Medidenta Sonus Operation instructions

Medidenta

Toll Free: 800.221.0750

Web: www. Medidentaendo.com

Email: [email protected]

3575 W. Post Rd. , Las Vegas, NV 89118

LED Piezo U l trason ic Scaler

User and Operating Manual

Read this manual carefully before operating.

Keep it in a safe place for further consultation

Contents

1. Installation. Components description ........................................... 3

2. Installation. Setup .......................................................................... . 7

3. Maintenance. Troubleshooting.................................................... 16

4. Cleaning, disinfection and sterilization ...................................... 20

5. Precautions. Contraindications……………………………….... 27

6. After service ...................................................................................32

7. Symbolsinstructions.....................................................................33

8. Environmental protection .............................................................34

9. Manufacturer’s liability..................................................................34

10. European authorized representative ..........................................34

11. EMC - Declaration of conformity .................................................35

12. Statement........................................................................................39

13. Tips Power Table ........................................................................... 40

3

1. Installation. Components description.

1.1 Introduction

Thanks for purchasing the SonusTM LED Piezo Ultrasonic Scaler.

The Medidenta medical device that you are about to install

and use in your practice is a medical device designed for

professional use. It comprises the chosen tool with which you will

provide treatment within the context of your work.

To ensure optimum safety for yourself and your patients, comfort in

your daily practice and to benefit fully from the technology of your

medical device, please read the documentation provided carefully.

If youhave received this medical device by mistake, please contact

Medidenta to arrange for it to be collected.

This piezoelectric unit is used for preservation and restoration

dentistry, including hygiene, periodontics, endodontics,implant

maintenance, restorative and prosthesis.

WARNINGS:

•Read all instructions before operating this unit. The manufacturer

accepts no liability for any damage resulting from improper use of this

unit and/or for any purpose other than those covered by these

instructions.

•US Federal law restricts this unit to sale by or on the order of a

dentist.

•As per Endodontic Standards of Care, always use a rubber dam

when performing endodontic treatment.

•Do not use dry heat sterilization on any of the device’s components.

1.2 Components description

1.2.1 The components are listed in the packing list.

1.2.2 Sonus LED Piezo Ultrasonic Scaler is composed of circuit board,

water pump, reservoir (tank and accessory bottles), and ultrasonic

transducer handpiece.

1.2.3 Sonus LED Piezo Ultrasonic Scaler is used dental procedures

4

such as hygiene, periodontics, endodontics, implant maintenance

and cavity preparations.

1.3 Technical specifications

1.3.1 LED Piezo Ultrasonic Scaler:

a) Main unit input: 110V~ 50Hz/60Hz 280 mA.

b) Output primary tip vibration excursion: ≤90μm.

c) Output half-excursion force: <2N.

d) Output tip vibration frequency: 28kHz±3kHz.

e) Output power: 3W to 20W.

f) Main unit fuse: T0.5AL 250V.

g) Water pressure: 0.01MPa to 0.5MPa.

h) Weight of main unit: 3.97 pounds (1.8 Kg).

i) Operating mode: Continuous operation.

j) Type of protection against electric shock: class II equipment.

k) Degree of protection against electric shock: Type BF applied part.

l) Applied part of the equipment: handpiece and tip. Degree of

protection against harmful ingress of water: ordinary equipment.

Foot switch is drip-proof equipment (IPX1).

m) Degree of safety of application in the presence of a flammable

anesthetic mixture with air, oxygen or nitrous oxide: equipment not

suitable for being used in the presence of a flammable anesthetic

mixture with air, oxygen or nitrous oxide.

5

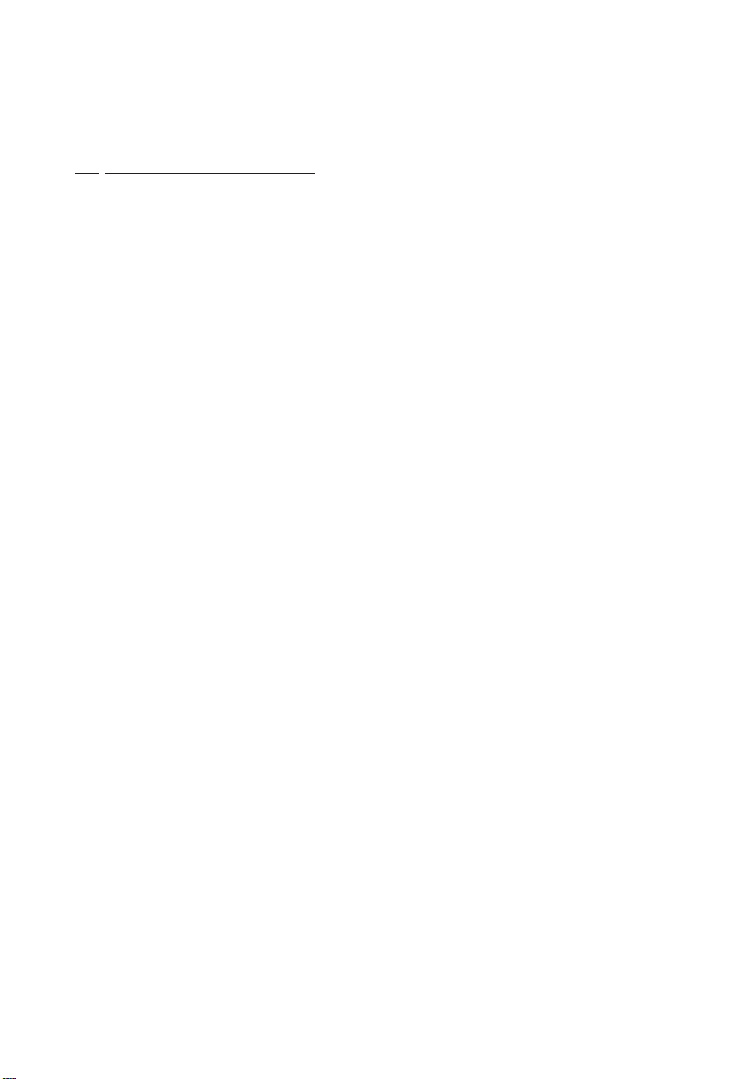

1.4.2 Main components

Main unit (front)

Fig. 1. Front view details.

Main unit (back)

Fig. 2. Back view details.

6

Handpiece components

Fig. 3. Handpiece.

Handpiece/handpiece cable coupling

Fig. 4. Handpiece and handpiece cable connection alignment guides

matching.

Tip installation. Torque Wrench/ Wrench

Fig. 5. Torque wrench and wrench.

7

Touch screen display with water, vibration and power (amplitude)

controls.

Fig. 6. Touch screen display.

Accessory bottles.

Fig. 7. Accessory bottles (300 ml maximum) for irrigants.

2. Installation/Setup

2.1 Unpacking the device

WARNING:

When you receive your medical device, check for any damage that

may have occurred during transportation. If you have received this

medical device by mistake, please contact the supplier to arrange for

it to be collected.

2.1.1 Open the packing box. Make sure that all parts and

accessories are complete according to the packing list. Take the main

8

unit out of the box, and place it on a secure and flat surface facing to

the operator.

2.1.2 Installing cords. Check if the cords do not hinder the

movement or free circulation of anyone.

2.1.3 Never rotate the handpiece connector on its cord as this

can damage your medical device.

2.1.4 Never wrap the handpiece cord around the medical

device.

2.1.5 Make sure that it is not possible to wheel over or walk on

the different cords.

2.1.6 Set the device to OFF position (power switch, Fig. 2).

Check that the power voltage is compatible with that indicated

on the device or its power plug.

WARNING:

Sonus voltage is 110V, 50-60Hz, 280 mA.

2.1.7 Next, connect the cord to the wall socket in compliance

with the standards in force in the country of use.

2.1.8 A different voltage would cause damage to the medical

device and could injure the patient and/or user. Any variation in

the electrical network voltage or electromagnetic field that is

non-compliant with the limits in force, could interfere with the

medical device’s operation.

2.1.9 The medical device’s ground must be connected to a

supply network equipped with a protective ground.

2.1.10 Turn the irrigation flow control knob (Fig. 1) to maximum

turning the knob counterclockwise. Turn the water line flow control

knob (Fig. 2) to maximum turning the knob counterclockwise. Do not

screw it over tight.

2.1.11 Insert the foot pedal cord plug to its socket (Fig. 2).

9

If you are going touse the water line:

2.1.12 Connect one end of the water pipe to the water entrance, and

the otherend to the clean water source (Fig. 2).

NOTE:

The water line hoseand its connectors are not included in this

device package.

WARNINGS:

•The CDC recommends that dental unit water used in

nonsurgical procedures measure less than or equal to 500 colony

forming units of heterotrophic bacteria per milliliter (≤500 CFU/mL)

of water, the standard set for drinking water by the Environmental

Protection Agency (EPA).

•Use sterile saline or sterile water as a coolant/irrigant when

performing surgical procedures (such prophylaxis, scaling and/or

periodontics treatments).

•Follow dental unit manufacturer’s instructions for maintaining

and monitoring the quality of dental unit water.

2.1.13 With the water connections in place, press the water line mode

button on the touch panel (Fig. 6).

If you are going to use the reservoir (tank) or bottles:

WARNING:

The device is equipped with a reservoir (tank) and accessory bottles

(Fig. 7) designed to hold the irrigation solution. The irrigation solution

reservoir is fitted with a cover. Neither the reservoir, the cover or

accessory bottles can be sterilized.

2.1.14 Fill the reservoir up to the line with distilled water. Do not

overfill. With the reservoir/bottles in place, press the

reservoir mode button on the touch panel (Fig. 6).

2.1.15 Sonus comes with accessories bottles (Fig. 7) to be used

during endodontic irrigation. Place the bottle for different solutions

10

activation/irrigation.

WARNING:

Do not leave the reservoir (original tank or accessorybottles) with

irrigants in place after finishing the procedure. The permanent

contact of the reservoir/bottles filled with endodontic irrigants (i.e.,

sodium hypochlorite, EDTA, chlorhexidine and others) can cause

permanent corrosion of the internal parts of the device.

2.1.16 Choose the tip accordingly (see tips Tip Power Table, pg. 40),

and install it using the torque wrench (Fig. 5). For install endodontic

(E) tips, use the wrench (both included).

WARNING:

The screw thread of the tips produced by other manufacturers

maybe coarse, rusty and collapsed, which will damage the

screw thread of the handpiece irretrievably. Please use Medidenta

brand tips.

2.1.17 Turn on the power switch (Fig. 2).

WARNING:

Every time that the device is turn off and turn on again, the system

will be pre-configurated for power (amplitude) 1, vibration mode E

(for endodontics tips) and reservoir/tank/bottle irrigant mode (Fig. 8).

Fig. 8. Pre-set configuration after turning the device on.

11

2.1.18 Use the touch panel for adjusting the water/irrigant supply mode

(water line or reservoir modes), vibration intensity modes (G, P or E)

and power (1-10, amplitude).

2.1.19 Vibration intensity mode (buttons G, P and E): adjust the

vibrating intensity according to the procedure:

•G(scaling, hygiene)

•P(periodontics, and cavity preparation)

•E(endodontics, including endodontics irrigation/activation)

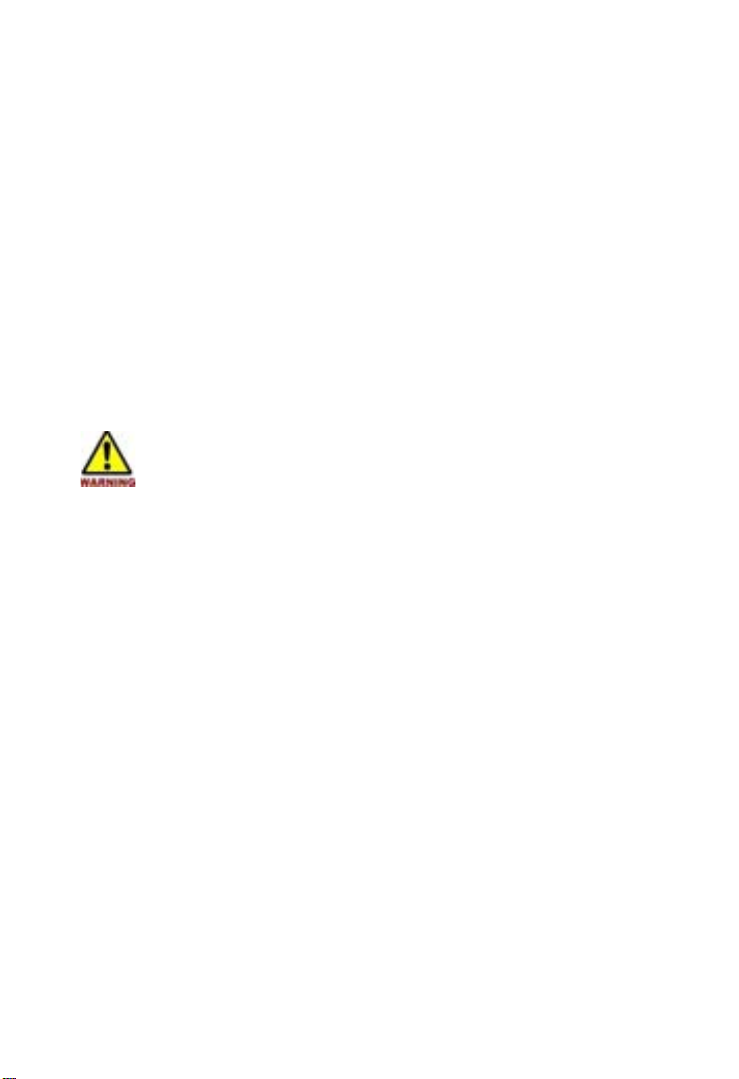

2.1.20 Sonus uses the Stype tips screw thread design configuration.

Sonus tips are identified by letters and numbers. The first letter

indicates the vibration intensity model, starting with G (scaling,

hygiene), P (periodontics), E (endodontics), and SB (for cavity

preparation). The second letter refers to the screw design type (Fig.

9).

Fig. 9. Example of Sonus tip with the number/letters code identification. Letter

Estands for endodontic tip; letter Dstands for S type screw design tip.

WARNING:

Always use Stype tips for Sonus. It is highly recommended to use

Medidenta ultrasonic tips with the Sonus LED Piezo Ultrasonic

Scaler. Do not use Etype tips (consult tip instructions for use before

using ultrasonic tips). The screw thread of the tips produced by

other manufacturers maybe coarse, rusty and collapsed,

which will damage the screw thread of the handpiece

irretrievably. It is highly recommended to use Medidenta brand

12

tips.

2.1.21 Choose the vibration intensity mode (G, P or E) based on the

procedure/tip you are willing to perform (Fig. 6).

IMPORTANT:

Pressing twice the Ebutton the system will go to irrigation mode (E

mode at power amplitude 3). This feature allows the proper set for

polymer irrigation tips. In this setup the Ebutton at the touch panel

will blink.

2.1.22 Choose the water/irrigant source pressing the water line

mode or reservoir mode button.

2.1.23 Water/irrigant volume adjustment: step on the foot switch (control

pedal). The tip begins to vibrate.

•If you are using the reservoir mode: turn the irrigation flow control

knob (Fig. 1) clockwise/counterclockwise.

•If you are using the water line mode: turn the water line flow control

knob (Fig. 2) clockwise/counterclockwise.

Adjust the knob to achieve a suitable irrigant spray to cool down the

handpiece and helps to rinse the treatment area. This adjustment

depends on the tip design and procedure. As work habits, feedback and

professional training differ from one professional to another, the user

must make sure that the irrigation flow is perfectly adapted to the

treatment to be carried out to avoid burning the treatment area. Adjust

to the minimal irrigant volume for continuous flow endodontic irrigation

(CUI).

CAUTION:

•Always use PPE devices such as visor, face mask and high

evacuation system to evacuate aerosol from the field of operation.

Clean thoroughly the area around the perimeter of usage with

proper disinfectants.

13

2.1.24 Operating power adjustment (scale number from 1 to 10):

always start the power at a minimal rate (1), adjusting/increasing

during the clinical treatment according to the procedure

development. Various factors need to be evaluated such as patient's

sensitivity, and/or volume of calculus, among others.

WARNING:

Consult “Tips Power Table”(pg. 40) before starting the procedure.

Special attention needed to endodontic procedures such as

activation/irrigation with polymer tips (Polysonic tip using the

ED70 connector). These tips need to be activated (turned on)

only when inside the canal, with operating power level from 1

(minimum) to 3 (maximum).

2.1.25 Start the ultrasonic vibration stepping on the foot switch pedal.

Once the tip begins to vibrate, a LED light on the top of the handpiece

(Fig. 3) turns on. Once the foot switch is released, the LED ilumination

will stay on for 10 seconds.

When using hygiene/scaling/periodontics tips, do not use

excessive pressure when the tip touches the enamel surface.

Always use horizontal orientated movements (Fig. 10) with the tip

slightly angled toachieve efficiency with lower sensitivity.

Fig. 10 Horizontal movements with the tip slightly angled.

WARNING:

14

2.1.26 After finishing operation, remove the reservoir

and dispose the remaining irrigant. Rinse the tank with

water. Fill the tank with distilled water to a quarter of its

capacity. Reinstall the tank. Start the cleaning mode by

pressing simultaneously the two buttons on

the touch screen panel (water line mode and reservoir

mode buttons, Fig. 6). A single beep alarm will sound and the

reservoir mode button will start to blink. Step on the foot switch once

to start the cleaning mode (purge) cycle. A continuous flow volume

of distilled water will clean the system internally, preventing corrosion

or mineral accumulation automatically for 30 seconds. Step on the

foot switch for ending the cleaning mode cycle before 30 seconds if

necessary. After the cleaning cycle, press again the two buttons

simultaneously to exit cleaning mode.

2.1.27 Unscrew the tip, verify any worn or distortion. Clean and

sterilize it.

WARNING:

Do not screw/unscrew tips when the device is on (stepping on the

foot switch pedal).

2.2 Cleaning mode (purge cycle)

It is important to clean internally (purge) the device after use to

prevent corrosion or mineral deposits alongside the system.

2.2.1 Operation:

a. After finishing operation, remove the reservoir and dispose the

remaining irrigant. Rinse the tank with water. Fill the tank with distilled

water to a quarter of its capacity.

b. Reinstall the tank. Press simultaneously the two buttons on the

touch screen panel (water line mode and reservoir mode

buttons, Fig. 6).

c. A single beep alarm will sound and the reservoir mode button

will start to blink . Step on the foot switch once to start the

15

cleaning mode (purge) cycle. A continuous flow volume of distilled

water will clean the system internally, preventing corrosion or mineral

accumulation automatically for 30 seconds.

d. Step on the foot switch pedal for ending the cleaning mode

cycle before 30 seconds if necessary. After the cleaning cycle, press

again the two buttons simultaneously to exit cleaning mode.

WARNING:

•Cleaning mode (purge cycle) needs to be done always after the

use of reservoir (tank) or accessory bottles.

•Do not leave irrigants/water inside the reservoir/bottles after use.

Discard the irrigants used ina proper way.

•Special attention with corrosive irrigants like sodium hypochlorite

is need. Do not use concentrations more than 2.5%. Handle

sodium hypochlorite with maximum care.

16

3. Maintenance

3.1 Troubleshooting

Fault Possible cause Solutions

No operation. The

tip doesn't vibrate,

and there is no

water flowing out

when stepping on

the foot switch.

No electrical current. Contact your electrician.

Faulty connection

between the power cord

and the electrical wall

socket.

Connect the power cord

to the electrical wall

socket properly.

The foot switch is in

loose contact.

Insert the foot switch to

its socket tightly.

Internal fuse is not

working.

Contact

Medidenta.

The tip doesn't

vibrate but there is

water flowing out

when stepping on

the switch.

The tip is in loose

contact.

Make sure that the

right tip (S type) is

being used. Screw the

tip on the handpiece

tightly.

Handpiece and

handpiece cord are in

loose contact.

Make sure there is no

gap between the

handpiece and the

handpiece cord

coupling.

The tip vibrates

but there is no

spray when

stepping on the

foot switch.

The water control knob

is off or at minimum.

Turn on the water

control knob. Adjust

the flow turning the

knob counterclockwise.

No irrigation solution at

the tank.

Fill the tank with

irrigation solution.

17

The tip does not

vibrate at the

expected

frequency, the

treatment is not

progressing as

normal and is

taking longer or is

at a standstill.

The tip hasn't been

screwed on completely

to the handpiece.

Make sure that the

right tip (S type) is

being used. The E type

screw thread is very

similar but with a

slightly different thread

configuration. Replace

with a S type

(Medidenta

recommended) and

screw the tip on the

handpiece tightly.

The tip is loose.

Screw on the tip tightly.

The coupling between

the handpiece and the

handpiece cord isn't

dry.

Thoroughly fry the

electrical contacts.

The tip is damaged. Replace the tip.

Polymer tip is

melting at the end

part of the tip.

Excessive heat during

vibration.

Do not activate (turn

on) the tip outside the

canal. Use the right

vibration (E) mode and

the right power (1-3).

Make sure there is

irrigation.

There is liquid

leaking from the

coupling between

the handpiece

and handpiece

cord.

The waterproof O-ring is

damaged. Replace the waterproof

O-ring.

18

The handpiece

generates heat.

Low irrigant flow.Adjust the flow to

a higher rate.

No spray. Low

spray.

Low irrigant flow.

Turn the knob to

a high

grade [note 1].

The water pressure is

not

enough.

Enhance the

water

pressure.

The water pipe is

jammed.

Clean water pipe

with air-water

syringe

[note2].

The vibrating

intensity control

knob is seized

up.

The potentiometer is

damaged.

Contact

Medidenta.

LED light is off.

Poor contact.Contact tightly.

LED worn.Replace the LED.

If the problem still can't be solved, contact Medidenta.

19

3.2 Corrective maintenance

In the event of faulty operation, the following corrective maintenance

actions may be performed by the user.

3.2.1 Clean the water pipe with the air-water syringe (Fig. 11):

Fig. 11. Water line at the back of the unit.

a. Snip the water pipe at a distance of 5 to 7 inches from the

external water connection.

b. Turn on the power switch.

c. Adjust the tip of the air-water syringe to the water pipe.

d. Screw off the tip or pull out the handpiece.

e. Step on the foot switch.

f. Turn on the air-water syringe pressing air or water into the water

pipe to unblock the system.

3.3 Cleaning mode

It is important to purge the system after use preventing corrosion or

mineral deposits alongside the internal system.

3.3.1 Operation:

a. After finishing operation, remove the reservoir and dispose the

remaining irrigant. Rinse the tank with water. Fill the tank with distilled

water to a quarter of its capacity. Reinstall the tank. Press

simultaneously the two buttons on the touch

screen panel (water line mode and reservoir

mode buttons, Fig. 6).

20

b. A single beep alarm will sound and the reservoir mode

button will start to blink. Step on the foot switch once to start

the cleaning mode (purge) cycle. A continuous flow

volume of distilled water will clean the system internally, preventing

corrosion or mineral accumulation automatically for 30 seconds.

c. Step on the foot switch pedal for ending the cleaning mode cycle

before 30 seconds if necessary. After the cleaning cycle, press again

the two buttons simultaneously to exit cleaning mode.

4. Cleaning, Disinfection and Sterilization

The cleaning, disinfection and sterilization of handpiece, tip, and

wrench (include torque wrench and wrench) are as follow.

Unless otherwise stated, it will be hereinafter referred to as “products”.

WARNINGS:

•The use of strong detergent and disinfectant (alkaline pH>9 or acid

pH <5) will reduce the life span of products. And in such cases, the

manufacturer takes no responsibility.

•Do not clean the handpiece with ultrasound cleaning machine. This

device shall not be exposed to high temperature above 138℃.

•Processing limit. The products have been designed for a large

number of sterilization cycles. The materials used in manufacture were

selected accordingly. However, with every renewed preparation for

use, thermal and chemical stresses will result in ageing of the

products. The maximum number of sterilizations for handpiece is 600

times. For tips, it is 300 times. And for wrench, it is 1000 times.

4.1 Initial processing

4.1.1 Processing principles

It is only possible to carry out effective sterilization after the completion

of effective cleaning and disinfection. Please ensure that, as part of

your responsibility for the sterility of products during use, only

sufficiently validated equipment and product-specific procedures are

used for cleaning/disinfection and sterilization, and that the validated

Table of contents

Other Medidenta Media Converter manuals

Popular Media Converter manuals by other brands

Behringer

Behringer ULTRAGAIN PRO-8 DIGITAL ADA8000 quick start guide

Mitsubishi Electric

Mitsubishi Electric AJ65SBT2B-64DA user manual

Avenview

Avenview 3G/HD/SD-SDI to HDMI Converter user guide

Radial Engineering

Radial Engineering MR5 user guide

Lantronix

Lantronix S3100 Series install guide

ABB

ABB TEIP11 operating instructions

URIT Medical Electronic

URIT Medical Electronic VRN DA-20 user manual

D-Link

D-Link 1000Base-T to mini-GBIC Media Converter... Quick installation guide

IMC Networks

IMC Networks McBasic-Gigabit Operation manual

Singmai Electronics

Singmai Electronics SM06 user manual

CTS

CTS IAC-3012 user guide

CYP

CYP DCT-9 Operation manual