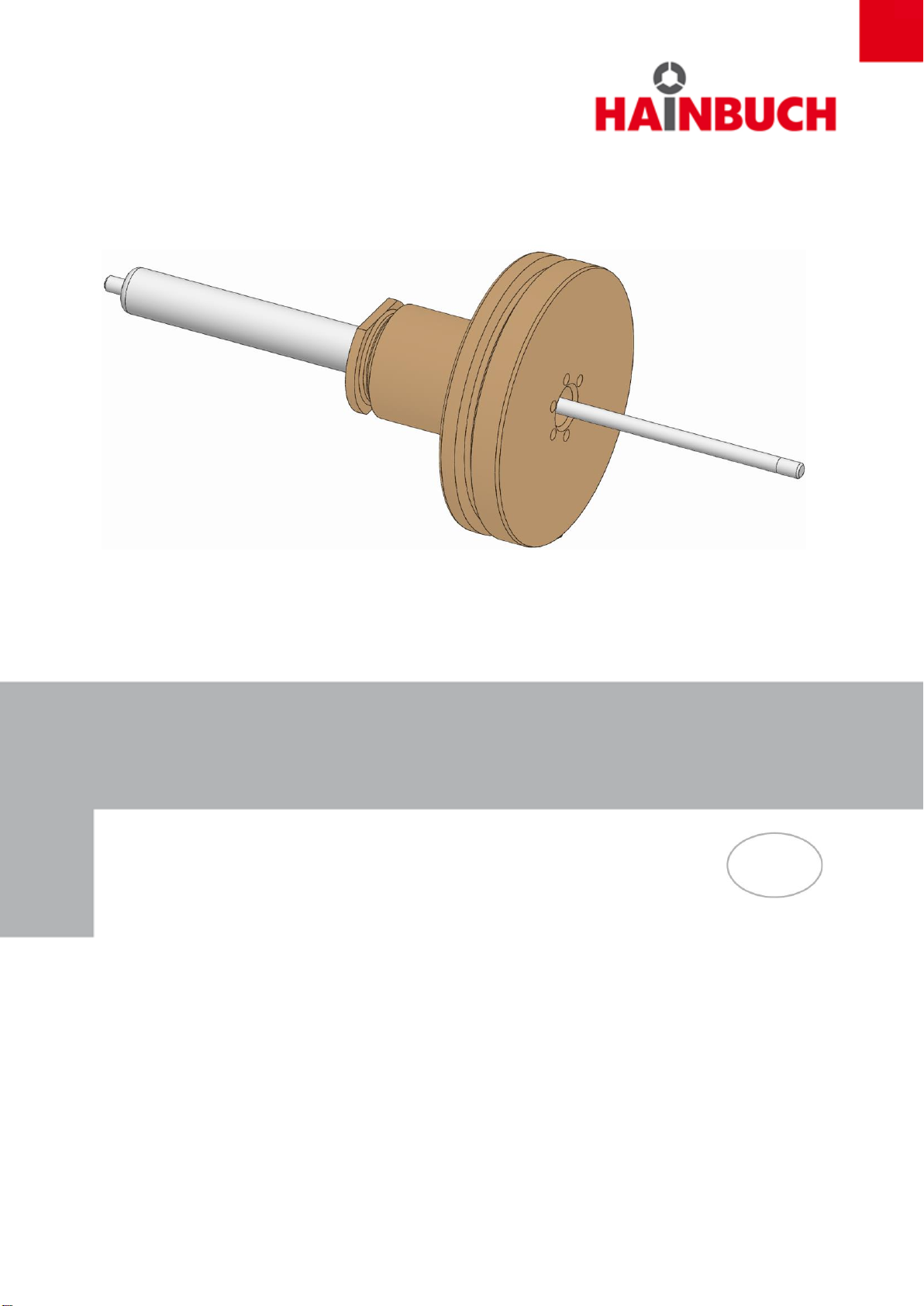

vario flex

Order hotline +49 7144.907-333

Contents

1General.................................................................................................................6

1.1 Information about this manual......................................................................6

1.2 Key to symbols.............................................................................................6

1.3 Definition of terms........................................................................................8

1.3.1 Release setting...............................................................................8

1.3.2 Complete clamping reserve............................................................8

1.4Limitation of liability......................................................................................8

1.5 Copyright......................................................................................................8

1.6 Scope of delivery .........................................................................................8

1.7 Spare parts and accessories........................................................................9

1.8 Warranty terms ............................................................................................9

2Safety.................................................................................................................10

2.1 Responsibility of the operator.....................................................................10

2.2 Personnel requirements.............................................................................10

2.3 Intended use..............................................................................................12

2.4 Personal protective equipment...................................................................14

2.5 Particular hazards......................................................................................15

2.6 Other safety instructions ............................................................................16

2.7 Screws.......................................................................................................17

2.8 Functionality...............................................................................................18

2.9 Environmental protection ...........................................................................18

3Technical data....................................................................................................19

3.1 General information....................................................................................19

3.2 Performance values...................................................................................20

3.3 Speed.........................................................................................................21

3.4 Operating conditions..................................................................................21

3.5 Type designation........................................................................................21

4Layout and function............................................................................................22

4.1 Overview and brief description...................................................................22

4.2 Accessories required..................................................................................22

4.2.1 Clamping device...........................................................................22

4.3 Optional accessories..................................................................................22

4.3.1 Workpiece end-stop......................................................................22

5Use and limits of use..........................................................................................23

5.1 Use.............................................................................................................23

5.2 Limits of use...............................................................................................23

6Transport, packaging, storage............................................................................24

6.1 Safety, transport, packaging, storage ........................................................24

6.2 Symbols on the packaging.........................................................................25

6.3 Transport inspection...................................................................................25

6.4 Unpacking and internal transportation........................................................25