Medidenta MediLECTRIC EJ0008-MEDI User manual

INDICATION FOR USE

The MediLectric System is intended to convert pneumatic output from a dental treatment

center into electrical energy in order to drive an electric micromotor that operates electrical-

ly-driven dental handpieces. This system is designed for use by a trained professional in the field

of general dentistry.

ELECTRICAL SAFETY INFORMATION

• Do not handle the power cord with wet hands to prevent an electric shock.

• Do not expose the device to water to prevent an electric shock.

• Do not use the device in a place where flammable materials are found due to risk of explosion.

• No part of the control unit shall be repaired by the user. Do not disassemble the device.

• Place the device on a stable location. Do not drop the device or exert an external force that

may damage the device.

• Do not use a mobile phone or wireless RF communication device close by as such adjacent

use may adversely influence this electrical device.

• This product shall be used only under the rated power specified. Power outside the rate

indicated may damage unit

• Do not use device with a handpiece that does not meet the standard requirements.

• If motor begins to run rough, discontinue use and send in for request to the supplier.

• Check if the speed is set within the acceptable speed range prior to using the speed

control button on the control panel.

• Use only the adapter that is provided by the manufacturer for this device.

• Do not disassemble or tamper with micromotor or control unit as it may damage the device.

• Micromotor generated greater power and torque than traditional air turbines of air motors.

Therefore, handpiece that equipped with micromotor with poorly serviced, damaged or

used improperly can overheat which can cause serious burn injuries to the patients.

• The following guide lines should be followed to ensure the safe operation of electric

handpieces:

• Follow maintenance instruction of handpiece manufacturer.

• Examine the handpiece for damage before each use

• Never apply pressure on the chuck button while handpiece is in operation or use handpiece

as a cheek or tongue re-tractor.

INSTRUCTIONS FOR USE

Read before use. Keep in a safe place for future reference.

CAUTION: Federal (US) law restricts this device to sale by or on the order of a licensed professional.

Item

Code: EJ0008-MEDI

GENERAL OPERATION / PRECAUTIONS

1. Read the instructions for use thoroughly prior to the first use.

2. Use the device only in accordance with the instructions for use.

3. Pay a close attention to safety of the patient while using the device.

4. Scrap and recycle the device and its parts in accordance with the applicable local laws and

regulations.

5. For any issues relating to the use of the product including technical inquiries, please contract

Medidenta.

SPECIFICATIONS

Input 100-240V~, 1.4-0.7A, 47-63Hz

Power Consumption 105 VA(Max.)

Dimension 133 × 170 × 35 mm [Width × Length ×

Height]

Speed range 1,000 ~ 40,000 rpm

Gear ratio display 1:5, 1:1

Spray on/off 0

Program memory 3

Select a rotational direction 0

Class of protection IPX0

Micromotor

Max. Speed 40,000 rpm

Dimension Ø20 × L63 mm

Weight 69g

Optic White LED

Internal Irrigation Yes

Coupling type E-type connection per ISO 3964 type 3

Max. torque 3.0 N-cm

Air intake Max. quality per ISO 7494-2 4 bar (58 psi)

Water pressure intake Max. 2.5 bar (29 psi)

AC/DC Adapter

Input 100-240 VAC , 1.4-0.7A

Frequency 47-63Hz

Output 36-38 VDC, 2.92 A

Power 105 W

Dimension 76 × 146 × 40 mm [Width × Length × Height]

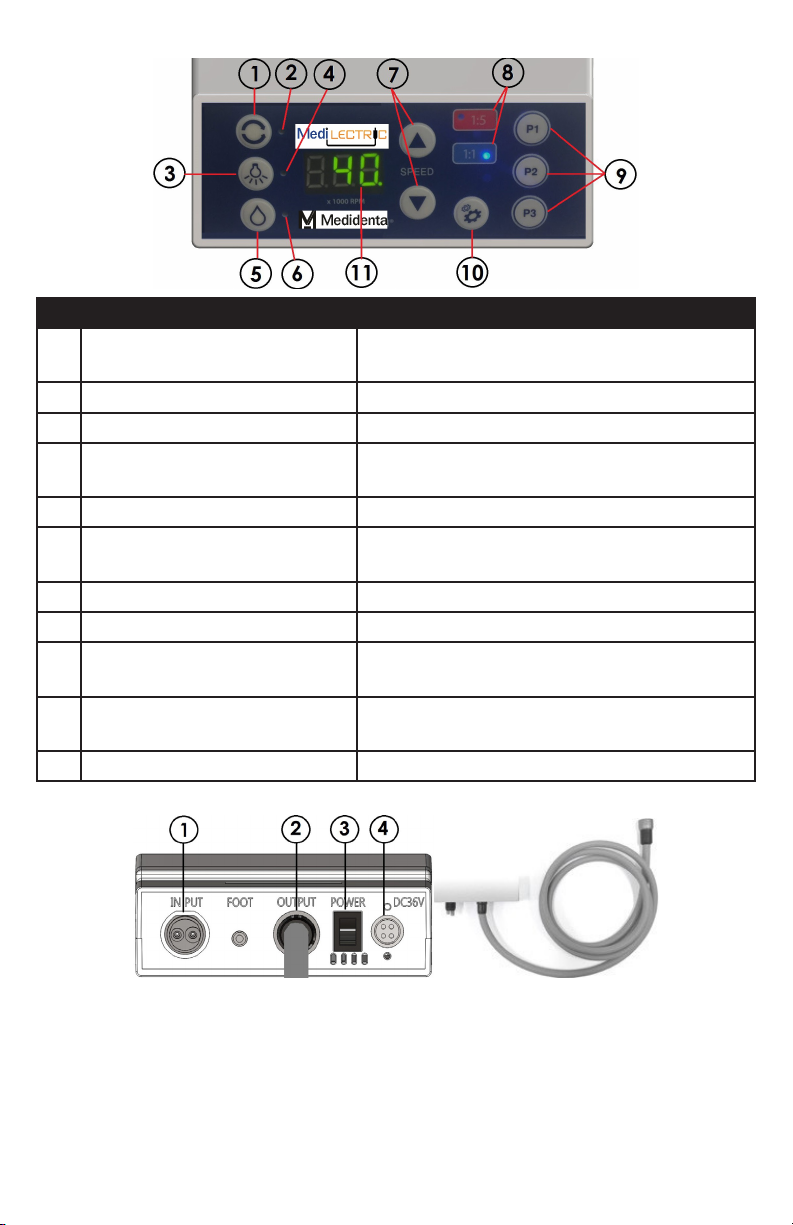

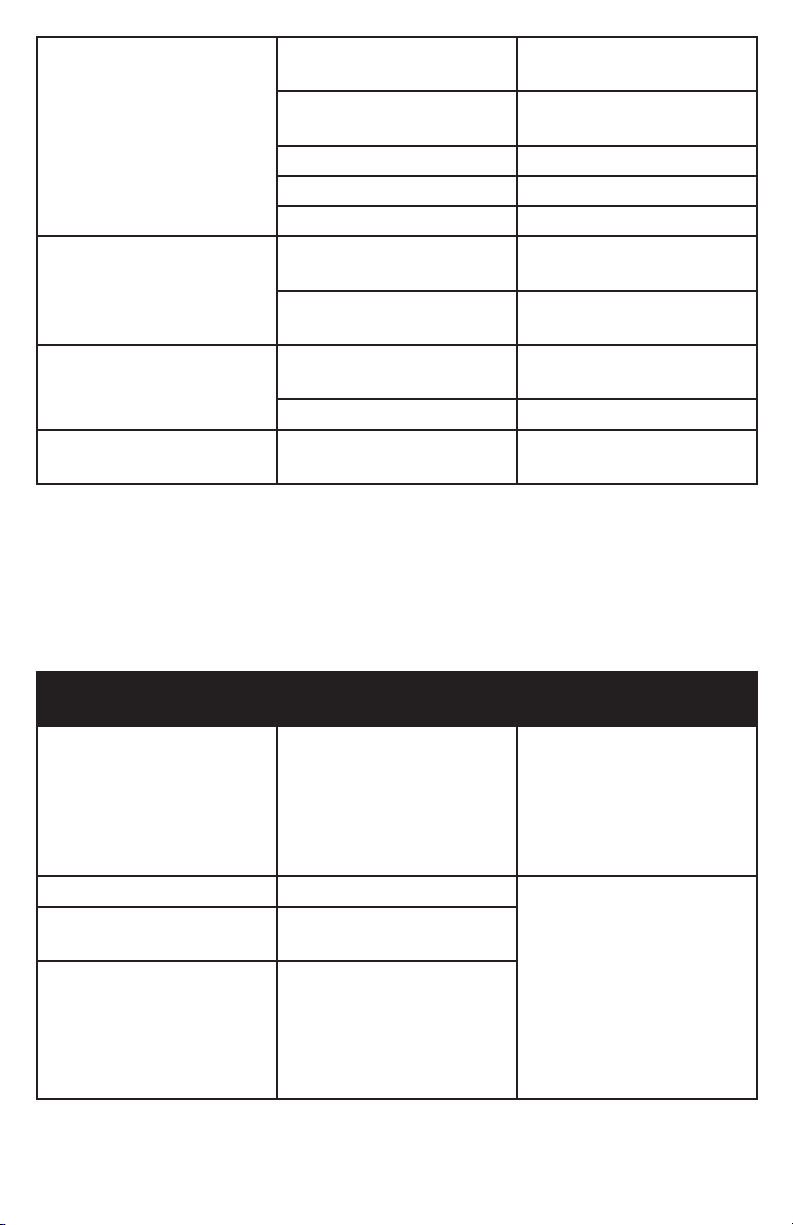

DISPLAY AND CONTROLS

NO. DESCRIPTION FUNCTION

1 Rotational direction Used to select a rotational direction (Fwd/Reverse)

of the micromotor.

2Micromotor operation direction. Displays the direction of the micromotor.

3Micromotor LED ON/OFF button Used to turn on and off LED.

4Micromotor LED indicator Indicates whether micromotor LED is running (LED

On signals LED is turned on).

5Spray On/Off button Used to switch on or off the spray function.

6Spray indicator Displays the operational state of the spray function;

water is sprayed when it is On.

7 Speed controller Used to set the operating speed of the motor.

8 Indicator of gear ratio selection Displays the selected gear ratio of the handpiece.

9Memory program selection button. Used to save the program values set in the memory

and select the saved program.

10 Gear selection button Used to select the gear ratio of the handpiece

connected to the motor.

11 Speed indicator Displays the operating speed of the handpiece.

Rear

NO. DESCRIPTION FUNCTION

1 Tubing connector-standard 4-hole

handpiece hose connector

Connect to handpiece hose from dental unit to

supply air & water, tubing connector per ISO

9168 type 3

2 Motor tubing / cable Motor tubing/cable, supplies power to the

motor, distributes air and water (it cannot be

separated from the control unit.)

3Power switch Main power switch for unit.

4Adapter connector Through which power gets supplied from the

adapter.

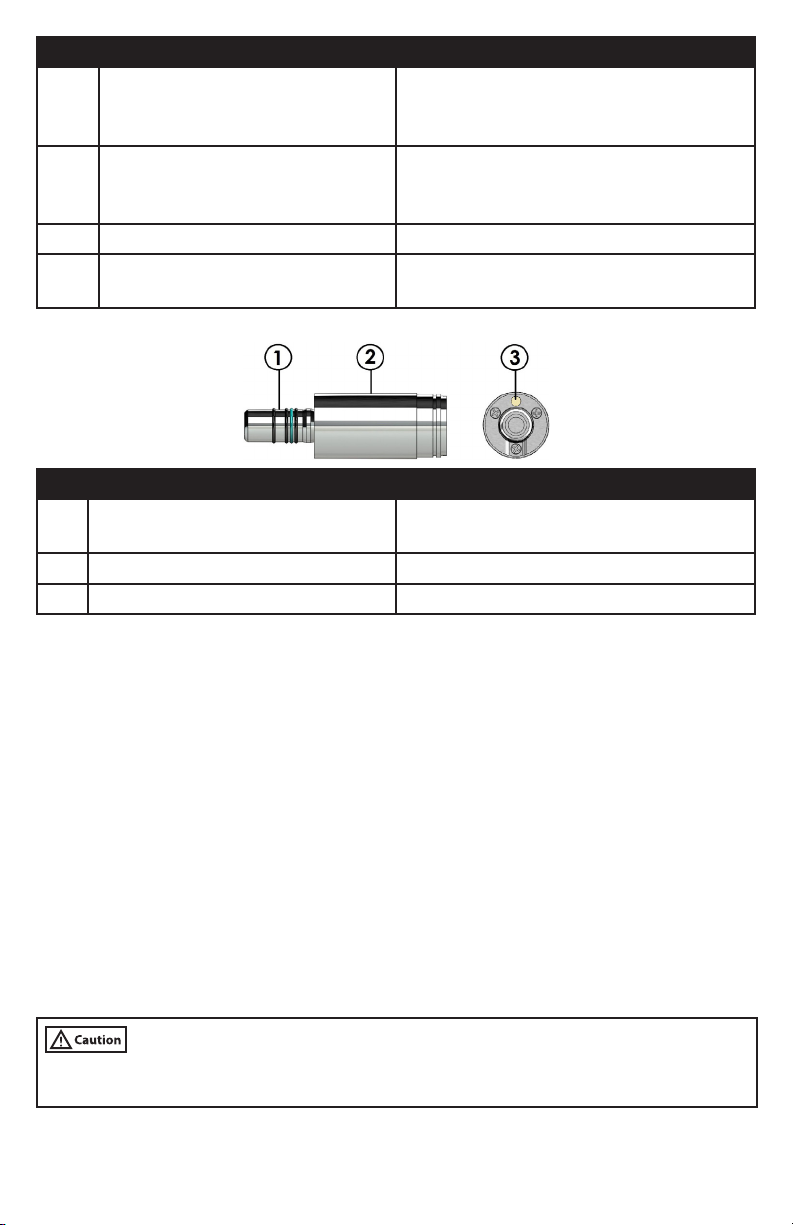

Micromotor

NO. DESCRIPTION FUNCTION

1Handpiece coupling connector Connect micromotor and a handpiece per ISO

3964 type 3

2Body Convert electrical energy to rotational motion

3Led Provide light

Additional Device Information

1. Type of protections against electric shocks Class I equipment

2. Degree of protections against electric shocks type B applied parts

3. Mode of operation Continuous operation

4. Applied parts

Handpiece: Used in connection with a micromotor Handpiece sold separately.

Environmental Conditions (Storage, Relocation, Operation,Shelf-life)

1. Storage condition

Temperature : 0°C ~ +50°C Humidity : 10 ~ 80% Air pressure : 500hPa ~ 1060hPa

2. Relocation conditions

Temperature : 0°C ~ +50°C Humidity : 10 ~ 80% Air pressure : 500hPa ~ 1060hPa

3. Operation conditions

Temperature : +10°C ~ +35°C Humidity : 30 ~ 80% Air pressure : 700~1060 hPa

4. Shelf-life

1 year based on standard fatigue shelf life of bearings the key components in the micromotor.

• Operation of the device in an environment other than those specified by manufacturer may

damage the device.

INSTALLATION & SET UP

• Check for damage to the cable and the connection pins prior to connecting with the

micromotor.

• Check system connection diagram and cable / motor connection illustration below prior to

installation.

System connection diagram

1. Medilectric Control box

2. Micromotor and hose

3. AC/DC Adapter 4-AC power plug

Connecting the micromotor with a cable / tubing and handpiece

1. Identify slot on micromotor and pin on motor tubing

connector (Fig.1)

2. Align and insert the pin on motor tubing connector

into slot on the motor terminal (Fig.2)

3. Turn the motor back nut clockwise to secure the

connection. (Fig.3)

4. To attach a handpiece (handpiece sold separately ) to

the micromotor, identify guide stud on handpiece and

hole on micromotor. (Fig. 4)

5. Lightly press the handpiece against the micromotor

while turning it slightly counterclockwise until the

guide stud click and lock into the hole . Pull the hand-

piece back to make sure the handpiece is securely

attached to the micromotor . (Fig.5) The micromotor

coupling is designed to fit most E-Type electric hand-

piece for dental procedure with coupling standard per

ISO 3964 type 3

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Handpiece Tubing Connector

1. Confirm that the delivery system tubing matches with

the back terminal of the control unit for connection

(Fig. 6) (coupling connection per ISO 9168 type 3

standard 4-hole handpiece hose)

2. Connect the tubing to the control unit and secure the

connection to prevent the air or water leakage (Fig.7) Fig. 6

Fig. 7

Connecting the AC/DC adapter Connection

• Only use power adapter supplied with this unit.

1. Insert the AC/DC adapter plug into the adapter

connector (Fig. 8)

Fig. 8

GENERAL OPERATION / PRECAUTIONS

Speed adjustment (Main function)

1. The speed can be set up to a maximum of 40,000 rpm (1:5 : 200,000 rpm, 1:1 : 40,000rpm)

by pressing the speed control button on the display.

Setting a rotational direction

1. The direction of the micromotor can be set by pressing the rotational direction selection

button on the control panel when the motor is not running.

2. When rotational direction indicator light is off, the motor is running in forward direction

(clockwise)

Setting optic LED On/Off

1. The LED installed in the micromotor can be turned on or off by pressing the OPTIC button on

the control panel.

Setting indicator for gear ratios of handpiece

1. The gear ratio can be displayed as 1:5, 1:1 depending on the gear ratio of the handpiece

selected with the use of the control panel.

2. The gear ratio can be adjusted to 1:5, 1:1 in a sequential order each time the operator

presses GEAR button. The selected gear ratio is highlighted.

Setting water spray

1. The water spray function can be turned on or off by pressing the SPRAY button on the

display. Selection of the program mode

2. Press and hold the button for selecting micromotor’s operational direction and the LED on/off

button simultaneously for 3 seconds or longer..

Memory program

1. How to save memory program : Customize settings of rotational direction, optic and so on;

Press and hold one of the three program buttons M1, M2, or M3 for 3 seconds or longer.

2. How to retrieve pre-saved program : Select the saved program by pressing P1, P2 or P3

button.

CLEANING & MAINTENANCE

Manual cleaning

NOTE:

• The Micromotor is provided Non-Sterile

• Clean and disinfect the micromotor and tubing before first use and after each patient

• Sterilize the motor after manual cleaning and disinfection.

• Routinely monitor dental unit water quality to ensure microbial counts are below the

levels for drinking water recommended by your local agency. The U.S. Centers for Disease

Control and Prevention (CDC) recommends a level of <500 CFU/ml of heterotrophic water

bacteria.

• After each patient use, disinfect the tubing waterlines include the handpiece and micro-

motor waterlines by flushing with cleaning water to prevent cross-contamination according

to handpiece waterlines disinfection procedure of main dental unit.

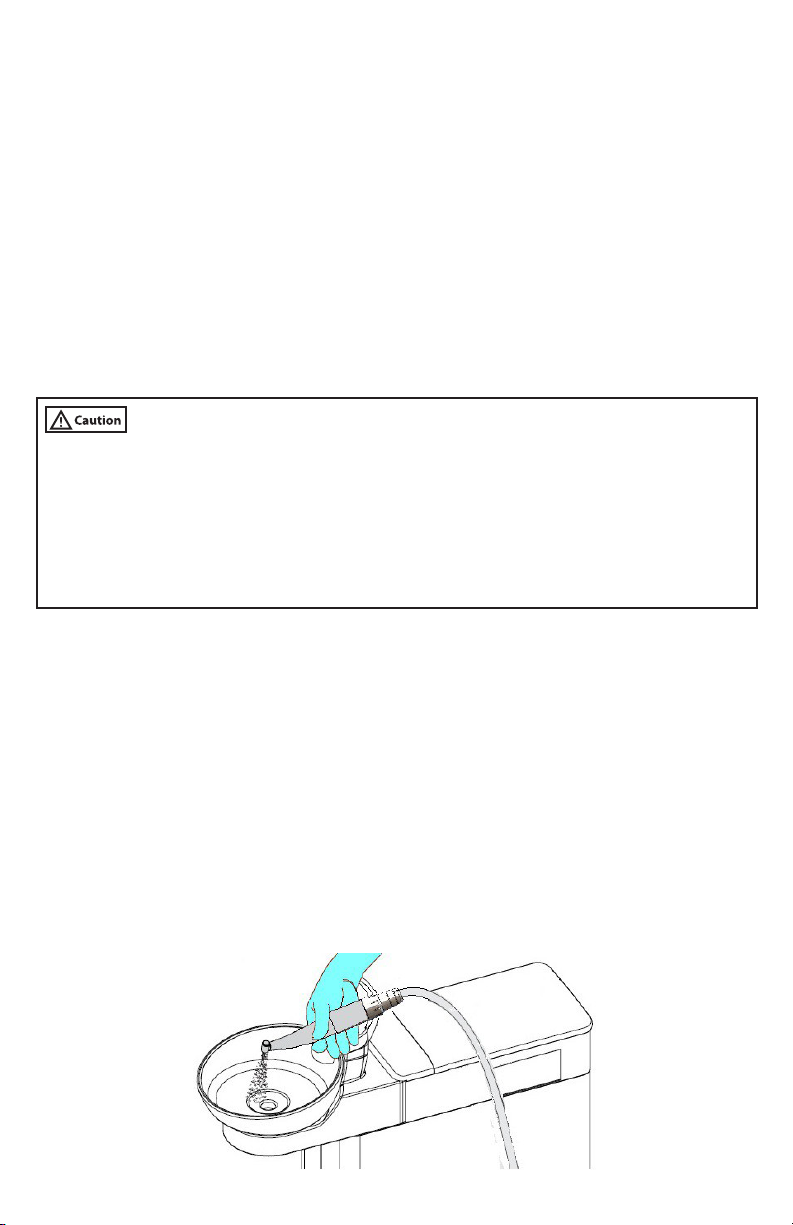

Manual internal cleaning for micromotor and motor tubing:

1. Internal cleaning waterlines , the Medilectric System must be conducted through the

main dental unit by connecting to standard 4 hole handpiece connector and follow the

instruction for handpiece and hose waterlines disinfection of the main dental unit.

(using the same procedure to disinfect waterlines of high speed handpieces on main dental

unit)

+ It is recommend to use Waterline Maintenance Tablets for main dental unit, it is the simple

way to maintaining clean dental unit waterlines.

2. Do not remove attached handpiece and the micromotor from the connecting cable during

internal waterlines cleaning and disinfection procedure.

3. Hold the handpiece with micromotor over the cuspidor or over a watertight container on main

dental unit with sufficient capacity and press the purging key on the main dental unit. Setting

time to clean and disinfect the waterlines base on manual instruction of main dental unit.

(Fig.9)

Fig. 9

Manual external cleaning for micromotor and motor tubing:

Recommendation for external cleaning accessories:

• Clean cotton cloth

• Soft brush-Nylon Bristles

• Alcohol 70% Isopropyl

• Protective glove uses during cleaning procedure.

1. For control box, micro motor cable / tubing (non removable) can be disinfected by wiping off

using soft cotton cloth with isopropyl alcohol.

2. For the micromotor, Disconnect the motor from the motor cable / tubing by turning motor

back nut counter- clockwise and gently pull the motor out. (Fig.10)

Fig. 10

• Use air spray to purge the waterline & remove excessive moisture from the micromotor. (Fig. 11)

• Use soft brush with isopropyl alcohol to clean exterior surface then wipe off with soft cotton

cloth.

• Visual inspection the cleanness of the micromotor prior to sterilization cycle.

Fig. 11

Fig. 12

STERILIZATION:

• Micro motor must be sterilized before first use and between each patient use by moist heat

accordance with ISO 17665-1 in a steam sterilizer (Autoclave)

• After manual cleaning(internal & external cleaning), follow the instruction below to autoclave

the micromotor:

1. Autoclave using Air Removal Steam type Sterilizer (pre-vacuum)

• Insert the motor into sterilization bag and load into autoclave. (We recommended using steril-

ization bag with at least one paper side.) The motor should be processed in the autoclave set

for a minimum of 4 minutes at a sterilization temperature of 1320C / 2700F and a minimum

dry time of 30 minutes.

2. For sterilization of attachment handpieces:

• Follow sterilization instructions provided by the manufacture of the handpiece.

Note: Replace the O-ring if

• Water or air leaks occur,

• The handpiece vibrates abnormally,

• The supply of water or air cannot be stopped, or

• It is difficult to install or remove the handpiece.

• There is no specific replacement period.

Changing the O-ring

To replace the motor O-rings: (Fig.13)

Fig. 13

1. Squeeze the O-ring together between your thumb and forefinger to form a loop.

2. Pull the O-ring off the motor.

3. Repeat steps 1 and 2 for the other three O-rings.

4. Slide on the new O-rings

NOTE: Always replace all four O-rings to ensure a secure connection between the motor and

attachment.

To replace the two small O-ring at the motor connection

back end: (Fig. 14)

1. Lift up the O-ring with a pair of tweezers and remove

the O-ring.

2. Carefully replace the two O-ring with new ones.

Fig. 14

NOTE: The ISO 11498 standard stipulates a durability of at least 250 sterilization cycles. We

recommend that you have the Medilectric Micromotor serviced after 500 sterilization cycles

or one year, whichever comes first.

TROUBLESHOOTING

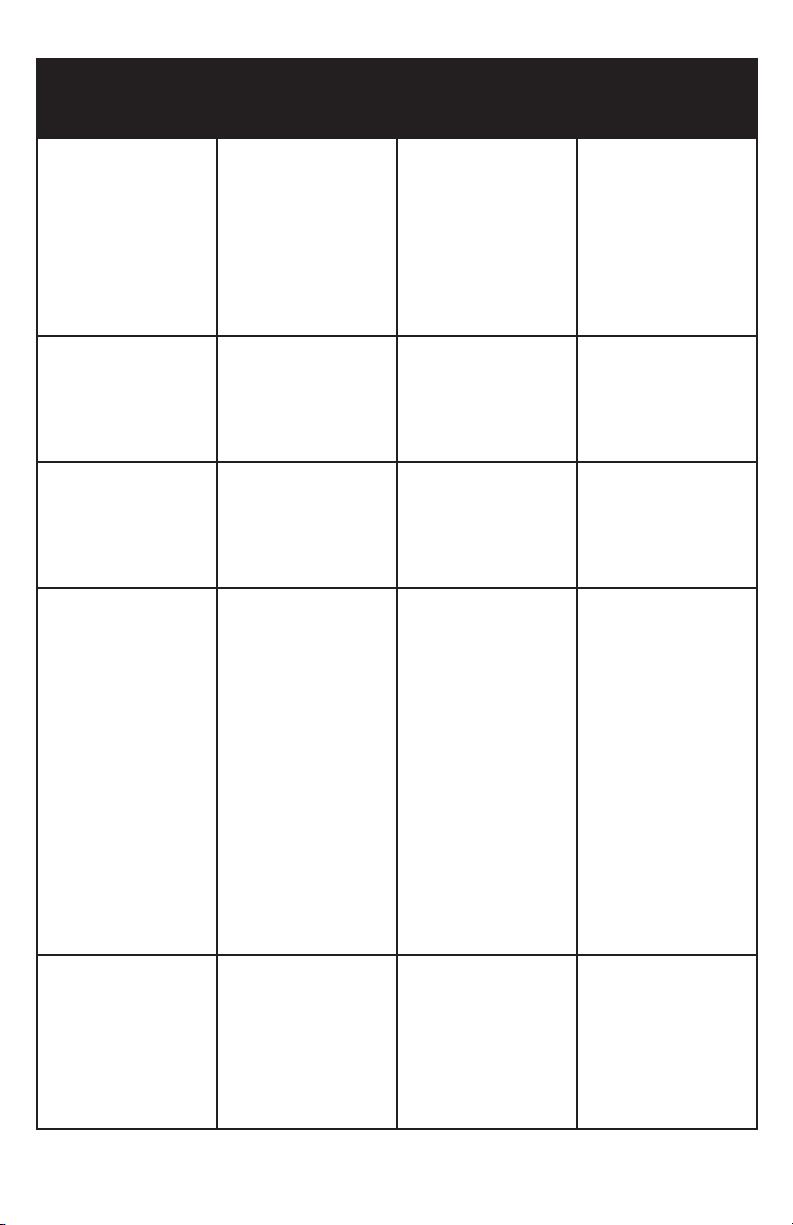

Error Message Reference Guide Types of Errors

ERROR CODE STATUS CAUSE OF ERROR REMEDY

E1 Micromotor connec-

tion error

Poor connection with

cable / tubing

Visually check

the micromotor

connection.

E2 Micromotor defect Poor micromotor

connection or micro-

motor damage

Replace the micro-

motor if the micro-

motor connection has

no issues.

E3 Micromotor overload Micromotor is being

overloaded

Stop running the

micromotor and

restart after cooling

it down for 3-5

minutes.

Descriptions of Malfunctions

MALFUNCTION TYPES CAUSE OF ERROR REMEDY

When the micromotor is not

running

Poor connection with a power

cable Check the power connection.

Poor connection with the

connection cable

Check the connection condi-

tion with the cable.

Control panel malfunction Contact the manufacturer.

Controller malfunction Contact the manufacturer.

Micromotor malfunction Contact the manufacturer.

When the micromotor speed

can’t get controlled.

Poor connection of the

connection code.

Check the connection

condition.

Control panel malfunction Contact the manufacturer for

a repair request.

When micromotor rotational

direction cannot be changed.

Poor connection with the

connection code.

Check the connection

condition.

Control panel malfunction Contact the manufacturer.

When the optic LED is not

working.

Failure of LED inside the

micromotor Contact the manufacturer.

ACCESSORIES

570-0685 Micromotor 570-0686 AC/DC Adapter 570-1058 O-ring Kit

ELECTROMAGNETIC COMPATIBILITY

Electromagnetic Emission

The product is suitable for use in a specific electromagnetic environment. The customer and/

or the user of the product should assure that it is used in an electromagnetic environment as

described below.

EMISSION TEST COMPLIANCE ELECTROMAGNETIC

ENVIRONMENT GUIDANCE

RF-emission CISPR 11 Group 1

The product use RF energy

only for its internal function.

Therefore, its RF emissions

are very low and not likely

to cause any interference in

nearby electronic equipment.

RF-emission CISPR 11 Class A The product is suitable for

use in all establishments,

including domestic estab-

lishments and those directly

connected to the public

low-voltage power supply

network that supplies build-

ings used for domestic

purpose.

Harmonic emissions IEC

6100-3-2 Class A

Voltage fluctuations/ flicker

emissions IEC 61000-3-3 Complies

Electromagnetic Immunity

The product is suitable for use in a specific electromagnetic environment. The customer and/

or the user of the product should assure that it is used in an electromagnetic environment as

described below.

IMMUNITY TEST EC 60601-LEVEL COMPLIANCE LEVEL ELECTROMAGNETIC

ENVIRONMENT

GUIDANCE

Electrostatic

discharge(ESD)

IEC61000-4-2

± 6kV contact

± 8kV air

± 6kV contact

± 8kV air

Floor should be

wood, concrete or

ceramic tile. If floors

are covered with

synthetic material,

the relative humidity

should be at least

30 %

Electrical fast

transient/bursts

IEC61000-4-4

± 2kV for power

supply lines

± 1kV for input/

output lines

± 2kV for power

supply lines

± 1kV for input/

output lines

Mains power quality

should be that of

a typical commer-

cial and/or hospital

environment

Surge IEC61000-4-5 ± 1kV differential

mode

± 2kV common mode

± 1kV differential

mode

± 2kV common mode

Mains power quality

should be that of

a typical commer-

cial and/or hospital

environment

Voltage dips, short

interruptions and

voltage variations

on power supply input

lines IEC61000-4-11

<5% UT (>95% dip in

UT) for 0.5 cycle 40%

UT (60% dip in UT)

for 5 cycles 70% UT

(30% DIP IN UT) for

25 cycles

<5% UT (>95% dip in

UT) for 5 sec

<5% UT (>95% dip in

UT) for 0.5 cycle 40%

UT (60% dip in UT)

for 5 cycles 70% UT

(30% DIP IN UT) for

25 cycles

<5% UT (>95% dip in

UT) for 5 sec

Mains power quality

should be that of

a typical commer-

cial and/or hospital

environment. If the

user of the product

requires continued

operation during

power mains inter-

ruptions, it is recom-

mended that the

product be powered

from an uninterrupted

power supply or a

battery.

Power frequency

(50/60 Hz) magnetic

field IEC 61000-4-8

3A/m 3A/m Power frequency

magnetic fields

should be at levels

characteristic of a

typical lo - cation in a

typical commercial or

hospital environment.

IMMUNITY TEST EC 60601-LEVEL COMPLI-

ANCE LEVEL

ELECTROMAGNETIC ENVIRONMENT

GUIDANCE

Conducted RF

IEC 61000-4-6

Radiated RF IEC

61000-4-3

3 Vrms

150 kHz

to 80 MHz 3V/ m

80 MHz

to 2.5 GHz

3 Vrms

3 V/m

Portable and mobile RF communi-

cations equipment should be used

no closer to any part of the product,

including cables, than the recom-

mended separation distance calcu-

lated from the equation applicable to

the frequency of the transmitter.

Recommended separation distance: d

= 1.2√P

d = 1.2√P for 80 MHz to 800 MHz d =

2.3√P for 800 MHz to 2.5 GHz

where P is the maximum output

power rating of the transmitter in

Watt (W) according to the transmitter

manufacturer and d is the recom-

mended separation distance in meters

(m) Field strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey a, should

be less than the compliance level b in

each frequency

range Interference may occur in the

vicinity of equipment marked with the

symbol described lateral

Note 1: At 80 MHz and 800 MHz, the higher frequency range applies.

Note 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected

by absorption and reflection from structures, objects, people and animals.

a-Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless)

telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast

cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due

to fixed RF transmitters, an electromagnetic site survey should be considered, if the measured

field strength in the location in which the product is used exceeds the applicable RF compliance

level above, the product should be observed, additional measures may be necessary, such as

reorienting or relocating the product.

b-Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

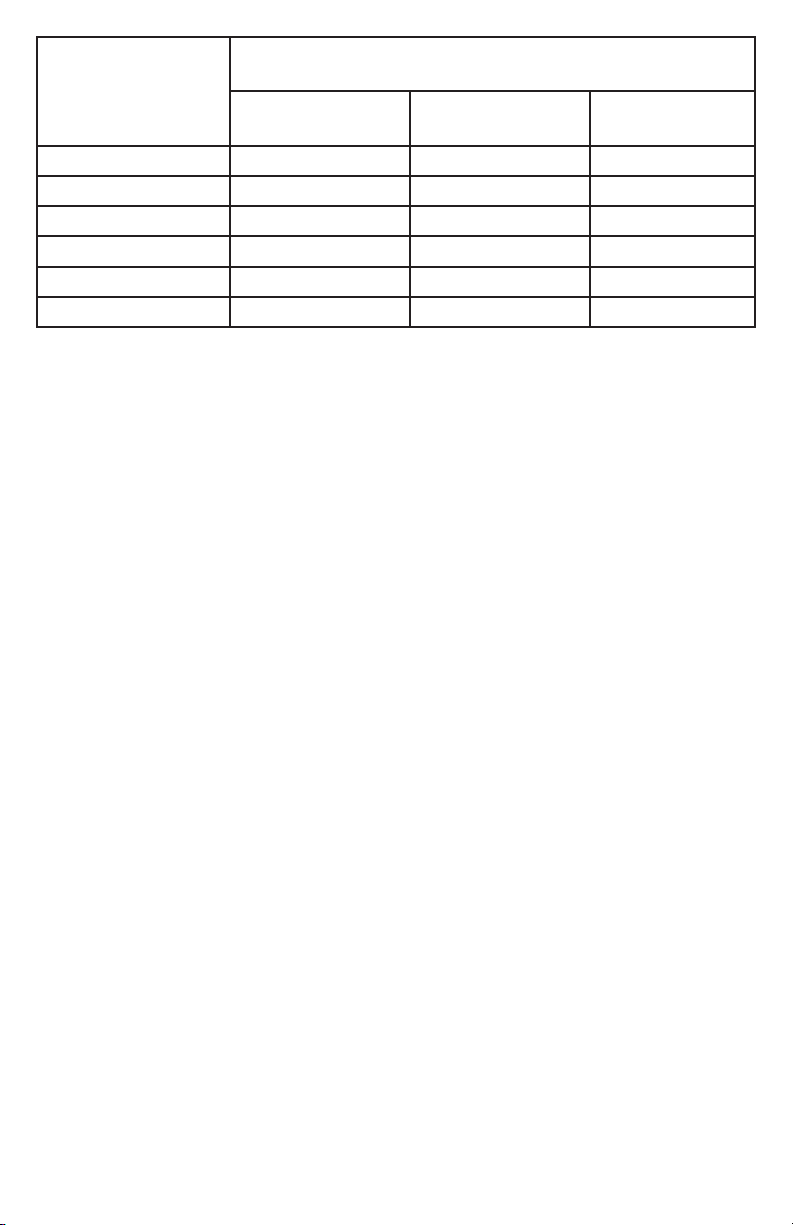

Recommended Separation Distances between portable and mobile HF- communications equip-

ment and the product

The product is intended for use in an electromagnetic environment in which radiated

RF disturbances are controlled. The customer or the user of the product can help prevent elec-

tromagnetic interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the product – according on output power and

frequency of the communications equipment – as recommended in the following table.

Rated maximum output

power of transmitter in

watts (W)

Separation distance according to the frequency meters (m) of trans-

mitter in meters (m)

150 kHz to 80 MHz d

= 1.2√P

80 MHz to 800 MHz d

= 1.2√P

800 MHz d = to 2.5

2.3√P

GHz

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

11.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

PRODUCT DISPOSAL GUIDELINE

Disposal of Medical Devices

1. Follow your country specific laws, directives, standards and guidelines for the disposal of

used electrical devices

2. Ensure that the parts are not contaminated on disposal

Disposal of the packaging material

1. All packaging materials have been selected considering environmental protection and can

be recycled. Please send old/used packaging materials to the collection and reprocessing

centers appropriate per local laws and regulations to minimize waste.

WARRANTY

This product is designed for use in a dental office and this warranty is not applicable to other

uses. This product is warranted against manufacturing defects in materials and workmanship for

2years from date of purchase.

Medidenta will repair or replace product at its sole discretion. This warranty shall be limited

to replacement or repair of the product or its parts and shall not extend to any other claims,

including but not limited to loss of profit, cost of removal or replacement, incidental or conse-

quential damages or other similar claims arising from use of this product. Damage to product

resulting from acts of God, faulty installation, misuse, tampering, accident, abuse, negligence,

alterations, unauthorized repairs or problems unrelated to materials and workmanship are not

covered by this warranty.

Distributed by

MADE

IN

SOUTH

KOREA

Medidenta

731 Pilot Rd, Ste L

Las Vegas, NV 89119

IFU-MEDILECTRIC

001

REV.

11/19

Phone: 800-221-0750

Fax: 702-749-8610

Table of contents

Other Medidenta Media Converter manuals

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide