin oil,

suitable for sterilisation.

•In order to guarantee proper performance of the system, the medical bees GmbH Company

recommends an annual maintenance and inspection to be carried out by one of their medical

customer service stations.

•The Power Pack shall by no means be processed (by manual or automatic cleaning) or

sterilised

•It is imperative that the sterile funnel is sterilised after each use in order to guarantee the

system sterility, when a non-sterile Power Pack is inserted into a sterile handpiece.

1.5.3 Combination products and tools

•New cutting tools shall be used for each surgical procedure.

•For protection against heat necrosis of tissues, cutting tools shall always be flushed with

a coolant.

•In order to guarantee proper performance of the system, only original cutting tools shall be

used, obtained either from the medical bees GmbH or from another vendor, recommended by

the medical bees GmbH (the same shall apply to the battery-loading equipment)

1.5.4 The User / Application

•The User shall be responsible for proper intraoperative handling and use of the products.

•If the system is used in connection with some implant system, then its use shall be

subordinate to the surgical technique of the procedure

•The Manufacturer shall assume no responsibility for damages, which may arise from improper

operation of the system or from its maintenance provided by unauthorised service stations

•The machines get heated under continuous load. In order to avoid exceeding of permissible

surface temperature of the device, appropriate cooling phases shall be implemented. A

description of the issue is provided in the Instructions for Use.

1.5.5 Users and/or patients

•Note to the user and/or patient: All serious incidents relating to the device must be notified to

the manufacturer and the competent authority of the Member State in which the user and/or

patient is established.

1.5.6 Operation and battery mode

•In order to avoid injuries, the locking mechanism of the device shall be activated before the

device is put aside, i.e., the selection switch shall be set at the LOCK position (the symbol of

locked padlock). In addition, the bee-system device shall be handled in its lateral position in

order to avoid possible tipping and falling down.

•The device shall be put in operation only with its fully charged power pack. It must be ensured

that the power pack has been charged in good time. It is recommended that the power pack is

returned to the charging unit immediately after a given procedure is completed.

In order to guarantee sterility, the power pack can be replaced during surgical procedure only

according to the instructions provided in the User’s Manual.

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

9 of 88

1.6 Combination products and accessories

1.6.1 Accessories to be used / Scope of delivery

The system comprises multiple handpieces (drilling machine, reaming machine, sagittal saw, sternum

saw, 2° and 4° oscillating saw, oscillating reaming machine). One or more power packs (battery, motor

and electronic), as well as various attachments which belong to the system.

The power packs shall be charged with an appropriate charger of the medical bees (F-30-900-50 /

F30-900-51 / F-30-900-52)

In order to ensure trouble-free performance of the system, the manufacturers of cutting tools,

recommended by the Medical bees, shall be used. Otherwise, the Medical bees GmbH shall assume

no guarantee for flawless performance of the system.

For cleaning and care of the system, special means are recommended, such as cleaning brushes and

oil spray (F-30-900-60) or oil, as well as suitable for sterilisation medical paraffin oils (F-30-900-61).

The medical bees GmbH recommends the use of a tray, specifically designed for the system (e.g. F-31-

910-13) to sterilize and store the system. Otherwise, the medical bees GmbH shall assume no

guarantee for flawless performance of the system.

The following components shall (at least) be absolutely necessary for the system operation:

Handpiece (e.g. F-31-100-00)

Power pack (F-30-900-00)

Sterile funnel (F-30-900-20)

Charging unit (e.g. F-30-900-50)

At least one attachment, belonging to the system

An overview of the system components can be found at the end of this User’s Manual

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

10 of 88

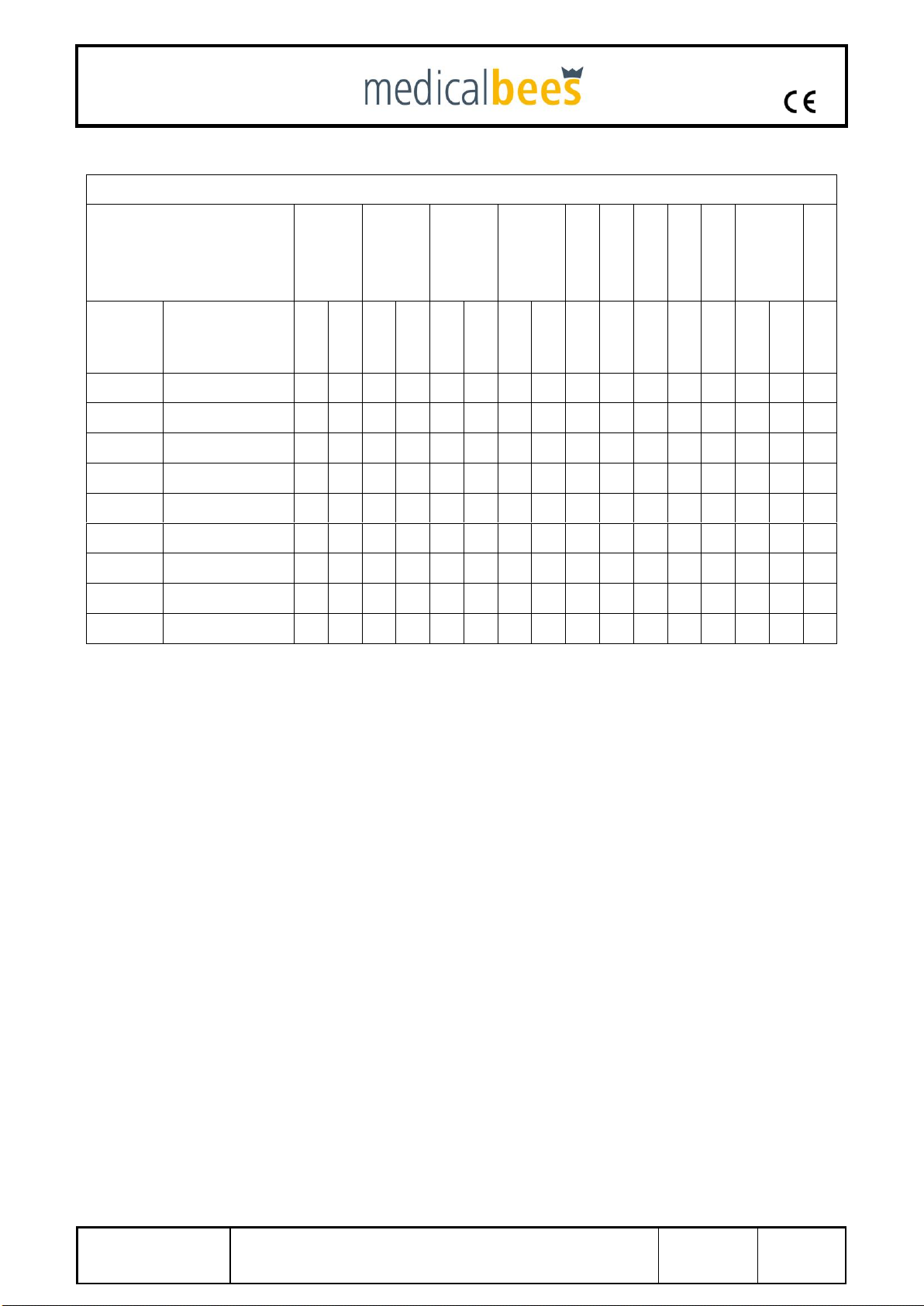

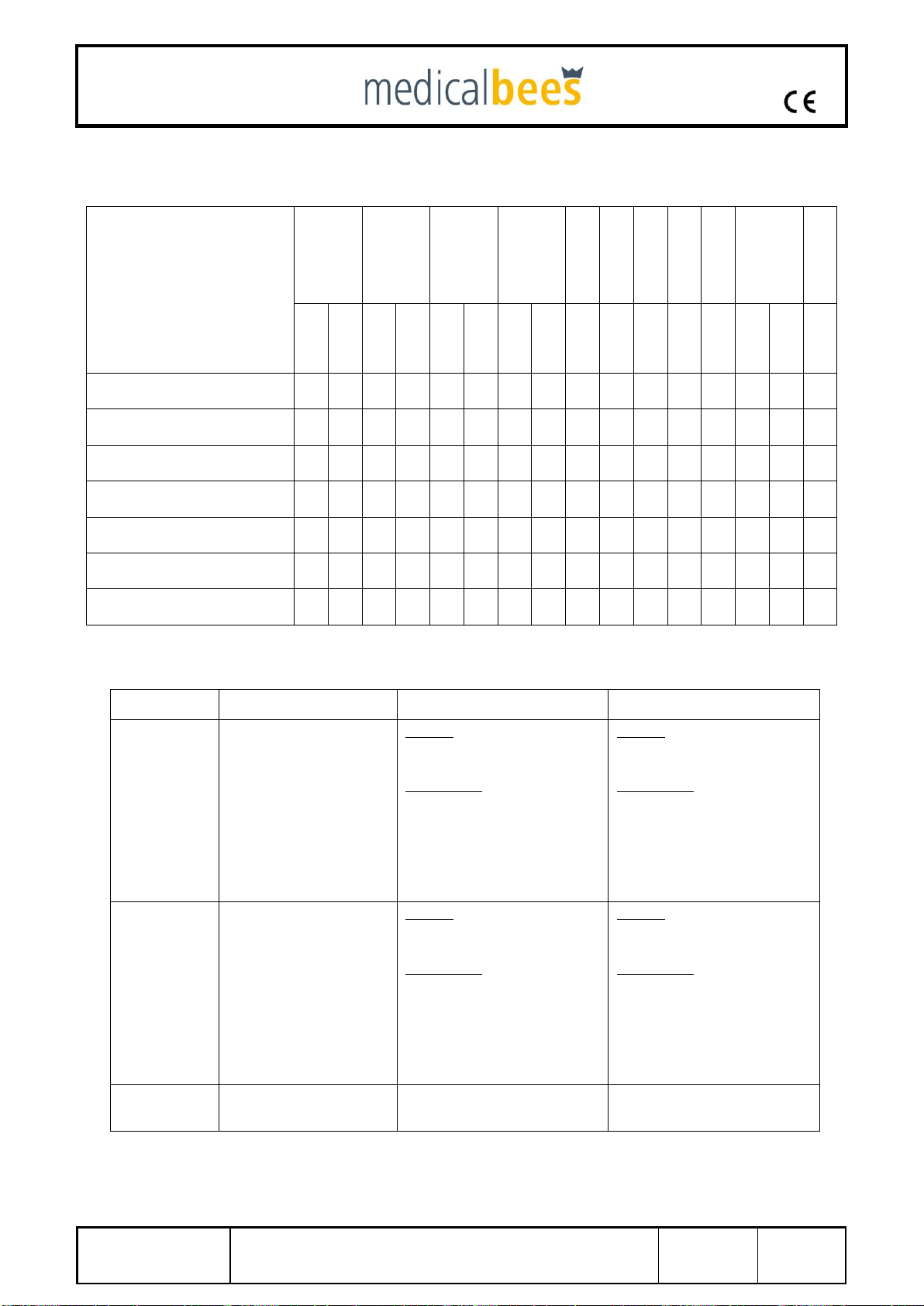

1.6.2 Combinability of individual beesystem components

System overview

Drilling and

reaming machine

Drilling machine

4° oscillating saw,

Synthes

2° oscillating saw,

Synthes

Oscilla-ting saw

Stryker 2°/4°

Straight saw

Styker 2°/4°

Straight saw

Synthes 2°/4°

Reciprocating saw

Sternum saw

Sternum saw with

keyless chuck

Oscillating

reaming machine

Item No.

Accessories

Name

F-30-100-00

F-31-100-00

F-30-150-00

F-31-150-00

F-30-300-00

F-31-300-00

F-30-301-00

F-31-301-00

F-31-310-00

F-31-311-00

F-40-100-00

F-40-101-00

F-40-110-00

F-40-111-00

F-30-400-00

F-30-600-00

F-30-601-00

F-31-601-00

F-31-700-00

F-30-900-00

Power Pack

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-50

Charging unit (1 charging

slot)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-51

Charging unit (2 charging

slots)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-52

Charging unit (4 charging

slots)

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-53

Country-specific plug

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-54

Country-specific plug

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-55

Country-specific plug

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-56

Country-specific plug

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-57

POAG cable for charging

units

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

11 of 88

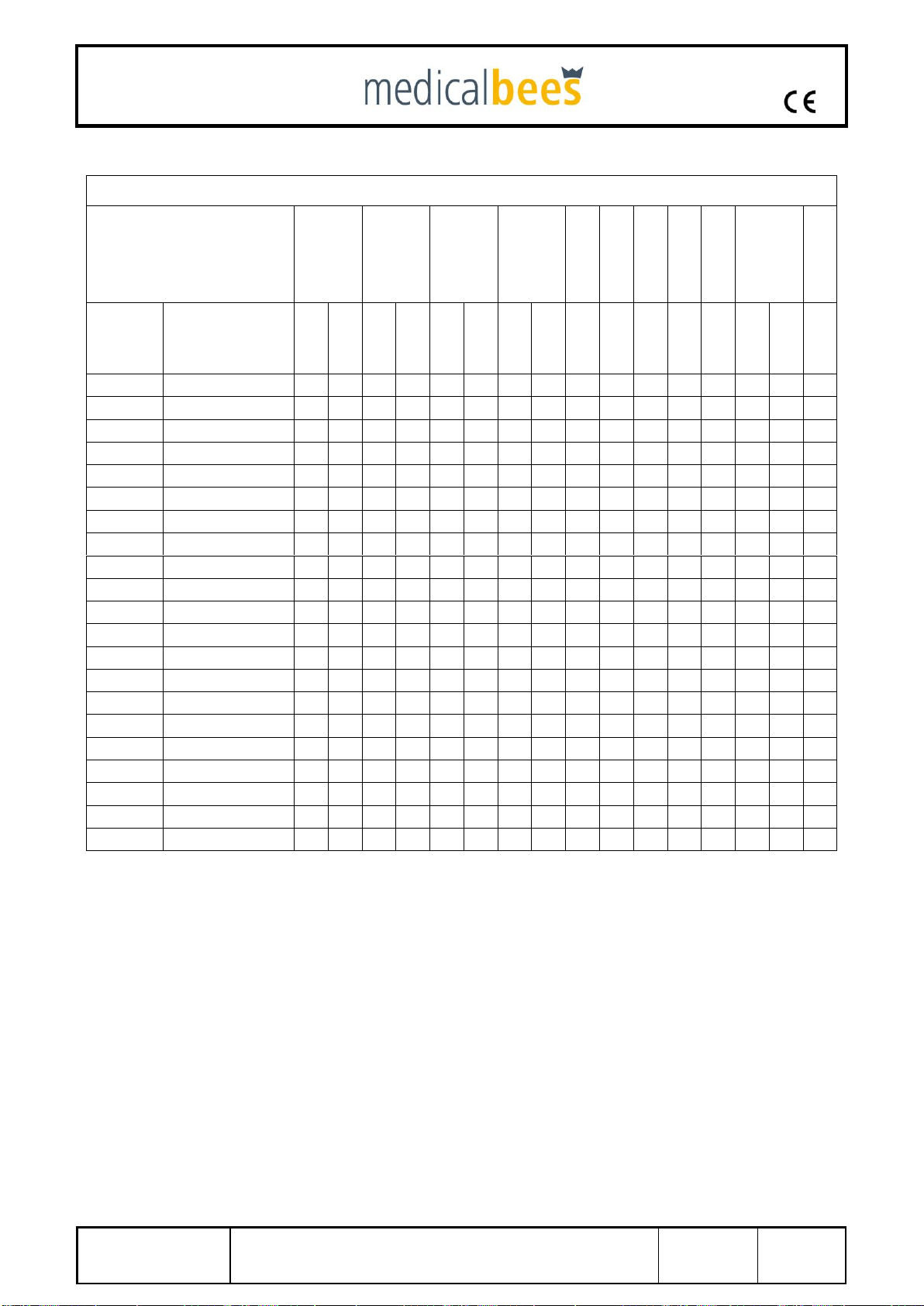

System overview

Drilling and

reaming machine

Drilling machine

4° oscillating saw,

Synthes

2° oscillating saw,

Synthes

Oscilla-ting saw

Stryker 2°/4°

Straight saw

Styker 2°/4°

Straight saw

Synthes 2°/4°

Reciprocating saw

Sternum saw

Sternum saw with

keyless chuck

Oscillating

reaming machine

Item No.

Accessories

Name

F-30-100-00

F-31-100-00

F-30-150-00

F-31-150-00

F-30-300-00

F-31-300-00

F-30-301-00

F-31-301-00

F-31-310-00

F-31-311-00

F-40-100-00

F-40-101-00

F-40-110-00

F-40-111-00

F-30-400-00

F-30-600-00

F-30-601-00

F-31-601-00

F-31-700-00

F-30-100-10

Kirschner wire chuck (for

drill/ream)

x

x

F-30-100-15

Kirschner wire chuck (for

standard)

x

x

F-30-100-19

Extension for Kirschner

wire chuck

x

x

x

x

F-30-100-25

Adapter for radiolucent

x

x

x

x

F-30-100-50

AO chuck, small

x

x

x

x

F-30-100-51

AO chuck, big

x

x

x

x

F-30-100-52

1/4 " attachment

x

x

x

x

F-30-100-53

Hudson chuck

x

x

x

x

F-30-100-54

Harris chuck

x

x

x

x

F-30-100-55

Hexagonal chuck, SW6

x

x

x

x

F-30-100-56

DIN-clutch for tools

x

x

x

x

F-30-100-57

Zimmer Hall Chuck

x

x

x

x

F-30-100-60

Jacobs drill chuck, small

x

x

x

x

F-30-100-61

Jacobs drill chuck, big

x

x

x

x

F-30-100-62

Rohm drill chuck

x

x

x

x

F-30-100-63

Quick-action chuck with

lock

x

x

x

x

F-30-100-64

Quick-action chuck without

lock

x

x

x

x

F-30-100-65

Albrecht quick action chuck

x

x

x

x

F-30-100-66

Large drill chuck

x

x

x

x

F-30-400-05

Keyless top for sternum

x

F-30-400-10

XL Keyless top for sternum

x

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

12 of 88

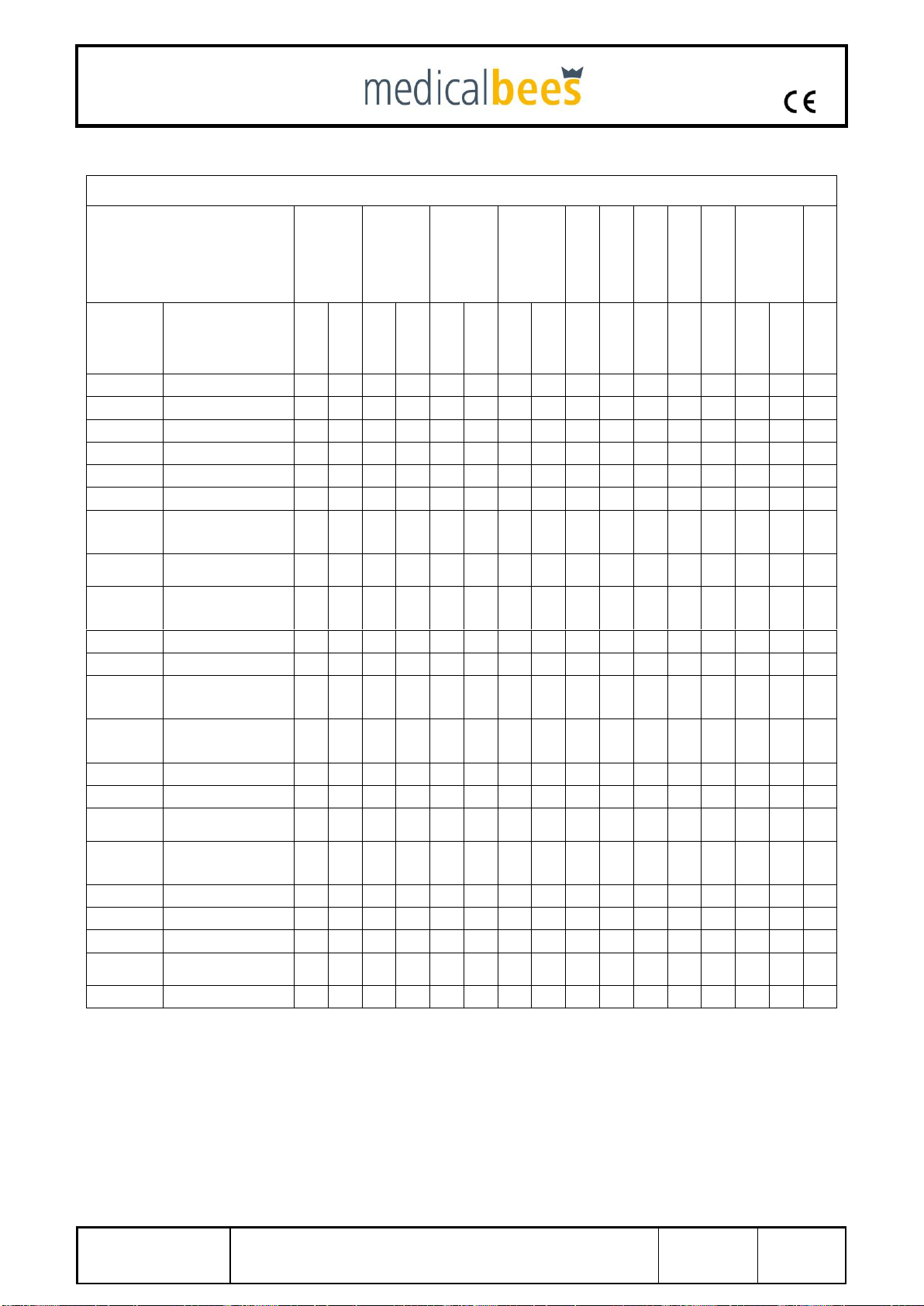

System overview

Drilling and

reaming machine

Drilling machine

4° oscillating saw,

Synthes

2° oscillating saw,

Synthes

Oscilla-ting saw

Stryker 2°/4°

Straight saw

Styker 2°/4°

Straight saw

Synthes 2°/4°

Reciprocating saw

Sternum saw

Sternum saw with

keyless chuck

Oscillating

reaming machine

Item No.

Accessories

Name

F-30-100-00

F-31-100-00

F-30-150-00

F-31-150-00

F-30-300-00

F-31-300-00

F-30-301-00

F-31-301-00

F-31-310-00

F-31-311-00

F-40-100-00

F-40-101-00

F-40-110-00

F-40-111-00

F-30-400-00

F-30-600-00

F-30-601-00

F-31-601-00

F-31-700-00

F-30-900-10

Lubrication stand

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-20

Sterile funnel

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-900-60

Spray oil of the Beesystem

GmbH

x

x

x

x

x

x

x

x

x

x

x

x

x

X

x

x

F-30-900-61

Oil Pen

x

x

x

x

x

x

x

x

x

x

x

x

x

X

x

x

F-30-900-70

Universal spray adapter

(for all machines)

x

x

x

x

x

x

x

F-30-900-72

Spray adapter for drilling

machine

(for F-30-100-00 / F-30-

150-00)

x

x

F-30-900-74

Spray adapter for saws

(for F-30-400-00 / F-30-

600-00 / F-30-601-00)

x

x

x

F-30-900-78

Spray adapter for drilling

machine

(for F-30-100-00 / F-30-

150-00)

x

x

F-30-910-05

Lid for cleaning and

sterilisation tray with a lock

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-31-910-13

Cleaning and sterilisation

tray (1 machine) with lid,

bare grip –for beesystemI

and beesystemII

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-31-910-18

Cleaning and sterilisation

tray (2 machines) with lid,

bare grip - for beesystemI

and beesystemII

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-910-30

Universal rinsing adapter

(for all machines)

x

x

x

x

x

x

x

x

x

F-30-910-31

Rinsing adapter for drilling

machine

x

x

x

x

F-30-910-33

Rinsing adapter for

reciprocating- sternum saw

(for F-30-400-00 / F-30-

600-00 / F-30-601-00)

x

x

x

F-30-910-40

Rinsing set

x

x

x

x

X

x

x

x

x

x

x

x

x

x

x

x

F-30-910-42

beesystem chuck: Miele /

Stielco / Webeco

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-910-43

beesystem adapter

Belomed

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-910-44

beesystem adapter

Maquet / MediKomp /

Getinger

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

F-30-910-50

Cleaning brushes - set

x

x

x

x

x

x

x

x

x

x

x

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

13 of 88

1.6.3 Recommended cutting tool

Third-party products

(Recommendations of the Medica-Bees

GmbH Company; not included in the list of

products)

Drilling and

reaming machine

Drilling machine

4° oscillating

saw, Synthes

2° oscillating

saw, Synthes

Oscilla-ting saw

Stryker 2°/4°

Straight saw

Styker 2°/4°

Straight saw

Synthes 2°/4°

Reciprocating

saw

Sternum saw

Sternum saw

with keyless

chuck

Oscillating

reaming machine

F-30-100-00

F-31-100-00

F-30-150-00

F-31-150-00

F-30-300-00

F-31-300-00

F-30-301-00

F-31-301-00

F-31-310-00

F-31-311-00

F-40-100-00

F-40-101-00

F-40-110-00

F-40-111-00

F-30-400-00

F-30-600-00

F-30-601-00

F-31-601-00

F-31-700-00

3-flute spiral drill bit

(Synthes Company)

x

x

x

x

Saw blades with Synthes

joint

x

x

x

x

x

Saw blades with Stryker

joint

x

x

x

x

x

x

Saw blades of the Gomina AG Company

x

x

x

x

x

x

x

Saw blades of the Risa GmbH Company

x

x

x

x

x

x

x

x

x

x

x

Saw blades of the company mahe medical

GmbH

x

x

x

x

x

x

x

Hol reamers of the Richard Wolf GmbH

Company

x

Saw blades of the following manufacturers are recommended with their dimensions and connections.

Gomina AG Company

mahe medical GmbH

Risa GmbH Company

Synthes connection

Oscillating saw

70 mm long, 25 mm wide, 0.90 –1.47 mm

thick

70 mm long, 19 mm wide, 0.90 –1.47 mm

thick

90 mm long, 25 mm wide, 0.90 –1.47 mm

thick

90 mm long, 19 mm wide, 0.90 –1.47 mm

thick

90 mm long, 12 mm wide, 0.90 –1.47 mm

thick

90 mm long, 12-19mm wide, 0.90 –1.47 mm

thick

Crossed teeth

48-95mm long, 22-50mm wide, 0.4-1.2 mm thick

18-68mm long, 4.0-15 mm wide, 0.4-0.6 mm thick

Diamond-ground teeth

90-120 mm long, 25-31 mm wide, 0.89 mm-1.47 mm

thick

50-110 mm long, 25 mm wide, 0.89mm-1.47 mm thick

90-120 mm long, 19-22 mm wide, 0.89 mm-1.47 mm

thick

50-100 mm long, 13-19 mm wide, 0.89 mm-1.47 mm

thick

Crossed teeth

48-95mm long, 22-50mm wide, 0.4-1.2 mm thick

18-68mm long, 4.0-15 mm wide, 0.4-0.6 mm thick

Diamond-ground teeth

90-120 mm long, 25-31 mm wide, 0.89 mm-1.47 mm

thick

50-110 mm long, 25 mm wide, 0.89mm-1.47 mm thick

90-120 mm long, 19-22 mm wide, 0.89 mm-1.47 mm

thick

50-100 mm long, 13-19 mm wide, 0.89 mm-1.47 mm

thick

Stryker 6

connection

oscillating saw

70 mm long, 25 mm wide, 0.90 –1.47 mm

thick

70 mm long, 19 mm wide, 0.90 –1.47 mm

thick

90 mm long, 25 mm wide, 0.90 –1.47 mm

thick

90 mm long, 19 mm wide, 0.90 –1.47 mm

thick

90 mm long, 12 mm wide, 0.90 –1.47 mm

thick

90 mm long, 12-19mm wide, 0.90 –1.47 mm

thick

Crossed teeth

48-95mm long, 22-50mm wide, 0.4-1.2 mm thick

18-68mm long, 4.0-15 mm wide, 0.4-0.6 mm thick

Diamond-ground teeth

90-120 mm long, 25-31 mm wide, 0.89 mm-1.47 mm

thick

50-110 mm long, 25 mm wide, 0.89mm-1.47 mm thick

90-120 mm long, 19-22 mm wide, 0.89 mm-1.47 mm

thick

50-100 mm long, 13-19 mm wide, 0.89 mm-1.47 mm

thick

Crossed teeth

48-95mm long, 22-50mm wide, 0.4-1.2 mm thick

18-68mm long, 4.0-15 mm wide, 0.4-0.6 mm thick

Diamond-ground teeth

90-120 mm long, 25-31 mm wide, 0.89 mm-1.47 mm

thick

50-110 mm long, 25 mm wide, 0.89mm-1.47 mm thick

90-120 mm long, 19-22 mm wide, 0.89 mm-1.47 mm

thick

50-100 mm long, 13-19 mm wide, 0.89 mm-1.47 mm

thick

Stryker connection

n.a.

60mm long, 10mm wide, 0,6mm thick

80mm long, 10mm wide, 1,00mm hick

60 mm long, 10 mm wide, 0.6 –1.47 mm thick

80 mm long, 10 mm wide, 1.00 –1.47 mm thick

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

14 of 88

1.6.4 Storage and Transport

All the products, traded by us on the market, are delivered as non-sterile and shall thus demand

processing before use. The medical bees GmbH Company recommends single use of corresponding

drilling and cutting tool.

On product safety grounds, only original packaging systems shall be used for shipment and transport.

If this is no longer available, please contact the Medical bees GmbH Company.

The environmental conditions for storage and transport are addressed in this User’s Manual. Before

disposal or return transport to the medical bees GmbH Company, the devices/handpieces, as well as

the chucks, shall undergo the complete procedure of clinical processing for protection against

infections. In addition, the products shall appropriately be marked as either „hygienically safe" or “not

decontaminated".

1.6.5 Disposal

Defective devices can mostly be repaired, see the User’s Manual for this issue. The devices contain

lithium-ion batteries (Li-ion = chem. Symbol of harmful substance) and, on grounds relating to the

protection of the environment, shall thus be properly disposed. Battery disposal shall comply with

national laws or with the European battery directive: 2006/66/EC, as well as with the Waste of

Electrical and Electronic Equipment (WEEE) directive - 2002/96/EC.

A special care shall be taken here with regards to fire, explosion and burn hazards. It must be kept in

mind that battery cells shall not be damaged, opened, torn, shorted, crushed or allowed in contact with

fluids.

Before disposal, the devices/handpieces, as well as the chucks, shall undergo the complete procedure

of clinical processing for protection against infections. The device shall not be disposed of with the

household waste.

1.6.6 Guarantee

The guarantee for the devices and accessories shall be cancelled in case of their unintended use

and/or inappropriate operation, storage or transport. The Manufacturer shall assume no responsibility

for damages, which may arise from improper operation of the system or from its maintenance provided

by unauthorised service stations

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

15 of 88

2 Operation of the device

2.1 Description of the controls, indication functions and

symbols

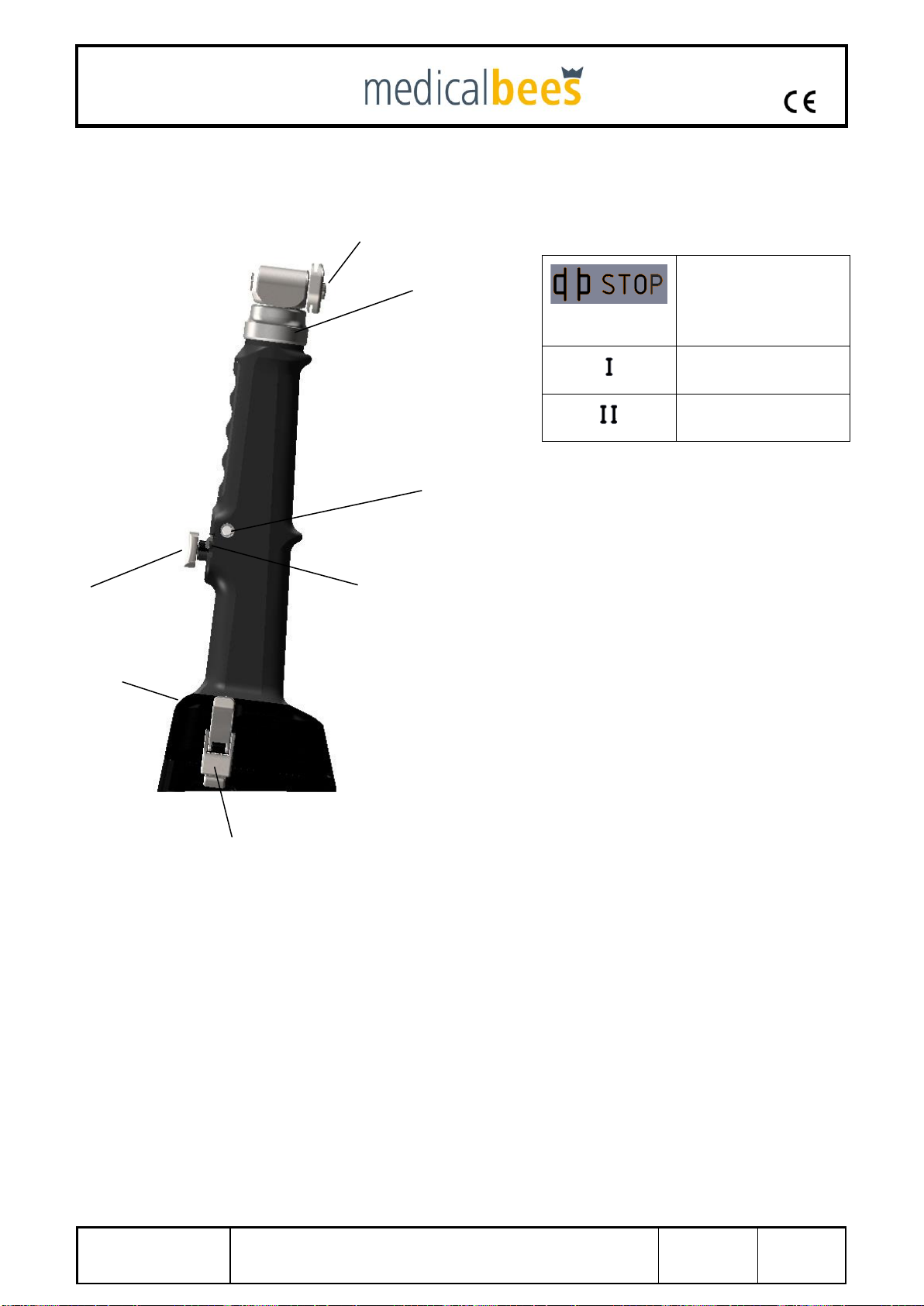

2.1.1 Drilling / reaming machine (F-31-100-00)

1 Release sleeve for attachments

2 Trigger for speed regulation

3 Slider for switching in the right direction, locking (safety position), left-hand rotation

4 Locking latches

5 Switch lever to switch oscillating mode ON or OFF

6Rotating ring for the DRILL mode or REAM mode

7Sight glass for LED indications and lighting

The slider in the middle position

→INTERLOCK / SAFETY

POSITION

The device cannot be

unintentionally started

The slide retracted →CW rotation

The slide extended →CCW

rotation

The oscillating mode is on

The oscillating mode is off

1

2

6

3

5

7

4

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

16 of 88

2.1.2 Drilling machine (F-31-150-00)

1 Release sleeve for attachments

2 Trigger for speed regulation

3 Slider for switching in the right direction, locking (safety position), left-hand rotation

4 Locking latches

5 Switch lever to switch oscillating mode ON or OFF

6Sight glass for LED indications and lighting

The slider in the middle position

→INTERLOCK / SAFETY

POSITION

The device cannot be

unintentionally started

The slide retracted →CW rotation

The slide extended →CCW

rotation

The oscillating mode is on

The oscillating mode is off

4

1

3

2

5

6

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

17 of 88

2.1.3 Oscillating saws Synthes AO connection (F-31-300-00; F-31-301-

00)

1 Locking ring for saw blade tension

2 Trigger for speed regulation / oscillation frequency

3 Slider for switching ON, locking (safety position), ON

4 Locking latches

5 Switch lever to switch the I “Normal” and II “Quick” mode

6 Unlocking sleeve for setting the saw head in 45° steps

7Sight glass for LED indications and lighting

The slider in the middle

position →INTERLOCK /

SAFETY POSITION

The device cannot be

unintentionally started

Frequency/CPM set at step

“I”

Frequency/CPM set at step

“II”

1

2

3

4

5

6

7

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

18 of 88

2.1.4 Oscillating saw Stryker Sawblade connection (F-31-310-00/F-31-

311-00)

1 Locking ring for saw blade tension

2 Trigger for speed regulation / oscillation frequency

3 Slider for switching ON, locking (safety position), ON

4 Locking latches

5 Switch lever to switch the I “Normal” and II “Quick” mode

6 Unlocking sleeve for setting the saw head in 45° steps

7Sight glass for LED indications and lighting

The slider in the middle

position →INTERLOCK /

SAFETY POSITION

The device cannot be

unintentionally started

Frequency/CPM set at step

“I”

Frequency/CPM set at step

“II”

1

2

3

4

5

6

7

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

19 of 88

2.1.5 Straight Oscillating saw Stryker Sawblade connection (F-40-100-

00/F-40-101-00)

1 Locking knob for saw blade tension

2 Trigger for speed regulation / oscillation frequency

3 Slider for switching ON, locking (safety position), ON

4 Locking latches

5 Switch lever to switch the I “Normal” and II “Quick” mode

6 Unlocking sleeve for setting the saw head in 45° steps

7Sight glass for LED indications and lighting

The slider in the middle

position →INTERLOCK /

SAFETY POSITION

The device cannot be

unintentionally started

Frequency/CPM set at step

“I”

Frequency/CPM set at step

“II”

1

2

3

4

5

6

7

0483

Data

05 February 2021

IFU GA-001-02

Revision

03

Page

20 of 88

2.1.6 Straight Oscillating saw Synthes AO connection (F-40-110-00/F-40-

111-00)

1 Locking ring for saw blade tension

2 Trigger for speed regulation / oscillation frequency

3 Slider for switching ON, locking (safety position), ON

4 Locking latches

5 Switch lever to switch the I “Normal” and II “Quick” mode

6 Unlocking sleeve for setting the saw head in 45° steps

7Sight glass for LED indications and lighting

The slider in the middle

position →INTERLOCK /

SAFETY POSITION

The device cannot be

unintentionally started

Frequency/CPM set at step

“I”

Frequency/CPM set at step

“II”

1

2

3

4

5

6

7

This manual suits for next models

1

Table of contents