MEGABRAS MD 5060x User manual

Formato: 135mm x 190mm

GU-1329

EXP100240

5 kV digital insulation tester

• User guide

• Technical specifications

3

MD-5060x

5 kV digital insulation tester

User guide

GU-1329

© 2009 MEGABRAS. All rights reserved.

Printed in Brazil.

4

Safety warnings

•Before to use this instrument the User guide and Safety warnings must be read

and understood.

•Safety procedures and rules for working near high voltage energized systems

must be observed during the use of this equipment. The generated voltages may

be dangerous.

•Do not connect or disconnect the test leads during the measurement.

•Do not touch the test leads before the high voltage indicator turn-off.

•Be careful not to make short-circuit between the high voltage terminals and the

“R” or “Guard” terminals while a measurement is running, because it could be

dangerous for the operator.

•Be sure that there are not any voltage difference between the points to which the

equipment will be connected to, neither between them and ground.

•The panel, terminals and connectors of the equipment must stay dry and clean.

This equipment should be used only by a trained and competent

person, strictly applying suitable safety rules.

Used symbols

Caution, risk of electric shock.

Caution, refer to User guide.

Equipment complies with current EU Directives.

Battery

Printer

Voltmeter

5

Index

1. Description............................................................................................................6

2. Control panel functions.........................................................................................7

2.1. Connections and panel items ........................................................................7

2.2. Keyboard .......................................................................................................8

2.3. Indicators .....................................................................................................10

2.3.1. Display..................................................................................................10

2.3.2. Built-in chronometer .............................................................................10

2.3.3. Real time clock .....................................................................................10

2.3.4. Test number .........................................................................................10

2.3.5. Model and serial number ......................................................................10

2.3.6. High voltage indicator ...........................................................................11

3. Power supply ......................................................................................................11

3.1. Battery status check ....................................................................................11

3.2. Battery charger............................................................................................12

4. Connecting the equipment..................................................................................13

4.1. Using the Guard terminal.............................................................................14

5. Tests definition ...................................................................................................14

5.1. Test voltage definition..................................................................................15

5.2. Selection of the operation mode..................................................................16

5.2.1. “TIMER” Mode ......................................................................................16

5.2.2. SVT Mode (step voltage tests) .............................................................17

5.2.3. “Pass / Fail” Test mode ........................................................................18

5.2.4. Normal mode ........................................................................................19

6. How to perform tests ..........................................................................................19

6.1. Polarization index (PI) .................................................................................20

6.2. Dielectric Absorption Index (DAI) ................................................................21

7. Other functions ...................................................................................................22

7.1. Filter.............................................................................................................22

7.2. Voltmeter .....................................................................................................22

7.3. Hold .............................................................................................................22

7.4. Internal memory...........................................................................................23

7.5. Auto power-off .............................................................................................23

8. Software..............................................................................................................24

8.1. USB Drivers.................................................................................................24

8.2. MegaLogg2 Software ..................................................................................27

8.3. HyperTerminal®- Real time data transfer....................................................28

8.3.1. COM number ........................................................................................28

8.3.2. HyperTerminal ......................................................................................30

9. Printer .................................................................................................................33

10. Technical specifications....................................................................................34

11. Application note 32 ...........................................................................................36

12. Warranty ...........................................................................................................39

6

1. Description

The Megabras MD-5060x is a smart, microprocessor-controlled, 5 kV

insulation tester and analyzer. Besides the conventional measurement of

insulation resistances up to 5 TΩ, its advanced features allow to

automatically measure both the Polarization Index and Dielectric

Absorption Index, thus significantly simplifying testing of transformers.

This insulation tester is portable, battery-powered equipment. Test

voltage may be chosen from 500 V to 5 kV in 100 V increments. Due to its

measurement principle (actual voltage and current readings) the accuracy

of resistance measurement is not affected by any test voltage error.

The built-in chronometer automatically counts the elapsed time since the

start of measurement. Measured values are transmitted through the data

output (USB) and are printed in the built-in printer as a registration of the

performed test. Furthermore, the measured values are stored in a non-

volatile internal memory. Up to 4000 measurements may be stored, to be

transferred afterward to a computer running the MegaLogg2 program.

This software allows a further analysis of the test results, including a

graphical representation and automatic report generation. The real time

clock and calendar, and the sequential test number, facilitates the

identification of each test, and the organization of a predictive

maintenance system by trend analysis.

Some other advanced features are useful to run the most sophisticated

insulation analysis. Step Voltage Test, configurable Pass-Fail and timed

measurements are automatically performed, with a very simple and user-

friendly setup. The measurement parameters are stored in the non-

volatile memory for an easy configuration.

The cabinet is strong and lightweight, easy to carry, impact-resistant and

suitable to be used under severe weather conditions. Thus the insulation

tester supplies very reliable and accurate measurements both in

laboratory and out in the field.

7

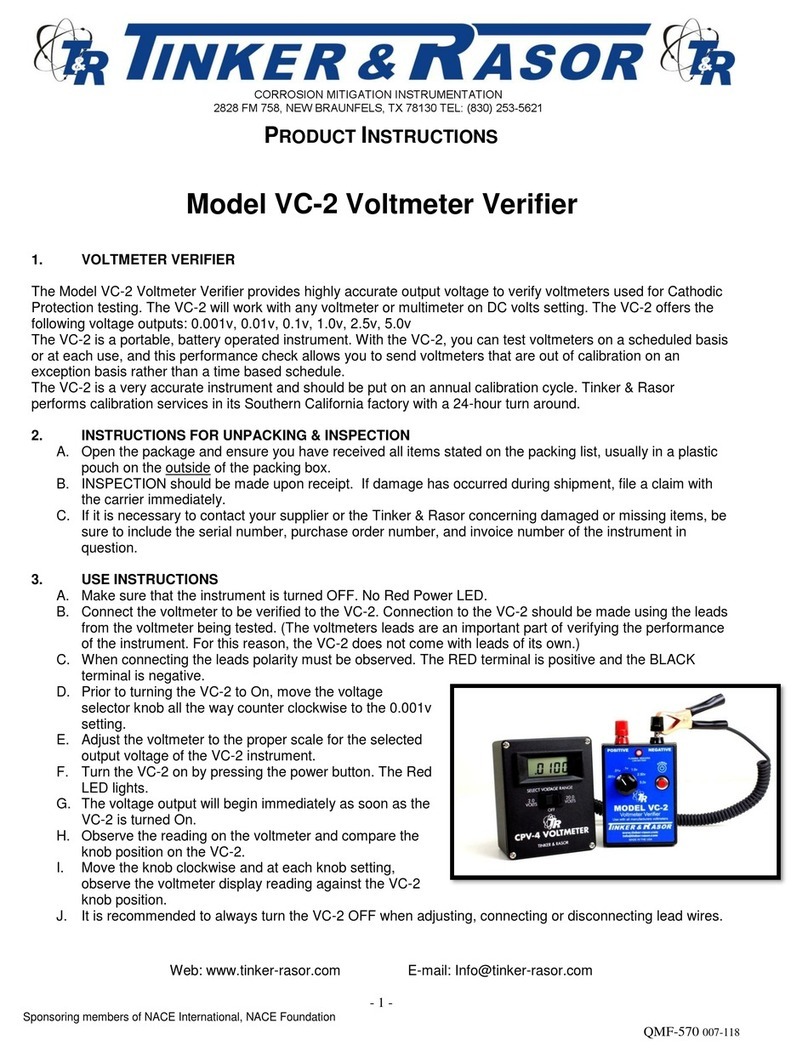

2. Control panel functions

2.1. Connections and panel items

Voltage output terminal (-V)

Zero reference terminal (+R)

Guard terminal (G)

Display

Keyboard

USB communication port

Power supply input

Paper feed control

8

2.2. Keyboard

Button Function Led

On/Off switch. -

It activates the filter that minimizes external

noise interference.

Indicates filter function

is on.

It shows the battery charge status on the

display.

Indicates that the

battery charger is in

operation.

When activated, it allows to program test

voltage in steps of 500 V. It enables the fast

voltage selection keys .

500 V steps test

voltage.

When activated, it allows to program test

voltage in steps of 100 V. It enables the fast

voltage selection keys .

100 V steps test

voltage.

Fast selection of 500 V test voltage. 500 V test voltage.

Fast selection of 1 kV test voltage. 1 kV test voltage.

Fast selection of 2.5 kV test voltage. 2.5 kV test voltage.

Fast selection of 5 kV test voltage. 5 kV test voltage.

9

When activated, it allows to program the

Operation Mode (Normal, SVT or TIMER).

Indicates Operation

Mode is enabled.

When activated, it allows to program the limit of

the “Pass-Fail test”.

Indicates LIM function

is on.

Turns On/Off the printing of the measured

values on the printer.

The printer is on.

Increase the value that is being programmed. -

Decrease the value that is being programmed. -

Starts the test. Indicates that the test

is being carried out.

Displays the actual voltage applied. -

Hold - freeze the last reading on the display. Hold function is on.

It displays the calculated value as the result of a

Step Voltage Test (SVT) or Polarization Index

(PI).

-

It displays the calculated value as the result of a

Dielectric Absorption Index. -

End of test. -

10

2.3. Indicators

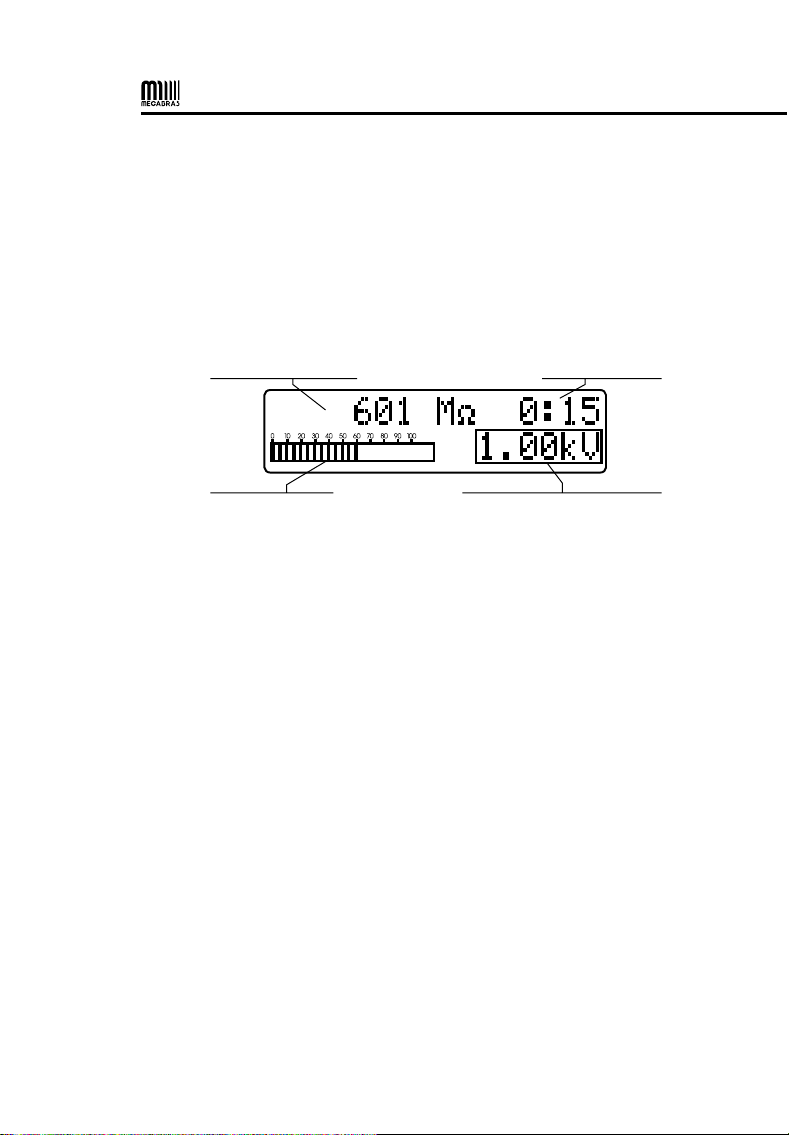

2.3.1. Display

Alphanumeric LCD where the measurement result, the corresponding

measuring unit, the elapsed time since the measurement started, the

analogue indication by means of a bargraph and messages to the

operator are displayed (in English).

messages to the operator

test number

measurement results

measuring unit

analogue indication

(bargraph)

selected voltage

messages to the operator

time indication

2.3.2. Built-in chronometer

It features the elapsed time (in minutes and seconds) since test voltage is

applied.

2.3.3. Real time clock

It has a real time clock with date, hours and minutes indication, to make

identification of tests recorded in paper or in memory easier.

2.3.4. Test number

Tests are automatically numbered by the equipment to make their

identification easier. The test number is printed at the beginning of each

test and it is stored in memory.

2.3.5. Model and serial number

At the beginning of each test, the equipment model, as well its serial

number, are registered, making it possible to relate the obtained results

with their respective equipment Calibration Certificate.

11

2.3.6. High voltage indicator

A

light indicator warns the occurrence of high voltage on the

output terminal during the measurement and keeps lit until the

discharging process has been completed.

3. Power supply

This equipment is powered by an internal rechargeable battery (12 V -

2.3 Ah).

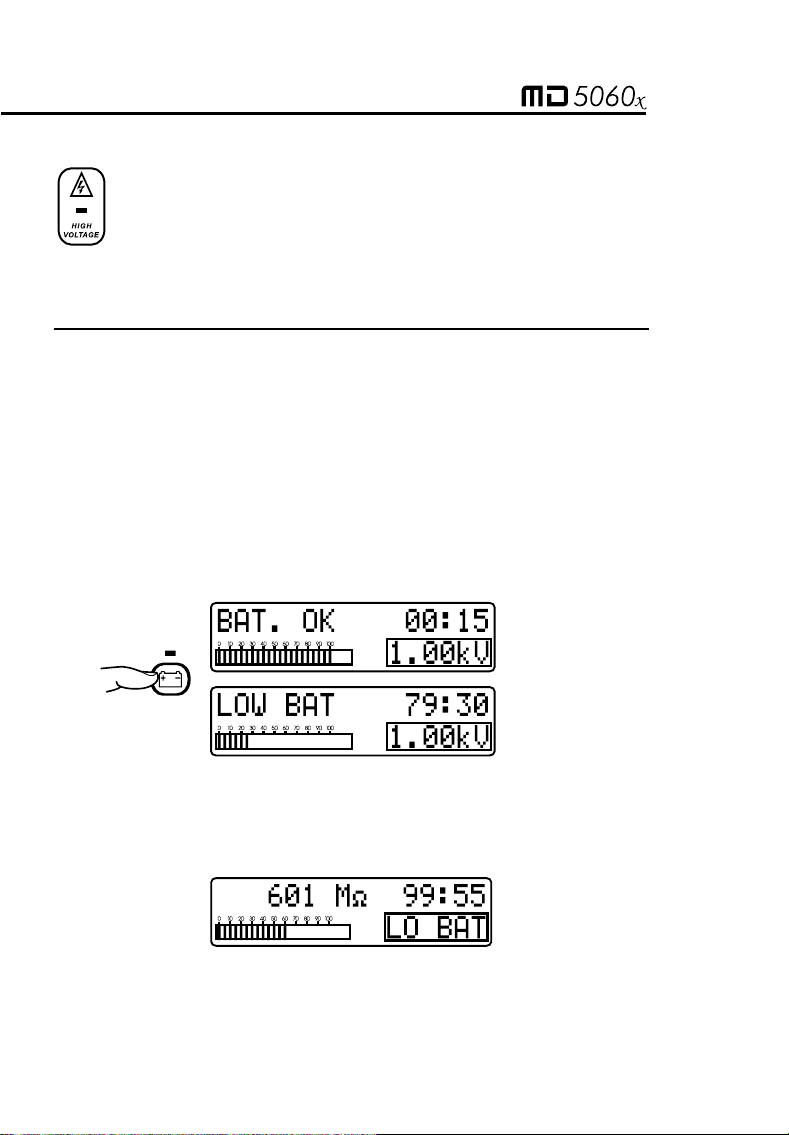

3.1. Battery status check

During the measurement, it is possible to check the battery status. The

key must be pressed. If the battery charge is enough, it will read

“BAT OK”. If the charge is not enough, the message will be “LOW BAT”,

and the battery should be recharged. The analogue bargraph will give an

approximate idea of the remaining charge percentage (at least 20% is

required for a normal operation).

When the battery charge reaches the normal operation minimum value,

the message LO BAT appears automatically in the area where the test

tension value is indicates, alternating it every 1 second.

12

3.2. Battery charger

This equipment has an intelligent built-in circuit that controls the battery

charge and doesn’t allow the equipment to operate during the

charging process. In order to charge the battery, follow this procedure:

•Verify that the On/Off switch is switched off.

•Connect the equipment into the mains supply. The charging indicator

(led over key ) will turn-on red and will remain that way until the

battery is totally charged. Then the light will remain green and keep in

that way until the equipment is disconnected of the mains supply.

The following chart summarizes the meaning of LED luminous indications:

Green and red

flashing alternatively

Test of the initial condition of the battery when plugging

the mains, during one second.

Permanent red Battery under charge.

Flashing red Charging current is less than normal.

Permanent green The charging process has been successfully finished.

Battery OK.

Flashing green The charging process has finished, nevertheless the

battery hasn’t received the complete charge.

A

t the end of battery useful life, the battery must be recycled or

disposed of properly, in order to protect the environment.

The rechargeable battery does not have “memory effect” and there are no

restrictions to start charging it as many times as is needed. However the batter

y

could be damaged if remains in deep discharge for a while.

To avoid this effect, charge the battery before left the equipment in storage and

don’t let pass more than 30 days without recharge, even if the instrument wasn’t

used (under storage, the battery loses part of its charge).

13

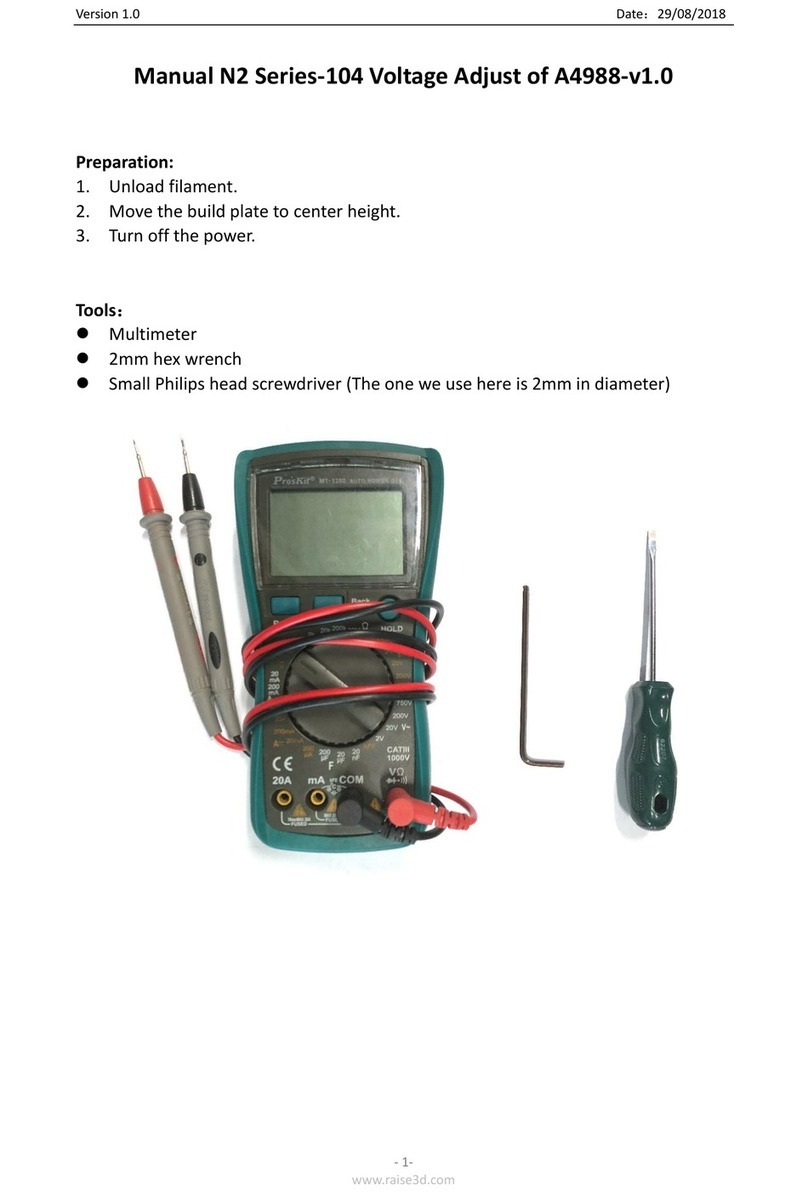

4. Connecting the equipment

ATTENTION: For a safety operation the procedures detailed below

should be carried out with the device Powered-Off.

Check if there is no differences of potential voltage between the points

where the equipment shall will be connected to, nor between them and

the ground.

Connect the red security terminal (red cable) to the insulation tester (-V)

output terminal. Connect BNC terminal to the zero reference (+R) terminal

and the “alligators” terminals to the element to be measured as indicated

in the figure below.

The test leads in the picture are illustrative.

14

4.1. Using the Guard terminal

The G (Guard) terminal can be used or not, according to the

measurement that is going to be carried out. During measurements, the

equipment must be electrically referred to earth in order prevent the

equipment from being on a high potential, which may produce unstable

readings. When insulation is measured regarding grounding, the R

terminal is connected to earth and the condition by means of which the

equipment potential setting is fulfilled. If the measurement is performed

between two parts, which are not grounded (for example, between two

phase conductors in a tree-phase cable), the insulation tester Guard

terminal must be grounded. This implies that whenever a measurement

is performed, one of the GUARD or R terminals must be grounded,

but not both of them simultaneously.

MEGABRAS Application Note 32 explains the usage of Guard terminal for

minimizing the parasite resistance effect, whose influence one intends to

minimize.

5. Tests definition

The MD-5060x is an extremely versatile instrument that enables

automatic performance of several types of insulation tests, and records

them in its internal memory and/or prints the results. Thus, it is necessary

to appropriately define the tests to be performed, setting the following

parameters before starting the measurement:

• Test voltage

• Test duration for “TIMER” mode test

• Maximum Voltage for step voltage test (SVT)

• Minimum resistance limit for “Pass/ Fail” tests

15

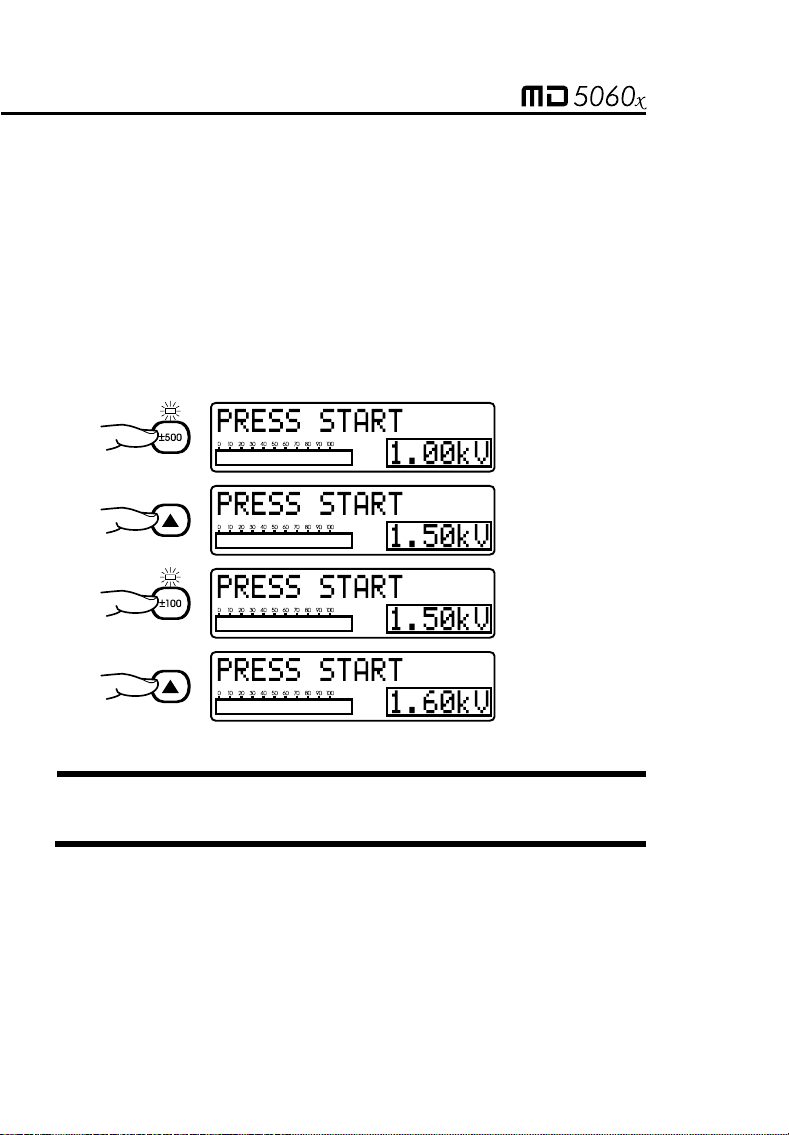

5.1. Test voltage definition

In order to define the test voltage value, first it is necessary to select one

of voltage adjustment keys: or . These keys enable both the pre-

programmed voltage selection (, , and ) and the and

keys which increase or decrease the value of the step voltage test

for 100 V or 500 V, depending on the selected voltage adjustment key. As

long as the equipment is on, the voltage adjustment key will be

selected. Press again the adjustment key selected at the moment to

leaving the test voltage selection mode.

Note: Test voltage is the only parameter that can be modified during

tests.

16

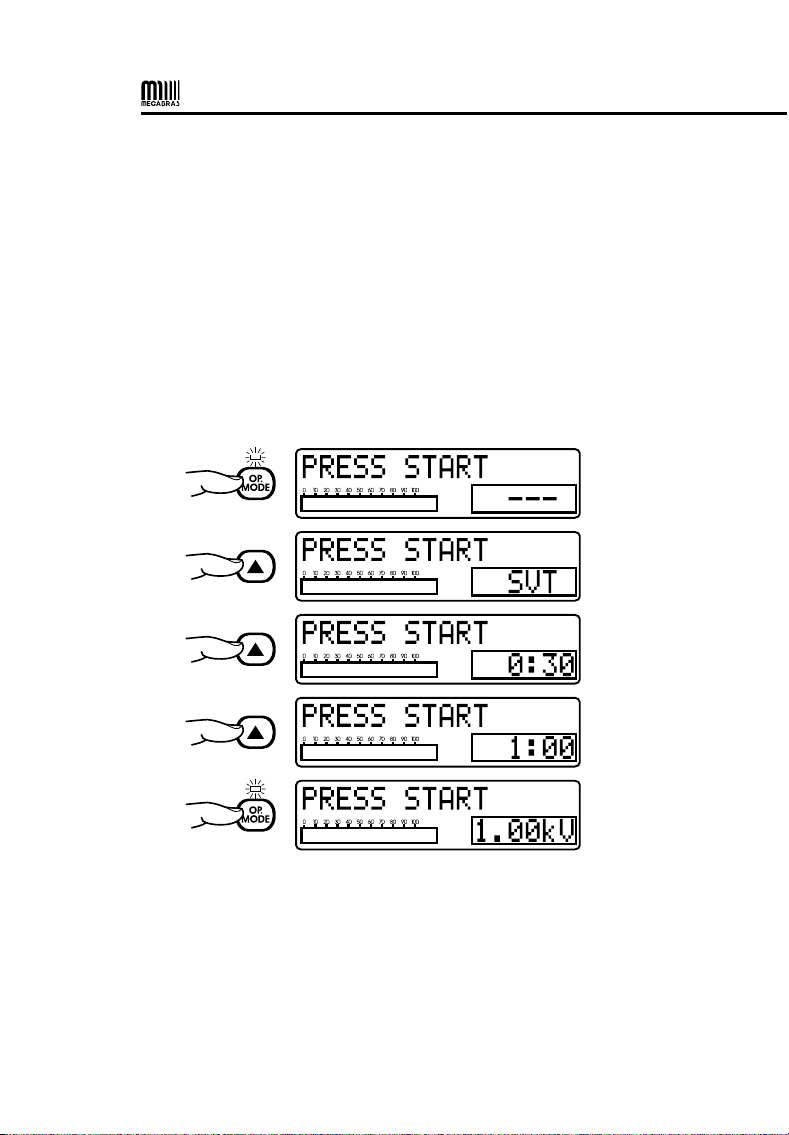

5.2. Selection of the operation mode

The MD-5060x insulation tester has four operation modes: Normal, with

“TIMER”, SVT and “Pass / Fail test”. The first three modes are selected

using the key; the “Pass/ Fail test” mode is activated pressing

key.

5.2.1. “TIMER” Mode

The use of key allows the MD-5060x setting for the performance of a

pre-set - duration test; when this mode is selected, the display shows the

programmed time. Use and keys to define the duration of the

tests in 30 seconds, 1 minute, 3 minutes, 10 minutes or 30 minutes.

17

5.2.2. SVT Mode (step voltage tests)

The use of key allows the MD-5060x setting for the performance of a

step voltage test; when this mode is selected, the display shows the SVT

abbreviation.

Under this operation mode, the user does not define a specific voltage

test, but a maximum voltage value. The device will start tests applying a

500 V voltage and increase this value in 500 V steps each minute until

reaching the programmed voltage. At each stage, the MD-5060x

measures the resistance before advancing towards the following step.

The use of voltage adjusting keys, determines the value of the highest

voltage – which will be, in all cases, a multiple of 500 V, up to a 5000 V

limit. It is advisable to use the key in order to select this value;

key may be used, but if the selected value is not a multiple of 500, it will

be rounded down.

18

The test result is calculated according to the following formula:

=

SVT

R

R

V MAX

500

After test ending, the value may be recovered by pressing key.

5.2.3. “Pass / Fail” Test mode

Press key in order to determine the lower insulation limit for type

“Pass / Fail test”. Select this value using and keys. Possible

values are 10 MΩ, 100 MΩ, 1 GΩ or 10 GΩ.

During a “Pass/ Fail test”, the MD-5060x will indicate when the insulation

resistance is lower than the programmed limit, with an intermittent beep

and the key led flashing. The key led will remain flashing until the

end of tests, or until the measurement of the resistance value is greater

than the programmed limit.

19

5.2.4. Normal mode

The normal mode is used in the resistance measurement with unique

voltage, without time limit. When selected, there are no special indications

in the display. To return to normal mode, press the key and use the

or to select the “- - -” option.

6. How to perform tests

Press key. The high voltage led turns on immediately, indicating that

the equipment internal generator is applying voltage to the element that is

being tested. The display will show the test number, the selected voltage

value and it will start the elapsed time count.

For a few seconds, the auto-range system will search for the most

convenient range for the value being measured. Meanwhile, the display

will show the message:

20

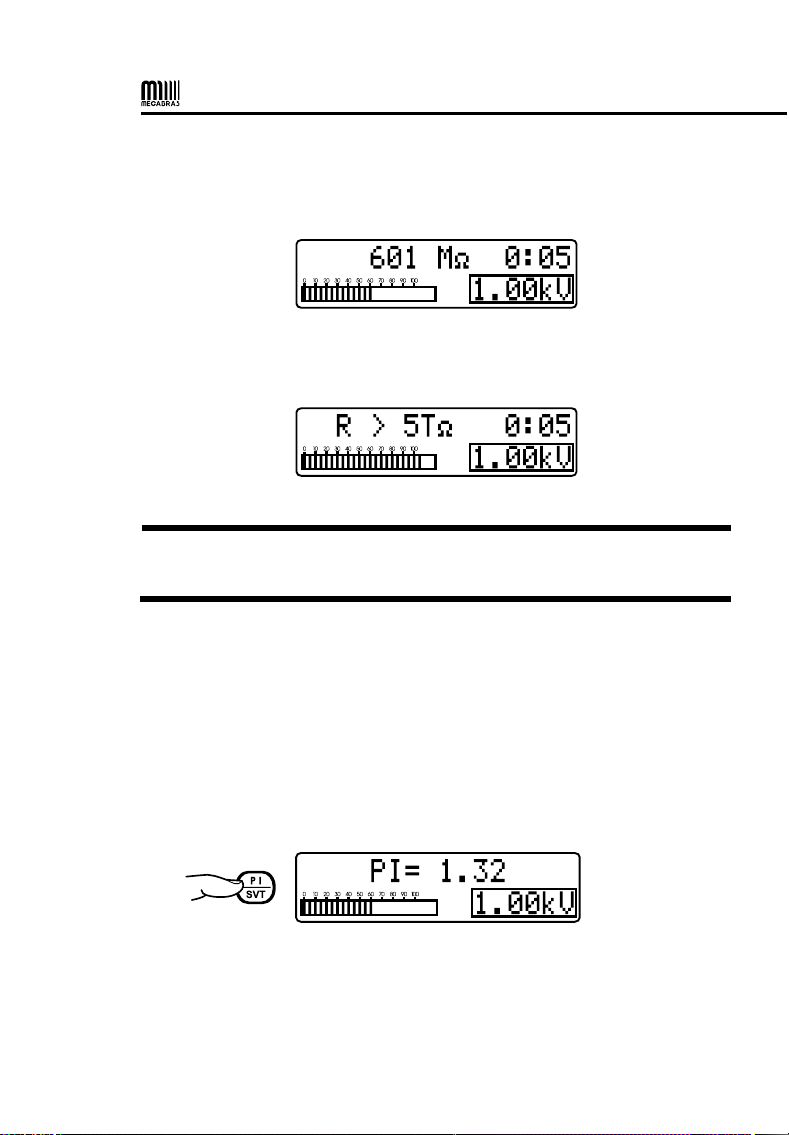

If the measured value is within the device range, the display will show the

resistance value indication and its corresponding unit, and it will start the

analogue bargraph indication.

If the measured value exceeds 5 TΩ @ 5 kV, the following message will

be read:

Note: If, during the test, it is necessary to change the test voltage, item

5.1 sequence shall be repeated

6.1. Polarization index (PI)

The key makes it possible to visualize the Polarization Index value on

the display. For this type of test, the equipment must be connected and

applying voltage to the sample for 10 minutes. After this period, the

operator must press the key to show the PI value on the instrument

display. If the key is pressed before the 10-min period has elapsed, the

display will show PI= - - -.

21

The polarization index is the ratio between the insulation resistance value

measured after 10 min and the value measured after 1 min. This index is

useful to determine whether it is necessary to perform preventive and

predictive Maintenance in order to detect any insulation resistance wear

and tear due to the excess of dust, dirt, grease, or else the action of

chemical or physical agents, etc.

=

PI R

R

10 minutes

1 minute

6.2. Dielectric Absorption Index (DAI)

The key makes it possible to visualize the Dielectric Absorption Index

value on the display. For this kind of test, the equipment should be

connected, applying voltage to the sample for 60 seconds. After this

period, the operator must press the key to read the absorption index

value on the display. If this key is pressed before the 1-minute period has

elapsed, the display will show DAI = - - -.

The Dielectric Absorption Index is the ratio between the insulation

resistance value measured after 60 seconds and the value measured

after 30 seconds. This value is useful to determine whether it is necessary

to perform preventive and predictive maintenance on the coils

(transformers, engines and motors, generators, etc.).

=

DAI R

R

60 seconds

30 seconds

Table of contents

Other MEGABRAS Test Equipment manuals