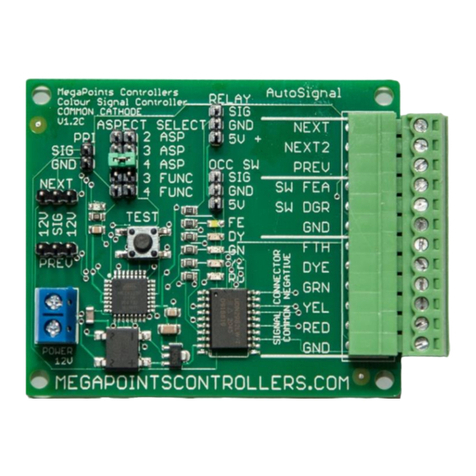

MegaPoints Controllers Servo Controller User manual

MegaPoints Servo Controller

Covers MegaPoints Servo Controller boards 1.5h –1.6.

A flexible and modular device for controlling model railway

points and semaphore signals using inexpensive R/C servos

and relays.

User guide

Revision 24 April 2016

© MegaPoints Controllers 2015

Contents

Introduction ...................................................................................................................................... 3

New features................................................................................................................................. 3

Semaphore bounce program ......................................................................................................... 3

Before starting............................................................................................................................... 4

Quick setup guide.......................................................................................................................... 4

Web site........................................................................................................................................ 5

Reference section.............................................................................................................................. 6

Hooking up.................................................................................................................................... 6

Servo connectors........................................................................................................................... 6

Switch connectors ......................................................................................................................... 6

Memory connectors ...................................................................................................................... 6

Remote setup connector ............................................................................................................... 7

Servo installation........................................................................................................................... 8

Additional advice........................................................................................................................... 8

Servo installation images............................................................................................................... 9

Initial set-up .................................................................................................................................. 9

Power connection...................................................................................................................... 9

Servo connection....................................................................................................................... 9

Switch connection ................................................................................................................... 10

Using the memory function ......................................................................................................... 10

Input selection............................................................................................................................. 10

Setting up a master (switches) ................................................................................................. 10

Setting up a slave (network)..................................................................................................... 10

Clearing slave mode................................................................................................................. 10

Double heading ....................................................................................................................... 11

Factory reset (when servos mounted on baseboard) ................................................................... 11

Expansion.................................................................................................................................... 12

Using high power or digital servos ............................................................................................... 12

External high power voltage regulator ..................................................................................... 12

Driving relays............................................................................................................................... 13

Connecting a relay board ......................................................................................................... 13

Normal relay use...................................................................................................................... 13

Pulsed relay (Dapol) use........................................................................................................... 13

Specifications .............................................................................................................................. 14

Appendix......................................................................................................................................... 15

Summary of menu commands ..................................................................................................... 15

Changing the slave unit network address..................................................................................... 17

Pop-on switch board (optional).................................................................................................... 18

Expansion diagram ...................................................................................................................... 19

Contacting us............................................................................................................................... 20

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 3

Introduction

The MegaPoints Servo Controller is a sophisticated

microprocessor capable of managing up to 12 inexpensive

servos for points or semaphore signals independently in a

scale like manner. Each of the servos can be individually

configured and have their movement limit set for each

direction, reversed and the speed adjusted to suit your

particular application. It is also capable of advanced features

such as master/slave pairing and offers a useful memory

recall feature.

Each of the 12 servos is operated by a toggle switch requiring

a single wire that is switched to a common feed (ground). This

gives a huge reduction in cabling as the MegaPoints Servo

Controller can be placed close to the servos on the layout

requiring only a single wire for each servo to the mimic panel.

New features

The table below lists new features and the board version

introduced. See the respective sections for details.

Feature

Board version introduced

Remote programming, page 7.

1.5h

Relay support, page 13.

1.5i

External high current voltage regulator support,

page 12.

1.5i

Removed semaphore cycle on power up.

1.5i

NOTE: See the vertical bar on the left margin for changes between document versions.

Semaphore bounce program

All units shipped in 2015 include a bouncing semaphore signal option that is accessed by cycling

through the MODE options while in programming mode. Programs 1 &2 are for points and 3 & 4 are

for semaphore signals. See the appendix for a full list of configuration options. See YouTube videos

via our web site for examples and setup.

Note: No additional programming hardware is required to operate or configure this unit.

MegaPoints Controllers use

static sensitive components

that must be handled with

care.

Avoid touching any

components or the circuit

printed on the bottom of

the board.

Avoid placing the board on

any metallic surfaces

including track.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 4

Before starting

Connect the board to a smoothed (regulated) DC power supply in the range of 10 –14 volts. 12 volts

is ideal. Your power supply should be capable of supplying a minimum of 2 amps per MegaPoints

Controller. See the FAQ section of the web site for power supply recommendation.

Quick setup guide

We recommend you become familiar with the units operation before installing on any layout. Each

servo output has been set for a wide range of motion during manufacture. This is perfect for testing

on the bench, but unsuitable for installation into a layout as servos may be overdriven. Before

installing on a layout read the paragraph below and factory reset the unit.

IMPORTANT: Before installing servos into your layout we recommend you perform a factory reset by

holding down the LOW and HIGH buttons while applying power. During the reset the lights will flash

(takes about 5 seconds). When complete all servos will move to their mid-point and the range of

motion reduced to zero. Connecting a servo will centre it ready for installation on the baseboard.

Before the servo will move you MUST set the end points for each individually. Following this

procedure will simplify servo installation and prevent any accidental over driving if movement is

restricted.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 5

If you are familiar with servos this section will get you up and running quickly. It is recommended

you initially hook up the board, servos and switches on a bench to become familiar with its

operation.

1. Connect servos to connectors on right side of board (1-12).

2. Connect switches to S1-S12 using supplied cables (left side).

3. Connect switch common to SC and memories (lower left).

4. Apply DC power to GND & +VE (lower right), yellow LED will begin to flash indicating run

mode.

5. Short press PROG button once. RED light is on to indicate programming mode. Yellow light

now flashes in groups to indicate which servo is being programmed (1-12).

6. Press and hold LOW button (bottom of board) to set servo low motion limit.

7. Press and hold HIGH to set servo high motion limit.

8. Short press PROG to advance to next servo.

9. After the 12th servo has been programmed the next press of the PROG button returns the

unit back to run mode.

10. Operate your switches to move the servos across the programmed movement range.

IMPORTANT: Servos operate differently from coil type points motors traditionally used in model

railway layouts. This is because servo motors are constantly powered and draw current based upon

the servo load. It is therefore important that when the servo end points are set, care is taken to

ensure the servo moves freely to each end point and does not suffer from any binding or mechanical

restriction. Ultimately the end point of the servo must be set by the electronics and not by driving a

servo under load into a mechanical limit. Over driving a servo or leaving it under constant load will

shorten the servo life and increase current drain.

Web site

Check out our web site (www.loolee.org) for instructional videos, updates, further ideas and

examples of installation.

If using the MegaPoints Servo Controller in a networked environment we suggest also reading the

Networking Guide from our web site.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 6

Reference section

Hooking up

Servo connectors

Each servo can be plugged into the connector on the right side of the board. Ensure the signal wire

(usually white or yellow) is towards the middle of the board (left side of connector) and the negative

wire (black or brown) is towards the outer edge. Servo cables can easily be extended with a servo

extension cable or by soldering cable to a recommended maximum length of 5 meters.

Switch connectors

The unit is supplied with 6 cables and plugs. Connect these to the switch inputs on the left side of

the board. Extend the cable as necessary to the switches installed on your control panel. The SC

(switch common) should be wired to the common of all toggle switches and memory buttons. When

the circuit is closed the servo will move to the high position. The switch inputs are arranged in threes

using a servo type connector.

Memory connectors

The memory buttons are dual function (long press / short press) you must use press to make type

pushbuttons. Toggle switches will not work for memory inputs.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 7

Two identical cables will connect to the memory pushbuttons and switch common (M1, M2, M3, MR

& SC). See picture for cable identification. NOTE: There are two “SC” connectors. These are identical.

Remote setup connector

Just above the four setup buttons you will observe the 5 pin remote setup connector. This is an

optional feature and allows you to place the board in an inaccessible location yet retain the ability to

reconfigure all settings remotely.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 8

Each of the four setup buttons is connected to the corresponding pin on the connector (left to right).

The right most connector is the common ground.

Use a pair of standard servo extension leads with plugs fitted or make your own to suit your

requirements. Connect each of the left four cables to one connector of a pushbutton and connect

the other pushbutton connector to each other and the common ground. Each pushbutton will mimic

the four setup buttons on the board (LOW, PROG, HIGH, and MODE).

Servo installation

The attraction of R/C style servos is their scale like speed, adjustability, flexible mounting options

and low cost. Servos can be mounted on the top of the board using pushrods or flexible Bowden

tubes, or hidden underneath using piano wire to fit Peco style points. However you choose to mount

your servos it is important you centre the servo before committing it to the layout as you would

using solenoid point motors.

1. To centre a servo connect it to the MegaPoints Servo Controller. When delivered all servos

will centre and the range of movement is set to 0.

2. Without moving or rotating the servo output shaft, locate the output arm to the centre of

the range of motion.

3. When attaching the servo to the points the points should be in the mid position (neither in

the straight or turned position).

4. Once the servo is fitted you can press (and hold) the Low or High buttons to accurately set

the end points or range of motion while in programming mode.

5. Press the PROG button to advance to the next servo. After the 12th servo has been selected

the unit will exit programming mode.

The above procedure only needs to be completed once during installation. All end points, speeds

and directions of travel will be remembered by the controller.

Additional advice

Keep the servo output arm short. Points typically do not require a large range of motion. It is

therefore better to have the servo shaft rotate as much as possible by having a shorter output arm.

Use the inner most hole when several are available. This increases the servo resolution and

controllability while maximising the output torque. If the arm is too long, the servo range of motion

will be small and accuracy will be impaired.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 9

Servo installation images

In the above image thin aluminium plate was used as a pivot for 1.2mm diameter piano wire

connecting the servo to the points.

Below, aluminium channel provides the most flexible and easiest under baseboard mounting

method. See web site for videos and channel specifications.

Initial set-up

The MegaPoints Servo Controller is ready for use out of the box. Just hook it up to a regulated DC

power source (12 - 13.8 volts) observing the correct polarity and begin to use it.

WARNING: This device uses a linear voltage regulator that will get hot during usage. The greater the

input voltage the greater amount of heat will be dissipated by the regulator. Do not touch the

voltage regulator while the board is in use.

Power connection

Connect a regulated DC power source of at least 2 amps capacity to the GND and +VE connectors

(located on the lower right side of the board).

Servo connection

Plug in servos to the connectors on the right side of the board (numbered 1 –12). The signal (white

or yellow wire) should be towards the inside of the board. Black or negative is to the outer edge.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 10

Switch connection

Connect a single wire from a toggle switch or lever to the single connector posts on the left side of

the board (labelled 1 –12).

Connect a common connection to the SC connector on the lower left of the board.

When the switch cable is pulled low to the supply voltage the servo will move to the opposite end of

its motion. Disconnecting or breaking the connection will cause the servo to move back.

Using the memory function

Before storing a memory, set your points into the position you want to memorise.

1. Press and hold down a memory button (M1 –M3) for two seconds (you’ll see the red light

flash on the MegaPoints Servo Controller board to indicate the memory has been stored).

2. Move the points into a different position using the switch panel.

3. Momentarily press the memory button and observe the points take up the pre-set position.

4. While a memory is active, the RED light will illuminate continuously on the MegaPoints

controller board.

5. To deactivate a memory and go back to normal switches on the panel, momentarily press

the MR button. The RED led will extinguish.

6. To overwrite a memory, repeat the procedure above.

Input selection

This section explains how to change from switch input to network input and back. Only one mode

can be active at a time.

Setting up a master (switches)

Master mode is the default mode and will read the inputs from the switches connected to the S1 –

S12 connectors. This mode should be selected when the MegaPoints Servo Controller operates

standalone.

To configure a MegaPoints Servo Controller as a master unit, press and hold the HIGH button while

turning the power on. The RED led will flash five times to indicate it is in master mode. This is the

default mode.

Setting up a slave (network)

Slave mode should be selected when the MegaPoints Servo Controller receives commands via the

network connector such as when connecting to a DCC module or MultiPanel.

To configure a MegaPoints Servo Controller as a slave unit, press and hold the LOW button while

turning the power on. Both LEDs will flash against each other for a few seconds when the controller

is powered on to indicate the unit is in slave mode.

Clearing slave mode

Hold the HIGH button during power on to return the unit to master mode.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 11

Double heading

This unit can be paired with another for more complex layouts. When paired one unit becomes the

master and the other the slave. The slave units toggle switches and memory functions are disabled;

however the on-board programming and servo reversing function as normal.

What is double heading?

When in a double header configuration the switch inputs from the master also operate the slave

unit. Each servo channel is linked on both units so that when servo 1 is moved on the master, it will

also move on the slave unit. This means that on large or complex layouts such as pyramid or

rhombus fiddle yards as one set of points is opened at one end of the track, the corresponding

points are moved in synchronisation thus preventing the need for complex interlock mechanisms.

Factory reset (when servos mounted on baseboard)

With the unit powered off, hold down the LOW and HIGH buttons and turn the unit on. The red light

will blink for about 5 seconds indicating a factory reset. This will also reset the memories to factory

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 12

defaults and master/slave mode to master. The default slave address of 2 is reconfigured. This will

also reset servo travel range back to the centre. You will have to individually set the range of travel

for each set of points again.

Expansion

The following table lists the expansion options for the MegaPoints Servo Controller.

Expansion

Description

Availability

Double Heading

Links two MegaPoints Servo Controllers together

eliminating interlock mechanisms.

Now

Remote controller

(Mimic Panel)

Reduces cabling to three wires for control panels.

Allows multiple control panels to operate the units.

Provides LED panel feedback on points settings.

Allows the linking of up to 16 MegaPoints Servo

Controllers.

Expands to 192 switches for points control.

Expands the memory capability to 192.

Adds routing functionality.

Now

DCC Interface

Hooks up the MegaPoints Servo Controller to the

DCC bus.

Now

Routing processor

Adds up to 24 routes to your layout.

Now

Relay driver

Can drive 1 –12 relays on the servo outputs.

From board 1.5i

onwards.

Using high power or digital servos

The MegaPoints Servo Controller is designed to use low cost 9 gram analogue servos. These offer an

excellent performance at their price point and are absolutely fit for purpose. There are extreme use

cases where it is required to deviate from the recommended servo range. Possible reasons may

include:

Using digital servos to eliminate the switch on kick when power is applied because the

device being operated is too delicate or small to tolerate the movement.

Using waterproof servos in an all weather installation such as in a garden.

Using high torque servos for a larger or non model railway application.

There is no use case for improving resolution with an expensive digital servo. You are more likely to

experience the opposite as the microcontroller may jitter by as much as 8 µsec as stated in its data

sheet so plan and test carefully when deviating (or contact me for advice).

External high power voltage regulator

Provision has been made to bypass the internal voltage regulator on the MegaPoints Servo

Controller and connect an external switching regulator that can offer up to 3.5 Amps current

capacity (over six times more than the built in regulator) by using the high current voltage regulator

available from out web site.

See the separate MegaPoints Servo Controller Relay Guide documentation for wiring details,

available from the web site (www.loolee.org).

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 13

To configure an external regulator do the following:

Disconnect the power cables from the screw terminals. Do not reconnect!

Connect 12 volt stabilised power supply to the input cables of the switching regulator.

Connect the servo plug to one of the middle servo connectors (suggest S6 or S7) to even

power distribution (ensure the RED socket goes into the middle connector and the BLACK

socket goes to the right connector (when viewed from above).

Use as normal.

NOTE: When using the external voltage regulator for higher power it can consume up to 4 amps at 12

volts. You may also need to increase the power supply to cope with the higher current requirements.

NOTE: If you are using all 12 servo outputs with an external voltage regulator you must use a “Y

lead” so the voltage regulator and servo can connect to the same MegaPoints Controller connector.

Driving relays

The MegaPoints Servo Controller can optionally drive relays under the following conditions:

Only MegaPoints Relay boards are supported.

An external high current voltage regulator must be fitted.

The board must be hardware version 1.5i or later.

Programming modes 5 and 6 support relay types. Mode 5 is for normal relay use and will turn a relay

on or off as commanded by the MegaPoints Controller. Mode 6 will generate a single shot pulse of

between ¼ to ½ second duration every time the input changes.

Warning: Do not attempt to connect a relay directly to the output of a MegaPoints Servo Controller.

You WILL damage the unit and this is not covered by our warranty. Only connect MegaPoints

Controllers Relay Boards as these are isolated and current limited.

Connecting a relay board

Before connecting a relay board ensure you have installed the external high power voltage regulator

as detailed on page 12.

See the separate MegaPoints Servo Controller Relay Guide documentation for wiring details,

available from the web site (www.loolee.org).

Normal relay use

Mode 5 can be used to isolate track power, switch electro frogs or switch just about any electrical

application on your layout.

Pulsed relay (Dapol) use

Mode 6 can operate a Dapol semaphore signal. NOTE: It is recommended to fit a bypass pushbutton

if using Dapol semaphore signals in this mode to resynchronise the output following power on if

required. This is because it is not possible to move a Dapol semaphore signal to a specific position

(i.e. danger or clear) it is only possible to toggle the output.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 14

Specifications

The MegaPoints Servo Controller was lovingly designed and crafted in the United Kingdom by

railway enthusiasts, for railway enthusiasts.

Channels

12 servo / points outputs, each with the following independent settings:

High and low end point adjustment

Rotation speed (1 –3)

Reverse

Memories

3 (M1 –M3)

Power supply

9 –14 volts smoothed DC (reverse polarity protected) .

Current

Less than 200 mA + servo load. 2 amps peak with built in voltage regulator.

Expansion

Yes, via 2 x network connectors (on lower right of board).

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 15

Appendix

Summary of menu commands

Condition

Explanation

Boot up.

These are features accessed by holding a button or combination as power is applied to

the board.

Normal

These functions are accessed by pressing a button during normal use.

PROG

Feature available while in programming mode.

Condition

Button

Purpose

Boot up

LOW

Slave enable

Turns the unit into a slave controller. Can now be connected to a

master unit and will only accept commands from the master. Local

switch reading is now disabled. The YELLOW and RED LEDs will flash

alternately for 3 seconds to indicate slave mode is set. Subsequent

power on of the board will also result in the YELLOW and RED LEDs

flashing to remind you the board is slaved.

Boot up

LOW & PROG

Slave enable & set slave address

As above (Slave enable) plus reads switches S1-S4 to set slave address.

Boot up

HIGH

Master enable

Disable slave controller mode.

Boot up

LOW & HIGH

Factory reset –perform prior to installation!

Perform an installation reset. RED LED flashes for about 5 seconds

during the reset. After resetting, all end points and servo directions are

reset back to the factory condition (centre). Slave controller mode is

disabled. As the end points of all servos have been reduced to 0, no

servos will move until the end points have been individually

programmed. This feature ensures all servos are correctly centred

ready for installation and prevents the servo from over driving and

stalling.

Boot up

PROG &

HIGH

LAB reset

Perform a LAB factory reset. As above (Factory Reset) but with

endpoints for each servo. Only to be used for software testing and

development. Do not use when installing on a layout as servos may be

overdriven and stalled.

Normal

S 1 - 12

Operate the points corresponding to switch number.

PROG

M1 –M3

Servo speed (points mode)

Select memory button 1 –3. M1 sets the servo speed to slow, M2 to

normal and M3 to fast operation.

Normal

M1 –M3

Memory recall

Select memory 1 –3. The RED LED will illuminate to indicate a memory

is currently in use.

Normal

MR

Disables memory mode and resumes reading the switches S1 –S12.

Normal

M1 –M3

Program memory

Long press (more than 2 seconds) programs the memory for the button

pressed. The unit will memorise the points as they are currently set.

Normal

PROG

Programming mode

Enter servo programming mode. The RED LED illuminates in

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 16

programming mode. Solid means a servo is operating normally,

flashing indicates it has been reversed.

PROG

PROG

Advance to next servo

While in programming mode, subsequent presses of the PROG button

moves you onto the next servo to be programmed. As each servo is

selected, it will jump to its centre position. The yellow indicator will

flash in groups. The number of flashes indicates which servo is being

programmed, so 6 flashes means servo channel 6 is currently being

programmed. After the 12th servo has been selected, the next press

will end programming mode.

PROG

MODE

Cycles through channel modes and is indicated by the number of

flashes on the right LED during programming mode. The MegaPoints

Servo Controller currently supports six modes of operation. Before

pressing the MODE button, count the number of flashes on the right

LED first to determine the current programmed mode.

Channel modes:

1 flash –Points, normal direction.

2 flashes –Points, reversed direction.

3 flashes –Semaphore, normal direction.

4 flashes –Semaphore, reversed direction.

5 flashes –Relay control.

6 flashes –Relay control (pulse).

NOTE: Modes 5 & 6 are only available on boards 1.5i and later.

PROG

LOW

Moves a servo slowly to a new low end point. Release button to stop.

PROG

HIGH

Moves a servo slowly to a new high end point. Release button to stop.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 17

Changing the slave unit network address

To change the address of a slave unit, throw input switches (S1 –S4) to set slave addresses 2 –17.

Use the following table to help set the device address:

Points Switch Circuit (S1 –S4)

Address

MultiPanel

Switch Input

1

2

4

8

2

1 - 12

CLOSED

CLOSED

CLOSED

CLOSED

3

13 - 24

OPEN

CLOSED

CLOSED

CLOSED

4

25 –36

CLOSED

OPEN

CLOSED

CLOSED

5

37 –48

OPEN

OPEN

CLOSED

CLOSED

6

49 –60

CLOSED

CLOSED

OPEN

CLOSED

7

61 –72

OPEN

CLOSED

OPEN

CLOSED

8

73 –84

CLOSED

OPEN

OPEN

CLOSED

9

85 –96

OPEN

OPEN

OPEN

CLOSED

10

97 –108

CLOSED

CLOSED

CLOSED

OPEN

11

109 –120

OPEN

CLOSED

CLOSED

OPEN

12

121 –132

CLOSED

OPEN

CLOSED

OPEN

13

133 –144

OPEN

OPEN

CLOSED

OPEN

14

145 - 156

CLOSED

CLOSED

OPEN

OPEN

15

157 –168

OPEN

CLOSED

OPEN

OPEN

16

169 - 180

CLOSED

OPEN

OPEN

OPEN

17

181 - 192

OPEN

OPEN

OPEN

OPEN

The address is set by holding down LOW and PROG whilst powering the board on.

Follow these steps to configure your network address. In this example we’ll set network address 3.

Power off the board.

Set toggle switch one contact OPEN (or if using the pop-on board set the top switch OFF).

Press and hold down the LOW & PROG buttons whilst applying power.

When the RED light begins to flash, release the buttons.

You can check the address is programmed with this procedure:

Power off the board.

Power ON the board.

Both LEDs will flash alternately to indicate slave mode has been set.

The yellow LED will flash a number of times to indicate the board address. In this example it

should flash three times.

The board is now ready for use and will remain in this mode until you change it.

The network address will be flashed out using the YELLOW LED as the board is powered up. Count

the number of flashes to read the network address.

If a unit is moved out and back into slave mode and none of the servo switches (S1 –S4) are set, the

last programmed slave address will be used. A factory reset will return the address to the default

value of 2.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 18

NOTE: Master units simultaneously communicate with all 16 network addresses. It doesn’t matter

what slave address is programmed, the master will find it. Further expansion and control panel

headers will require each of the slaves to have a unique address.

NOTE: The pop-on switch board has an ON position marked on the switch, this is synonymous with

CLOSED in the above chart.

Pop-on switch board (optional)

The pop-on switch board simplifies network address setting if using the MultiPanel with many

MegaPoints Servo Controllers. When connected it attaches all 12 toggle switches and the four

memory/speed pushbuttons in a single connector so that the servo speed and network address can

be configured quickly. Once configured the pop-on switch board can be removed.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 19

Expansion diagram

This diagram shows the expansion possibilities for the MegaPoints system when used in conjunction

with the MultiPanel and expansion boards. See web site for up to date product details and

expansion options.

MegaPoints servo controller Revision 24 April 2016

www.loolee.org Page: 20

Contacting us

Web: www.loolee.org

Email: mp@loolee.org

Phone: 07846 409320

All parts ©MegaPoints Controllers 2015

If you have any product improvement suggestions we’d be very pleased to hear from you.

NOTE: We operate on a policy of continuous improvement. Colours, specifications and even the

placement of components may vary from time to time. Documentation will continue to be updated to

reflect changes or answer frequent customer questions.

Table of contents

Other MegaPoints Controllers Controllers manuals

Popular Controllers manuals by other brands

Okolab

Okolab H301-PRIOR-NZ100-H107 user manual

Carel

Carel uPC Technical leaflet

Carrier

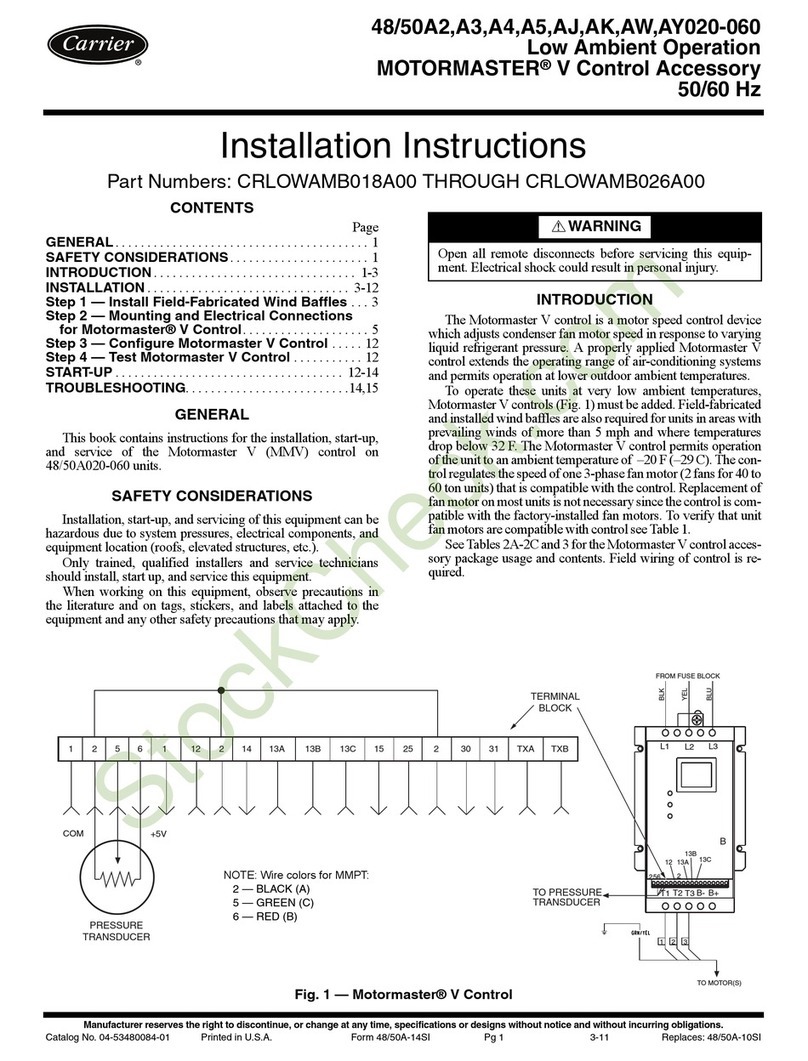

Carrier MOTORMASTER CRLOWAMB018A00 installation instructions

Delta Electronics

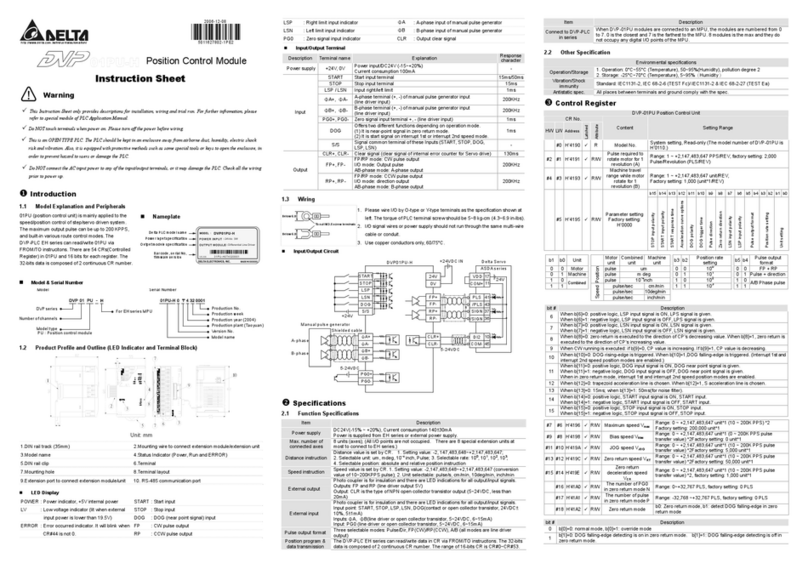

Delta Electronics Position Control Module DVP01PU-H instruction sheet

S&P

S&P CONTROL ECOWATT manual

Mangrove Jack's

Mangrove Jack's 71140 instructions

Hubbell

Hubbell Electric Fire Pump Controllers LXi 1900 Specifications

Vacon

Vacon 20 CP/X Applications manual

Servomech

Servomech SA Instructions for installation, use and maintenance manual

Tecomec

Tecomec GEOline REGAL Series instruction manual

RaceChip

RaceChip XLR 5 user manual

Mosa

Mosa EAS 15-806 Use and maintenance manual