Medivators VERISCAN LT User manual

User Manual

Automated Endoscope

Leak Tester

REPROCESSING SYSTEMS

LT

Veriscan®is a registered trademark of Minntech Corporation.

Fujinon®is a registered trademark of Fujinon Corporation.

OLYMPUS®is a registered trademark of Olympus Corporation.

PENTAX®is a registered trademark of Pentax Precision Instrument Corporation.

Storz®is a registered trademark of Karl Stroz.

50096-988 Rev A

© 2009, MINNTECH CORPORATION

All rights reserved. This publication is protected by copyright. Copying, disclosure to

others, or the use of this publication is prohibited without the expresswritten consent

of Minntech Corporation.

Minntech reserves the right to make changes in the specications shown herein

without notice or obligation. Contact your Medivators representative or Medivators

customer service for more information.

USERS MANUAL | 3

Table of Contents

Introduction ................................................................... 5

Using this Manual ....................................................... 5

Product Description .................................................... 5

Product Specications ............................................... 6

Safety ..............................................................................7

Intended Use .............................................................. 7

Electrical Compliance ................................................. 7

Operator Safety ......................................................... 7

General Cautions ....................................................... 7

Guidelines .................................................................. 8

Cleaning and Disinfection ..................................... 8

System Components..................................................... 9

System Features.......................................................... 10

System Setup............................................................... 11

Performing a Leak Test ................................................14

Performing a Screening test ...................................... 17

Testing a Failed Endoscope ....................................... 19

Daily Quality Assurance Test ..................................... 21

Data Access and Management....................................22

Main Menu ............................................................... 22

Printing and Quick Reports ...................................... 26

ProV-LT Data Management Software ...................... 28

Maintenance, Handling and Care............................... 30

Troubleshooting .......................................................... 33

Warranty ....................................................................... 34

USERS MANUAL | 5

Introduction

Using this manual

This manual describes the features of the Medivators Veriscan LT Automated Endoscope Leak Tester, including

system, setup, operation, safety, maintenance and troubleshooting procedures. It is important to follow the provided

instructions to keep the device in proper operating condition, to ensure accurate endoscope leak testing, and to

ensure long product life.

This is not a service manual and does not provide detailed instructions for service beyond general maintenance,

handling and care. Contact the manufacturer’s service representative if you have any questions regarding this

product, its use or operation.

Product Description

Flexible endoscopes are highly vulnerable to damage-causing moisture that enters the endoscope’s sensitive

interior through holes, tears, broken seals, cleaning cap leaks and loose contact pins. Prior to Veriscan LT, leak

detection has always been hampered by testing equipment that lacked precision, and required extraordinary skills

of observation beyond the capabilities of even the most experienced cleaning technician. As a result, undetected

leaks allow moisture to enter the endoscope’s interior through no fault of the technician. These leaks invariably

result in extensive endoscope damage, expensive endoscope repairs, and raise the risk of cross-patient infection

due to pathogens passing into subsequent patients through undetected leaks and moisture invasion.

The Veriscan’s automated endoscope leak testing technology transforms leak testing from a frustrating guessing

game into a simple, highly accurate, repeatable process that can be quickly mastered by cleaning technicians

and nurses. Veriscan’s innovative dry leak testing method accurately detects damage-causing endoscope leaks

without the need of immersing an endoscope in water. The endoscope is dry-leak tested through a process of

pressurizing the endoscope, monitoring the internal pressure level, and identifying if an endoscope leak exists

through a loss of pressure. An endoscope does not have to be placed in a uid-bath and visually observed for air

bubble leaks; the Veriscan’s visual display and printout automatically identify if an endoscope leak is detected.

Carefully review the User Manual to familiarize yourself with Veriscan’s features, operation and testing procedures.

We are condent the Veriscan system will quickly become an invaluable tool for enhancing reprocessing room

efciency, reducing endoscope damage and repair expense due to undetected leaks, and reduce the potential risk

of cross-patient infection.

6| USERS MANUAL

Product Specications

Power Requirement: Universal Power Supply 100-240VAC, 50/60 Hz, .25 Ampere

Fuse Rating: 250V, 1 Ampere, Type S, 3AG style.

Dimensions: 13.125 H x 8.25 W x 19.25 L inches

(33.3 H x 21 W x 48.9 L cm)

Weight: 15.8 lbs. (7.18 kg)

PSI range: 3.500 - 3.999 PSI (comparable to current manual leak testers)

Display: Liquid Crystal Display (LCD) with LED backlight

ProV-LT Data Management

Connectivity Ports: USB communications port

Operating Temperature Range: +10°C (50°F) to + 40°C (104°F)

Storage Temperature Range: +20°C (68°F) to +45°C (113°F)

Humidity: 20% to 80% non-condensing

Electrical Safety Certications: UL Standard 61010-1

CAN/CSA Standard 61010-1

Environmental Rating: Standard

Designed for Use: Indoor Use Only

Warranty Period: One (1) Year

USERS MANUAL | 7

Safety

Intended Use

The Medivators Veriscan system is intended for endoscope leak testing of exible, immersible endoscopes. The

Medivators Veriscan system has been validated by Medivators for use on Olympus, Pentax, Fujinon, and Storz

exible, immersible endoscopes.

Electrical Compliance

The Medivators Veriscan system was tested to stringent electrical certications and safety standards. This device

complies to UL Standard 61010-1 and CAN/CSA Standard 61010-1.

NOTE: This device must always be plugged into an electrical wall outlet that includes an approved Ground

Fault Interrupter (GFI) prior to operation.

Operator Safety

1) Veriscan is to be operated solely by properly trained and qualied personnel, and only used for its intended use.

2) WARNING: To avoid biological contamination and chemical burns, always wear appropriate personal protective

equipment (PPE) including clothing, gloves, and safety glasses when handling used endoscopes.

General Cautions

1) Veriscan users should be properly trained and instructed on the current procedures used to inspect, prepare,

clean, disinfect, rinse, dry, and store endoscopes. Follow recommended standards as referred by ASTM,

ASGE, SGNA and APIC.

2) The Veriscan system is intended to be used in conjunction with the instructions and labeling provided by the

endoscope manufacturer.

3) This is a dry leak test only - Do not place endoscope in water while testing.

4) Veriscan’s leak test parameter settings are pre-set at the factory for highly accurate endoscope leak test

measurements. Parameter settings should not be changed or adjusted, unless specically recommended by

Medivators. Parameter changes should only be performed by trained and qualied personnel.

5) The Veriscan system must be grounded in accordance with applicable electrical and safety regulations.

6) Read all precaution labels on the device before using.

7) Never use the device in a manner not specied or intended by the manufacturer.

8) The Veriscan system uses coin lithium batteries in the internal electronics for retaining memory settings. The

coin lithium batteries contain perchlorate material and if replaced, special handling may apply.

9) The Veriscan’s Quick Connect Tubings are not autoclavable and can only be decontaminated using low

temperature decontamination methods.

10) Inspect Quick Connect Tubings often and replace if damaged or worn.

11) Lubricate Quick Connect Tubing O-ring weekly with silicon oil to ensure a secure connection.

12) Monitor the condition of the desiccant drying crystals on a regular monthly basis. Replace as needed as

determined by comparing the crystals to the Drying Crystals Color Comparison Chart.

13) Monitor the condition of the coalescent lter for oil and particulates on a regular monthly basis. Replace once

yearly, or more if needed.

For service or service-related questions, contact Medivators Technical Support at 1.800.444.4729 or your

authorized Medivators distributor.

8| USERS MANUAL

Guidelines

Endoscope Leak Testing and Pre-cleaning

An effective endoscope leak test and pre-cleaning process is an essential step in the reprocessing of an

endoscope. Always follow the endoscope manufacturer’s instructions and established professional guidelines to

properly leak test and clean an endoscope. If an endoscope leak is detected, the endoscope should be immediately

taken out of service and sent in for repair.

Endoscopes should always be dry leak tested before submersion in uid to prevent additional uid invasion and

internal endoscope contamination. Leak testing detects endoscope leaks within the interior and exterior of an

endoscope.

Cleaning and Disinfection

Professional Guidelines

The following organizations have published recommended guidelines for cleaning and disinfecting endoscopes.

Society of Gastroenterology

Nurses and Associates, Inc.

401 North Michigan Ave.

Chicago, Ill. 60611-4267 USA

Tel: 800.245.7462

Fax: 312.527.6658

www.sgna.org

Association of Professionals in Infection

Control and Epidemiology, Inc.

1275 K. Street NW, Suite 1000

Washington, DC 20005-4006 USA

Tel: 202.789.1890

Fax: 202.789.1899

www.apic.org

American Society for Gastrointestinal Endoscopy

1520 Kensington Rd. Suite 202

Oak Brook, Ill. 60523-2141 USA

Tel: 630.573.0600

Fax: 630.573.0691

www.asge.org

American Society for Testing and Materials

100 Barr Harbor Drive

West Conshohocken, PA 19428-2959 USA

Tel: 610.832.9585

Fax: 610.832.9555

www.astm.org

Association of periOperative Registered Nurses, Inc.

2170 S. Parker Rd., Suite 300

Denver, CO 80231-5711 USA

Tel: 800.755.2676

Fax: 303.750.3462

www.aorn.org

Canadian Society of Gastroenterology

Nurses and Associates

27 Nicholson Dr.

Lakeside, NS B3T 1B3 Canada

Fax: 902.473.4406

www.csgna.com

British Society of Gastroenterology

3 St. Andrews Place

Regents Park, London, NW1 4LB England

Tel: +44.020.7387.3534

ww.bsg.org.uk

Societe Francaise d’Hygiene Hospialiere S.F.H.H.

Hopital de la Croix-Rousse

Unite h’Hygiene Hospitaliere-Epidemiologie

93 Grande Rue de la Croix-Rousse

69317 Lyon Cdx04 France

Tel: 04.72.07.19.83

Fax: 0.4.72.07.19.85

www.sfhh.net

USERS MANUAL | 9

System Components

If any of the components are missing, contact Medivators

Customer Support at 1-800-444-4729

or your authorized distributor.

Veriscan Box

This box contains the following components:

• One (1) Veriscan-LT System

• One (1) Power cord

• One (1) Crystal desiccant bag

• One (1) Silicon Oil

• One (1) ProV-LT Link Database Software

• One (1) Quick Start Guide

• One (1) Veriscan Users Manual

Installation Kit (endoscope specic)

This box contains the following components:

• One (1) Quick connect tubing

• Five (5) printer paper rolls

• One (1) Crystal desiccant bag

• One (1) USB cable

10 | USERS MANUAL

System Features

1. Display Screen

Displays information and test results

2. Control Keypad

Touchpad used to operate Veriscan System

3. Printer

Provides printout of test results

4. Quick Connect Port

Veriscan connector for Quick Connect Tubing

to endoscope

5. Power Switch

Used to turn Veriscan system ON/OFF

6. Power Cord Outlet

Receptacle for AC power cord

7. Power Cord

Provides electrical connection for Veriscan to

AC wall outlet

8. RS232 Port

Not currently used

9. USB Port

Port to connect Veriscan to separate computer

via USB cable

10. Drying Crystals Bulb

Receptacle for desiccant crystals

11. Metal Bulb Receptacle

Removable metal receptacle for securing

drying crystals bulb

12. Receptacle Release Button

Button to release metal bulb receptacle to

provide access to drying crystals bulb

13. Bulb Housing Structure

Housing for securing and linking drying

crystals bulb and metal bulb receptacle to

the device

14. Coalescent Filter Housing

Housing for securing and linking the oil and

particle lter to the device

15. Coalescent Filter

Oil and particle lter removes foreign

substances from air that enters and exits the

endoscope during testing

LT

4

5

2

3

1

69

8

7

USERS MANUAL | 11

System Setup

Installation

• Position Veriscan system on a at, level surface and within six (6) feet/

two (2) meters of the electrical AC wall outlet.

• Veriscan’s electrical requirements can be found under the “Introduction,

Product Specications” section.

Attaching the Power Cord

• WARNING: Exercise caution when plugging in this electrical

device. Risk of electric shock.

• Connect power cord to power cord outlet located on rear of unit. Gently

push cord in until fully inserted. (see gure 1)

• Plug the other end of the power cord into a standard AC wall outlet.

• NOTE: This device must always be plugged into an electrical wall

outlet that includes an approved Ground Fault Interrupter (GFI)

prior to operation.

Powering the Veriscan System “ON”

• Press the power switch located on the back of the unit to turn system

power ‘on’. (see gure 2)

• When Veriscan is turned on, it will automatically perform an initialization

process which includes a series of diagnostic self-tests. When this

process is complete, the display will indicate that the unit is ready for

testing as displayed below:

mm/dd/yy hh:mm

Connect Scope

Press “Start”

Setting the Time and Date

The Veriscan’s internal clock will record the time of all leak test

procedures. To set the clock:

• Press the MENU button on the display keyboard

• Press the arrow down key until Set Date/Time selection is reached

• Press the CONTINUE key to select the Set Date/Time option

• To enter the month, press CONTINUE and then enter the correct month

in the “month = “ area: 1 = January, 2 = February, etc.. If an incorrect

entry is made, press CANCEL to start the process over. Press

CONTINUE when nished.

• To enter the date, press the down arrow key from the “month” row until

the “date” row is reached. Press CONTINUE to reach the date set

area. Enter the date. For single digit numbers, it is not necessary to

enter a “0” before the number (e.g. enter 3 for the 3rd). Press

CONTINUE when nished.

• To enter the year, press the down arrow key from the “date” row until

the “year” row is reached. Press CONTINUE to reach the year set

area. Enter the year as a single digit where 6 = 2006, 70 = 2007, etc.

Press CONTINUE when nished.

Figure 1

Figure 2

Figure 3

12 | USERS MANUAL

• To enter the hour, press the down arrow key from the “year” row until

the “hour” row is reached. Press CONTINUE to reach the hour set

area. Using the 24 hour system, enter the hour (e.g. 5 A.M. = 5,

noon = 12, 2 P.M. = 14, midnight = 24, etc.). Press CONTINUE

when nished.

• To enter the minute, press the down arrow key from the “hour” row until

the “minute” row is reached. Press CONTINUE to reach the minute set

area and enter the minute. For single digit numbers it is not necessary

to enter a “0” before the number (e.g. enter 3 for :03). Press

CONTINUE when nished.

• When the date and time are all set, press CANCEL to return to the

MENU area. Press CANCEL again to return to the main display screen.

Attaching the Quick Connect Tubing

• The Veriscan uses Quick Connect Tubing to attach to Olympus®,

Pentax®, Storz®and Fujinon® exible, immersible endoscopes. Verify

the endoscope name labeled on the Quick Connect Tubing to ensure it

matches the specic endoscope brand being leak tested. If

replacement or additional tubings are needed for connecting other

brands of endoscopes, contact Medivators Customer Support at

1-800-444-4729 or your authorized distributor.

NOTE: Inspect Quick Connect Tubings often and replace if damaged

or worn.

NOTE: Lightly Lubricate Quick Connect Tubing O-ring with silicon oil

weekly to ensure a secure connection.

• Insert the Quick Connect Tubing prong into the quick connect port located

on the side of the Veriscan unit and apply inward pressure until the prong

clicks into place (see gure 3). To remove the tubing, gently push inward on

the quick

connect port’s outer metal housing, until the Quick Connect Tubing

prong is released.

Installing or Replacing the Desiccant Drying Crystals

The drying crystals must be installed before leak testing an endoscope. The

drying crystals ensure that only dry air is introduced into the endoscope during

leak testing.

NOTE: Monitor the condition of the drying crystals on a regular basis.

Replace as needed as determined by comparing the crystals to the

Desiccant Drying Crystals Color Comparison Chart.

CAUTION: Disconnect system power before installing or replacing the

drying crystals.

Step 1: Turn off and unplug the Veriscan system before installing

the drying crystals.

Step 2: Locate a new, unopened crystal desiccant bag. (see gure 4)

Step 3: Carefully position the Veriscan system so that the back of the unit can

be easily accessed with a six (6) inch clearance off of the counter surface. The

recommended method for installing or changing the drying crystals is to extend

the last six inches (6”) out over the end of the counter surface.

System Setup

Figure 4

Figure 5

Figure 6

USERS MANUAL | 13

Step 4: Push the metal housing release button down and hold. (see gure 5)

Step 5: While continuing to hold the button, gently pull down on the metal

bulb housing and rotate it to the left, until it releases down and away from the

machine’s bulb housing structure. Gently lower the bulb housing unit away from

the machine. (see gure 6)

Step 6: Remove the drying crystal bulb from the bulb housing structure by placing

one hand on top of the Veriscan, grasping the dry crystal bulb with the other hand

and pulling downward in a twisting motion (either direction) until the bulb can be

removed from the housing structure. (see gures 7 and 8).

Step 7: Empty and discard any used drying crystals from the bulb, and carefully

pour the entire bag of new crystals into the bulb. (see gure 9). Do not allow

crystals to enter the metal tube located in the center of the bulb.

Step 8: Return the bulb to its original housing by placing one hand on the top

of the unit and grasping the glass bulb with other hand, while inserting the glass

bulb vertically up and into the bulb housing structure until the top of the structure

is reached. This is a reverse of the process described in Step 6. Apply careful

upward pressure while turning the bulb (either direction) to help the bulb pass

through the tight gasket seal and seat to the top of the bulb housing structure.

(see gure 7)

Step 9: Return the metal bulb housing unit to the Veriscan by holding down the

bulb receptacle release button and lifting up on the bulb receptacle over the

drying crystal bulb. This is a reverse of the process described in step 5. Align the

release button with the center of the bulb housing structure and lift until resistance

is felt. While holding the button down, turn the receptacle to the left until it

reaches a slot and can be lifted in an upward direction. (see gure 6)

Step 10: Let go of the release button and turn the metal bulb housing unit until

the receptacle button clicks into place. (see gure 5)

WARNING: THE METAL BULB HOUSING STRUCTURE MUST BE IN PLACE

BEFORE OPERATING THE VERISCAN DEVICE. THE GLASS DRYING

CRYSTAL BULB CAN BECOME DISLODGED DURING LEAK TESTING, AND

LEAK TEST RESULTS WILL BE AFFECTED IF THE METAL BULB HOUSING

IS NOT PROPERLY IN PLACE.

Figure 7

Figure 8

Figure 9

System Setup

14 | USERS MANUAL

Performing a Leak Test

Attaching a exible, immersible endoscope to the Veriscan System

• Ensure the Quick Connect Tube is connected to the Veriscan

system. If not, refer to the System Setup section.

• Check the endoscope cleaning cap to ensure it is securely in place over the

endoscope’s ETO connector. A faulty cleaning cap connection or O-ring seal

onto the endoscope will be detected as an endoscope leak by Veriscan.

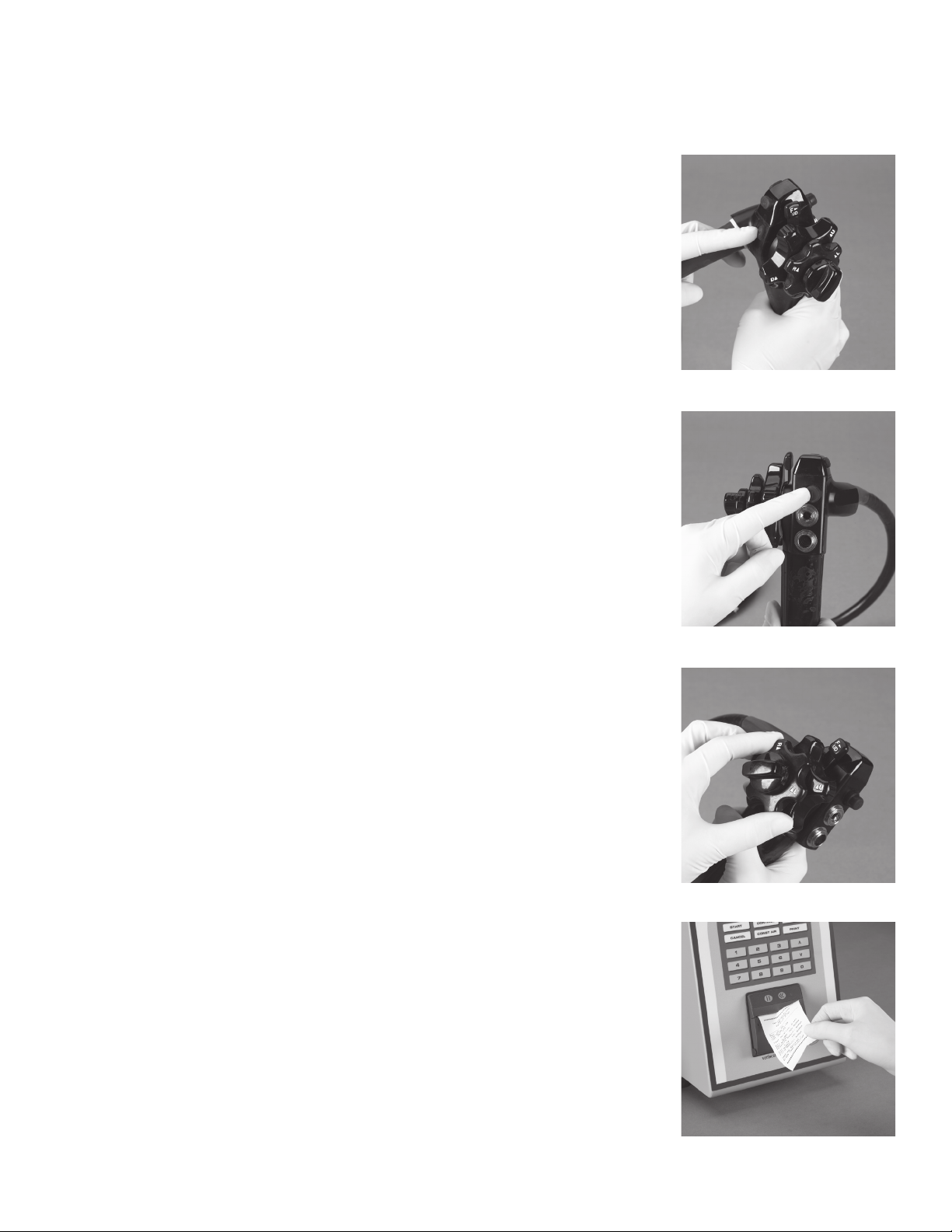

• Align Veriscan’s Quick Connect Tubing connector to the pin on the

endoscope’s cleaning cap leak test tting, and then push the connector over

the tting. Rotate the connector until the pin reaches the end of the channel on

the connector. Verify the Quick Connect Tubing connecting the endoscope

to the Veriscan system is not twisted. (see gures 10, 11 and 12)

NOTE: If the connector rotates with difcultly, then verify the o-ring is

properly lubriated.

NOTE: This is a dry leak test only – Do not place or immerse the

endoscope in any type of uid or water while testing.

Performing the Leak Test

The heat of an endoscope can affect leak test measurement accuracy though the

expansion of the soft components of the endoscope. Leak test accuracy is

maximized by identifying if the endoscope was used in a patient procedure

within the last 30 minutes.

If the endoscope was used within the last 30 minutes, then the factory default

“Standard Test” setting should be used.

If the endoscope was not used within the last 30 minutes, then the “Screening

Test” setting should be used. Go to the section labeled “Performing a Screening

Test” for further instructions.

• To begin the leak test, press the START button located on the

Veriscan keypad.

• If optional “OPERATOR ID” screen activated, the following information

will display:

Leak Test Start

Enter Operator ID

Press “Continue”

Enter Operator ID number (maximum 4 digits) and then press CONTINUE.

• If optional “PATIENT ID” screen activated, the following information

will display:

Leak Test Start

Enter Patient ID

Press “Continue”

Enter Patient ID number (maximum 10 digits) and then press CONTINUE.

• The “ENTER SCOPE S/N” screen will now display as:

Leak Test Start

Enter Scope SN

Press “Continue”

Enter last three digits of endoscope’s serial number and then press CONTINUE

(A maximum of 10 digits can be entered).

Figure 10

Figure 11

Figure 12

USERS MANUAL | 15

• The leak test will now automatically begin when Veriscan is operating in the

factory default “STANDARD TEST” mode, and the following information will

be displayed:

Leak Test Start

Please standby...

• If Veriscan is operating in the “MANUAL” mode, the following information will

display: (The manual mode is used for selecting alternative parameter settings,

other than the factory default “STANDARD TEST” settings.)

Select Test Setting

Standard Test 1

Standard Test 2

Standard Test 3

Use the up/down arrow keys to select the desired test, and then press

“CONTINUE” to begin the leak test.

• After a pre-set period of time, an audible tone will sound. The Veriscan will

display the below listed information which prompts the operator to turn all of

the endoscope’s angulation knobs and to press all of the camera buttons. (see

gures 13, 14 and 15). These endoscope areas are common uid invasion

problem spots which can only be accurately leak tested when all knobs and

buttons are activated.

Leak Test

Oper Knobs & Buttons

“Continue” to Ack

Results in 112 Seconds

NOTE: Turn all endoscope angulation knobs and press all camera buttons

when audible tone is heard.

When all knobs and buttons have been manipulated, press the CONTINUE

button on the display keypad and the test will automatically continue.

• The endoscope leak test continues.

• When the endoscope leak test completes, a humidity test is initiated which

veries the condition of the dry air used during the leak test.

• At the completion of the humidity test, an audible tone is heard and the

Veriscan screen displays the PASS or FAIL, test results.

If a PASS result is displayed, then go to “Printing Results”.

If a FAIL result is displayed, then go to “Testing a Failed Endoscope” section.

Printing Results

• Press the PRINT button to print results, or CONTINUE to start a new

endoscope leak test. Tear the printout off by pulling upwards on the printout

towards the tear bar, and tear from one side to the other across the serrated

edge (see gure 16). For directions on how to load printer paper, see the

“Changing Printer Paper” heading located in the Maintenance, Handling &

Care section.

• For other printing options, (e.g., printing quick reports on daily, weekly

and monthly summary activity,) see the Quick Report Printing heading located

in the Data Access and Management section.

Performing a Leak Test

Figure 13

Figure 14

Figure 15

Figure 16

16 | USERS MANUAL

Disconnecting the Endoscope

• Disconnect the Quick Connect Tubing from the endoscope (see gure 17).

The endoscope is now ready for the next step in the manual cleaning process.

Shut Down and Start Up of the Veriscan system

• Shut Down: The Veriscan system should be turned off

at the end of each day. To turn off the machine, toggle the on/off

switch to the right (see gure 18) and the Veriscan display will go blank.

• Start Up: To start the Veriscan system, toggle the on/off switch to the

left. The system will automatically begin a series of diagnostic self-

tests during the initializing process. When initialization is complete,

the display will appear as below indicating that the system is ready

to begin testing endoscopes.

mm/dd/yy hh:mm

Connect Scope

Press “Start”

Performing a Leak Test

Figure 17

Figure 18

USERS MANUAL | 17

Veriscan’s “Screening Test” is an extremely accurate, dry endoscope leak test which is

ideal for evaluating “cold” or stable temperature endoscopes.

Use the “Screening Test” to:

1) Evaluate an endoscope that was not used on a patient within the last 30 minutes.

2) Evaluate a facility’s inventory of endoscopes.

Due to Veriscan’s extreme

leak detection accuracy, it is recommended that all

endoscopes be tested within

a facility when a Veriscan unit is received for the rst

time. A facility can also routinely test endoscopes using the “Screening Test” to

ensure ongoing early endoscope leak detection.

NOTE: The screening test is only to be used on stable temperature endoscopes

which have not been used within the last 30 minutes.

Performing the “Screening Test”

• Press the “Menu” button located on the keypad and the following

information will display:

Main Menu

Stored Runs

Quick Reports

Screening Test

Set Test Parameters

• Use the up/down arrow keys to align the curser with the “Screening Test” and then

press “CONTINUE” followed by “START” to begin the leak test.

• If optional “OPERATOR ID” screen activated, the following information

will display:

Screening Test Start

Enter Operator ID

Press “Continue”

Enter Operator ID number (maximum 4 digits) and then press CONTINUE.

• If optional “PATIENT ID” screen activated, the following information

will display:

Screening Test Start

Enter Patient ID

Press “Continue”

Enter Patient ID number (maximum 10 digits) and then press CONTINUE.

• The “ENTER SCOPE S/N” screen will now display as:

Screening Test Start

Enter Scope SN

Press “Continue”

Enter last three digits of endoscope’s serial number and then press CONTINUE (a

maximum of 10 digits can be entered).

• The leak test will now automatically begin when Veriscan is operating in the

factory default “SCREENING TEST” mode, and the following information will

be displayed:

Leak Test Start

Please standby...

Performing a Screening Test

18 | USERS MANUAL

• If Veriscan is operating in the “MANUAL” mode, the following information will display:

(The manual mode is used for selecting alternative parameter settings, other than the

factory default “SCREENING TEST” settings.)

Select Test Setting

Screen Test 1

Screen Test 2

Screen Test 3

Use the up/down arrow keys to select the desired test, and then press “CONTINUE” to

begin the leak test.

• After a pre-set period of time, an audible tone will sound. The Veriscan will display

the below listed information which prompts the operator to turn all of the endoscope’s

angulation knobs and to press all of the camera buttons. (see gures 13, 14 and 15).

These endoscope areas are common uid invasion problem spots which can only be

accurately leak tested when all knobs and buttons are activated.

Leak Test

Oper Knobs & Buttons

“Continue” to Ack

Results in 112 Seconds

NOTE: Turn all endoscope angulation knobs and press all camera buttons when

audible tone is heard.

When all knobs and buttons have been manipulated, press the CONTINUE button on the

display keypad and the test will automatically continue.

• The endoscope leak test continues.

• When the endoscope leak test completes, a humidity test is initiated which veries the

condition of the dry air used during the leak test.

• At the completion of the humidity test, an audible tone is heard and the Veriscan screen

displays the PASS or FAIL, test results.

If a PASS result is displayed, then go to “PRINTING RESULTS”.

If a FAIL result is displayed, then go to “Testing a Failed Endoscope” section.

Printing Results

• Press the PRINT button to print results, or CONTINUE to start a new

endoscope leak test. Tear the printout off by pulling upwards on the printout

towards the tear bar, and tear from one side to the other across the serrated

edge (see gure 16).

• For other printing options, (e.g., printing quick reports on daily, weekly

and monthly summary activity,) see the Quick Report Printing header located in

the Data Access and Management section.

USERS MANUAL | 19

Testing a Failed Endoscope

Majority of FAIL leak test results are due to true endoscope leaks. On occasion, a FAIL test

result can be traced to other preventable and correctable issues such as:

• Nicks in the endoscope cleaning cap gasket: If the rubber seal or gasket on the inside

of the endoscope cleaning cap is damaged, a false FAIL leak test result can occur. If the

rubber sealing area is not in perfect condition, replace the cleaning cap with a new one.

• ETO valve loose on endoscope cleaning cap: If the ETO valve on the endoscope

cleaning cap is loose, air can escape and cause a false FAIL leak test results. If the

ETO valve is loose, replace the cleaning cap with a new one.

• Quick Connect Tubing: If the Veriscan’s Quick Connect Tubing is damaged due to a small

hole, or worn due to an O-ring leak, a false FAIL leak test result can occur. Always have a

spare Quick Connect Tubing available to test for a tubing leak.

• Screening Test used to test a warm, unstable temperature endoscope: A false FAIL

leak test result can occur if the “Screening Test” was used to leak test an endoscope used on

a patient within the previous 30 minutes. The screening test should only be used on stable

temperature endoscopes which have not been used within the last 30 minutes. Allow the

endoscopes the recommeneded time to cool, and then re-perform the leak test.

Retesting a Failed Endoscope

In the event of a FAIL test result, the endoscope leak test should be rerun as follows:

Retest Endoscope

Remove the Quick Connect Tubing from the endoscope.

Inspect the tubing for wear, damage or holes.

Inspect the O-ring for rips or tears.

Inspect the O-ring for sufcient silicon oil lubrication. The O-ring can tear if dry or not properly

lubricated.

Replace if worn or damaged.

• Remove the cleaning cap from the endoscope. Inspect the cleaning cap, cleaning cap

O-ring, and ETO valve, and replace if worn or damaged.

• Reattached cleaning cap and Quick Connect Tubing, and initiate a new endoscope leak

test by pressing CONTINUE and the START.

Endoscope Fails Again

If the endoscope fails a second time, then:

• Press the CONST AIR button on the keypad and visually observe the endoscope’s distal

end for ination.

1) Endoscope Distal End Inates:

If the distal end of an endoscope inates, then it can be safely submerged for cleaning before

being sent in for repair. The endoscope must be cleaned with a continuous air ow during

the entire cleaning process. The continuous air ow creates a constant internal endoscope

pressure that prevents uid from invading through the leak. Clean the endoscope as follows:

• Verify the CONS AIR button remains on and the endoscope’s distal tip is inated.

• Submerge the endoscope in uid and look for an air bubble leak.

• Hand clean according to your cleaning room protocol for handling endoscopes

with leaks.

• Remove endoscope from uid and dry. Press CANCEL to stop constant air ow.

• Remove endoscope from service.

• Contact endoscope repair company to arrange for endoscope servicing.

20 | USERS MANUAL

2) Endoscope Distal End Does Not Inate:

Do not submerge the endoscope in uid. This is an indication of a large endoscope leak. Press CANCEL to stop

the constant air ow. The endoscope must be hand cleaned before being sent in for repair by following these

steps:

• Do not submerge the endoscope in any uids or in an automated endoscope reprocessor.

• Hand clean the endoscope according to your cleaning room protocol for handling endoscopes with leaks.

• Remove endoscope from service.

• Contact endoscope repair company to arrange for endoscope servicing.

NOTE: DO NOT SUBMERGE ENDOSCOPE IN FLUID

Table of contents

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started