Putting Into Service

Principle of Operation

IMPORTANT - READ BOTH THE SAFETY INSTRUCTIONS ON PAGE 3 AND 4 AND THE PUMP UNIT INSTRUCTION

MANUAL CAREFULLY BEFORE PUTTING INTO SERVICE

When both hoses and control cable are connected to the Avder/Enerpac

®

hydraulic pump unit, the pull and return cycles

of the tool are controlled by depressing and releasing the trigger located in the handle.

When the switch is depressed the solenoid valve, located in the hydraulic pump unit, is energised and directs the

pressurised oil flow to the pull side of the piston in the placing tool. This also allows the oil in the return side of the

placing tool to return to the reservoir.

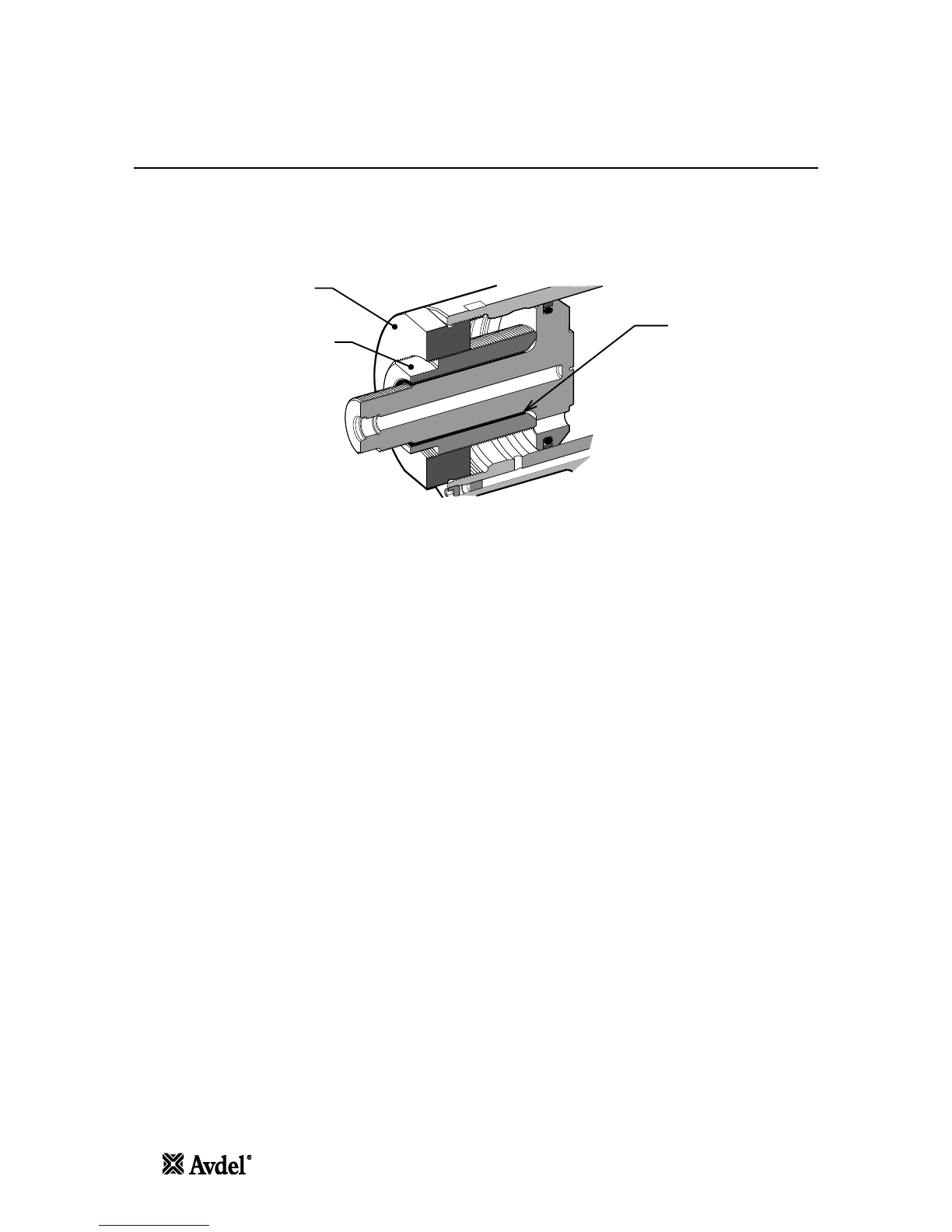

During the pull cycles the piston/collet assembly moves towards the rear of the tool allowing the 0-ring type cushion to

push the follower and jaws forward. If a fastener pin has been inserted in the nose assembly, the jaw set will clamp onto

the pintail and assembly will commence.

For Infalok® the cycle of installation will first clamp the joint to be fastened and then as the anvil continues to move

forward the collar will be swaged into the locking grooves of the pin. At the end of the swaging cycle the anvil will come

up against the joint and as movement continues the pintail will be broken off.

The trigger switch should be released immediately after pin break occurs.

If the trigger is not released, the piston will continue move towards the rear of the tool until it contacts the inner rear face.

When the piston reaches the end of the pull stroke, it uncovers flats on the rear end of a pressure relief valve rod. These

flats are designed to provide a passage for hydraulic fluid between the pull and return side of the piston. Thus allowing

pressurised fluid to be 'unloaded' or 'dumped' back to the reservoir, preventing unnecessary loading to the rear of the tool

body. The placing tool piston will be held in this position until the trigger is released.

Releasing the trigger switch will cause the solenoid to de-energise and reverse the flow of pressurised oil.

However, if during installation the pressure in the pull side achieves a preset 'High Pressure' value set at the pump. At

this point the solenoid valve will automatically de-energise and reverse the flow of pressurised oil to the return side of the

placing tool.

In either case, pressurised oil will now flow into the return side of the placing tool, with the oil in the pull side returning

to the reservoir.

The forward movement of the piston/collet assembly will eject the installed fastener from the anvil.

At the point of releasing the trigger or when the 'High Pressure' value is achieved, the solenoid valve will de-energise and

activate a preset 'Return Timer'. This controls the time that the pump motor will continue run before switching to the idle

mode. The timer can be manually set between 5 and 20 seconds to ensure that the placing tool piston always fully

returns to the forward position (refer to pump manual 07900-01030, pages 10 and 13).

When the piston returns to the fully forward position, the pressure will increase to preset low pressure value - c200bar.

The pump motor will continue to run until the Return Timer has expired. After this time period the motor will stop

automatically and valve will switch to the idle position. The solenoid valve will then automatically cycle to release

pressurised oil to the reservoir from both the pull and return side of the placing tool.

This keeps the installation tool in the forward position. No pressure will be present in the hydraulic system at this point.

The hydraulic pump unit will automatically start up on depression of the tool trigger switch.

nAvder

7

Putting Into Service

Principle of Operation

IMPORTANT - READ BOTH THE SAFETY INSTRUCTIONS ON PAGE 3 AND 4 AND THE PUMP UNIT INSTRUCTION

MANUAL CAREFULLY BEFORE PUTTING INTO SERVICE

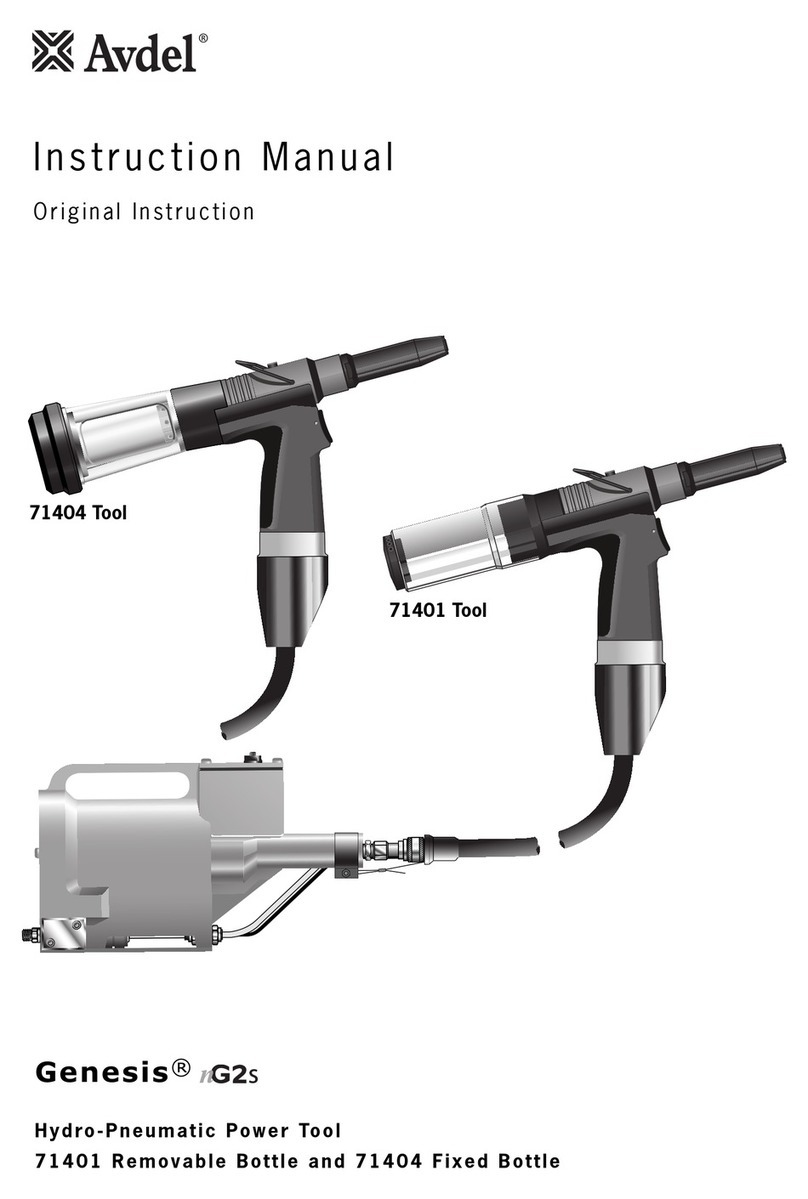

When both hoses and control cable are connected to the Avdel®/Enerpac®hydraulic pump unit, the pull and return cycles

of the tool are controlled by depressing and releasing the trigger located in the handle.

When the switch is depressed the solenoid valve, located in the hydraulic pump unit, is energised and directs the

pressurised oil flow to the pull side of the piston in the placing tool. This also allows the oil in the return side of the

placing tool to return to the reservoir.

During the pull cycles the piston/collet assembly moves towards the rear of the tool allowing the O-ring type cushion to

push the follower and jaws forward. If a fastener pin has been inserted in the nose assembly, the jaw set will clamp onto

the pintail and assembly will commence.

For Infalok®the cycle of installation will first clamp the joint to be fastened and then as the anvil continues to move

forward the collar will be swaged into the locking grooves of the pin. At the end of the swaging cycle the anvil will come

up against the joint and as movement continues the pintail will be broken off.

The trigger switch should be released immediately after pin break occurs.

If the trigger is not released, the piston will continue move towards the rear of the tool until it contacts the inner rear face.

When the piston reaches the end of the pull stroke, it uncovers flats on the rear end of a pressure relief valve rod. These

flats are designed to provide a passage for hydraulic fluid between the pull and return side of the piston. Thus allowing

pressurised fluid to be ‘unloaded’ or ‘dumped’ back to the reservoir, preventing unnecessary loading to the rear of the tool

body. The placing tool piston will be held in this position until the trigger is released.

Releasing the trigger switch will cause the solenoid to de-energise and reverse the flow of pressurised oil.

However, if during installation the pressure in the pull side achieves a preset ‘High Pressure’ value set at the pump. At

this point the solenoid valve will automatically de-energise and reverse the flow of pressurised oil to the return side of the

placing tool.

In either case, pressurised oil will now flow into the return side of the placing tool, with the oil in the pull side returning

to the reservoir.

The forward movement of the piston/collet assembly will eject the installed fastener from the anvil.

At the point of releasing the trigger or when the ‘High Pressure’ value is achieved, the solenoid valve will de-energise and

activate a preset ‘Return Timer’. This controls the time that the pump motor will continue run before switching to the idle

mode. The timer can be manually set between 5 and 20 seconds to ensure that the placing tool piston always fully

returns to the forward position (refer to pump manual 07900-01030, pages 10 and 13).

When the piston returns to the fully forward position, the pressure will increase to preset low pressure value - c200bar.

The pump motor will continue to run until the Return Timer has expired. After this time period the motor will stop

automatically and valve will switch to the idle position. The solenoid valve will then automatically cycle to release

pressurised oil to the reservoir from both the pull and return side of the placing tool.

This keeps the installation tool in the forward position. No pressure will be present in the hydraulic system at this point.

The hydraulic pump unit will automatically start up on depression of the tool trigger switch.