dis.

XXXXXX

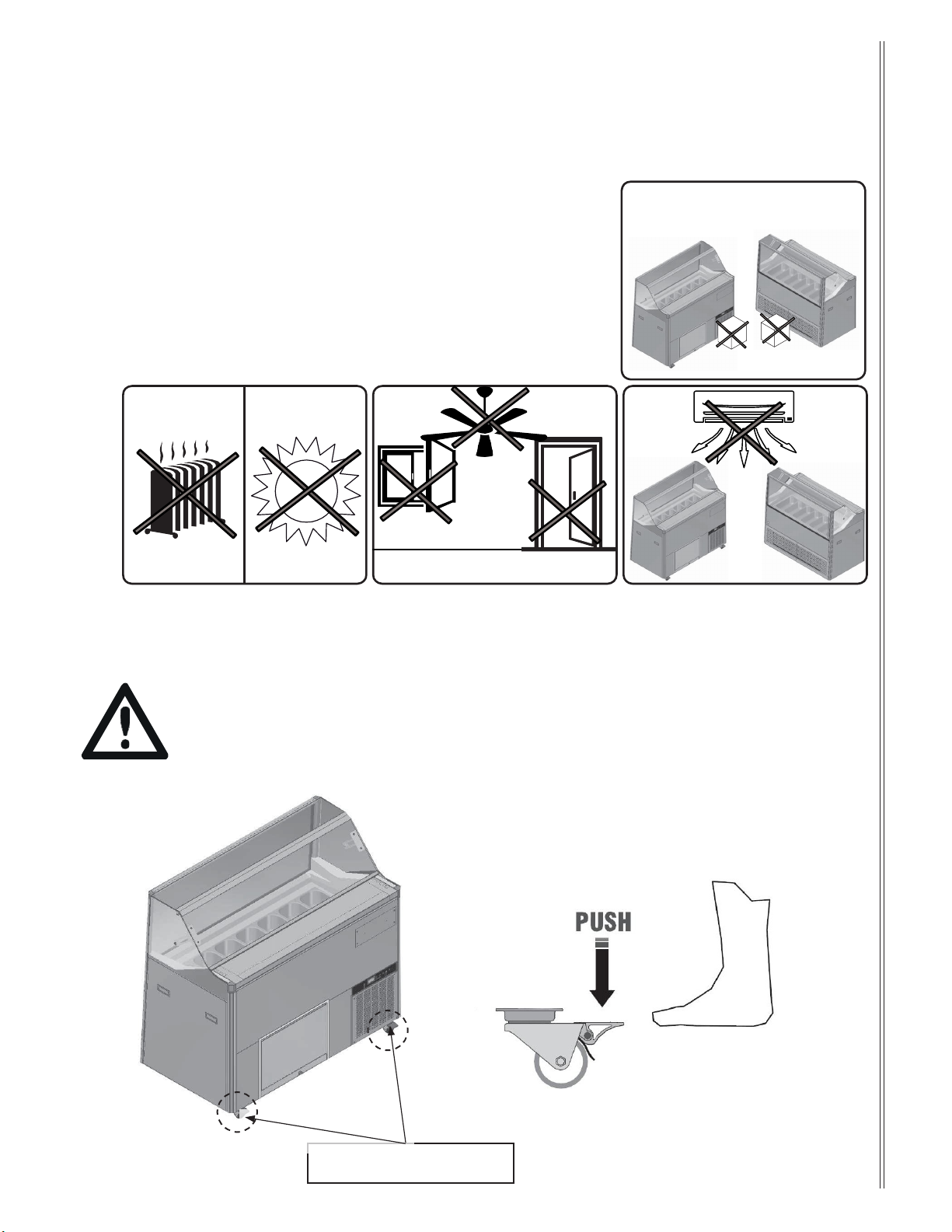

4. NOTES AND WARNINGS

The content of this manual is technical and the property of EPTA s.p.a. It is forbidden to reproduce,

distribute or modify entirely or partially its content without written authorization.

The owner company safeguards its rights pursuant to legislation in force.

The company cannot be held in any way liable for any damage to people, animals or the product conserved in the event of:

• Improper use of the equipment or use by unsuitable or unauthorized staff.

• Non-compliance with the standards in force

• Incorrect installation and/or faulty power supply

• Non-compliance with this manual

• Non-compliance with the maintenance program

• Unauthorized changes

• Installation of non-original spare parts on equipment

•

• Installation and use of the equipment for purposes other than those characterizing design and sale

• Tampering with or damage to the power supply cable

Responsibility for application of the safety provisions outlined below is the responsibility of the technical staff

responsible for the activities planned on the equipment, who must ensure the authorized staff:

• Are qualified to perform the task requested

• Know and strictly comply with the provisions contained in this document

• Know and apply the general safety standards applicable to the equipment

Tampering with or unauthorized replacement of one or more parts of the equipment, use of accessories that

change its use and use of spare parts differing from those recommended can cause risks of accidents.

Any intervention on the equipment strictly requires disconnection of the power socket and however no guard

(grids, casings) should be removed by unqualified staff; strictly avoid operating the freezer with these guards

removed.

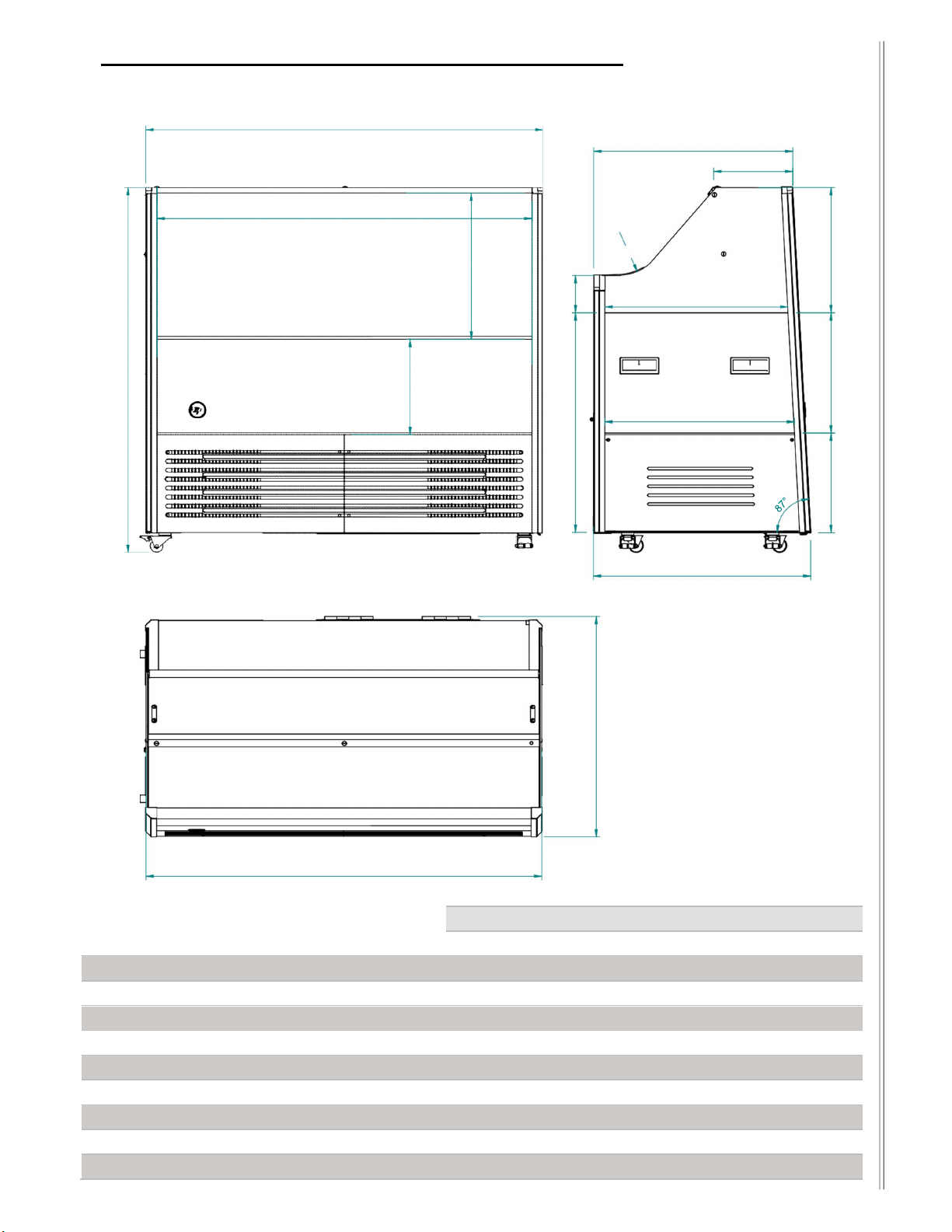

5. EQUIPMENT IDENTIFICATION

• Located on the plate affixed to the machine to detect the technical data.

• Check the model and power supply voltage before carrying out any operation.

• If discrepancies are found, immediately contact the manufacturer or the company that supplied the equipment.

1. Manufacturer

2. Model

3. Code

4. Conformity marking

5. Power supply voltage (V)

6. Power supply frequency (Hz)

7. Absorbed electrical power (W)

8. Light max. power (W)

9. Climate class

10. Type and quantity of refrigerant.

It is strictly forbidden to remove, tamper with the plate and change or alter the data contained in it.

XXXXXX

cod.

1

MOD. DELIGHT 2 3

5 XXX V ~6 XX Hz CLASSE CLIMATICA (EN 60335-2-89) X

CLIMATIC CLASS(EN 60335-2-89) (30°C-55% R.H.)

POTENZA NOMINALE

DEFROSTING POWER

CORRENTE NOMINALE

DEFROSTING CURRENT

HC - CYCLOPENTANE

FOAMING AGENT

ΛΛΛ

TIPO REFRIGERANTE

REFRIGERANT AMOUNT

TIPO REFRIGERANTE

REFRIGERANT TYPE

REFRIGERANT AMOUNT

CONTIENE GAS FLUORURATI AD EFFETTO SERRA DISCIPLINATI DAL PROTOCOLLO DI KYOTO; SISTEMA ERMETICAMENTE SIGILLATO

CONTAINS FLUORINATED GREENHOUSE GASES COVERED BY THE KYOTO PROTOCOL; SYSTEM HERMETICALLY SEALED

CLASSE CLIMATICA (EN23953)

X /XX

CLIMATIC CLASS (EN23953)

PRODUCT CODE

SERIAL NUMBER

PROPERTY NUMBER

GROSS VOLUME

XXX L

X