MEHEN M10C User manual

PLEASE WELL READ THIS MANUAL BEFORE USE

HEAT-FREEZE COMBINATION MACHINE

M10C

M15C

M20C

M30C

Version 4.6

- 2 -

On behalf of MEHEN, we hereby wish to express our sincerely thanks for

purchasing MEHEN machines.

MEHEN Machines are in conformity with EU Directive(s):

Machinery Directive: 2006/42/EC

Electromagnetic Compatibility Directive: 2004/108/EC

Food processing machinery — Basic concepts —Part 2: Hygiene requirements: EN

1672-2:2005+A1:2009

Electrical Equipment of Industrial machines: EN60204-1:2006+A1:2009

Immunity for industrial environments: EN61000-6-2:2005

Emissions for Industrial environments: EN61000-6-4:2007

Some models comply with the requirements of the Standard(s) for Special Purpose

Food Equipment & Devices (NSF-169) and are identified with the ETL Sanitation

Listed Mark.

_________________________________________________________________________

MEHEN FOOD MACHINE MANUFACTURE CO., LTD.

Xin Ling North Rd 1, ChunHua Street, Jiangning District, Nanjing, 211123,

P.R.CHINA Tel. 0086-25.68552699 Fax. 0086-25-68901895

_________________________________________________________________________

This handbook may neither be reprinted, reproduced, transferred for any

commercial purposes, nor translated in other languages unless agreed by MEHEN

in advance.

The purchasers are allowed to reprint or copy the handbook for own official use.

Provided that MEHEN's new products are upgraded with new model or new

design, MEHEN reserves the rights to make amendments and revisions when

necessary without making notice to the purchasers.

Product design and specifications are subject to change without notice. This

includes primary product specifications, controller and this manual.

The manufacturer assumes no liability for any errors or discrepancies in this

manual.

- 3 -

INDEX

FOREWORD

Handbook Instructions...............................................................................................

Symbol Annotation......................................................................................................

CHAPTER 1 GENERAL INFORMATION

1.1 Nameplate of Machine........................................................................................

1.2 Machine Layout...................................................................................................

1.3 Working Conditions............................................................................................

CHAPTER 2 INSTALLATION

2.1 Position..................................................................................................................

2.2 Room Condition....................................................................................................

2.3 Installation of Air-cooled Machine......................................................................

2.4 Installation of Water-cooled Machine...............................................................

2.5 Electrical Connection..........................................................................................

2.6 Change Cable.......................................................................................................

2.7 Refrigerant Gas Refill..........................................................................................

2.8 Machine Testing..................................................................................................

2.8.1 Check the Rotation Direction of Agitator............................................

2.8.2 Running Test of Freezer........................................................................

2.8.3 Running Test of Cooker.........................................................................

CHAPTER 3 EXPLOSION DIAGRAM

3.1 Components Position ...........................................................................................

3.2 Freezer Driving Parts Diagram.........................................................................

3.3 Freezer Blender Diagram..................................................................................

3.4 Freezing Cylinder Door Diagram.......................................................................

3.5 Valve Driving Parts Diagram.............................................................................

3.6 Cooker Blender Diagram....................................................................................

CHAPTER 4 CONTROLS AND OPERATION

4.1 Freezer Cylinder Door Operation.....................................................................

4.2 Transfer the Hot Mix From Boiler to Freezer Cylinder.................................

4.3 Electrical Control Panel.......................................................................................

4.4 Common Operations..........................................................................................

4.4.1 Language Setting.....................................................................................

4.4.2 Date and Time setting.............................................................................

4.4.3 Controller Initialization............................................................................

4.5 Freezer Operation.................................................................................................

4.5.1 Freezer Daily Operation..........................................................................

4.5.2 Freezer Producing Programs..................................................................

4.5.2.1 Hardness Mode..............................................................................

4.5.2.2 Time Mode....................................................................................

6

6

7

7

7

8

8

8

8

9

9

9

9

9

10

10

11

12

12

13

13

14

14

15

15

15

15

16

16

17

17

17

17

18

- 4 -

4.5.2.3 Temperature Mode.................................................................................

4.5.2.4 Granita Mode......................................................................................

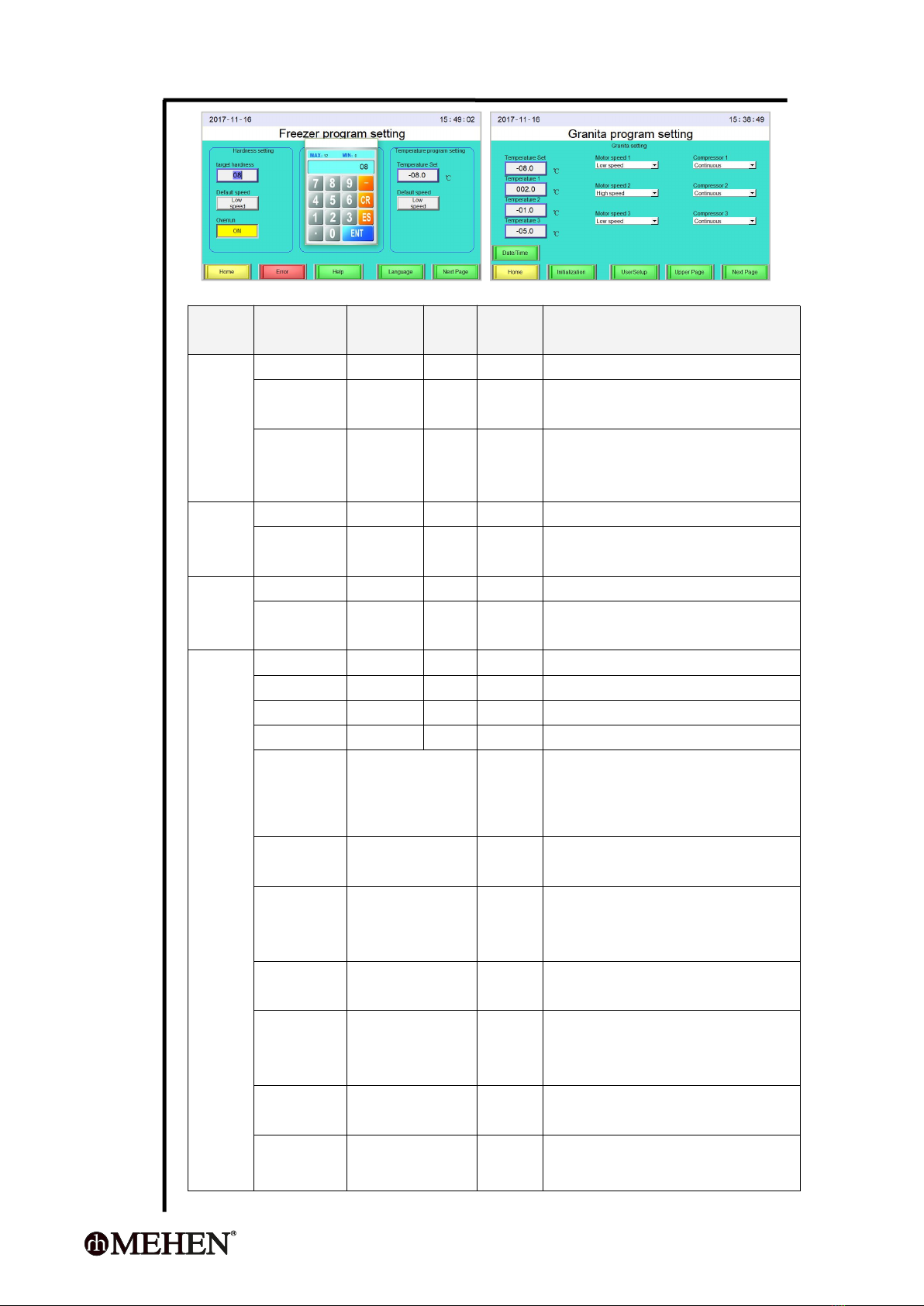

4.5.3 Freezer Program Setting..................................................................................

4.5.3.1 How to Set Freezer Program?........................................................

4.5.3.2 Freezer Programs Setting.................................................................

4.5.4 Freezer User Parameters Setting.............................................................

4.5.4.1 How to Set Freezer User Parameters?................................................

4.5.4.2 Freezer User Parameter List................................................................

4.5.5 Freezer Take Out the Product.................................................................

4.5.5.1 Normal Take Out.............................................................................

4.5.5.2 Filling Cups Take Out......................................................................

4.5.6 Clean the Cylinder.......................................................................................

4.5.7 Door Open.....................................................................................................

4.5.8 Compressor Overtime...............................................................................

4.5.9 Error Alarm.................................................................................................

4.5.10 Operation With Error................................................................................

4.5.11 A Typical Freezer Producing Operation................................................

4.6 Cooker Operation.................................................................................................

4.6.1 Cooker Daily Operation............................................................................

4.6.2 Cooker Producing Programs...................................................................

4.6.3 Cooker Program Setting...........................................................................

4.6.3.1 How to Set Cooker Program?.......................................................

4.6.3.2 Cooker Programs Setting..............................................................

4.6.4 Cooker User Parameters Setting.................................................................

4.6.4.1 How to Set Cooker User Parameters?...........................................

4.6.4.2 Cooker User Parameter List..........................................................

4.6.5 Cooker Error Alarm..................................................................................

4.6.6 A Typical Cooker Producing Operation.................................................

CHAPTER 5 FREEZING SYSTEM DIAGRAM

5.1 Freezing System Diagram.................................................................................

5.2 Cooking System Diagram.................................................................................

CHAPTER 6 HYGIENE

CHAPTER 7 SAFETY DEVICE

7.1 Safety Device Position.........................................................................................

7.2 Safety Device Explanation...................................................................................

7.2.1 Door Open Operate Forbidden Safety Device...................................

7.2.2 Compressor Overload Safety Device.................................................

7.2.3 Agitator Motor Overload Safety Device............................................

7.2.4 Refrigerate Gas Pressure High Safety Device...................................

7.2.5 Anti-over-heated Device (Independent Heater Explosion

-proof thermostat and probe)..........................................................................

18

18

19

19

20

21

21

21

22

22

22

23

23

23

24

24

25

25

26

26

26

26

26

27

27

27

28

28

28

28

28

29

29

29

29

29

29

29

- 5 -

CHAPTER 8 MAINTENANCE

8.1 Routine Maintenance.............................................................................................

8.2 Maintenance of Water-cooled Machine...............................................................

8.3 Maintenance of Air-cooled Machine....................................................................

8.4 Preventive Maintenance.......................................................................................

8.5 Order Spare Parts....................................................................................................

CHAPTER 9 TROUBLESHOOTING...................................................................

APPENDIX A Electric Diagram

APPENDIX B PR/ Producing Record

30

30

30

31

31

31

- 6 -

FORWORD

Handbook Instructions

This handbook is edited while taking needs of users into due account. Topics

regarding proper operation and ensuring long-term and stable running of the

machine in different areas and conditions have been illustrated.

Furthermore, the knowledge of maintenance is also provided with instructions in

this manual book.

The users can also contact manufacturer in case that any problems can not been

solved within this handbook.

Symbols Annotation

Caution of Electric Shock Danger, Non-compliance of safety principle in

carrying out the operation described under this symbol may cause an

electric shock.

Caution of General Danger, Non-compliance with safely principle

described related to this symbol may cause dangers to operators.

NOTE, It points out significant information for the staff involved.

Warning, Non-compliance of related warnings may cause harm to person

involved and damages to the machine.

Qualification of the Staff (Machine operator), Contents to describe what the

operator should grasp to use the machine.

Skilled Technician, Contents to describe what the skilled technician should

grasp.

Security Protection, Symbol means that the user must pay extra attention to

prevent risk during operation and increase the awareness of personal

protection.

- 7 -

CHAPTER 1 GENERAL INFORMATION

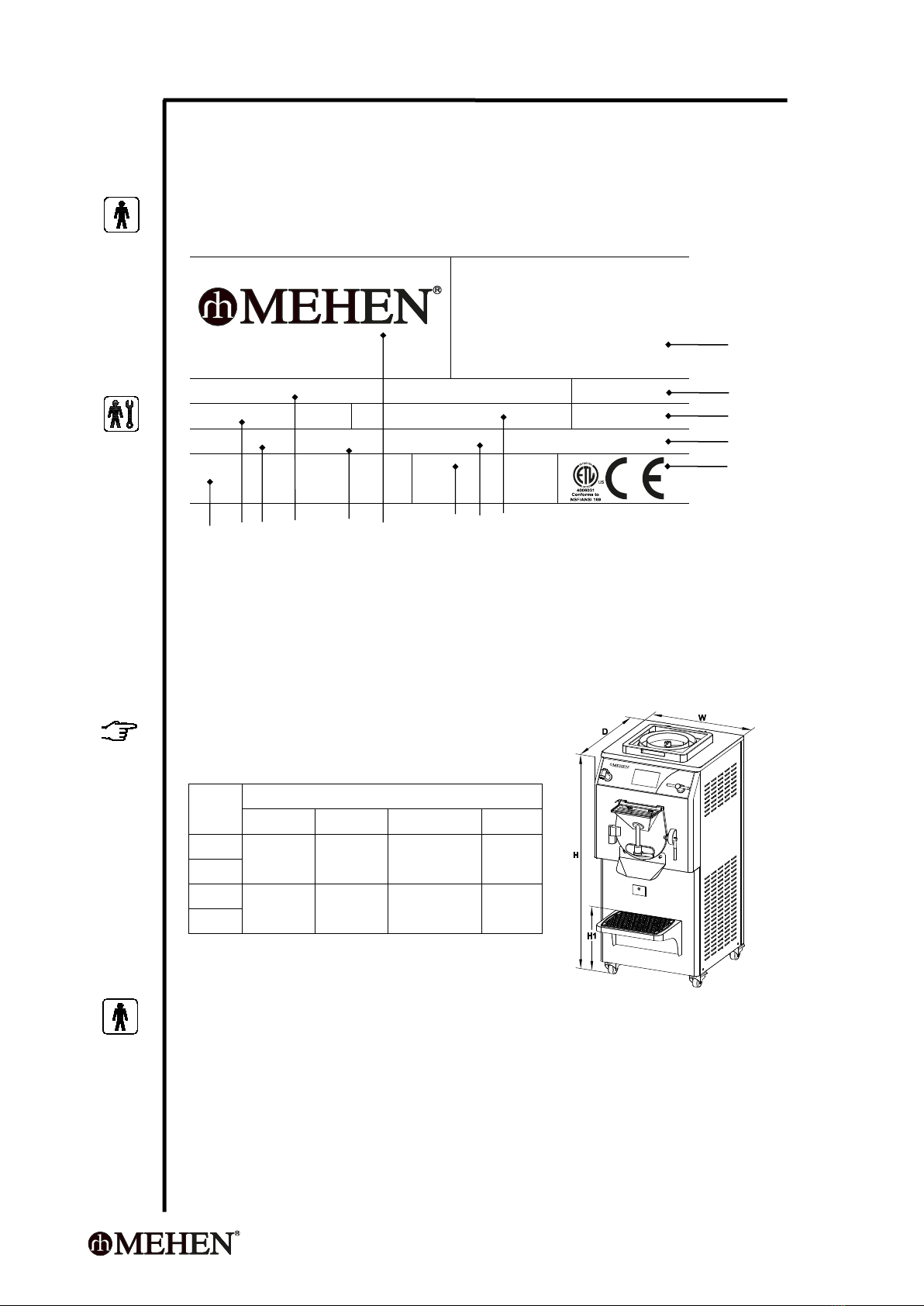

1.1 Nameplate of Machine

A nameplate consisting of manufacture's date is posted on the side panel of the

machine.

Xin Ling North Rd 1, ChunHua Street, Jiangning

District, Nanjing, 211122, P.R.CHINA

Tel: 0086-25-68552699

Http://www.mehen.com

Email:[email protected]

Model:

Cap.: Ltr

Gas: R404A Kg

Cooling:

~V. Ph. Hz. Amp.

N.W. Kg

P/N:

A B C D E F G H I

A=Net Weight B=Capacity C=Voltage D=Product Name E=Phase F=Brand

G=Product Number H=Frequency I=Gas & gas weight J=Certification

K=Electric Current L=Cooling method ( W-water, A-Air) M=Model

N=Manufacturer's contact information

1.2 Machine Lay-out

NOTE

Dimension may be various depending on

type of condensation.

1.3 Working Conditions

The following conditions are requested to ensure long term and steady operation:

Voltage Fluctuation: <10%

Ambient temperature: 0~35 ºC

Cooling water temperature: 5~30 ºC

Cooling water pressure: 1~8 bar

Max relative humidity: 85% ( without moisture condensation)

Model

Dimension (mm)

Width (W)

Depth (D)

Height (H)

H1

M10C

580

680

1320

410

M15C

M20C

680

980

1390

410

M30C

N

M

L

K

J

- 8 -

_________________________________________________________________________

CAUTION

The machine is not designed with anti-explosion standards. Thus make sure the

working place is out of explosive danger.

WARNING

MEHEN is NOT responsible for any accident happened to people or machine in

case the machine is used out of the designed condition.

_________________________________________________________________________

CHAPTER 2 INSTALLATION

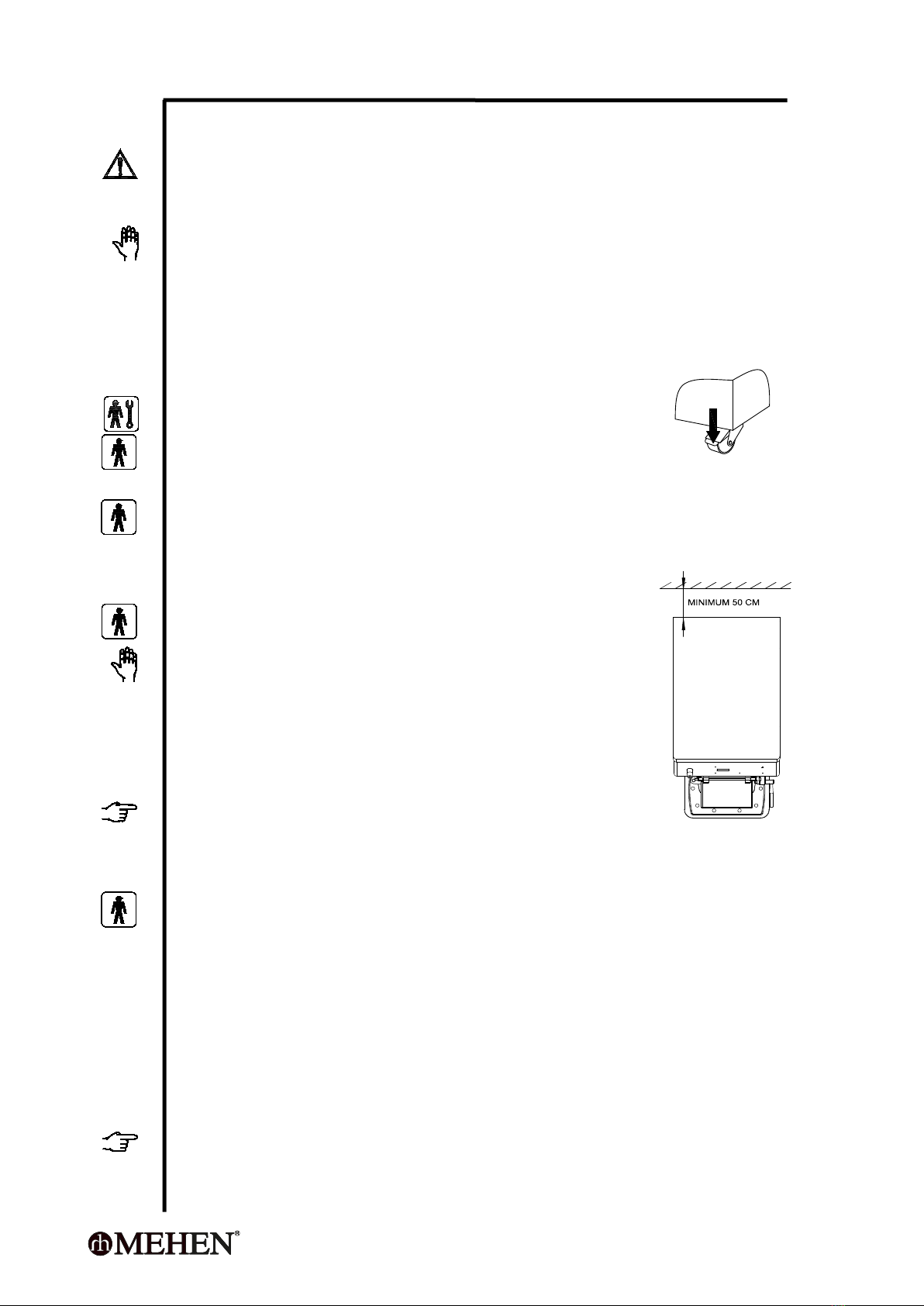

2.1 Position

After the machine is positioned, lock the caster immediately

to prevent movement of the machine during working.

2.2 Room Condition

The machine must be installed in room with a good air-ventilation so as to dispel

the hot air generated by the condenser. The room would be better with enough

space for operators to withdraw when necessary.

2.3 Installation of Air-cooled Machine

WARNING

Machine with air-cooled condenser must be installed no

less than 50 cm from the wall in order to allow free air

circulation around the condenser.

Clean the floor near and under the machine to avoid

paper and other stuffs entering into the condenser and

blocking a regular air flow.

TIPS

Insufficient air circulation affects both machine working and

its performance.

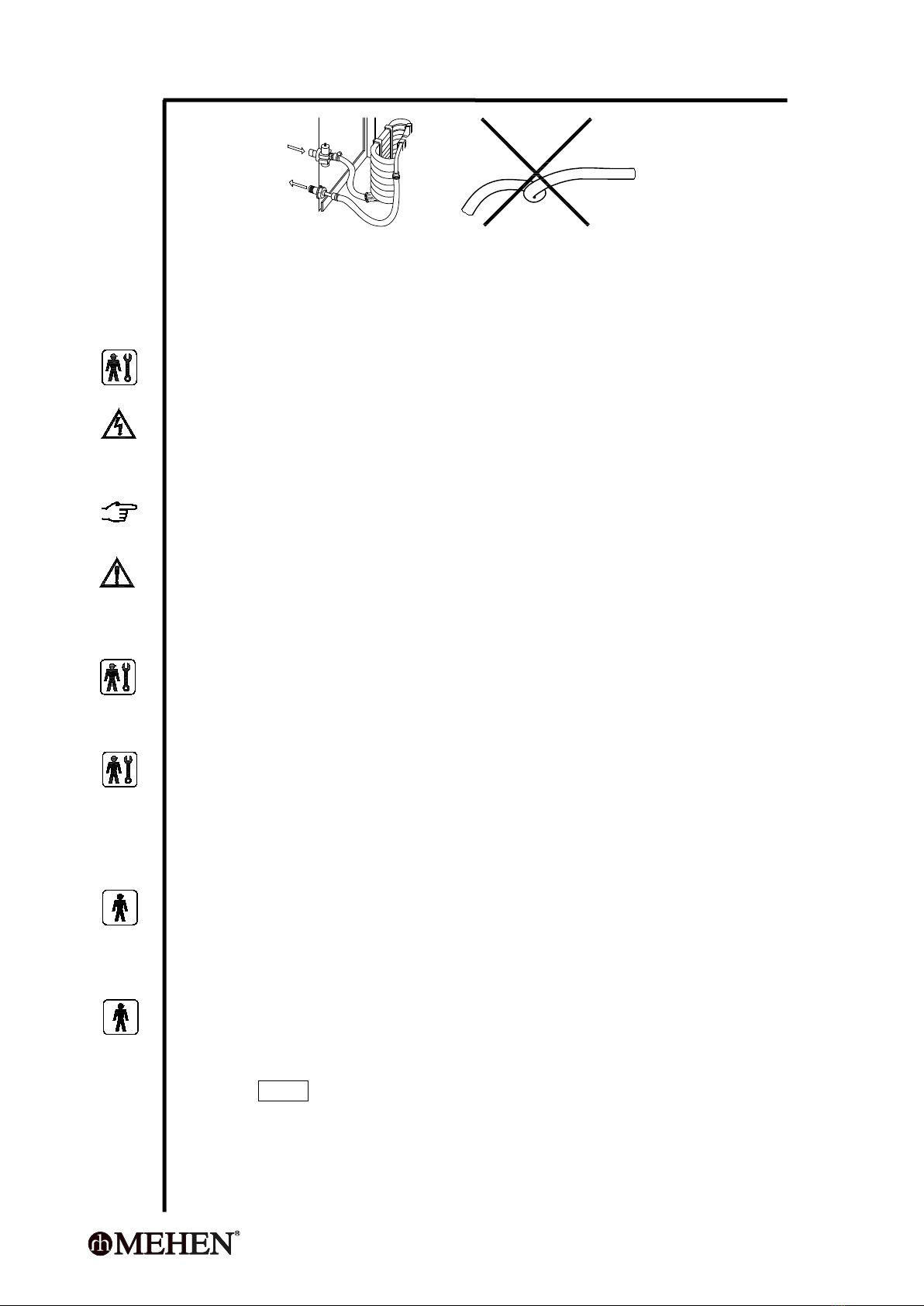

2.4 Installation of Water-cooled Machine

The inlet and outlet pipes of cooling water must be properly installed before

operation.

The requirements for the cooling water are:

Pure and no debris;

It's better to use soften water to prevent that furring appears inside of

the pipe to block the pipe and reduce the heat-exchange-efficiency.

Connect the cleaning water pipe to a drinkable water source if the machine is

equipped with a cleaning tap.

NOTE

MEHEN recommends to use steel pipe which can bear pressure up to 8 bar.

Keep the pipes fluent, don't bent.

- 9 -

TIPS

There is an electric water valve inside which can cut the water flow. Keep the

cooling water supply tap OPEN before starting the machine.

2.5 Electrical Connection

Before connecting the machine to the power mains, check power information

indicated on nameplate and choose a suitable power supply to the machine.

Get a circuit breaker protection device according to the parameters on nameplate

and install it to the power supply circuit during installation.

The specifications of the wires should strictly follow the requirements of the

machine and the minimum diameter is no less than 3 mm.

NOTE

Please refer to the label on the power wires.

WARNING

The PE For single phase and three phase, Yellow-green wire must be connected

to a good ground outlet.

2.6 Change Cable

If machine main cable is damaged, it must be replaced with same features and

carried out by an skilled technician.

2.7 Refrigerant Gas Refill

The freezing system has been filled with refrigerant gas and inspected by MEHEN

before delivery. If the machine met problem of gas leaking in use, a skilled

technician should be got to find the leakage, fix it then refill the refrigerant gas.

2.8 Machine Testing

Each machine from MEHEN is tested with full record before delivery. After the

machine is installed properly at the clients working site, it should be inspected

and tested by a skilled technician or engineer from MEHEN.

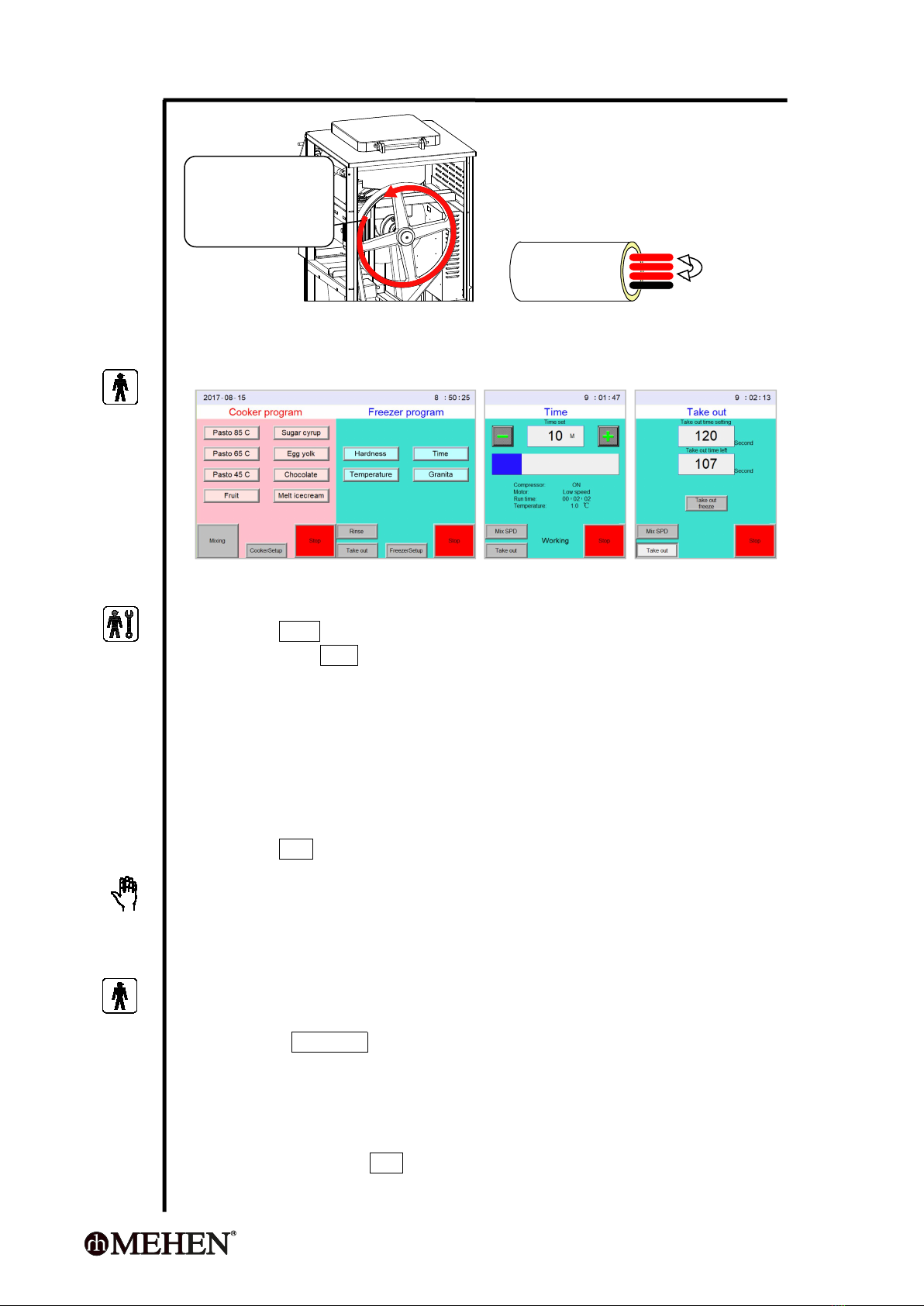

2.8.1 Check the Rotation Direction of Agitator (for three-phase machine only.)

Remove the side panel of the machine

Take out the blender from the cylinder, close and latch the cylinder door.

Test the rotation direction:

Push key RINSE to run it with empty freezing cylinder.

Check the rotate direction of the blending wheel according to above picture.

Otherwise, please exchange the connection of any two of three HOT-LINE to

change the rotating-direction, then test it again.

- 10 -

Assemble the machine panel after this test.

2.8.2 Running Test of Freezer

Prepare proper quantity (half of the named capacity) ice cream mix.

Well latch the cylinder door and outlet door then pull the mix into cylinder.

Press Rinse to mix the material for 30 seconds.

Then press Time to start freezing.

When the setting time finished, the compressor stop automatically, also the

buzzer will keep on beeping to remind the operator.

The operator can open the outlet door (part-47106) to take out the product.

If the operator want the product to come out slowly, use low speed.

If want it faster, use high speed.

When the cylinder is near to empty, please switch it to high speed to take

out it neatly.

Press Stop after take out all the product.

WARNING

Pure water can't be used to freeze in the cylinder under any condition,

otherwise may cause the blender seriously damaged.

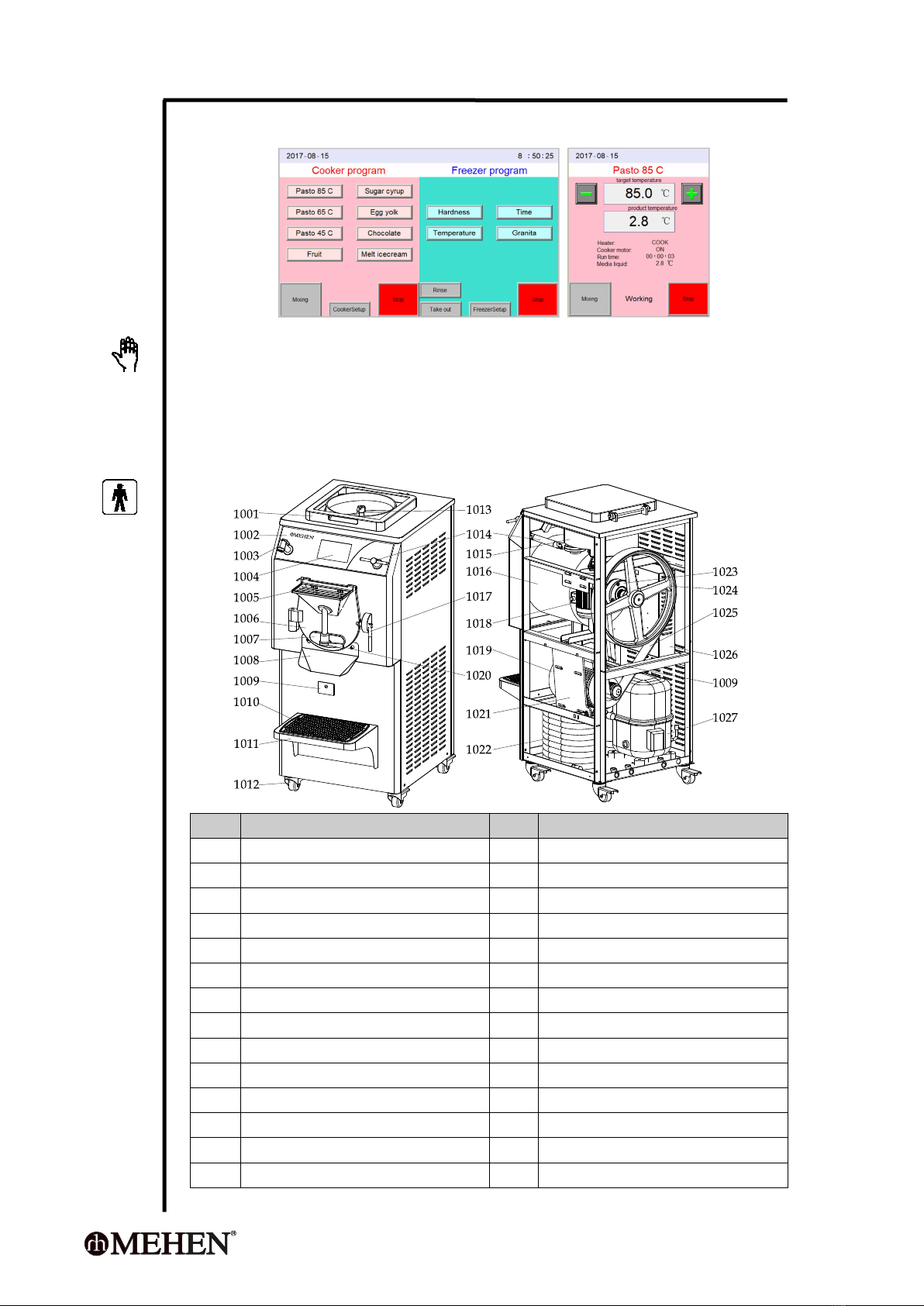

2.8.3 Running Test of Cooker

Prepare proper quantity (half of the named freezer capacity) of water, make

sure the valve is closed, pull into the cooker tank then close the cover.

Press Pasto 85 C to start cooking.

Inspect the blending and display, the temperature shall increase as time

being.

When the setting temperature achieved, the cooking stop and the blending

continues.

Push key left-side Stop to stop blending.

exchange wires

to change direction

Correct rotation

direction of

agitator

- 11 -

Open the valve to take out the hot water.

WARNING

Never start cooking when the mix tank is empty.

CHAPTER 3 EXPLOSIVE DIAGRAM

3.1 Components Position

Pos.

Description

Pos.

Description

1001

Cooker cover

1002

Plastic panel

1003

Rinse spigot

1004

Touch screen controller

1005

Inlet cover

1006

Cylinder door

1007

Outlet door

1008

Output groove

1009

Waste liquid collector

1010

Anti slip pad

1011

Pan holder

1012

Caster

1013

Cooker blender

1014

Valve handle

1015

Cooking tank

1016

Freezing cylinder

1017

Door latch//Valve wrench

1018

Agitating motor, freezer

1019

Agitating motor holder, freezer

1020

Output wrench

1021

Freezer motor shelf

1022

Condenser

1023

Agitating motor, cooker

1024

Driving pulley

1025

Belt

1026

Electrical components box

1027

Compressor

- 12 -

3.2 Freezer Driving Parts Diagram

47001

47002

47003

47004

47005

47006

47008

47007

47009

47010

Pos.

Description

Pos.

Description

47001

Bearing holder

47002

Shaft

47003

Bearing

47004

Bearing sleeve (small)

47005

Bearing sleeve (big)

47006

Bearing stop small nut

47007

Key

47008

Bearing stop big nut

47009

Drive pulley

47010

Pulley locking screw (3 pieces)

3.3 Freezer Blender Diagram

4801

4802

4803 4805

4804

Pos.

Description

Pos.

Description

4801

Radial support

4804

Plastic blade

4802

Blender frame

4805

Cylinder bottom seal

4803

Axis support

Pull to take out

- 13 -

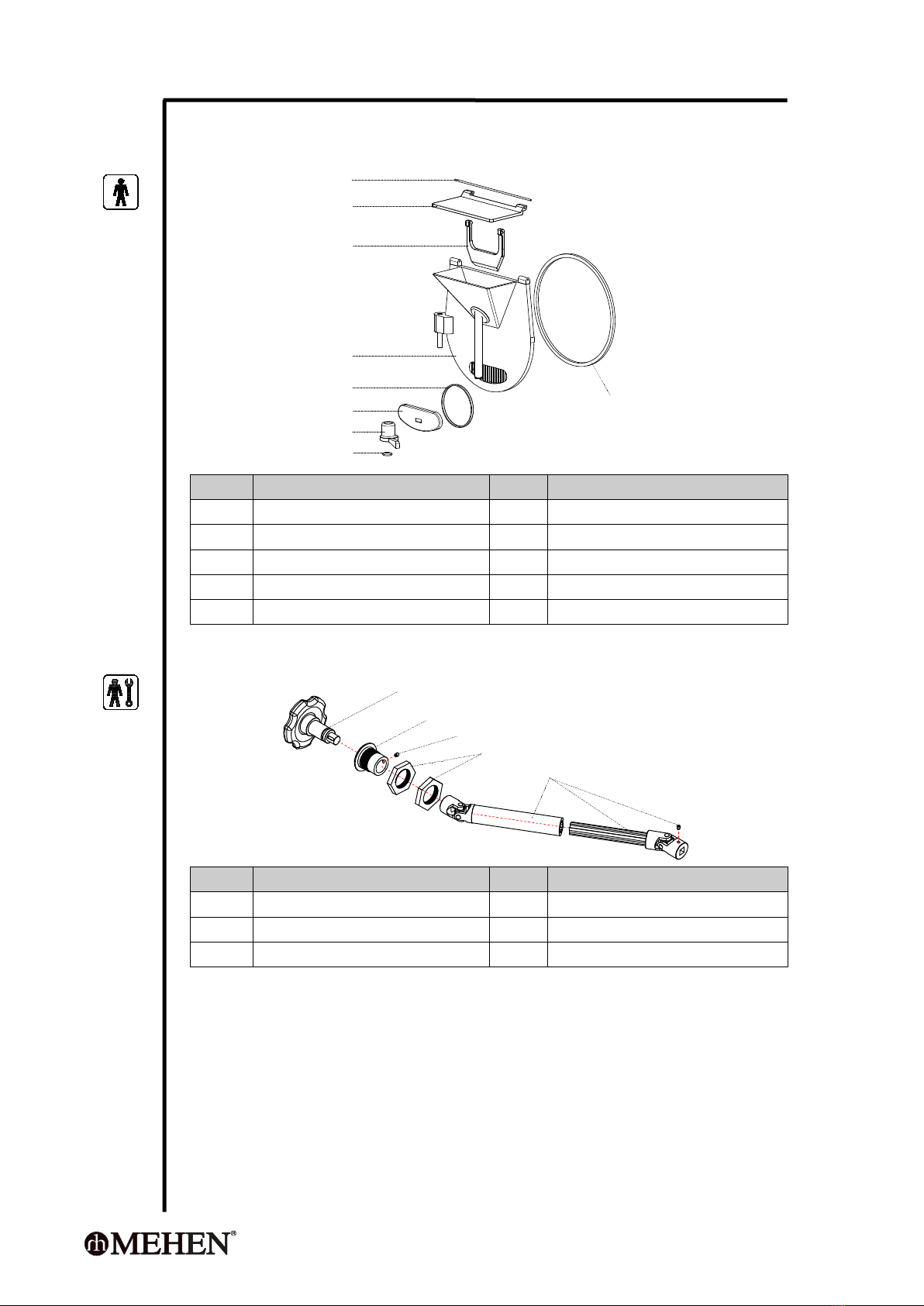

3.4 Freezing Cylinder Door Diagram

47101

47102

47103

47104

47105

47106

47107

47108

47109

Pos.

Description

Pos.

Description

47101

Cover axis

47106

Outlet door

47102

Inlet cover

47107

Handle

47103

Inlet stopper

47108

Handle stop ring

47104

Cylinder door

47109

Cylinder seal ring

47105

Outlet door seal ring

3.5 Valve Driving Parts Diagram

37001

37002

37003

37004

37005

Pos.

Description

Pos.

Description

37001

Valve wrench

37002

Holder

37003

Nuts

37004

Holding nuts

37005

Drive set

- 14 -

3.6 Cooker Blender Parts Diagram

37110

37111

37112

37113

37114

37105

37107

37108

39109

37106

37101

37102

37103

37104

37115

37101

37103

Pos.

Description

Pos.

Description

37101

Mixing blades

37102

Mixing frame

37103

Bottom blades

37104

Bearing

37105

Driving shaft

37106

Key

37107

Seal O-ring

37108

Waterproof bearing sleeve

37109

Seal O-ring

37110

Driving shaft holder

37111

Seal O-ring

37112

Motor support

37113

F connector

37114

Reduction gear

37115

Motor

CHAPTER 4 CONTROLS AND OPERATION

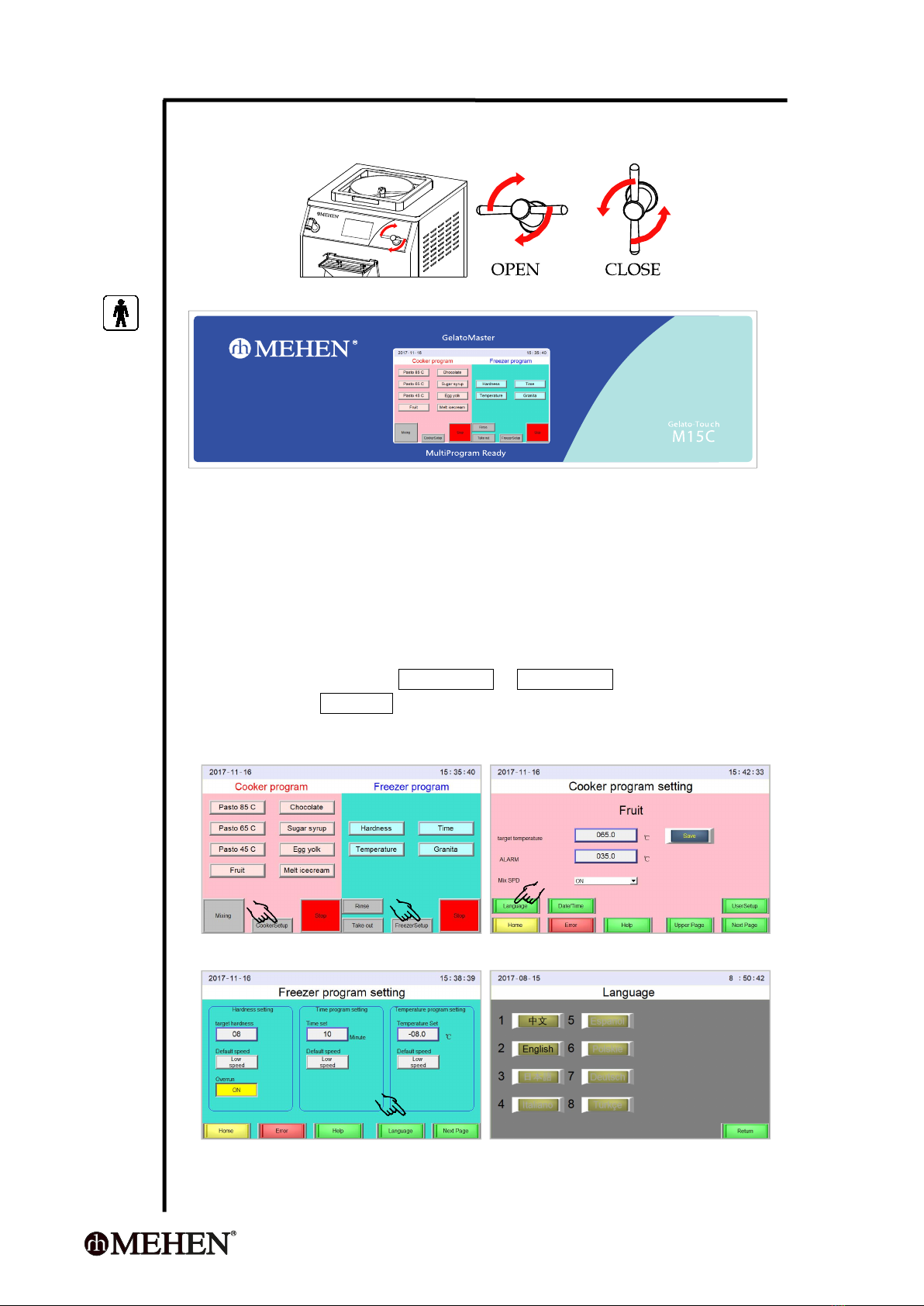

4.1 Freezer Cylinder Door Operation

1

2

1

2

1

2

- 15 -

4.2 Transfer the Hot Mix From Boiler to Freezer Cylinder

Turn the valve handle (part 1014) can open or close the valve.

4.3 Electric Control Panel

4.4 Common Operations

This machine has two independent parts, A boiler for pasteurization on the top

and another batch freezer below. They are connected together by pipe and an

valve. There is one controller, left side pasteurization and right side for freezer.

They can work at same time or independently. There are some common

operations here below:

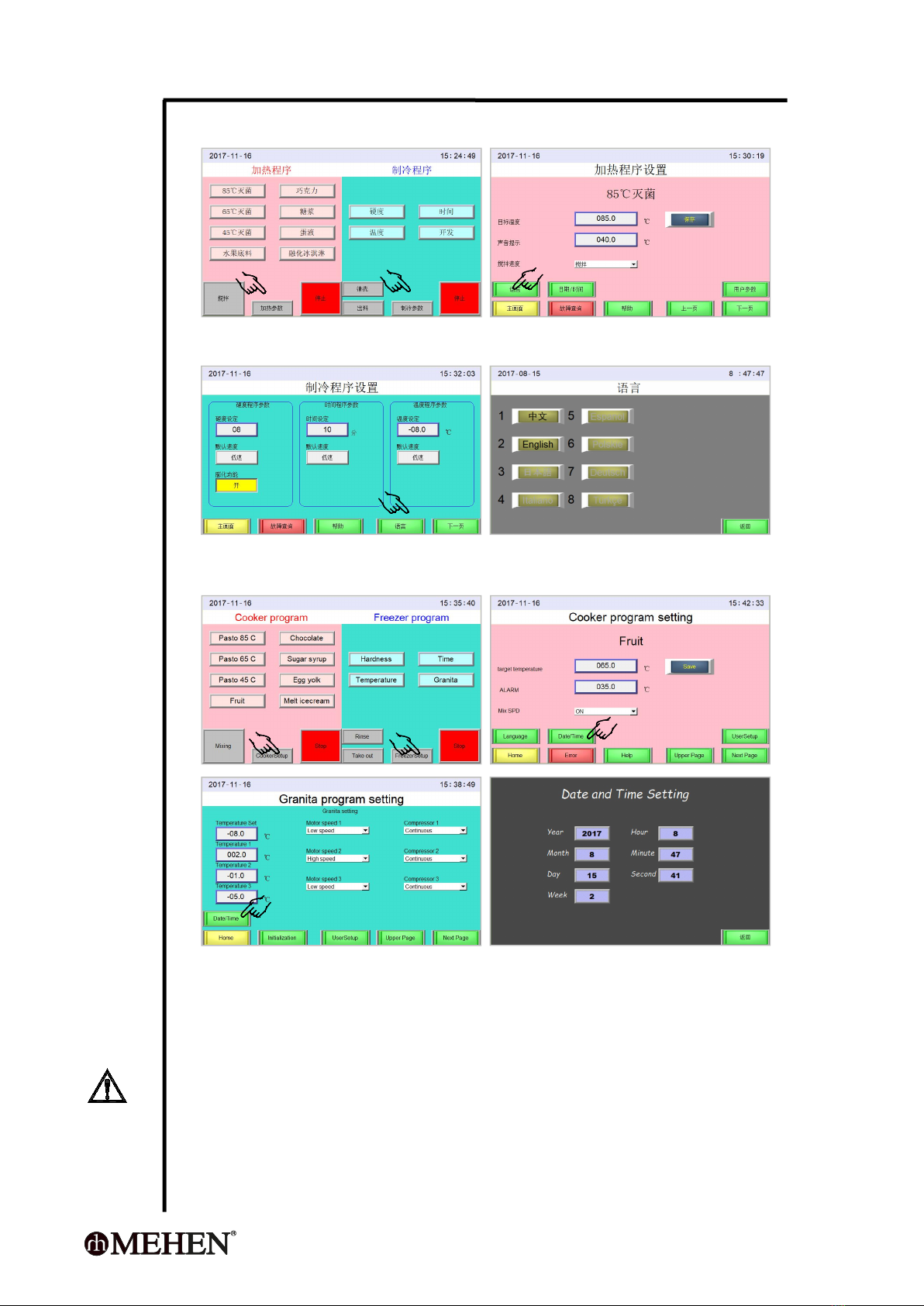

4.4.1 Language Setting

This controller offers a quick language setting.

On Home-page, press CookerSetup or FreezerSetup and program setting;

Then press Language to enter Language-setting;

Press the Language you want.

English to other language

step 1 step 2

step 2 step 3

- 16 -

Chinese to other language

step 1 step 2

step 2 step 3

4.4.2 Date and Time setting

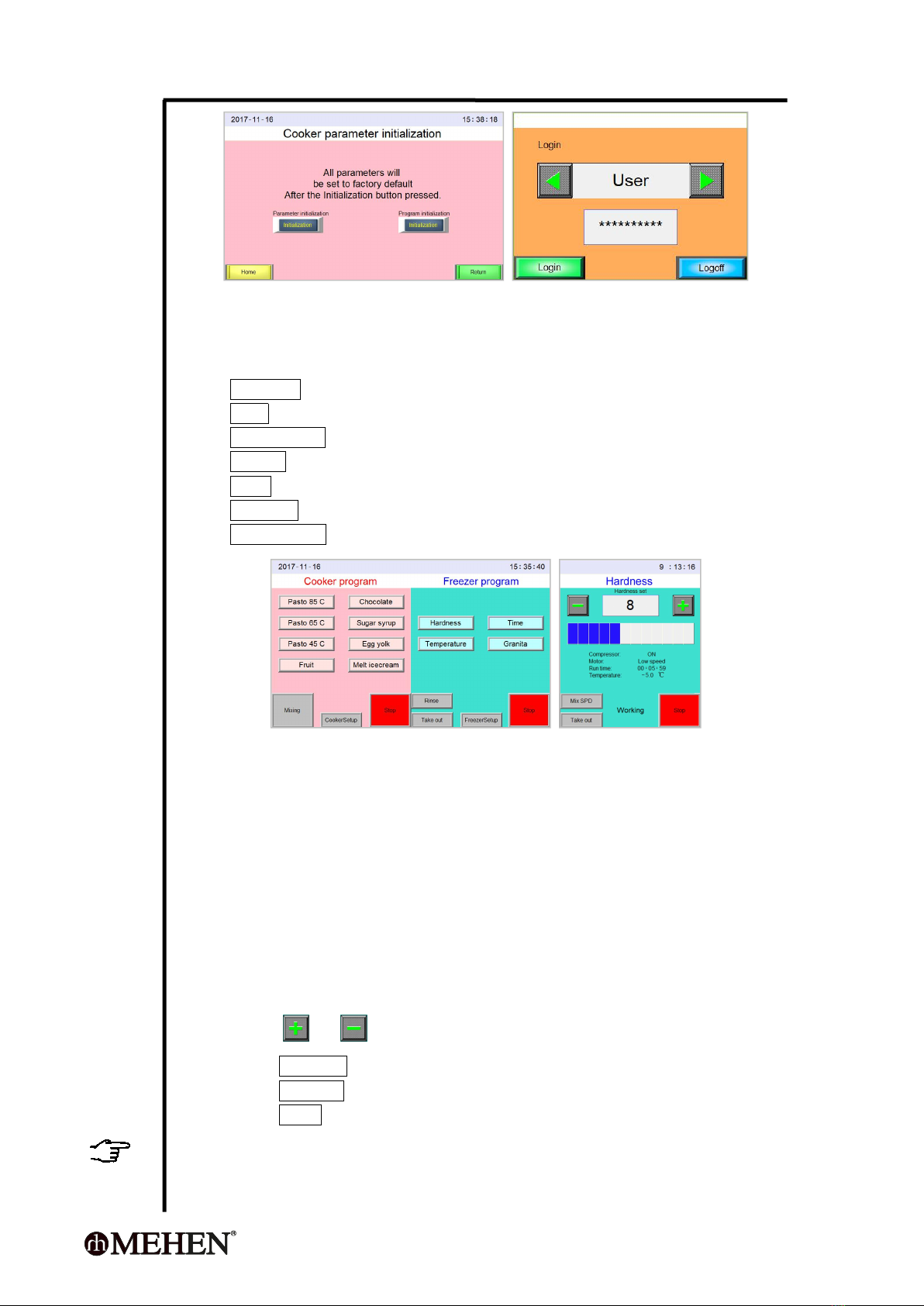

4.4.3 Controller Initialization

This initialization will reset all the parameters to factory setting.

This operation need to input the user security code 1111.

CAUTIOIN

The parameters are important to ensure the correct performance of the machine.

The initialization can be operated by a qualified technician only.

- 17 -

4.5 Freezer Operation

4.5.1 Freezer Daily Operation

It will enter home-page after power on and if there is no problems.

Press Hardness to start a product making with hardness-control-mode;

Press Time to start a product making with timer-control mode;

Press Temperature to start a product making with temperature-control-mode;

Press Granita to start a product making with developer-control-mode;

Press Rinse to perform a Rinse for cleaning;

Press Take Out to run a product taking out operation;

Press FreezerSetup to regulate the parameters.

4.5.2 Freezer Producing Programs

There are 4 programs for producing, you can use them according to your recipe or

habit accordingly.

4.5.2.1 Hardness Mode

Under this mode, the controller will:

Detect the product texture hardness, it will finish freezing and turn to

agitating only when the setting hardness achieved;

Detect the product temperature and change the agitating speed according

to setting.

During processing, the operator can:

Press or to increase or decrease the target hardness;

Press Take Out to finish the processing and turn to take out the product;

Press Mix SPD to switch the agitating speed;

Press STOP to stop the processing and turn to Standby mode.

Tips

The controller will automatically record the new setting and repeat from next time.

- 18 -

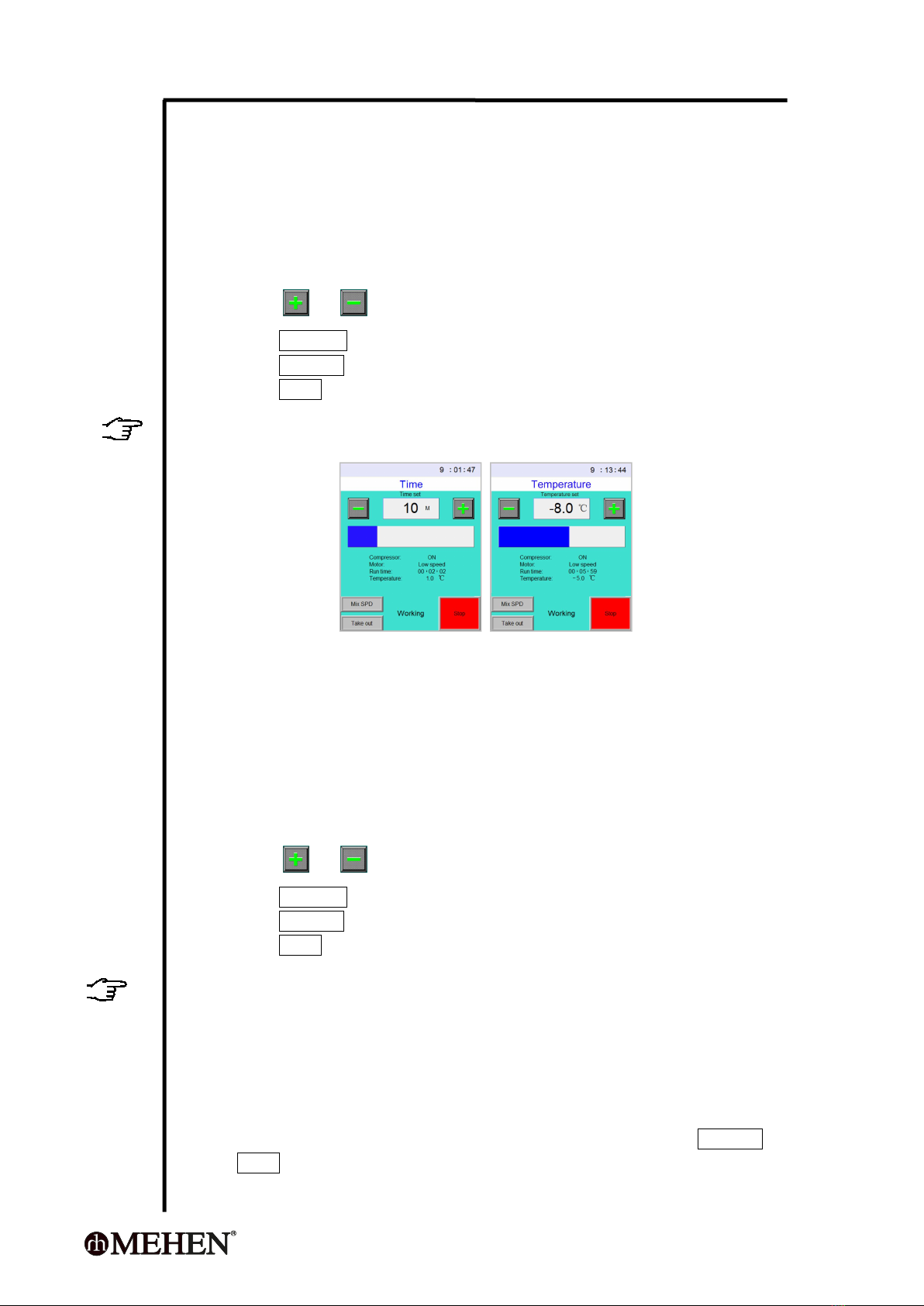

4.5.2.2 Time Mode

Under this mode, the controller will:

Perform a freezing processing according to the Time setting, it will finish

the freezing and turn to agitating only when the setting time is over;

Detects and display the product temperature.

During processing, the operator can:

Press or to increase or decrease the time setting;

Press Take Out to finish the processing and turn to take out the product;

Press Mix SPD to switch the agitating speed;

Press STOP to stop the processing and turn to Standby mode.

Tips

The controller will record the new setting and repeat from next time.

4.5.2.3 Temperature Mode

Under this mode, the controller will:

Perform a freezing processing according to the Temperature setting, it will

stop freezing and turn to agitating when the setting temperature is

achieved;

The compressor will restart if the product temperature increase 2 °C;

Detects and display the product temperature.

During processing, the operator can:

Press or to decrease or increase the temperature setting;

Press Take Out to finish the processing and turn to take out the product;

Press Mix SPD to change the agitating speed;

Press STOP to stop the processing and turn to Standby mode.

Tips

The controller will automatically record the new setting and repeat for next times.

Only Temperature-Mode has temperature holding function.

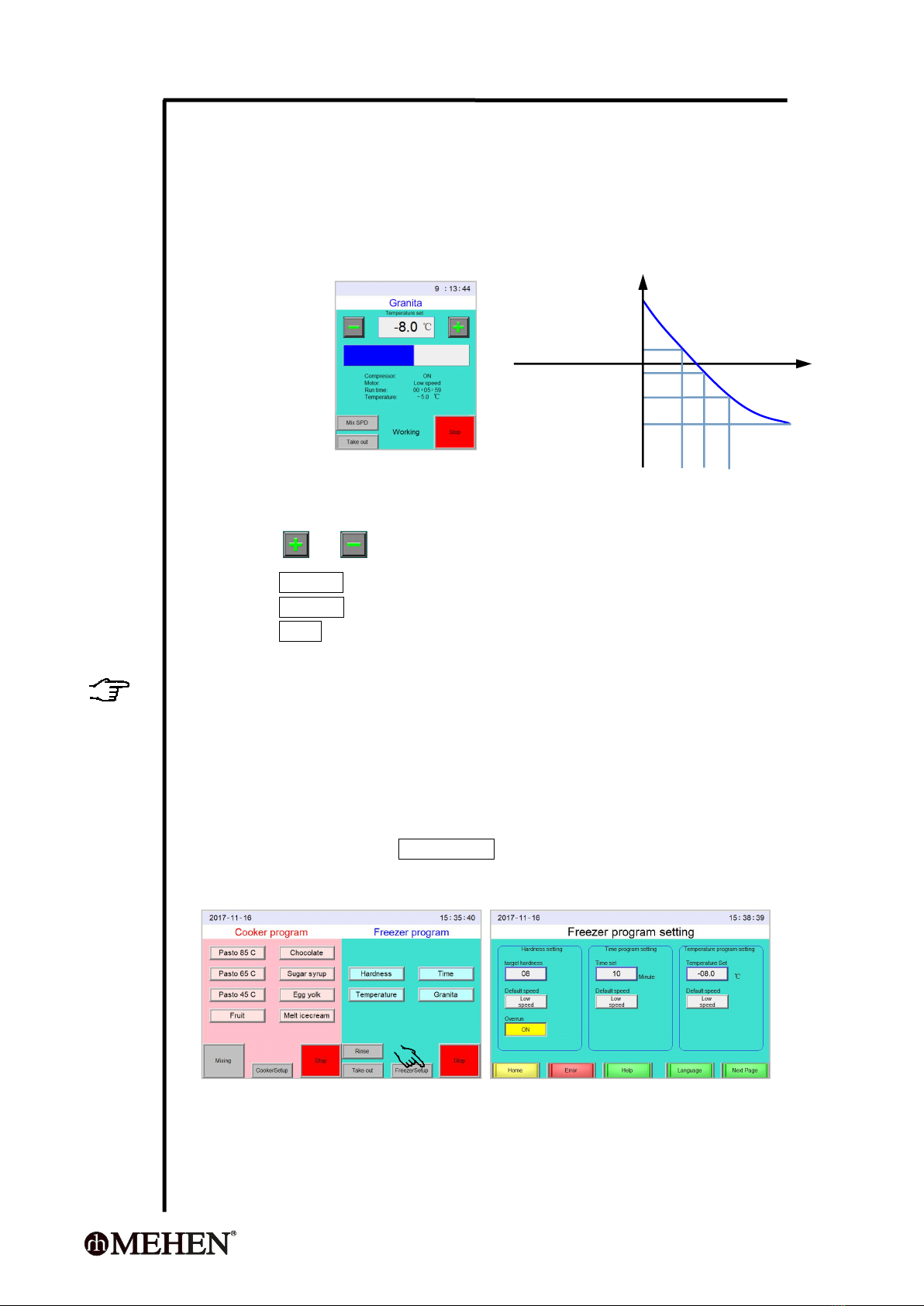

4.5.2.4 Granita Mode

This mode offers a flexible option for the chef to produce different

products;

The freezing will finish if the Setting Temperature is achieved;

The agitating will continuous until the operator manually press Take out or

STOP;

- 19 -

The entire temperature range is divided into 4 segments ( Fig 1.);

In each temperature range:

The operator can program the compressor: Continuous or Intermittent

working;

The operator can program the agitating motor: Low Speed,

Intermittent Low Speed, High Speed or Intermittent High Speed.

S1 S2 S3 S4

Fig 1

During processing, the operator can:

Press or to decrease or increase the temperature setting;

Press Take out to finish the processing and turn to take out the product;

Press Mix SPD or switch the agitating speed;

Press STOP to stop the processing and turn to Standby mode.

TIPS

The controller will automatically record the new Target Temperature Setting and

repeat from next time. We suggest you use this program only if you are

experienced.

4.5.3 Freezer Program Setting

4.5.3.1 How to Set Freezer Program?

On Home-page, press FreezerSetup will enter program setting mode;

Press the volume frame to regulate.

The new setting will be saved automatically.

time

temperature

Temperature 1

Temperature 2

Temperature 3

Target temperature

- 20 -

4.5.3.2 Freezer Programs Setting

Program

Parameters

Range

Unit

Factory

Volume

Explanation

Hardness

Target hardness

1~12

==

8

Higher volume results in harder product.

Default speed

Low/High

==

Low

Low: Low-speed agitation.

High: High-speed agitation.

Overrun

On/Off

==

On

The machine will automatically switch to

high-speed when the product temperature

is in the range of 1 °C ~ -3 °C.

Time

Time setting

2~35

minutes

10

Freezing time.

Default

speed

Low/High

==

Low

Low: Low-speed agitation.

High: High-speed agitation.

Temperature

Target temperature

-15 ~ 2

°C

-8

Target temperature.

Default

speed

Low/High

==

Low

Low: Low-speed agitation.

High: High-speed agitation.

Granita

Target temperature

-15 ~ 2

°C

-8

Target temperature.

Temperature1

-15 ~ 80

°C

2.0

Minimum temperature of S1 (refer to Fig 1)

Temperature2

-15 ~ 80

°C

-1.0

Minimum temperature of S2 (refer to Fig 1)

Temperature3

-15 ~ 80

°C

-5.0

Minimum temperature of S3 (refer to Fig 1)

Motor speed 1

Low speed

Intermittent low

High speed

Intermittent high

Low speed

Agitation speed in temperature range S1

(refer to Fig 1)

Compressor 1

Continuous

Intermittent

Continuous

Compressor mode in temperature range S1

(refer to Fig 1)

Motor speed 2

Low speed

Intermittent low

High speed

Intermittent high

High

speed

Agitation speed in temperature range S2

(refer to Fig 1)

Compressor 2

Continuous

Intermittent

Continuous

Compressor mode in temperature range S2

(refer to Fig 1)

Motor speed 3

Low speed

Intermittent low

High speed

Intermittent high

Low speed

Agitation speed in temperature range S3

(refer to Fig 1)

Compressor 3

Continuous

Intermittent

Continuous

Compressor mode in temperature range S3

(refer to Fig 1)

Motor speed 4

Low speed

Intermittent low

High speed

Low speed

Agitation speed in temperature range S4

(refer to Fig 1)

This manual suits for next models

3

Table of contents

Other MEHEN Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Rational

Rational MI 2076 Modification Instructions

Vollrath

Vollrath Bain Marie Two Pan Operator's manual

Henny Penny

Henny Penny LOV3 quick reference

ZANOLLI

ZANOLLI SYNTHESIS 08/50 V PW GAS Manual for installation

Rühle

Rühle GR 50 Translation of the original instructions

NORPOLE

NORPOLE NP1R-PT user manual