MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

Page 4

+617 3283 4536

Free AU 1800 669 006

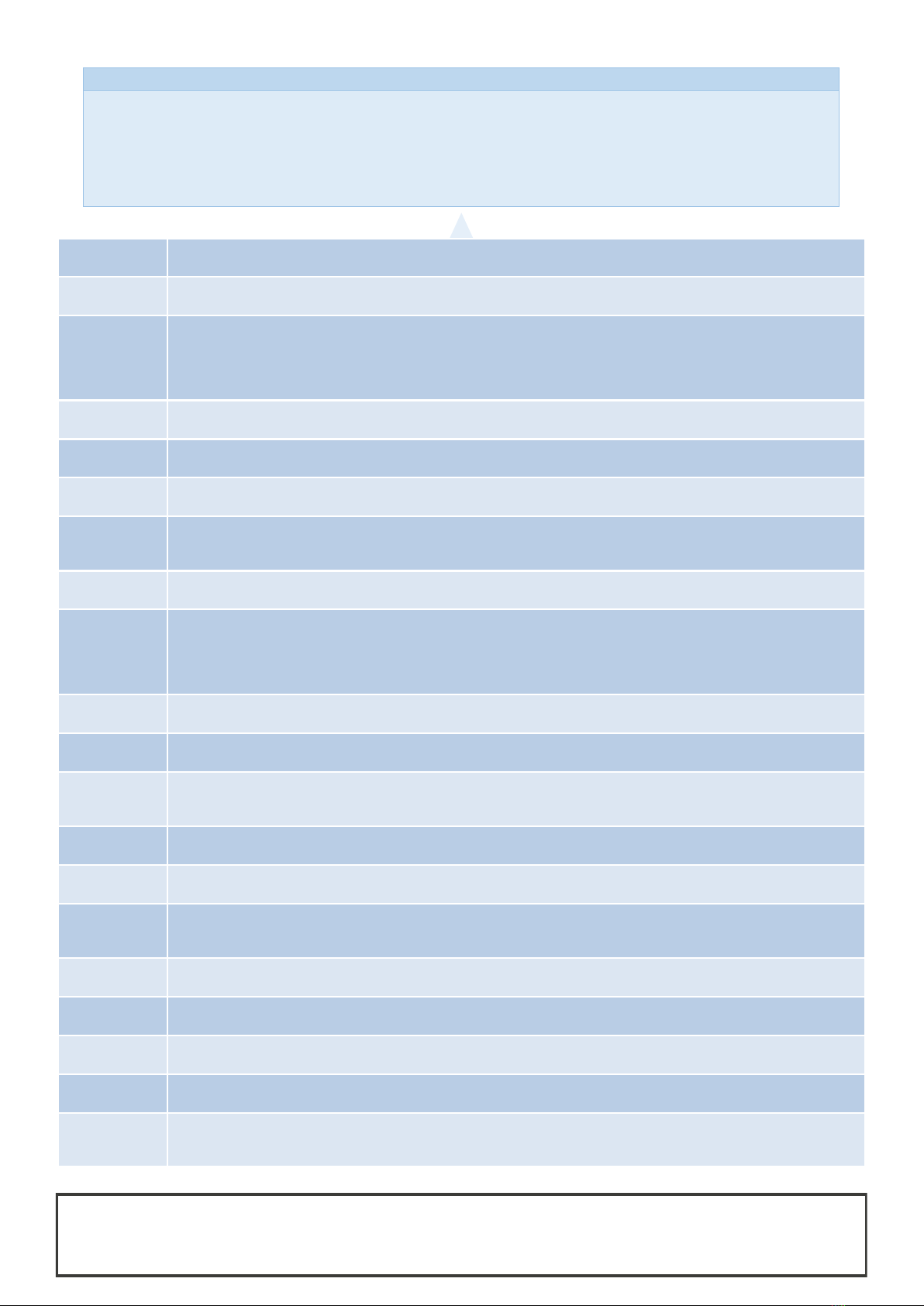

Fault Check

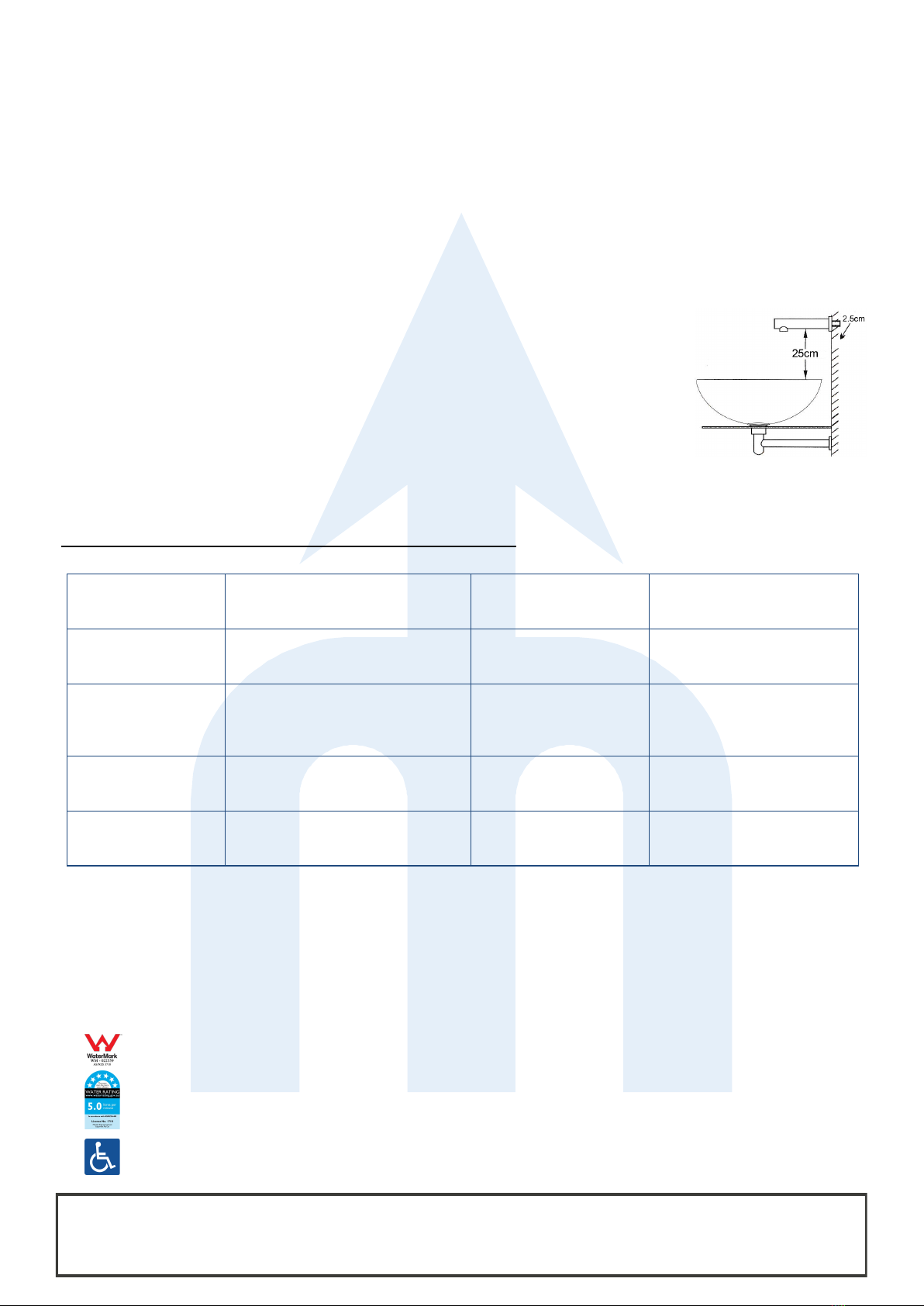

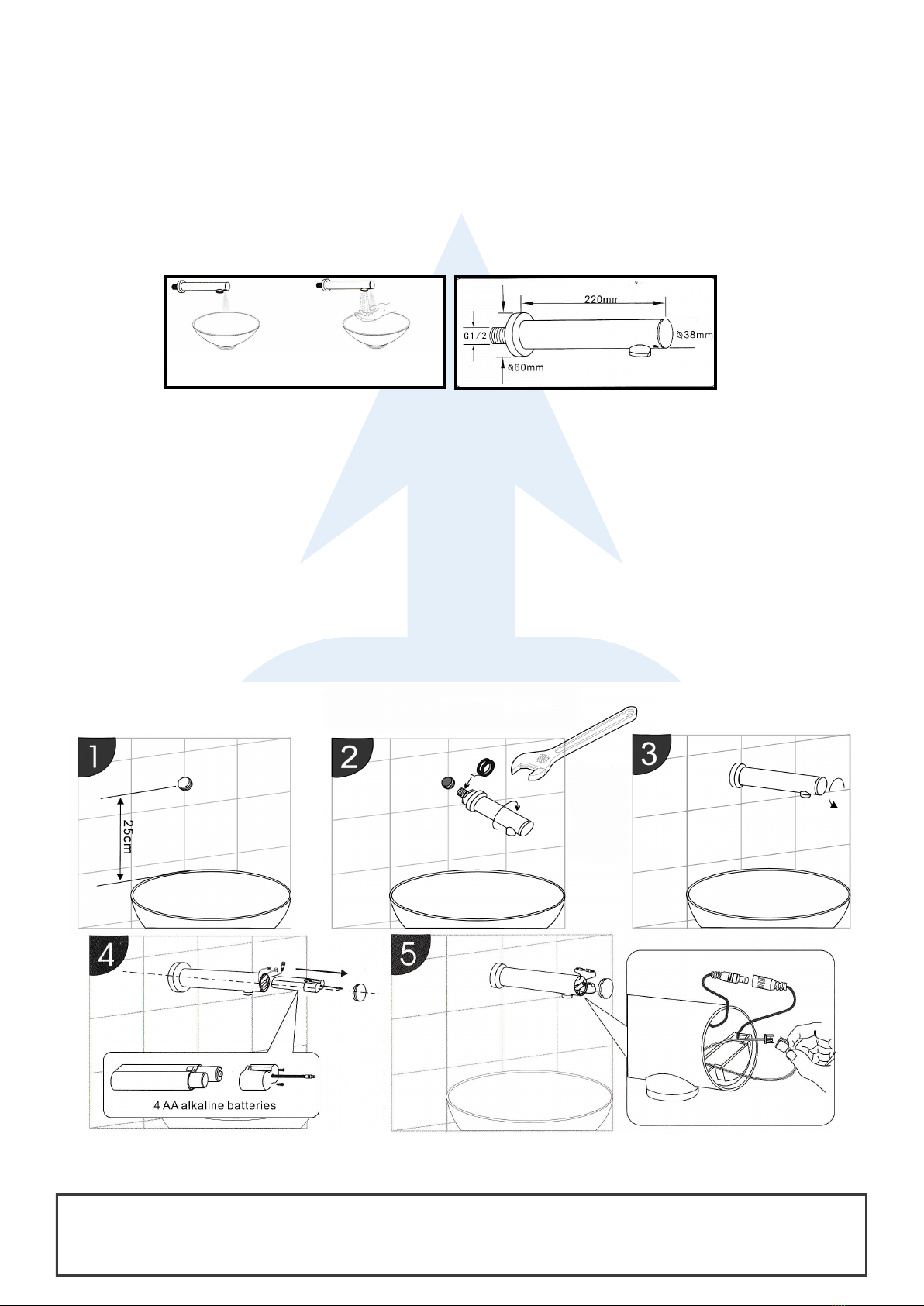

Before fault checking: please make sure the installaon distance is adequate and correct by referring to the Pre-

installaon instrucons.

The LED indicator will light up twice and then stop once aer the baeries are installed. To conrm the sensor is work-

ing, place your hand within the sensing range and check that the LED indicators lights once.

Problem The faucet has no water ow and there is no LED indicator light when within the sensing range

Cause The baeries are not supplying electricity to the sensor.

Soluon 1 Conrm the baeries have been correctly installed. Check that the posive pole is connected to “+” mark on

the plasc baery box. Check that the negave pole is connected to “-“ mark on the plasc baery box. Con-

rm the baeries are the correct size as per this manual and have not been forced.

Soluon 2 If the LED indicator does not light up and power is conrmed, replace the sensor control module.

Problem The faucet has no water ow and there is a LED indicator light when within the sensing range

Cause 1 Inadequate electricity supply.

Soluon Place hands under the sensing range for >5 seconds. If the LED indicator blinks every 1.5 seconds there is in-

adequate electricity.

Cause 2 Solenoid valve components are defecve.

Soluon

The LED indicator should spark for 2 seconds and then turn o. Place your hands within the sensing range, if

the LED indicator lights up once but you can not hear the audible “click” sound from the sole-noid valve,

please check the connecons between the sensor control model and solenoid valve. If the connecons are

good, change the solenoid valve components.

Problem The faucet has low water ow

Cause Low water pressure or water supply stop(s) are parally closed.

Soluon Refer to installaon step 3—at this point, increase water pressure and open the water supply stop (s) fully.

Problem The faucet has water ow but does not close completely

Cause 1 The solenoid valve is blocked by debris.

Soluon Disassemble the solenoid valve and clean it. Flush pipes and ensure water supply is free of debris. Change the

solenoid valve components if the problem is not solved.

Cause 2 Low water pressure.

Soluon Increase water pressure.

Problem The faucet has water ow but will not stop running

Cause Please conrm adequate electricity supply and solenoid valve connecons.

Soluon If the problem persists, check that the sensing range is adequate i.e. installed above the washbasin no less

than 25cm. Check that the basin surface is not stainless steel or reecve.