Megatron GeBE-COMPACT Plus User manual

!"#

$%&'%

All information in this specication takes precedence over all other specications, unless otherwise stated. All versions below version V1.0 are only preliminary versions.

The printer has been tested and approved with the standard Ge E test environment. It is the customer's responsibility to test and approve the printer for nal use.

MEGATRON, s.r.o. Mrštíkova 16, 100 00 Praha 10, T.: +1

"

:;0;

1 GENERAL................................................................................................................................................................................6

1.1 ASIC PRINTER MODULES............................................................................................................................................6

1.2 SYSTEM FEATURES......................................................................................................................................................6

1.3 PRINTER SENSORIC......................................................................................................................................................7

1.4 OPERATION ELEMENTS................................................................................................................................................8

1.4.1 FUNCTION KEYS...................................................................................................................................................8

1.4.2 STATUS LED.........................................................................................................................................................8

1.5 CONTROLLER FEATURES..............................................................................................................................................9

2 PRESENTER FUNCTIONS.....................................................................................................................................................10

2.1 FUNCTIONAL ELEMENTS............................................................................................................................................10

2.2 IMPORTANT HINTS FOR PRESENTER OPERATION.....................................................................................................11

2.2.1 PAPER WIDTH....................................................................................................................................................11

2.2.2 TICKET LENGTH.................................................................................................................................................11

2.2.3 PAPER THICKNESS............................................................................................................................................11

2.2.4 PAPER MEMORY EFFECT...................................................................................................................................11

2.2.5 PRE-PRINTED PAPERS.......................................................................................................................................11

2.2.6 CORRECT PAPER GUIDANCE..............................................................................................................................12

2.2.7 CORRECT INSTALLATION POSITION..................................................................................................................12

2.3 IMPORTANT HINTS FOR PRINTER OPERATION..........................................................................................................13

2.3.1 THERMAL PRINTING ON PRE-PRINTED FORMS................................................................................................14

3 ELECTRICAL PARAMETER....................................................................................................................................................19

3.1 GPT-467x - CONTROLLER GCT-46620-V1.4 / GCT-46630-V1.0...................................................................................19

4 MOTOR CURRENTS..............................................................................................................................................................21

4.1 CONTROLLER GCT-46620 AND GCT-46630.................................................................................................................21

4.1.1 GPT-4672 with CONTROLLER GCT-46620 / PRINTER MECHANISM HSP-2208.................................................21

4.1.2 GPT-4672 with CONTROLLER GCT-46620 / PRINTER MECHANISM HSP-2128 (12V)........................................21

4.1.3 GPT-4673 with CONTROLLER GCT-46630 / PRINTER MECHANISM HSP-3208 / HSP-3512..............................21

4.2 MOTOR TORQUE..........................................................................................................................................................22

4.2.1 HSP-2208 PRINTER AND CUTTER.....................................................................................................................22

4.2.2 HSP-2108 PRINTER, CUTTER AND PRESENTER................................................................................................22

4.2.3 HSP-3208 / HSP-3512 PRINTER AND CUTTER..................................................................................................23

4.3 GPT-467x CUTTER MOTOR..........................................................................................................................................24

4.3.1 ERROR HANDLING.............................................................................................................................................24

5 CONTROL OF PRINTING POWER..........................................................................................................................................25

5.1 CALCULATION OF THE PRINTING CURRENT...............................................................................................................25

5.2 CURRENT SETTING DEPENDING ON THE FUSE @24 VDC.........................................................................................26

5.2.1 SETTING GPT-4672 for HSP-2208 @24V / HSP-2108 @12 V............................................................................26

5.2.2 SETTING GPT-4673 for HSP-3208 @24 V..........................................................................................................26

5.2.3 SETTING GPT-4673-M 300dpi for HSP-3512 @24 V..........................................................................................26

6 TEST PRINTOUT...................................................................................................................................................................27

6.1 EXAMPLE: STANDARD TICKET WITH HSP-2208 / PRESENTER @24 VDC.................................................................27

7 PRINTER TESTS WITH HSP-2208-G ..................................................................................................................................28

7.1 LONG RUN TEST..........................................................................................................................................................28

7.2 ENVIRONMENTAL TEST..............................................................................................................................................28

7.3 MONDAY MORNING TEST...........................................................................................................................................28

7.4 CYCLE TEST................................................................................................................................................................28

2

MEGATRON, s.r.o. Mrštíkova 16, 100 00 Praha10, T.: +420 274 780 972, [email protected],www.megatron.cz

"

7.5 MOTOR TEMPERATURE AT PERMANENT PRINTING..................................................................................................29

7.5.1 MOTOR TEMPERATURE AT PERMANENT PRINTING GPT-4672-PM with HSP-2208.........................................29

7.5.2 MOTOR TEMPERATURE AT PERMANENT PRINTING GPT-4672-M with HSP-2128...........................................30

7.5.3 MOTOR TEMPERATURE AT PERMANENT PRINTING GPT-4673-PM with HSP-3208.........................................31

8 PAPER SPECIFICATION........................................................................................................................................................32

8.1 PAPER SPECIFICATION for printer with presenter and HSP-2208-G printer mechanism.........................................32

8.2 RELEASED PAPERS with limited specication...........................................................................................................32

8.3 RECOMMENDED PAPERS for printer without presenter.............................................................................................32

9 CONTROL MARK ( LACKMARK)..........................................................................................................................................33

9.1 POSITION OF CONTROL MARK....................................................................................................................................33

9.2 TICKET LENGTH..........................................................................................................................................................34

9.3 SENSORS FOR DETECTION OF PAPER END AND LACKMARK..................................................................................35

9.3.1 SENSOR INTERCONNECTION FOR STANDARD PRINTER..................................................................................35

9.3.2 SENSOR INTERCONNECTION FOR THE „EASY LOADING“ PRINTER..................................................................35

9.3.3 SENSOR RATIO TO PRINT LINE AND CUTTING POSITION.................................................................................36

10 CONTROLLER DESCRIPTION..............................................................................................................................................37

10.1 Ge E CONTROLLER GCT-46620 FOR GPT-4672........................................................................................................37

10.2 Ge E CONTROLLER GCT-46630 FOR GPT-4673........................................................................................................37

10.3 CONNECTION PINNING.............................................................................................................................................38

10.3.1 CONTROLLER GCT-46620 and GCT-46630.......................................................................................................38

11 POWER SUPPLY.................................................................................................................................................................41

11.1 GPT-467x WITH CONTROLLER GCT-46620 V1.4 / GCT-46630-V1.0..........................................................................41

11.2 STANDARD POWER SUPPLY.....................................................................................................................................42

12 INTERFACES.......................................................................................................................................................................43

12.1 RS232........................................................................................................................................................................43

12.2 US ...........................................................................................................................................................................44

13 EXTERNAL SENSORS.........................................................................................................................................................45

13.1 FOR GPT-467x with CONTROLLER GCT-46620-V1.4 / GCT-46630-V1.0....................................................................45

13.2 REFLEX FOR NPE, EXIT AND AUX4...........................................................................................................................46

14 ADDITIONAL CIRCUIT OARD............................................................................................................................................47

14.1 GCT-46620-20/30 / GCT-46630-20/30......................................................................................................................47

14.1.1 EZEL / PAPER EXIT / LED CONTROL..............................................................................................................47

14.1.2 CIRCUIT DIAGRAM GCT-46620-20 / GCT-46620-30..........................................................................................47

14.1.3 CIRCUIT DIAGRAM GCT-46630-20 / GCT-46630-30..........................................................................................47

14.1.4 CONNECTION PINNING....................................................................................................................................48

14.1.5 CA LE...............................................................................................................................................................48

14.2 NPE NEAR PAPER END SENSOR...............................................................................................................................49

14.2.1 NPE SENSOR CIRCUIT OARD WITH REFLEX SENSOR (#14188)...................................................................49

14.2.1.1 MECHANICAL DATA.......................................................................................................................................49

14.2.2 NPE SENSOR CIRCUIT OARD WITH REFLEX SENSOR (#14187)...................................................................50

14.2.3 CONNECTION PINNING....................................................................................................................................50

14.2.4 CA LE...............................................................................................................................................................50

15 FIRMWARE.........................................................................................................................................................................51

15.1 TA LE OF MOST IMPORTANT SYSTEM PARAMETERS.............................................................................................52

16 DRIVERS AND SOFTWARE DEVELOPMENT KIT (SDK).......................................................................................................53

16.1 PRINTER DRIVERS....................................................................................................................................................53

16.2 SDK...........................................................................................................................................................................53

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 '8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

3

"

17 PACKING AND LA ELING...................................................................................................................................................54

17.1 PACKING...................................................................................................................................................................54

17.1.1 SINGLE PACKING.............................................................................................................................................54

17.1.2 PACK OF 10......................................................................................................................................................55

17.2 LA ELING..................................................................................................................................................................56

17.2.1 ARCODE LA EL..............................................................................................................................................56

17.2.2 TYPE PLATE.....................................................................................................................................................56

18 SERVICE.............................................................................................................................................................................57

18.1 CLEANING INTERVAL................................................................................................................................................57

18.2 WARRANTY...............................................................................................................................................................57

18.3 SPAREPARTS AVAILA ILITY.....................................................................................................................................57

19 ASSEM LY.........................................................................................................................................................................58

19.1 ILLUMINA LE OUTPUT EZEL..................................................................................................................................58

19.1.1 SCREW FASTENING OF THE EZELS...............................................................................................................59

19.1.2 ADHESIVE FASTENING OF THE EZEL............................................................................................................60

20 PRINTER SPECIFICATION..................................................................................................................................................61

20.1 PRINTER MODULE 2“ GPT-4672-M............................................................................................................................61

20.1.1 OPTION GPT-4672-M with LED LIGHTING and EXIT SENSOR..........................................................................63

20.2 PRINTER MODULE 2“ GPT-4672-PM with PRESENTER.............................................................................................65

20.2.1 OPTION GPT-4672-PM with LED LIGHTING and EXIT SENSOR........................................................................67

20.3 PRINTER MODULE 3“ GPT-4673-M............................................................................................................................68

20.3.1 OPTION 3“ GPT-4673-M with SENSOR HOLDER...............................................................................................70

20.4 PRINTER MODULE 3“ GPT-4673-PM with PRESENTER.............................................................................................72

20.4.1 OPTION LED LIGHTING and EXIT SENSOR for GPT-4673-PM..........................................................................74

20.5 PRINTER MODULE 2“ GPT-4672-M with MOUNTING RACKET and EZEL..............................................................75

20.6 PRINTER MODULE 2“ GPT-4672-PM with MOUNTING RACKET and EZEL...........................................................77

20.7 PRNTER MODULE 3“ GPT-4673-M with MOUNTING RACKET and EZEL...............................................................79

20.8 PRINTER MODULE 3“ GPT-4673-PM with MOUNTING RACKET and EZEL...........................................................81

20.9 PAPER GUIDE FOR GPT-467x....................................................................................................................................83

20.10 PAPER ROLL HOLDER.............................................................................................................................................85

20.10.1 STANDARD PAPER ROLL HOLDER GPT-4672................................................................................................86

20.10.1.1 STANDARD PAPER ROLL HOLDER 70 mm............................................................................................86

20.10.1.2 STANDARD PAPER ROLLHOLDER 140 mm WITH TENSIONER.............................................................86

20.10.2 PAPER ROLL HOLDER RIGHT GPT-4672........................................................................................................88

20.10.2.1 PAPER ROLL HOLDER RIGHT 70 mm....................................................................................................88

20.10.2.2 PAPER ROLL HOLDER RIGHT 70 mm WITH TENSIONER......................................................................88

20.10.3 STANDARD PAPER ROLL HOLDER GPT-4673................................................................................................90

20.10.3.1 STANDARD PAPER ROLL HOLDER 80 mm............................................................................................90

20.10.3.2 STANDARD PAPER ROLL HOLDER 150 mm WITH TENSIONER............................................................90

20.10.4 PAPER ROLL HOLDER RIGHT GPT-4673........................................................................................................92

20.10.4.1 PAPER ROLL HOLDER RIGHT 80 mm....................................................................................................92

20.10.4.2 PAPER ROLL HOLDER RIGHT 150 mm WITH TENSIONER....................................................................92

20.10.5 EXTERNAL PAPER ROLL HOLDER..................................................................................................................94

20.10.5.1 PAPER ROLL RUNNING LENGTH EXAMPLES........................................................................................94

20.11 PAPER TRAY WITH ATTACHMENT..........................................................................................................................99

20.11.1 FOR GPT-4672-M............................................................................................................................................99

20.11.2 FOR GPT-4674-M..........................................................................................................................................100

21 DECLARATION OF CONFORMITY.....................................................................................................................................101

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

4

"

21.1 CE SIGN...................................................................................................................................................................101

21.2 CE FOR GCT-46620..................................................................................................................................................102

21.3 CE FOR GCT-46630..................................................................................................................................................103

22 FURTHER TEST CERTIFICATES........................................................................................................................................104

APPENDIX A..........................................................................................................................................................................106

PRINTER FOR ISO TICKETS............................................................................................................................................106

APPENDIX ..........................................................................................................................................................................107

PRINTER WITH HEAT SINK.............................................................................................................................................107

APPENDIX C..........................................................................................................................................................................108

VARIA LE PAPER ROLLEN HOLDER WITH NPE SENSOR...............................................................................................108

APPENDIX D..........................................................................................................................................................................110

PRESENTER SPACER FOR GPT-4673..............................................................................................................................110

APPENDIX E..........................................................................................................................................................................111

PRINTER WITH ARCODE SCANNER..............................................................................................................................111

HISTORY................................................................................................................................................................................112

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 68..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

1. Life cycle according to mechanism testing conditions of the manufacturer with specied paper only. Please inquire. The life cycle of the print head is an averaged expectable performance and

no guaranteed data. Under optimum conditions, the above listed data can be achieved using specied paper according to our documentation TI-DE-0606.

2. In case the print head reaches the maximum ambient temperature, the printer will interrupt operation until cooling down and sends an error message.

The Ge E logo is a registered trademark of Ge E Elektronik und Feinwerktechnik GmbH. All other brands named in this brochure are properties of the respective companies.

The technical data given are non-committal information and do not represent any assurance of certain features. Errors and changes reserved. This technical documentation is only valid until

release of a revision. Please always request the newest documentation edition.

Our terms of payment and delivery apply.

Copyright © 2021 Ge E Elektronik und Feinwerktechnik GmbH.

All rights reserved.

5

"

. <

This specication describes the characteristics of the printer family Ge E-COMPACT Plus.

.,. ;:<:<=;

Following basic printer modules are available:

2“ Compact Plus GPT-4672-M-C32-620-US /V.24 article #14118

2“ Compact Plus Presenter GPT-4672-PM-C32-620-US /V.24 article #14185

2“ Compact Plus 12 V GPT-4672-M-C32-620-US /V.24-12 V article #14129

3“ Compact Plus GPT-4673-M-C32-630-US /V.24 article #14195

3“ Compact Plus Presenter GPT-4673-PM-C32-630-US /V.24 article #14186

3“ Compact Plus 300 dpi GPT-4673-300-M-C32-630-US /V.24 article #14236

.,$ ;>;0<;

Special features of the systems:

Thermal printer mechanism

•Sophisticated printing unit, continuously improved for 10 years

•Heavy duty design (gear, cutter knifes ...)

•Stainless construction: metal parts rust-free or coated accordingly

•Cutter for 2 mio. cuts

•Modied version for high humidity

•Extension of the printhead temperature range from 5°C – 45°C to -25°C– +70°C by the printhead manufacturer

directly in connection with a Ge E control.

Presenter

•Loop presenter for safe output

•Up to 500 mm/s output speed

•Two optical IR sensors for paper path monitoring

Optional printer holder, bezel lighting with additional exit sensor

•Printer mounting bracket made of stainless steel

•Quick assemble to the transparent bezel without screws

•LED lighting flashes when a ticket is ready for output

•Additional exit sensor shows whether the output is occupied

Standard roll holder option

•GPT-4672 paper roll holder for rolls with D = 70 mm or 140 mm, for 25 mm paper core

•GPT-4673 paper roll holder for rolls with D = 80 mm or 150 mm, for 25 mm paper core

External roll holder option

•Paper roll holder for rolls with D = 250 mm, for 40 mm paper core (optional 76 mm)

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

6

"

.,' <:<;;<:

•Print head temperature NTC, integrated in the printhead

•Printer voltage AD converter, µ processor on PC

•Printhead lifted microswitch, integrated in the printing unit

•Cutter position microswitch, integrated in the printing unit

•Motor temperature NTC, on PC bottom side

•Paper End Fork IR sensor, integrated in the printing unit

•lackmark Reflex IR sensor, integrated in the printing unit

•Near Paper End Optional connection on PC via plug connection for reflex IR sensor

Via plug on external circuit board:

•Paper Exit sensor Reflex IR sensor

•AUX4 sensor Reflex IR sensor

In the presenter:

•Presenter Entry Reflex IR sensor, integrated in the presenter

•Presenter Exit Reflex IR sensor, integrated in the presenter

07.

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

7

"

., <:;

.,,. 0:?>;

;.#)31"@?A0B7"

If the paper feed button is pressed, the paper will not be fed until the printing of a print line has been completed. Then rst

only one line is fed and then a short pause is inserted. y briefly pressing the key, this enables a targeted feed of just one

line. If the key is still pressed after that, it will be advanced line by line as long as the key remains pressed. Then normal

printing is continued at the beginning of the next line.

;$#0"!"(@?A.B1!(

Macros are executed when the function key is pressed and released:

T1 when the button is pressed for at least 30 milliseconds

T15 when the button is pressed for at least 5 seconds and released again

T18 when the button is pressed for at least 10 seconds and released again

RESET when the button is pressed for at least 15 seconds and then released again

.,,$ ;;=

=.#;=7"

The status LED flashes in the event of a fault and lights up permanently if everything is OK.

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 -8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

8

"

.,6 <<0<;

•32-bit processor Cortex M4 with 2 Mbyte flash memory

•QR barcode (other 2D barcodes on request)

•History control:

The printer has a 2-stage Dot History Control so that the rst "cold dots" of a print image are not illegibly

printed. The dot history can be combined with the subdivision of the peak currents WITHOUT reducing the

printing speed.

•Optional:

Unicode with more than 37,000 characters. This contains all the necessary country-specic characters, such

as Chinese, Japanese, Russian, or Arabic. Fonts can be loaded proportionally as well as non-proportionally

(monospace). For large displays (time/date), the fonts can also be stored in the original resolution.

•Preheat the printhead to the desired temperature range.

•Head control via FET. Protection against head damage caused by moisture.

•Power consumption:

The printer is suitable for direct connection to voltages of 10.8–26.5 VDC. This initially eliminates the energy

loss due to the efciency of an upward DC/DC converter for a 24 V printing unit. A high speed 12V variant is

available.

•Power Off:

The printer can be used with a power off operation. For the power off operation, the printer is switched off by a

synchronized command. This means that the command can also be at the end of a ticket. The printer is

completely switched off. You can wake up by toggling the RTS line or by applying a voltage of 3–24 V to the

GPIO input of the printer. In serial mode, the printer is ready for operation again after approx. 40 ms. With US

interface after approx. 2–3 seconds, depending on the host system.

•Integrated statistics:

Storage of the most important operating data, e.g. cuts, operating time, mileage …… ..

•3 modes for creating tickets:

1. Line mode:

Typical standard text printing with extensive formatting functions.

2. Form mode:

In the form mode all data to be printed are sent rst, before a command triggers printing. This means that

formatting can be carried out much more freely and extensively. E.g. Elements can be rotated or printed

overlapping.

3. Graphics mode:

In graphic mode, the ticket is sent completely as a graphic. Powerful data compressions also allow this

mode with the serial interface.

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 +8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

9

"

$ <;<0:;

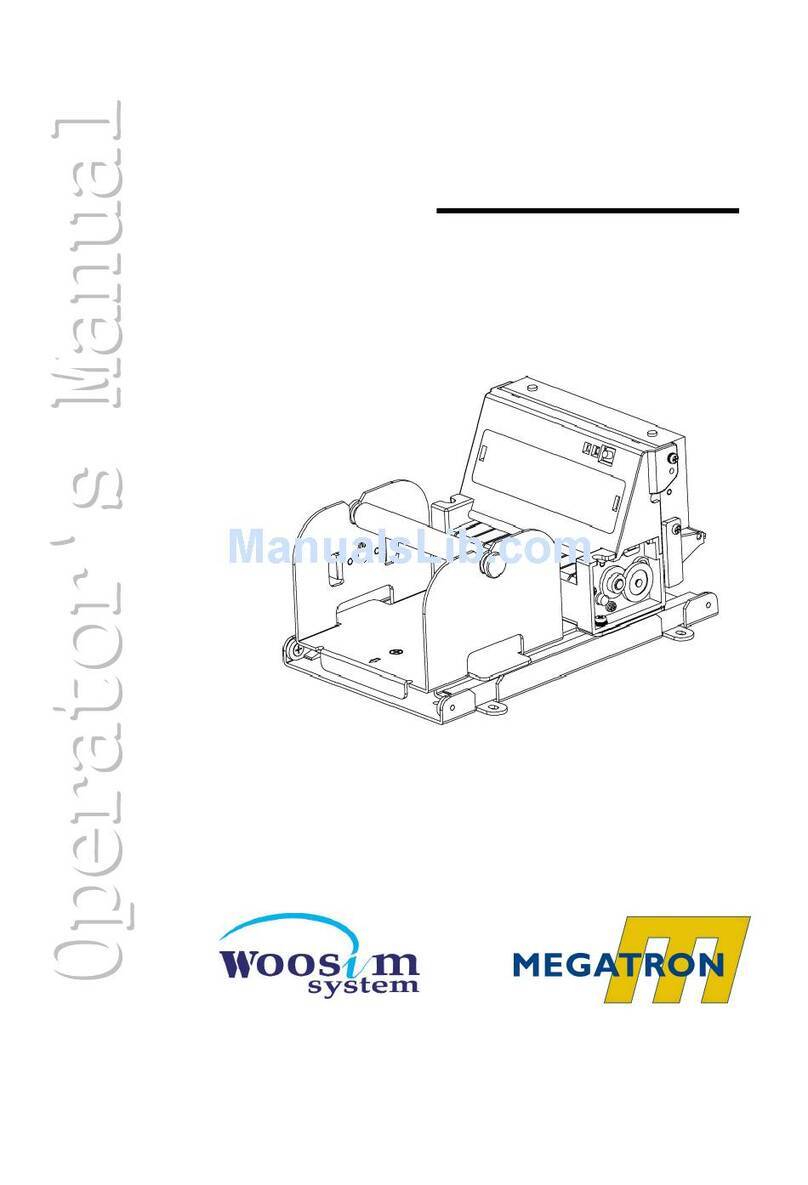

$,. 0:;

1. Paper insert

2. Paper End sensor

3. Printhead

4. Printer

5. Presenter sensor

6. Paper Exit sensor

7. Paper exit

8. Presenter motor

9. Cutter

07$

The GPT-4672-P / GPT-4673-P is a printer with loop presenter. The printout is saved in a loop during printing and is only

output as soon as the printing process has ended. y decoupling the output from the printing process, it can no longer be

disturbed by external manipulations. The output security is thereby signicantly increased.

The output speed can also be increased up to 500 mm/s.

It is selectable how far the printout leaves the presenter for removal. If the operator is pulling on the paper when removing

the printout, the presenter motor notices this and feeds the ticket towards the paper output.

If the ticket is not withdrawn after an adjustable period of time, it can either be fed out (eject) or withdrawn (retract).

A dispenser operation can also be set for thicker papers, which issues the ticket without forming a loop.

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .%8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

9

4

8

5

3

6

71

2

5

10

"

$,$ :<2:;0<<;<<:

$,$,. <C:=2

Paper width smaller as specied cannot be used due to the presenter paper guides.

$,$,$ :?2

The minimum ticket length is determined by the distance between the print head and the exit sensor and is 58 mm. The

maximum ticket length is 120 mm with full specication. If the ticket length is chosen to be longer, there is a risk that the

loop will collapse and a disruption will occur, especially when there is high humidity. Larger ticket lengths must be

precisely tested in the application. In the case of very long tickets, it may be possible to work with an additional paper

guide.

$,$,' <2:?;;

To create a loop, the paper must have the CORRECT rigidity. If the paper is too soft, it may not be properly transported into

the presenter or the loop collapses and a malfunction occurs. If it is too hard, the presenter cannot “bend” the paper and

therefore cannot create a loop. In addition, the presenter may not be able to feed the paper out. Paper thicker as specied

can be used in dispensing operations without the retract function.

$,$, <<>00

If the printer doesn‘t print for a long time, the paper will bend according to the paper guide in the printer and the external

paper feed. If printing starts again after this standstill, the curvature of the paper on the next ticket may lift the presenter

spring and the ticket cannot be transported into the presenter. We recommend that you “park” the paper in the presenter

while it is idle. For „parking“ purpose, the paper is fed into the presenter. In order to start with a new printout the paper will

then be withdrawn with the command "Retract to ToF".

!

$,$,6 <<:=<;

Tests have shown that preprinted paper behaves more critically under high humidity. This reduces the possible working

range of air humidity from 90% RH to 80% RH.

"#

$#%&'((#)

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 ..8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

11

"

$,$, <<<:=

Inadequate paper guidance is the most common cause of problems:

•The paper roll must be able to move freely. It must not drag or jam.

•If the paper roll diameter is large and a fast printout is required, a tension control is necessary. Please note that

the printer does not have to "pull" more than the specied max. traction.

•The paper guide just in front of the printer determines the correct paper flow, NOT the guide of the paper roll. If

the roll is close to the printer, the guideance in the printer is sufcient. If, on the other hand, the roll is large and

far away, a LONG paper guide on the printer is strongly recommended.

•The paper should be bent as little as possible in the feeder.

Such “bends” can cause disturbances due to the “memory effect”. The paper feed should be carried out as

straight as possible following the paper guideance in the printer.

*!

$,$, <<:;:;::

" )"#

The printer was designed for the installation situation "horizontal" to "vertical". Any angle in between is acceptable. If the

intended installation position is changed, the correct functioning of the printer cannot be fully guaranteed.

07'

" )"#

The function of the presenter depends on the paper maintaining the correct tension so that the loop cannot collapse. If

the installation position is not horizontal and the loop is too large, it can also collapse.

The printer was designed for the installation situation "horizontal". If the intended installation position is changed, the

correct functioning of the printer cannot be fully guaranteed.

07

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .$8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

12

"

$,' :<2:;0<<:<<:

•To ensure that the printer starts up correctly, it is advisable to program several FEED dot lines before each print

job.

•If the printing direction is changed, the printer automatically compensates the gear backlash. Nevertheless, there

may be small positioning deviations.

•Large changes in the printing speed, e.g. a discontinuous data stream can lead to bad print quality.

•In principle, thermal printers are not suitable for continuous operation without pauses in printing. Please note

the performance data.

•Not every possible combination of settings for print current consumption and print dynamics produces good

print results.

•An increase in the standard print density (blackening) leads in principle to a reduction in the service life of the

printhead.

•Printing horizontal lines:

When printing horizontal lines at low speed, there is inherently a high adhesive force between the printhead and

the paper. This adhesive force can extensively increase to damage a printout. In extreme cases, even the

printhead can be damaged.

•The printhead manufacturer species the mileage of the printhead as 100 km MT F. The printer achieves this

value with the specied paper under compliance with the test conditions.

•Humidity and temperature ranges depend essentially on the paper used. With the specied unprinted thermal

paper, the printer reaches the specications of the technical data. Changes can lead to a limitation of the

humidity and temperature range.

•The print speed is a function of voltage, printhead temperature, the speed at which the paper is moved and the

number of subdivisions per dot line. The maximum print speed specied can be achieved at room temperature if

all dots in a dot line are printed simultaneously without further subdivisions.

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .'8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

13

"

$,',. 2<<::<<:=0<;

Thermal printing technology also enables printing on pre-printed paper. However, a few things must be observed to avoid

damaging the sensitive printhead. The use of pre-printed paper increases the before mentioned effect. Since the

preprinted ink is located between the printhead and the heat-sensitive layer, it must be able to withstand high thermal and

mechanical loads. Unfortunately, even the best printing ink is not as resilient as a good thermal paper. This can result in

larger build ups during the printing process than with standard thermal paper. Therefore, the following rules must be

observed:

Rules for printing on pre-printed paper:

•The color coverage in the printing areas should be kept to a minimum, max. 25% ink application, preferably zero.

•Only using specied thermal printing inks with a minimum temperature tolerance of 230°C, recommended 250°C.

•Do not print on sensitive, metallic or luminescent paints. Hologram foil should be placed outside of the printing

area.

•Never use opaque white in the printing area.

•The heat output (blackening) must not be increased.

•When printing on pre-printed paper, the density parameter 18,6 must not exceed value of 25. It is recommended

to reduce the parameter to a value of 22.

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

14

"

2;$$%-?;<&2;$$%-?;<)"! "3$&$

Thermal printer mechanism HSP2208-KSR-G

(optimized for 12V and high humidity)

HSP2208-KSR

(optimized for 24 V and thicker paper)

Supply voltage 10.8 – 26.5 VDC

Print procedure thermal sensitive

Number of dots 448 dots/line

Resolution horizontal / vertical 203 dpi (8 dot/mm)

max. print width 56 mm

max. paper width 60.5 mm

Print speed max. 250 mm/s @24 VDC

max. 70 mm/s @12 VDC

Presenter speed max. 500 mm/s @24 VDC

max. 400 mm/s @12 VDC

Traction power 2.35 – 7.00 N ±20%

24 V 50 mm/s 900 g 7.00 N (not -G ) →

24 V 100 mm/s 750 g 5.90 N→

24 V 150 mm/s 600 g 4.70 N→

24 V 200 mm/s 450 g 3.50 N→

24 V 250 mm/s 300 g 2.35 N→

12 V 50 mm/s 750 g 5.90 N→

12 V 100 mm/s 600 g 4.70 N→

presenter motor / current =46% 500 mm/s approx. 2 N

MTTF printer 100 km paper length

50 million pulse

MTTF cutter vs. MT F 2 million cuts

(only under standard ambient conditions)

The cutter life time depends on the printer paper used. Pre-printed paper or a

diffraction foil reduce the cutter life time. This has to be tested separately with

standard paper JUJO AF50KS-E at 24 VDC / 20 – 25°C / head temperature max. 40°C

/ nominal energy ratings. The life time according to the APS printing unit test

conditions is only achieved with the specied paper. The printhead and cutter life

cycle is an average expected performance and is not a guaranteed data. Under

optimal conditions, the above data can be obtained using the specied paper.

Cutting time approx. 0.5 seconds @ 80 µm @ 24 VDC 0 – 50°C°

$()#(+,-

#(./

Cutter knife Steel 1.4034 + black coating

Sound level approx. 62 d A peak

GPT-4672-PM lying isolated on textile, measurement in a distance of 1 meter with

sound level meter SL-100

-(#!

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .68..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

15

"

2;$.$-?;<)"! "3$

Thermal printer mechanism HSP2128-KSR

Supply voltage 8 – 16 VDC

Print procedure thermal sensitive

Number of dots 448 dots/line

Resolution horizontal / vertical 203 dpi (8 dot/mm)

max. print width 56 mm

max. paper width 60.5 mm

Print speed max. 250 mm/s

Presenter speed max. 400 mm/s

Traction power 2.4 – 5.6 N

MTTF printer 100 km paper length

50 million pulse

MTTF cutter vs. MT F 2 million cuts

(only under standard ambient conditions)

The cutter life time depends on the printer paper used. Pre-printed paper or a

diffraction foil reduce the cutter life time. This has to be tested separately with

standard paper JUJO AF50KS-E at 24 VDC / 20-25°C / head temperature max. 40°C /

nominal energy ratings. The life time according to the APS printing unit test

conditions is only achieved with the specied paper. The printhead and cutter life

cycle is an average expected performance and is not a guaranteed data. Under

optimal conditions, the above data can be obtained using the specied paper.

Cutting time approx. 0.5 seconds @ 80 µm @ 24 VDC 0 – 50°C°

$()#(+,-

#(./

Cutter knife Steel 1.4034 + black coating

Sound level approx. 62 d A peak

GPT-4672-PM lying isolated on textile, measurement in a distance of 1 meter with

sound level meter SL-100

-(#!

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

16

"

2;'$%-?;<)"! "3'"'

Thermal printer mechanism HSP3208-KSR

Supply voltage 10.8 – 26.5 VDC

Print procedure thermal sensitive

Number of dots 640 dots/line

Resolution horizontal / vertical 203 dpi (8 dot/mm)

max. print width 80 mm

max. paper width 82.55 +/-1 mm

Print speed max. 250 mm/s @24 VDC

max. 60 mm/s @12 VDC

Presenter speed max. 500 mm/s @24 VDC

Traction power @25°C / 30%RH 6.3 – 9.5 N ±20%

24V 100 mm/s 1,200 g 9,5 N→

24V 200 mm/s 1,000 g 7,8 N→

24V 250 mm/s 800 g 6,3 N→

presenter motor / current =46% 500 mm/s approx. 2 N

MTTF printer 100 km paper length

50 million pulse

MTTF cutter vs. MT F 2 million cuts

(only under standard ambient conditions)

The cutter life time depends on the printer paper used. Pre-printed paper or a

diffaction foil reduce the cutter life time. This has to be tested separately with

standard paper JUJO AF50KS-E at 24 VDC / 20 – 25°C / head temperature max. 40°C

/ nominal energy ratings. The life time according to the APS printing unit test

conditions is only achieved with the specied paper. The printhead and cutter life

cycle is an average expected performance and is not a guaranteed data. Under

optimal conditions, the above data can be obtained using the specied paper.

Cutting time approx. 0.5 seconds @ 80 µm @ 24 VDC 0 – 50°C°

$()#(+,-

#(./

Cutter knife Steel 1.4034 + black coating

Sound level approx. 60 d A peak

GPT-4673-PM lying isolated on textile, measurement in a distance of 1 meter with

sound level meter SL-100

-(#!

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

17

"

2;'6.$?;<)"! "3'

Thermal printer mechanism HSP3512-KSR

Supply voltage 21.6 – 26.4 VDC

Print procedure thermal sensitive

Number of dots 960 dots/line

Resolution horizontal / vertical 300 dpi (H:11.82 x V:12.37 dots/mm)

max. print width 81.2 mm

max. paper width 82.55 +/-1 mm

Print speed max. 200 mm/s @24 VDC

Traction power @25°C / 30%RH 6.3 – 9.5 N ±20%

MTTF printer 100 km paper length

50 million pulse

MTTF cutter vs. MT F 2 million cuts

(only under standard ambient conditions)

The cutter life time depends on the printer paper used. Pre-printed paper or a

diffraction foil reduce the cutter life time. This has to be tested separately with

standard paper JUJO AF50KS-E at 24VDC / 20 – 25°C / head temperature max.

40°C / nominal energy ratings. The life time according to the APS printing unit test

conditions is only achieved with the specied paper. The printhead and cutter life

cycle is an average expected performance and is not a guaranteed data. Under

optimal conditions, the above data can be obtained using the specied paper.

Cutting time approx. 0.5 seconds @ 80 µm @ 24 VDC 0 – 50°C°

$()#(+,-

#(./

Cutter knife Steel 1.4034 + black coating

Sound level approx. 60 d A peak

GPT-4673-PM lying isolated on textile, measurement in a distance of 1 meter with

sound level meter SL-100

-(#!

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .-8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

18

"

' <:<<

',. <<$%/.,&'%/.,%

)"! "2;$$%-?;<42;$$%-?;<"2;'$%-?;<

•Supply voltage 24 VDC

•Current consumption

•In power down mode typical 70 µA, max. 200 µA

•Controller Idle current consumption Idle: @24 VDC

•US and RS232 connected

•NPE sensor connected

•Additional PC ezel connected, LEDs flashing

$% 2;$$%- typical 25 mA RMS up to max. 50 mA , short peaks up to approx. 370 mA

076

'% 2;'$%- typical 30 mA RMS up to max. 60 mA, short peaks up to approx. 500 mA

07

)%(-(

$

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 .+8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

19

"

Operation condition GPT-4672-M and GPT-4673-M:

•Storage temperature -30 to +80°C, without condensation

•Operation temperature -25 to +70°C, without condensation

•Operation humidity 10 – 90% RH, without condensation valid for KPW-460 blanco

10 – 80% RH, without condensation valid for other papers

07

Operation condition GPT-4672-PM and GPT-4673-PM:

•Storage temperature -30 to +80°C, without condensation

•Operation temperature -25 to +70°C, without condensation

•Operation humidity 110 – 90% RH, without condensation

valid for KPW-460 blanco / 70 – 120 mm ticket length

10 – 80% RH, without condensation

valid for other papers

07-

!"#$

%##%## !"&!"

("(" ) " *+,-+,-+..% !"",'$/.,%.%%.

0"(! "(12 3 *+,-+,-+..'' .+4$%$.

5".6 )7 $%8..$

-$..%"7 "3971," 7"31"1)),

" ,71," "! "75,

20

This manual suits for next models

6

Table of contents

Other Megatron Printer manuals

Megatron

Megatron WSP-R240 User manual

Megatron

Megatron UP-PN-II User manual

Megatron

Megatron PORTI-T380 User manual

Megatron

Megatron WSP-R241 User manual

Megatron

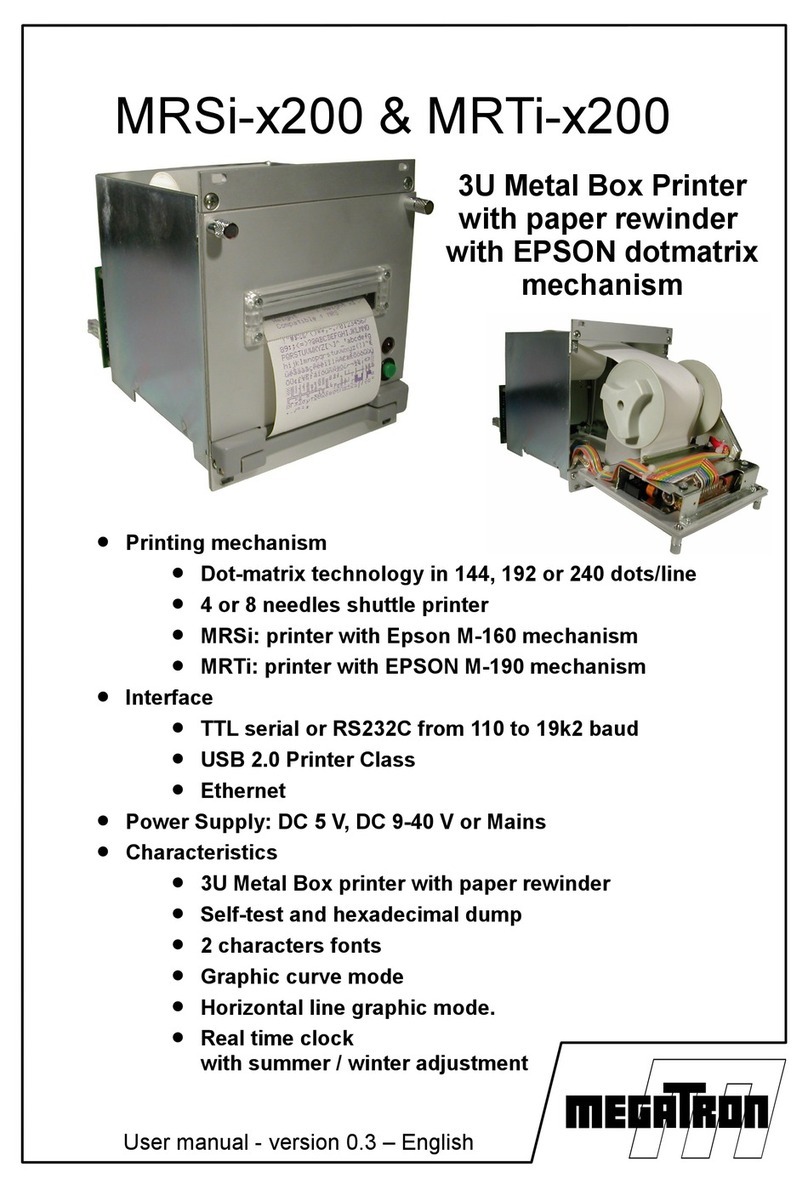

Megatron MRSi-x200 User manual

Megatron

Megatron WSP-CP260 User manual

Megatron

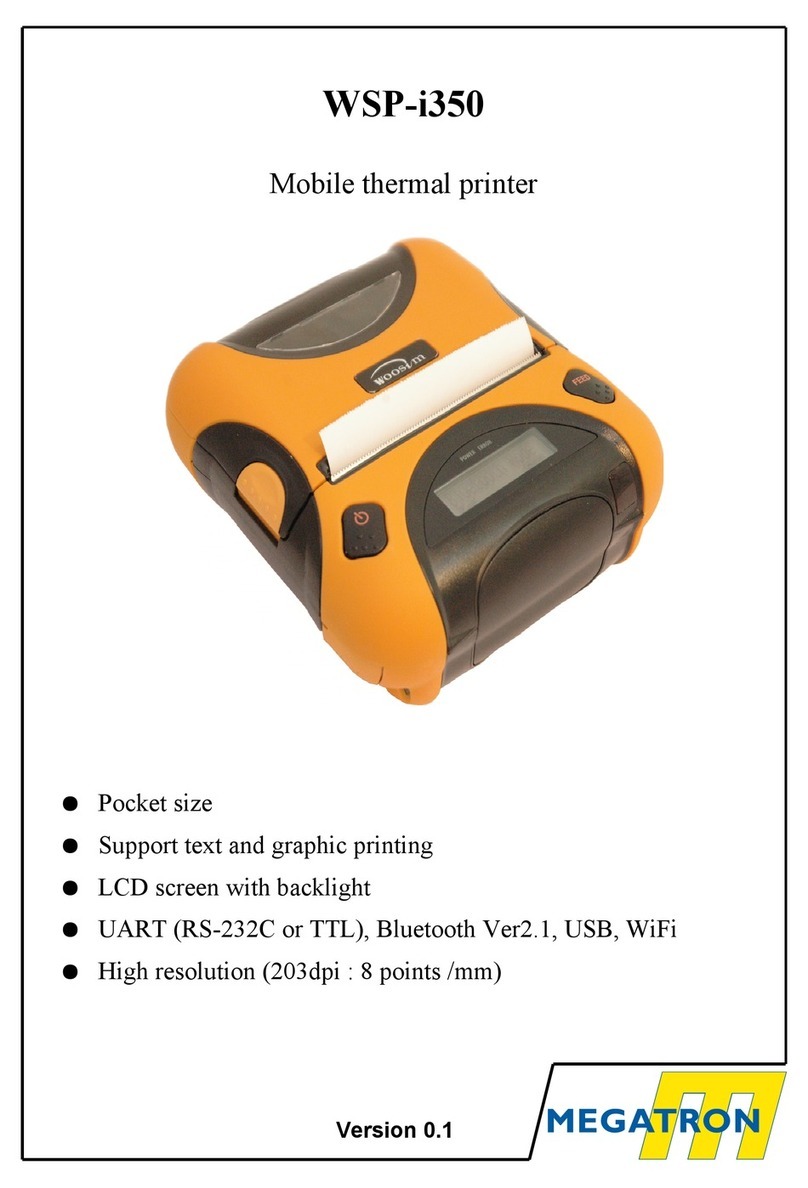

Megatron WSP-i350 User manual

Megatron

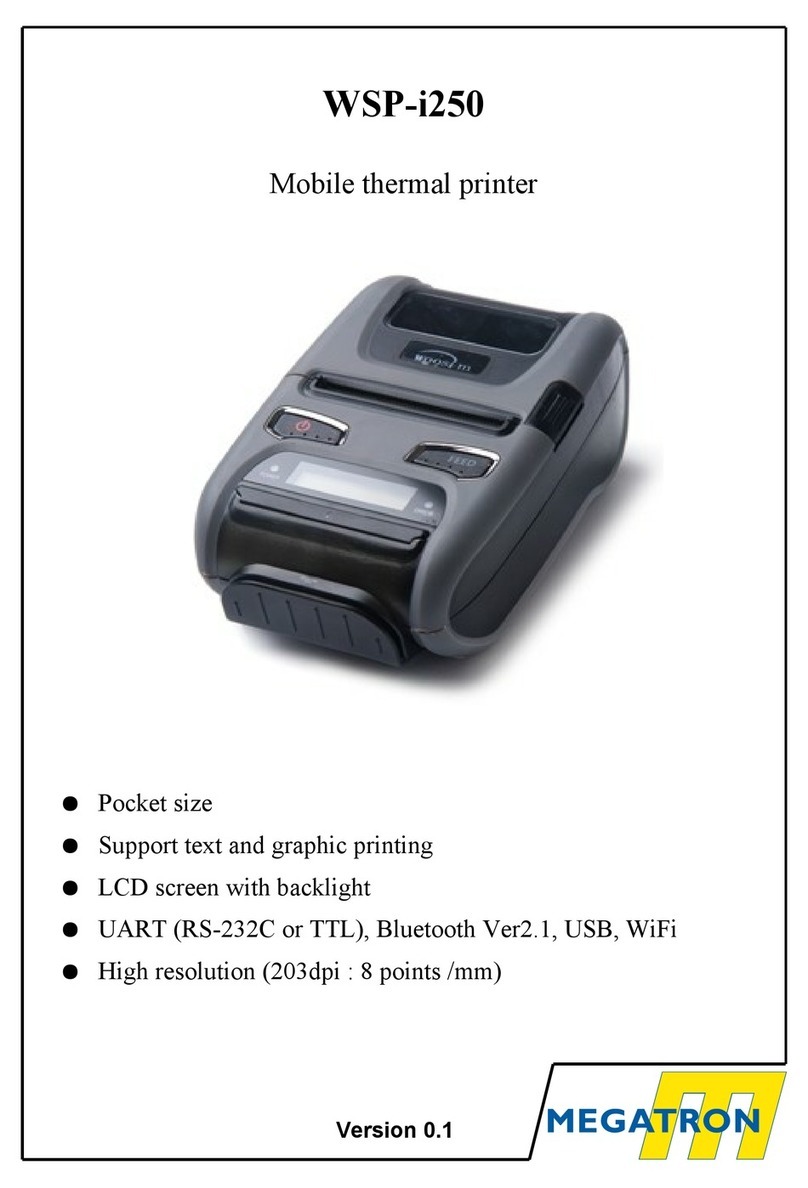

Megatron WSP-i250 User manual

Megatron

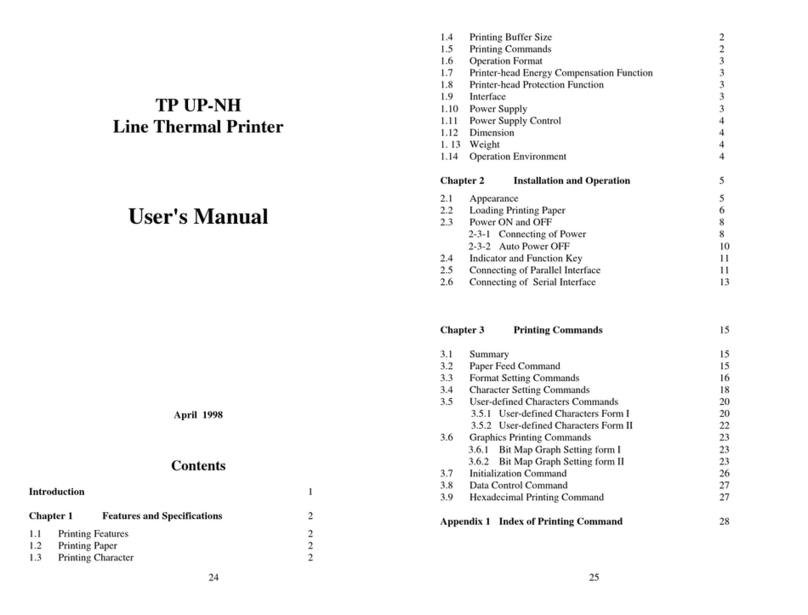

Megatron TP UP-NH User manual

Megatron

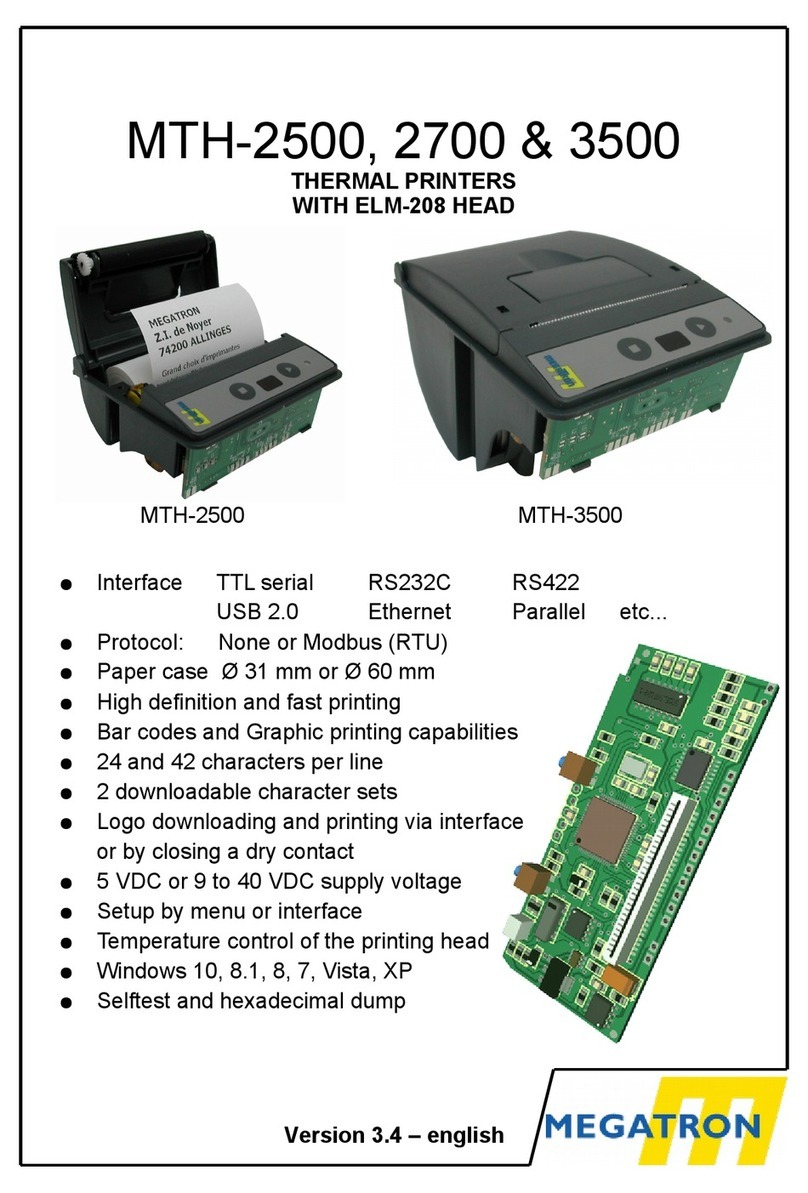

Megatron MTH-2500 User manual