3

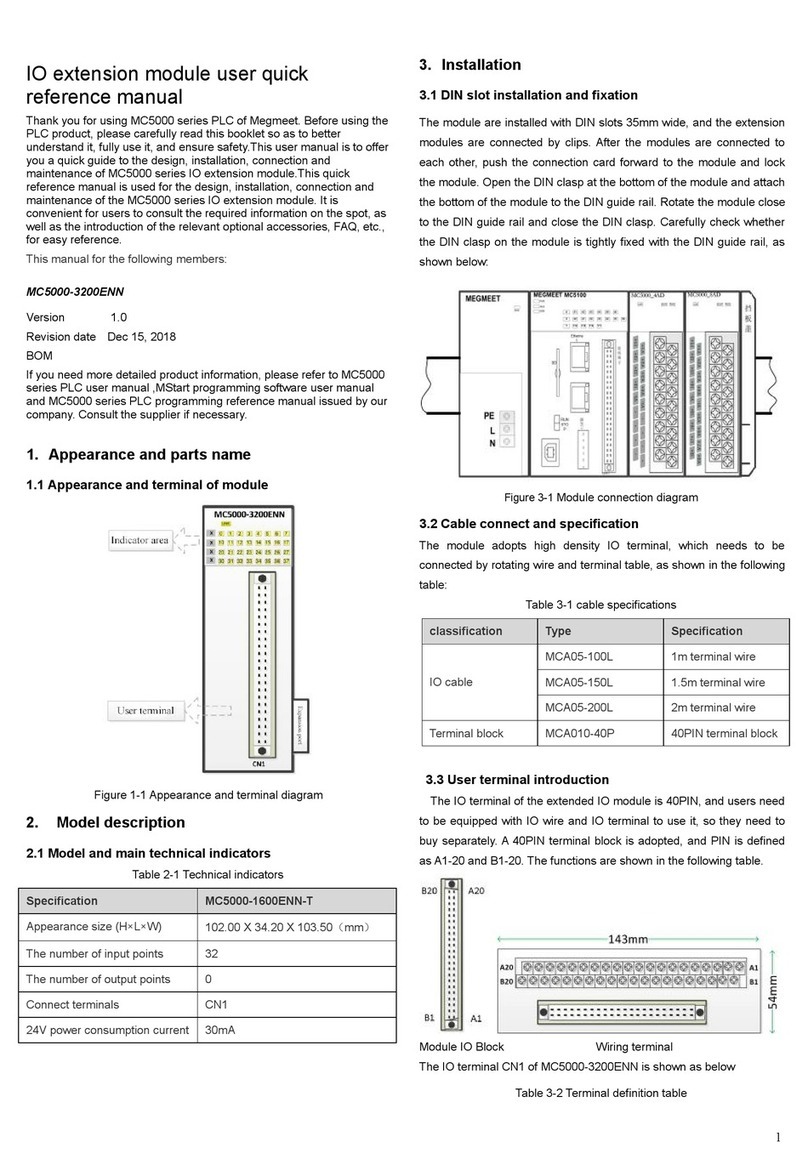

See the following table for the definition of terminal signals:

Table 3-1 MC5000-4TC / 8TC User Terminal Definition

External cold junction PT100

External cold junction PT100

The first channel thermocouple positive

The first channel thermocouple negative

The second channel thermocouple positive

The second channel thermocouple negative

The third channel thermocouple positive

The third channel thermocouple negative

Fourth channel thermocouple positive

Fourth channel thermocouple negative

Fifth channel thermocouple positive

Fifth channel thermocouple negative

Sixth channel thermocouple positive

Sixth channel thermocouple negative

Seventh channel thermocouple positive

Seventh channel thermocouple negative

Eighth channel thermocouple positive

Eighth channel thermocouple negative

4. Diagnostic and protection functions

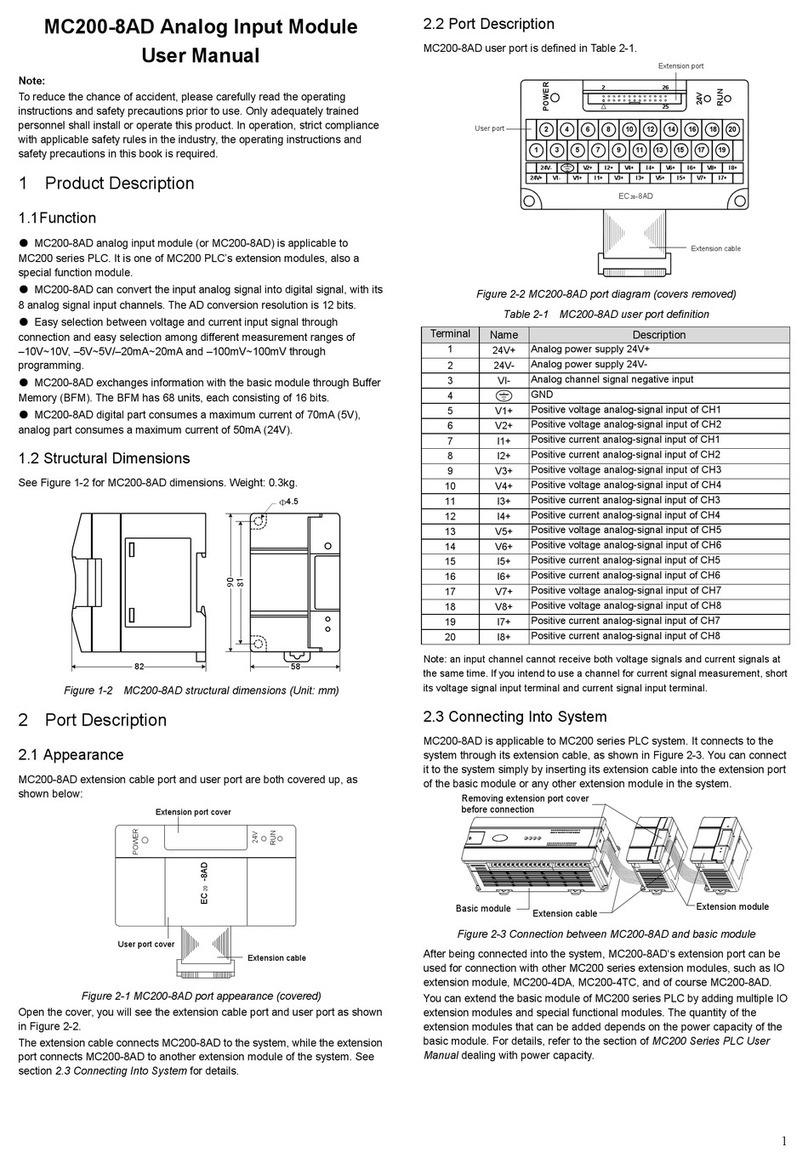

4.1 Panel status indicator

Table 4-1 Panel indicator function description table

ON: the extension

module was connected

successfully

Off: extension module

connection failed

1. Check whether the supply

voltage of the main module is

normal

2. Check whether the

expansion clasp is clamped

tightly

3. Check whether the baffle

cover is installed firmly

Flash: normally

Slow flash: module

failure or running error

See table 4-2 for the

description of the module fault

status register

Normal operation: off

Running error: on

See table 4-3 for details on

running the error status

register

Remarks: ①Fast flashing: (5Hz flashing)

②Slow flashing: (1Hz flashing)

4.2 Module fault and error status

Table 4-2 Module fault status register

Module fault

status (16Bit)

BIT0: Module operation error, see (Table 4-3)

Module operation error register for details

BIT4: The module parameter is wrong. For details,

please refer to (Table 4-4) Configuration

Parameter Error Register

BIT6: Temperature rate exceeds the limit

BIT8: Broken couple

BIT10: temperature exceeds the limit

Other: reserved

Table 4-3 Operation error status register

Operate fault status

(16Bit)

BIT0: cold junction temperature

measurement overrun (-50 ℃~90 ℃)

BIT1: ADC communication is abnormal

BIT2: Reading error of internal cold

junction temperature sensor

BIT3: External FLASH read error

Other: save

Table 4-4 Description of configuration parameter errors

Configuration parameter

error register

0: No parameter configuration error

Other: wrong parameter BFM address

4.3 Broken detection

If the temperature detection channel is open, the module will detect

whether the pair is broken. If the input is open, the module generates

an alert. The disconnected status register will be set and the ALM alarm

light will generate an alarm.

Table 4-5 description of the break state

Overrun status register

(16Bit)

0~7bit: channel 1 ~8 broken alarm

8~15bit: reserved

4.4 Temperature limit alarm

Users can set a temperature alarm upper limit and lower limit for each

channel. When the measured temperature is higher than the upper limit

or lower than the lower limit, the channel over-limit register will be set

and the ALM light will give an alarm.

Table 4-6 Description of overrun status

Overrun status register (16Bit)

0~7bit: channel 1 ~8 upper

alarm

8~15bit:channel 1 ~8 lower

alarm

4.5 Temperature rate alarm

The module has the function of detecting the temperature change rate

(℃/s,℉/s). When the temperature change rate exceeds the set value,

the channel temperature rate register will be set and the ALM light will

generate an alarm.

Table 4-7 Overrun state description table

Overrun status register (16Bit)

0~7bit: channel 1 ~8

Channel 1 ~ 8 heating rate alarm

8~15bit:channel 1 ~8

Channel 1 ~ 8 cooling rate alarm

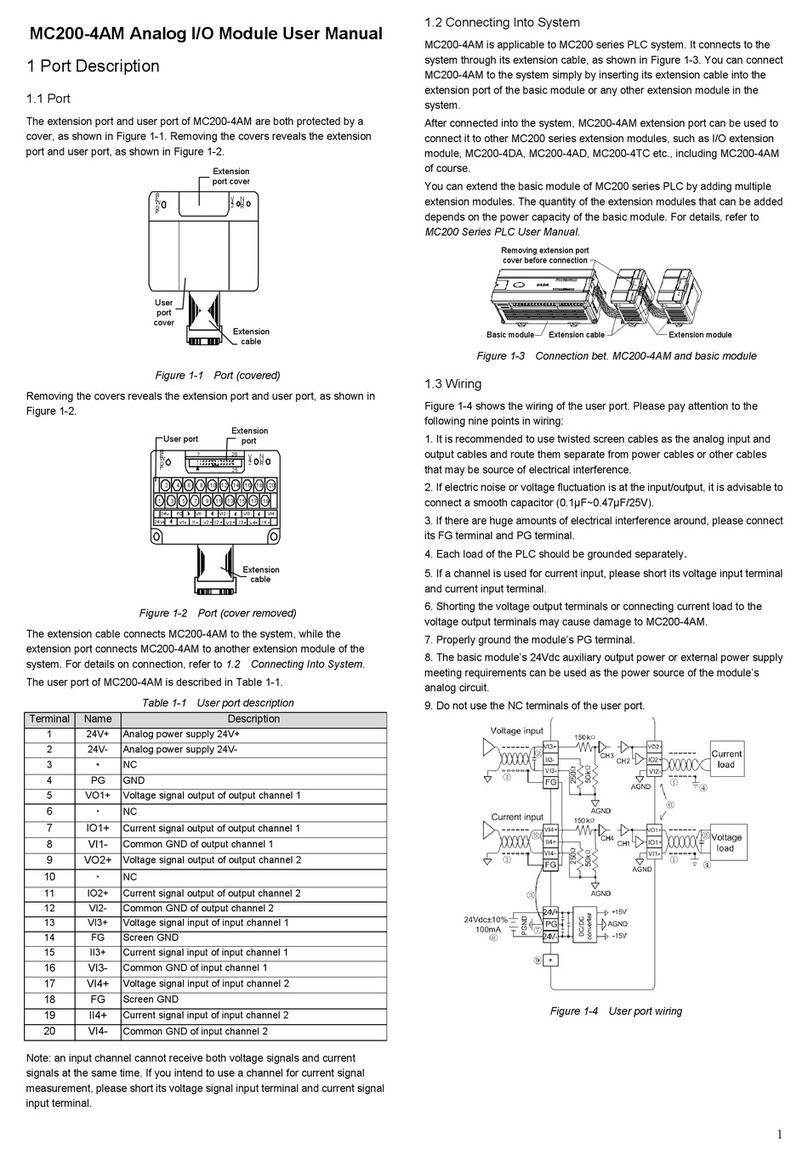

5. Operation check

1. Check whether the thermocouple wiring meets the requirements

2. Check the MC5000-4TC/8TC extension cable for reliable insertion

into the extension cable interface.

3. Check whether the module configuration and setting parameters are

correct.

4. Check whether the LINK light of Mc5000-4tc /8TC extension module

is always on and whether the RUN light flashes slowly.

6. Fault check

If the MC5000-4TC / 8TC does not operate normally, please follow the

procedure below to check.