MEGABRAS MPK257 User manual

Formato: 137mm x 190mm

P. 25

P. 03

Manual de uso

Micro-ohmímetro digital

Digital Micro-ohmmeter User guide

MPK-257

Digital micro-ohmmeter

User’s guide

GF-2072

© 2018 MEGABRAS. All rights reserved.

3

Safety Precautions

This equi ment should be o erated only by qualified and duly trained eo le,

closely observing the corres onding safety regulations and instructions

contained in the resent User guide.

It should be checked that the item to be measured is voltage free.

Before starting with the measurements, be sure that the battery is well

charged and that the line voltage is between s ecified limits.

Do not connect or disconnect the test leads during the measurement.

There are no adjustable arts or arts that can be re laced by the user within

the equi ment. Taking out the Control Panel in order to have an access to the

internal arts may be dangerous as there are high voltages inside, ca able of

causing fatal accidents.

Cleaning of this instrument should be carried out using a soft cleaning liquid,

after verifying that it doesn't attack the lastic arts used in the case and in the

Control Panel of this equi ment.

This equipment should e used only y a trained and competent

person, strictly applying suita le safety rules.

4

Used sym ols

Caution, refer to User Guide.

Battery.

Printer.

USB (Universal Serial Bus).

30 V max. (to ground): indicates the maximum otential allowed

in the terminals during resistance measurements.

Ground rotection: the terminal identified by this symbol is

intended for connection to an external conductor for rotection

against electric shock in case of failure, or the terminal of a

ground rotection electrode.

Equi ment com lies with current EU Directives.

Double insulation: symbol indicates that the equi ment is

classified as Class II (double isolated).

The rubbish bin with a line through it means that in the Euro ean

Union, the roduct must undergo selective dis osal for the

recycling of electric and electronic material, in com liance with

Directive WEEE 2002/96/EC.

5

Index

1. Descri tion.............................................................................................................7

1.1. O erating rinci le..........................................................................................7

2. Control anel..........................................................................................................8

3. Power su ly..........................................................................................................9

3.1. Battery condition.............................................................................................9

3.2. Battery charger...............................................................................................9

3.3. Auxiliary ower..............................................................................................10

4. Settings and Adjustments....................................................................................11

5. Measurement.......................................................................................................13

6. Dis lay messages................................................................................................16

7. Some notes about accuracy................................................................................17

8. Printer...................................................................................................................18

9. Internal memory...................................................................................................18

10. Software.............................................................................................................19

10.1. MegaLogg2 software..................................................................................19

11. Remote control...................................................................................................20

12. Cleaning.............................................................................................................21

13. Re lacement fuse........................................................................................21

14. Technical s ecifications.....................................................................................22

15. Warranty.............................................................................................................24

6

1. Description

The MPK-257 micro-ohmmeter is a ortable, micro rocessor controlled

instrument, used to accurately measure very low contact resistances of

breakers and switches, busbars, transformers and engines windings, etc,

with test currents from 1 mA to 10 A.

Micro rocessor controlled

Kelvin architecture (four-terminal method)

Digital reading, al hanumeric dis lay

U to 4½ digits readings

Powered by rechargeable battery

0.1 µΩresolution

Tem erature com ensation

2000 Ωmaximum reading

U to 10 A current

Remote control through an Android a

1.1. Operating principle

This device uses the Kelvin Bridge architecture, with four terminals,

avoiding testing leads resistance to cause error during measurement. The

o erator may choose test current and the reading is obtained by

com arison through internal high-stability standards. The result a ears

in the al hanumeric dis lay that is very easy to read.

7

2. Control panel

Connection of temperature sensor

Dis lay.

Current terminal (C+).

Potential terminal (P+).

Potential terminal (P-).

Battery charge indicator.

Current terminal (C-).

Selector of ranges and currents.

Battery key. To measure the battery

charge condition.

Safety ground.

Printer Key

Filter key.

Power cord connector.

Fuse.

Auxiliary su ly connector.

Printer.

USB connector.

On/Off switch.

3Test current control.

4Start key.

5Sto key.

6Tem erature com ensation button.

7 Save key.

8

3. Power supply

Mains supply or internal attery powered

Battery: LFP, rechargeable, 12 V - 6000 mAh.

Mains: 220 - 240 V~.

Auxiliary supply: 12 V.

Make sure that the voltage of the mains su ly is com atible with

the voltage su ly of the equi ment!

Before connecting the equi ment to the mains su ly, make sure

that the ower cord is not damaged. If damaged, do not connect

the equi ment to the mains su ly and contact the service center

for re lacing the ower cord.

3.1. Battery condition

The charge condition of the battery can be verified before or during the

resistance measurement. In order to achieve that, the o erator has to

ress the attery key while the equi ment is turned on. The bargra h

shows remaining charge as a ercentile value.

3.2. Battery charger

Charging procedure:

Check that the On/Off switch is in Off.

Connect the equi ment to the mains su ly.

The attery charge indicator ( ) will kee on

lightning with a red light u to com leting the charge. At that oint, it

will change to a green light, being like this u to the equi ment

disconnection from the mains su ly.

If during the charging of the battery the device was switched on, by

activating the key , the charge will be tem orarily interru ted. When

the equi ment is turned off, the charge will restart automatically.

9

The rechargeable battery has no "memory effect" so it can be charged as

many times as desired. On the other hand, its useful life is significantly

reduced if it is allowed to remain totally discharged.

To avoid this effect, charge the battery before storing the equi ment and

do not allow more than 30 days to ass without re eating the charging

rocess, even if the instrument has not been used (The battery loses art

of its charge when it is stored).

At the end of its useful life, the battery must be recycled or dis osed

of ro erly to reserve the environment.

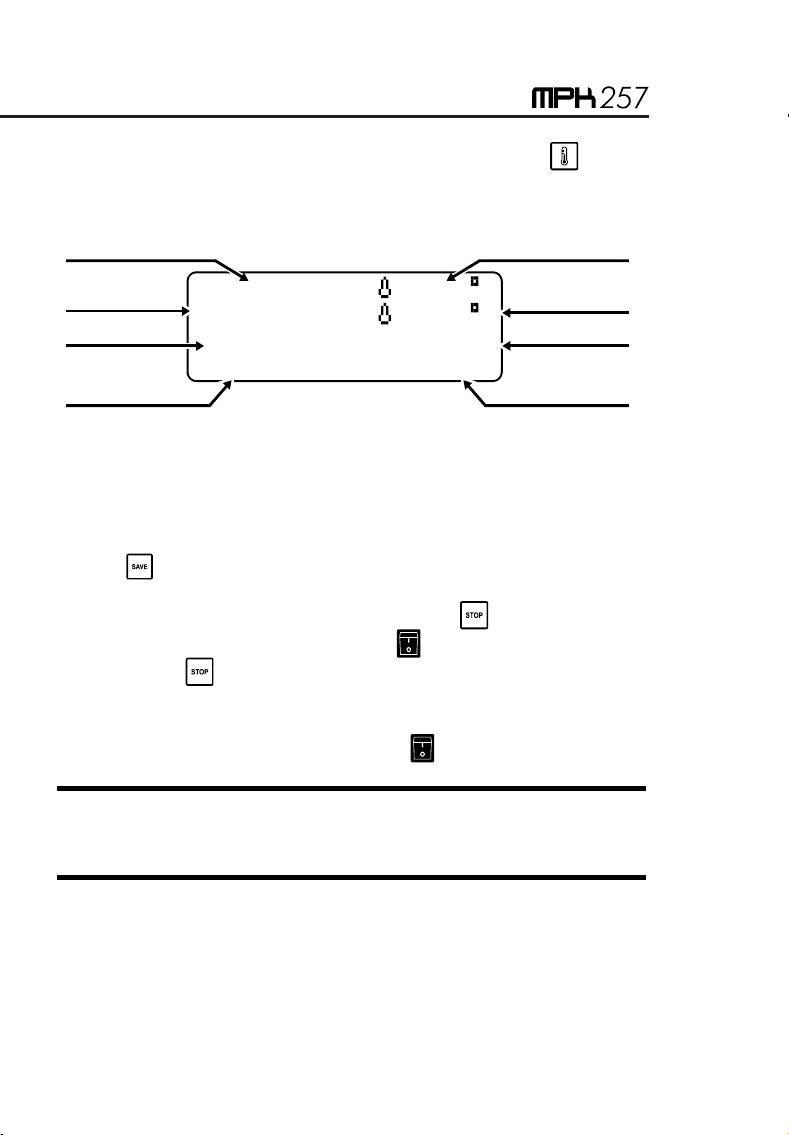

3.3. Auxiliary power

The MPK257 has a 12 V auxiliary ower in ut. This in ut can be used to

charge the battery or to ower the equi ment.

BLACK

RED

To make measurements or charge the battery.

10

4. Settings and Adjustments

This equi ment has a MENU for settings and

adjustments. To access the MENU, ress the

Selector / Adjust ( ).

All navigation is erformed through the and all anel keys are

disabled, with the exce tion of the key that has the function to cancel

and return to the initial screen.

Short ress: O en MENU, o en selected sub-menu /

confirm settings.

Long ress (1.5 s): Go back one level or cancel adjustment.

Change selection / values

Cancel and close the MENU

ATTENTION: The configuration MENU can not be accessed during the tests.

11

Filter

Auto save

Temperature

compensation

MENU SUBMENU DESCRIPTION

SETUP TEST

METAL SELECT ON Allows you to define the type of metal that will be

used in the calculation of temperature compensation.

COMP. TEMPERATURE t allows setting the reference temperature that will

be used in the calculation of temperature

compensation.

AUTO SAVE Save the last measured value in the internal memory

when the test is finished.

LANGUAGE Allows you to change the interface language

between: English, Spanish and Portuguese.

SETT NGS

SET DATE FORMAT Selecting the date format.

SET T ME FORMAT Selecting the time format.

DATE ADJUST Setting the date.

T ME ADJUST Setting the time.

D SPLAY ADJUST Setting the display.

SYSTEM NFO Displays the firmware version and serial number.

MEMORY

USAGE Displays the percentage of internal memory used.

DELETE Deletes all records from memory.

12

5. Measurement

• The User Manual and its res ective safety recautions must be read

and understood before using the micro-ohmmeter.

• The usual safety recautions and safety regulations must be strictly

observed.

• It should be checked that the item to be measured is voltage free.

• To ensure safety, use only the accessories su lied by the

manufacturer.

1. Before turning the equi ment On, connect the test leads to the item

to be measured and to the front anel terminals.

Sim le measurement

The alligator clamps in the drawings are only for illustration.

Sim le measurement with tem erature com ensation

The alligator clamps in the drawings are only for illustration.

13

Measurement with potential risk

Ex .: High voltage circuit breaker under external influence of electromagnetic fields

from nearby energized devices.

The alligator clamps in the drawings are only for illustration.

The safety ground terminal must be connected before making the

other connections to the equi ment.

2. Turn on the device with the On / Off key ( ).

3. The display of the equi ment will show the resentation

message MPK257.

4. The AUTO VERIFICATION message will appear next and then

PRESS START.

5. Select the range and current ( ).

6. Press the key .

7. The message LOW CURRENT will a ear. Turning the control

clockwise will increase the current until reaching the desired

stable value measured on the dis lay or in the bargra h current

indicator.

8. When the current value is greater than 20% of the nominal value

of the scale, the dis lay will indicate the measured resistance

value.

14

9. To activate the tem erature com ensation ress the button.

10. U on com letion of this rocess the display will indicate the

measured resistance value and other test information.

11. The unit of measured resistance shall be ex ressed in Ω (ohms),

mΩ (mili-ohms) or µΩ (micro-ohms).

12. This information can be saved in the machine's internal memory

during and / or after the test sim ly by ressing the save key

.

13. To finish the test ress the red stop key . Do not turn off the

roduct with the power switch without ressing the sto

button .

14. Finally, after all measurements have been com leted, switch the

device off using the on / off switch .

Caution: Never connect or disconnect the test leads with the equipment

in operation. If you have to make any changes to the connection, it must

be done with the equipment turned off.

15

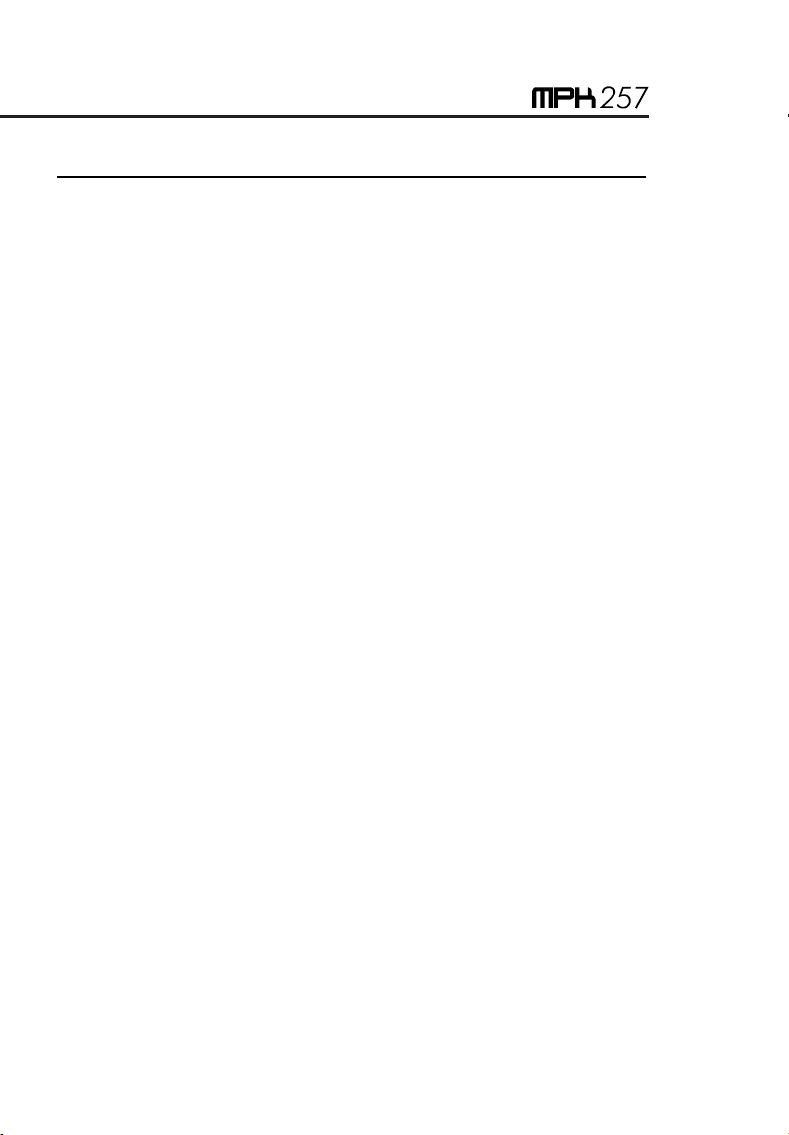

R= 9.876m :25.8 CΩ

Rc: 9.843m :25.0 CΩ

[ ] 8.5 Aίίίίίί

01:22 82mV

Measured resistance

Elapsed time

Reference

temperature

Measured voltage

Test current

Analog current

indication

Resistance

compensated

Measured temperature

6. Display messages

MEGABRAS MPK-257

When turning the equi ment On using the On/Off switch, this

introductory message a ears for a while. During that time, the

equi ment carries out some functional checking.

AUTO CHECK

Indicates that the equi ment is erforming internal checks.

PRESS START

Indicates that the equi ment is able to start a test, for which the o erator

must ress the key .

LOW CURRENT

This warning indicates that the test current is insufficient to erform the

measurement. The control must be turned clockwise to increase

current.

I=MAX

Indicates that the current reached the maximum value.

OVERRANGE

Indicates that the measured resistance exceeds the maximum value of

the selected scale.

16

7. Some notes a out accuracy

In order to obtain the s ecified accuracy, the o erator has to adjust the

test current to a value higher than the 80% and 100% of the nominal

value. For minor currents the measurement is only indicative.

MPK-257 has an auto-com ensation system that automatically eliminates

the error roduced by internal offset. Thus, it is not necessary to carry out

measurements by reversing the olarity in order to com ute the average

value. Nevertheless, if the o erator sus ect that there is a difference of

tem erature between the contact oints that would can generate

thermoelectric voltages, it is necessary to carry out two measurements by

reversing the current cables and so, the circulation sense of the current

through the resistance under measurement. The resistance value to be

measured will be the average between the values in one sense and in the

contrary (direct and inverse current).

17

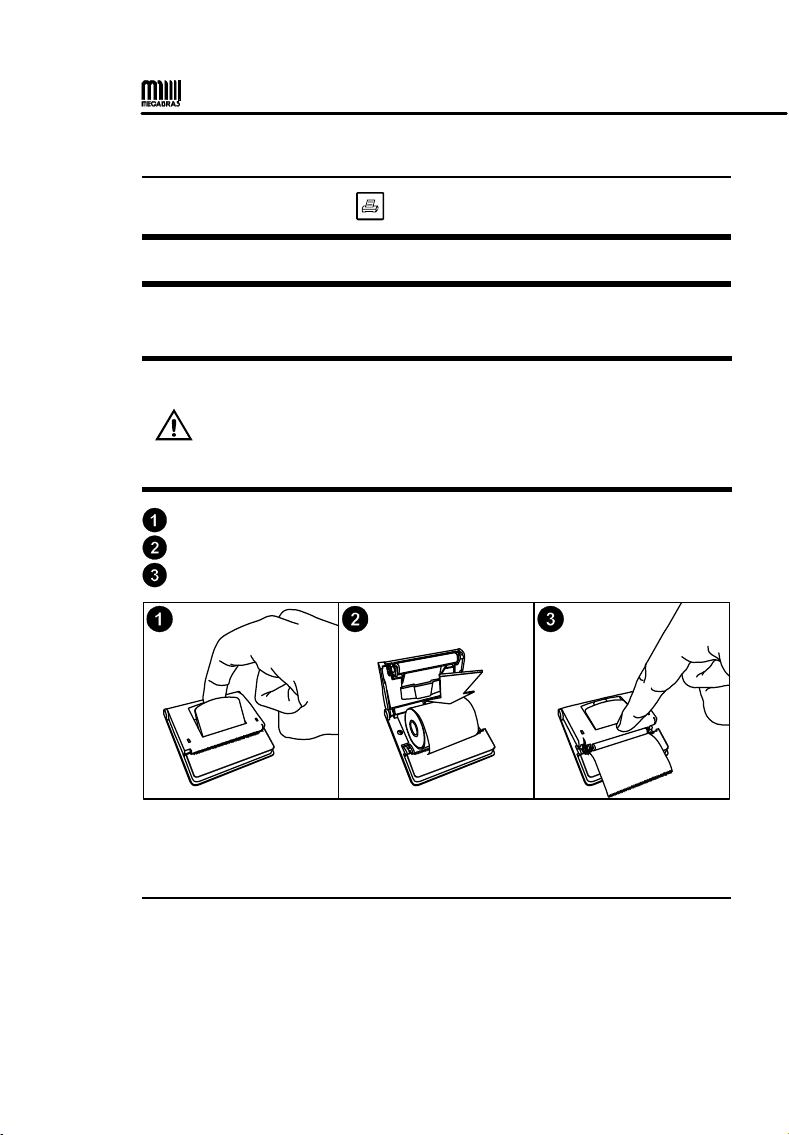

8. Printer

To rint a result, ress the key during a measurement.

ATTENTION: Don’t ull the a er. The rinter can be easily damaged.

This rinter uses 2.2” (57 mm) -wide thermal a er, which comes in a

1.18” (30 mm)-diameter reel.

Precautions

• Perform the rocedures below with the equi ment turned off.

• Disconnect the equi ment from the mains su ly and remove

the ower cord.

• Disconnect the test leads.

Pull the lever located on the lid.

Insert the a er reel as shown in the figure.

Kee the ti of the a er out of the rinter and close the lid.

9. Internal memory

This device has an internal memory of u to 30,000 measured values

(a roximately 10,000 tests).

18

10. Software

To install the USB drivers required for the communication between PC

and equi ment follow the instructions:

Connect the equi ment in the PC using the USB cable.

If there is an available Internet connection, Windows will silently

connect to the Windows U date website and install any suitable driver

it finds for the device. If no suitable driver is automatically found then

you need to insert the CD-ROM, su lied with the equi ment, in the

PC, run the executable “usb-install.exe” and click in “Install”.

10.1. MegaLogg2 software

This software makes communication between the equi ment and a

com uter with Windows o erative system easier. It makes it ossible to

synchronize the date and time of the equi ment internal clock with the

com uter date and clock, to transfer the stored date, to clear the memory,

to generate test re orts, etc. The installation and o eration instructions

are included in the software.

19

11. Remote control

The MEGABRAS equi ment that have Bluetooth interface can be

controlled remotely via an Android device (smart hone / tablet) running

the a lication.

DISPONÍVEL EM

• ndroid™ and Google Play™ Store is a trademark of Google LLC

• Bluetooth® is a registered trademark of Bluetooth SIG, Inc. worldwide

Minimum smartphone / ta let requirements

- Android 4.1 Jelly BEAN system (API 16) or higher;

- Bluetooth communication.

Pairing

To erform the airing between equi ment and the Android device, follow

the rocedure:

•To enable the Bluetooth, in screen “A lications”, ta "Settings"

> "Bluetooth" and drag the Bluetooth slider to the right.

•To air your equi ment, on screen "A lications", ta "Settings"

> "Bluetooth" > "Search". Select the equi ment and wait for the

end of the airing (If necessary, acce t the automatically

generated assword to confirm or enter the PIN 1234).

20

12. Cleaning

Cleaning of this instrument should be carried out using a soft cleaning

liquid, after verifying that it doesn’t affect the lastic arts used in the case

and in the Control Panel of this equi ment.

To avoid electrical shock, make sure that the equi ment is

com letely dry before Power it On.

13. Replacement fuse

Precautions

• Perform the rocedures below with the equi ment turned off.

• Disconnect the equi ment from the mains su ly and remove

the ower cord.

• Disconnect the test leads.

• Disconnect the equi ment from the mains, un lugging the ower cord.

• With a screwdriver, remove the fuse holder cover, lightly ressing the lid

and turning ¼ counter clockwise.

• Remove the blown fuse and insert a new fuse in the fuse holder cover.

• Place the cover in the com artment and with the screwdriver turn ¼

clockwise or until the fuse holder cover ro erly fits the fuse

com artment.

Fuse Schurter, model SPT 5x20 (Time-lag) 5A/250V. High reaking capacity.

To re lace the fuse, use only the fuse ty e s ecified in the

equi ment.

21

Table of contents

Languages:

Other MEGABRAS Test Equipment manuals

Popular Test Equipment manuals by other brands

Rohde & Schwarz

Rohde & Schwarz SMBV-K361 user manual

PIE

PIE PIECAL 211 operating instructions

ULTIMATE SPEED

ULTIMATE SPEED UAWSB 2 A1 operating instructions

Oakton

Oakton EcoTestr EC1 operating manual

Mecmesin

Mecmesin MultiTest 0.5-dV Service and repair manual

Extech Instruments

Extech Instruments MG320-NIST user manual