Meijer KOOI-REACHFORK Series Technical reference manual

RG2, RGN2

TFG2

RG4, RG8

RGE2, RGEN2

RGE4

TRG2

Instruction and parts manual

Manual Nº: MA210314-12ENG Language: ENG

Publishing date: 11-12-2017 Revision: 12

Table of contents

Denitions ............................................................................... 2

Note.......................................................................................... 2

Quality Standards/Norms and Directives .......................... 2

Safety....................................................................................... 3

Identication........................................................................... 4

Assembly................................................................................. 5

Working with KOOI-REACHFORKS® .................................. 6

Maintenance Schedule......................................................... 6

Wear......................................................................................... 7

Instructions for Replacement of Sleeve ............................ 8

Replacement of Hydraulic Parts ......................................... 10

Troubleshooting...................................................................... 12

Replacement parts list RG2, RGN2...................................... 14

Replacement parts list TFG2 ................................................ 15

Replacement parts list RG4.................................................. 16

Replacement parts list RG4.................................................. 18

Replacement parts list RG8.................................................. 20

Replacement parts list RG8 (cont’d) ................................... 21

Replacement parts list RGE2, RGEN2 ................................. 22

Replacement parts list RGE4................................................ 23

Replacement parts list TRG2................................................ 25

2

Warning:

Text blocks marked by a “Warning” icon (as shown on the left) and starting with the text “Warning:” provide

information on actions which may result in serious injury.

Caution:

Text blocks marked by a “Caution” icon (as shown on the left) and starting with the text “Caution:” provide

information on actions which may result in damage to the KOOI-REACHFORKS®, parts of the KOOI-REACH-

FORKS® or goods.

“Only applies to:” texts (italics) indicate that a text only applies to a certain situation or certain type of KOOI-REACH-

FORKS®.

Note

© Copyright 2006 - 2014, Meijer Handling Solutions B.V. All rights reserved.

Unless otherwise indicated, information provided in this manual, including but not limited to illustrations and text, may

not be reproduced without the prior written permission of Meijer Handling Solutions.

The information in this manual is provided without any form of guarantee. Under no circumstances shall Meijer Handling

Solutions B.V. be held liable for accidents or damages arising from the use of this manual.

Please note that information in this manual may be changed at any time without prior notice and that it may contain tech-

nical inaccuracies and typing errors. Meijer Handling Solutions B.V. makes every effort to avoid errors in this manual, but

cannot guarantee this. Please let us know if you encounter any typing errors or technical inaccuracies, or if you have

any suggestions.

KOOI-REACHFORKS® is a registered trademark of Meijer Handling Solutions. (Gebr. Meijer).

Other trade or product names used in this manual, but not mentioned here, are the trademarks of their respective hold-

ers.

Denitions

Quality Standards/Norms and Directives

Meijer Handling Solutions B.V. complies with the following quality standards: ISO 9001

KOOI-REACHFORKS® comply with the following norms/directives:

• ISO 13284 – Fork Arm Extensions and Telescopic Fork Arms;

• ISO 4406 – Hydraulic Fluid Power – Fluids – Method for Coding the Level of Contamination by Solid Particles

• ISO 2328 – Forklift Trucks – Hook-On Type Fork Arms and Fork Arm Carriages

• CE (2006/42/EC) – Machinery Directive

• ISO-FDIS-ISO 3834-2 – Quality Requirements for Fusion Welding of Metallic Materials – Part 2: Comprehensive

Quality Requirements

• CE (2014/43/EC) – ATEX (only applies to forks with an ATEX name plate!)

KOOI-REACHFORKS® are randomly subjected to dynamic testing in accordance with ISO 2330.

3

Safety

Warning:

Do not ride on the KOOI-REACHFORKS® or on

the load.

Warning:

Do no walk or stand under the KOOI-REACH-

FORKS®.

Warning:

Do not reach through the mast of the forklift

truck.

Warning:

Do not load the KOOI-REACHFORKS® beyond

the limits of the lifting capacities and load centre

stipulated by the manufacturer.

Warning:

Do not weld anything onto the KOOI-REACH-

FORKS® without the express permission of the

supplier. Welding carried out without permission

shall void any warranty.

Warning:

Do not use faulty KOOI-REACHFORKS® before

they have been either professionally repaired or

replaced.

Warning:

Do not carry out maintenance work on the

KOOI-REACHFORKS® whilst there is pressure

in the hydraulic system (remove key from forklift

ignition switch).

Warning:

Do not place limbs between pallet stops and the

inner fork (vertical section) of the KOOI-REACH-

FORKS®. If the load shifts, limbs can become

trapped which can result in serious injury.

Warning:

Do not use the KOOI-REACHFORKS® in areas

where the temperature is below -30ºC (-22ºF) un-

less otherwise agreed with the manufacturer.

Caution:

When leaving the forklift the engine must be

switched off and the handbrake applied.

Caution:

Bear in mind the space above and beneath the

KOOI-REACHFORKS®.

Caution:

The load must be distributed as evenly as pos-

sible on the KOOI-REACHFORKS®.

Caution:

Retract the (loaded) KOOI-REACHFORKS® as

soon as possible.

Caution:

If possible, retract the KOOI-REACHFORKS®

before driving.

Caution:

Always drive with the KOOI-REACHFORKS® in

the lowest possible position.

4

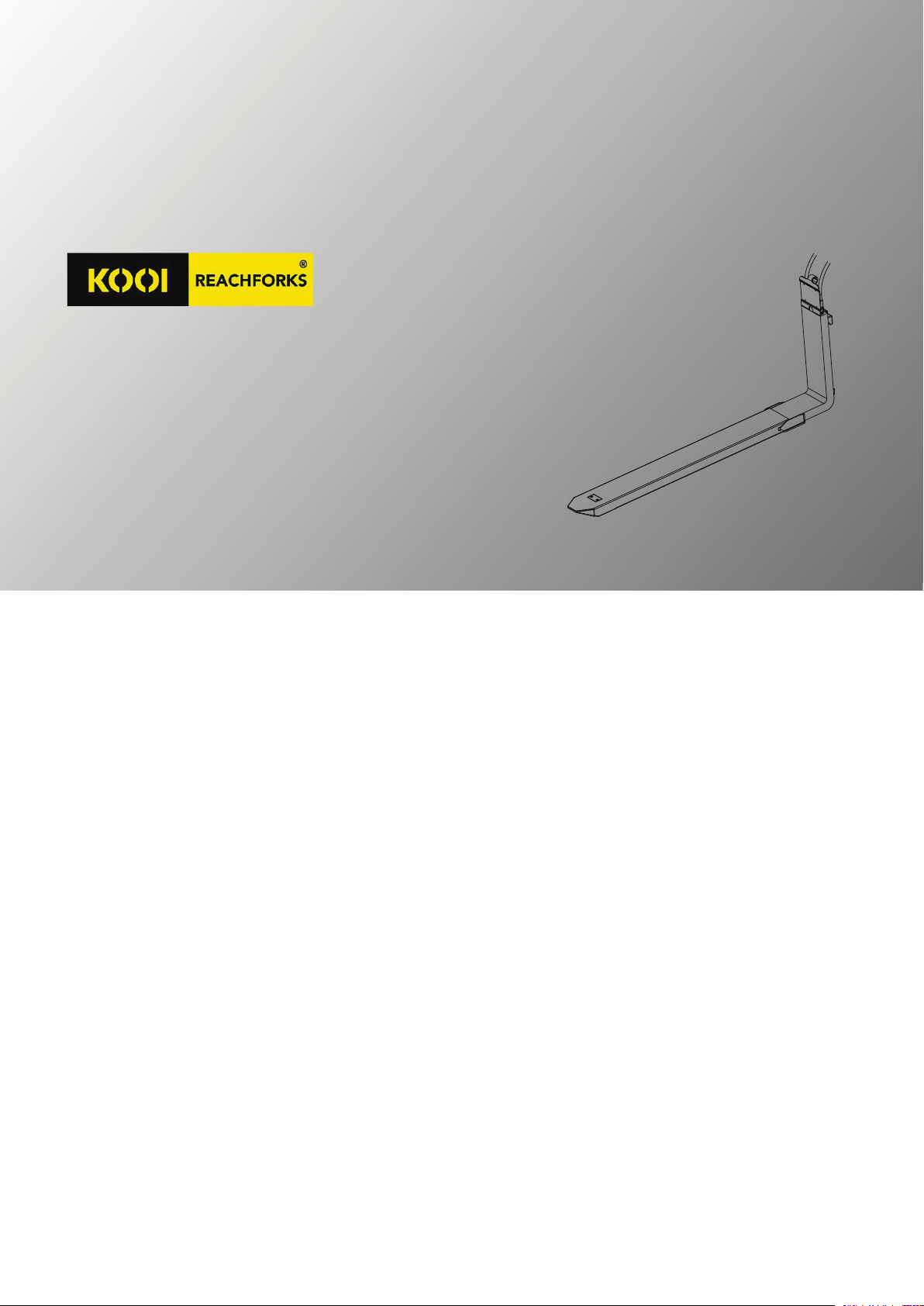

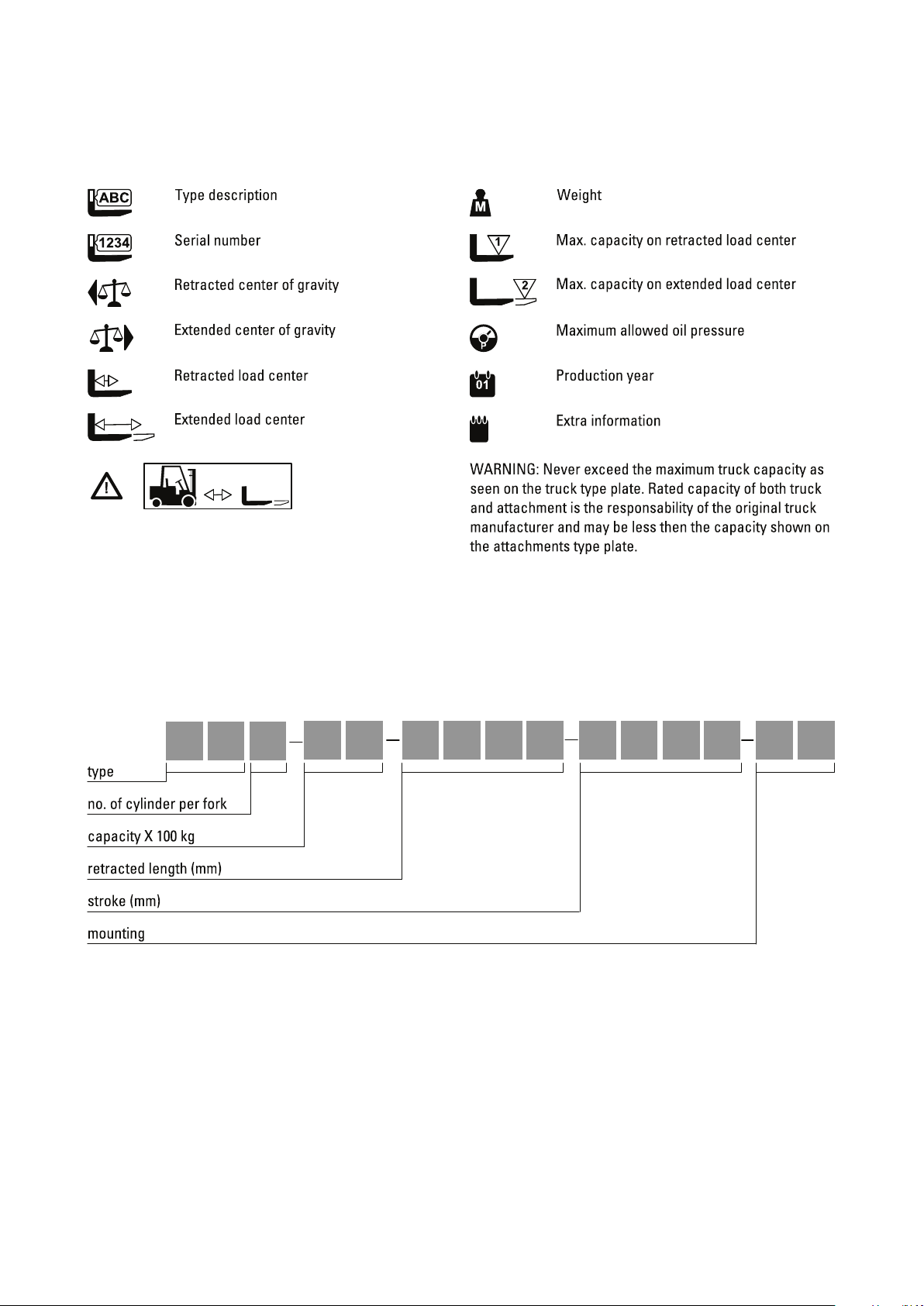

Identication

Type plate legend:

Mounting type description of KOOI-REACHFORKS®:

5

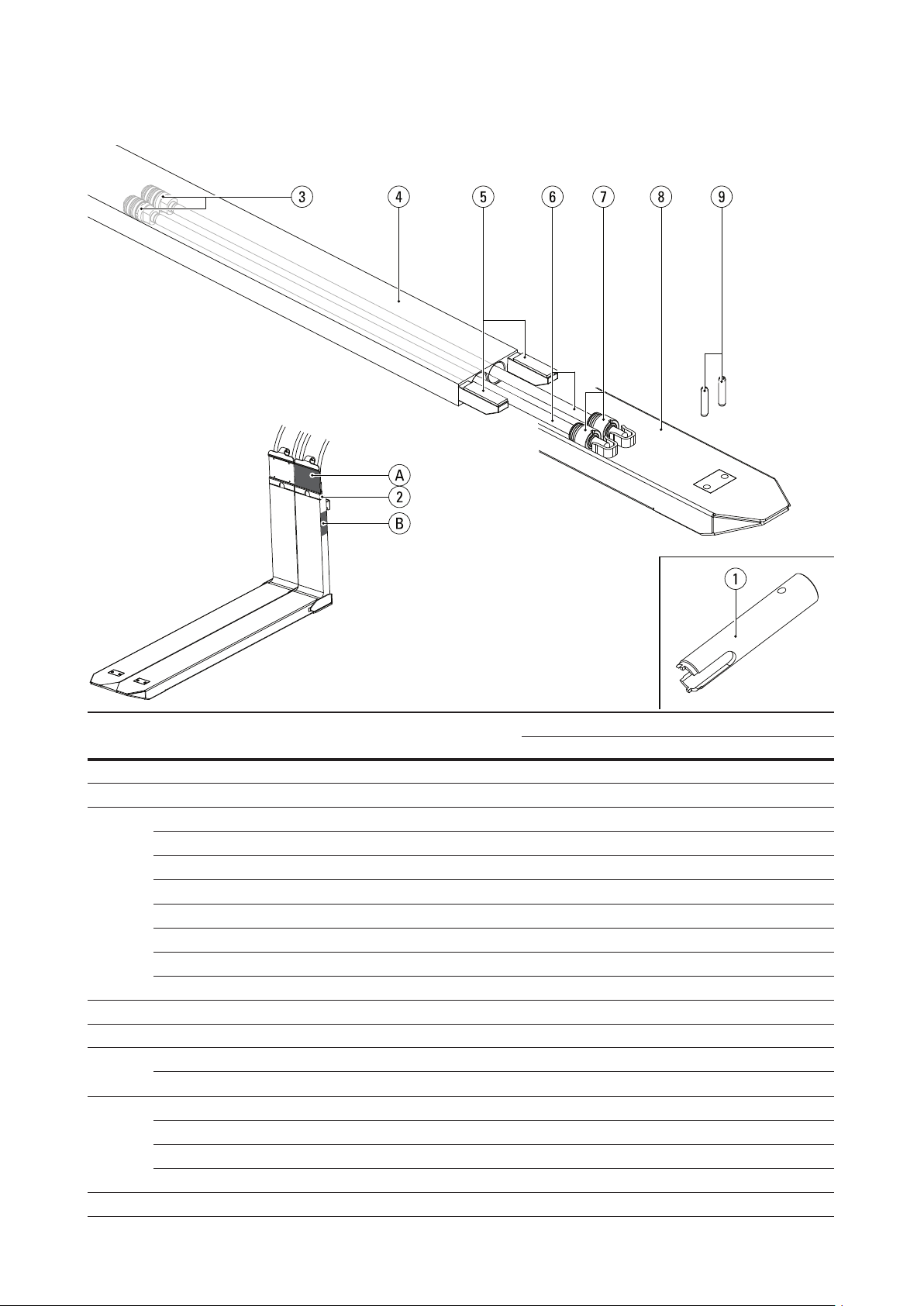

1

2

3

4

5Bleed the hydraulic system:

• Tilt the forklift truck mast forwards and back-

wards several times.

• Tilt the forklift mast forwards and slide the KOOI-

REACHFORKS® in. Operate the lever for about 30

seconds so that the KOOI-REACHFORKS® remain

retracted and they are ushed.

• Extend and retract the KOOI-REACHFORKS®

several times.

Check that hydraulic hoses are unobstructed and that

there are no oil leakages.

The KOOI-REACHFORKS® type plates are

stamped with an ‘L’ and an ‘R’. Mount the KOOI-

REACHFORKS® on the left (L) and right (R) as

viewed from the forklift operator’s seat.

Assembly

Slide the KOOI-REACHFORKS® onto the carriage plate.

Make sure that each of the KOOI-REACHFORK® lock-

ing pins (2) drops into one of the notches on the carriage

plate. Use catch (1) before operating.

Connect the KOOI-REACHFORKS® to the hydraulic sys-

tem.

Type

KOOI-RE-

ACHFORKS®

Recom-

mended oil

ow

Recom-

mended hose

diameter

Maximum

operating

pressure

Connection

RG2 /

RGE2 /

RGN2 /

TFG2 /

TRG2

7,5-12,5 (L/

min)

2-3.3 (gal/

min) 3/8” 250 bar

(3626 psi)

12L /

7/16”

JIC

(USA)

/ 9/16”

(USA)

RG4 /

RGE4

12,5-20 (L/

min)

3.3-5.3

(gal/ min)

6

Working with KOOI-REACHFORKS®

The KOOI-REACHFORKS®, type RG, feature an integrated synchronising system that enables both forks to extend and

retract simultaneously. However, should the KOOI-REACHFORKS® fail to operate simultaneously, slide the KOOI-REACH-

FORKS® fully in and, whilst the sleeves are in the retracted position, operate the valve for another ±10 seconds. This

gives the hydraulic system a chance to reset both sleeves in their rearmost position.

To minimise wear, avoid allowing the KOOI-REACHFORKS® to come in contact with the ground during operation . In

order to reduce wear:

• The manufacturer can weld a wear-resistant plate under the sleeve which can be replaced when worn out.

• The chains in the forklift mast can be shortened so that the KOOI-REACHFORKS® cannot reach the ground.

Maintenance Schedule

Nº Description Weekly Monthly 6 months or

every 1000

hours

Annually or

every 2000

hours

1. Grease the underside and topside of the

inner fork

2. Check inner fork for leaks

3. Check wear strips for any sign of wear*

4.

Check sleeve for signs of wear, espe-

cially the heel side* (REE/REEN type also

wear plate)

5. Check for and remove any dirt in the

sleeve

6. Check for any cylinder head leaks

7. Check inner forks in accordance with

ISO 5057* standards

*See chapter on ‘Wear’.

Notes on ‘Maintenance Schedule’

• Recommended lubricating grease: Nova-

tex EP2 (point 1).

• In the event of leakage, immediately

remove the forks from the forklift and

contact your supplier (point 2).

• If defects are detected, solve the problem

/ replace parts before proceeding to work

with the KOOI-REACHFORKS®.

• See chapter on ‘Instructions for Re-

placement of Sleeve’ and ‘Instructions

for Replacement of Hydraulic Parts’ for

further explanation about replacing parts

and required tools.

7

Wear

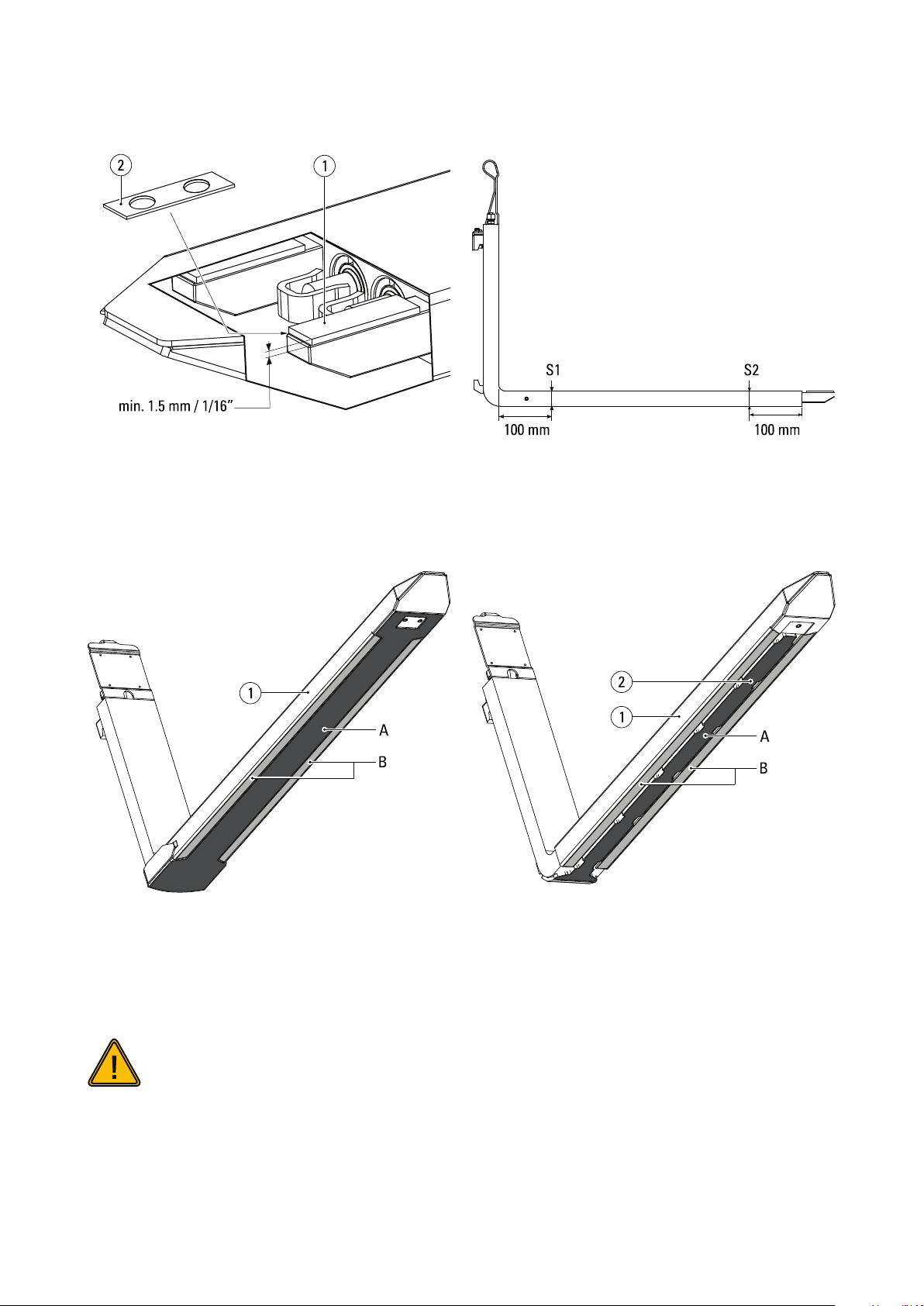

The thickness of Wear Strips (1) may not be less than

1.5 mm (1/16”). When Wear Strips (1) have worn to this

thickness, replace them or ll with spacers (2) (Art. Nº

RE0092002). See point 3 of the Maintenance Schedule.

The inner fork must be replaced when S1 is 5% thinner

than S2. See point 7 of the Maintenance Schedule.

When surface A (dark grey, integrated wear plate) is

worn to the extent that it is level with or below surface B

(light grey), then the sleeve (1) must be replaced or tted

with a welded-on wear plate. For more information about

welded-on wear plates, please contact your fork supplier.

See point 4 of the Maintenance Schedule.

Caution:

The sleeves must be removed from the KOOI-

REACHFORKS® before welding work can

proceed.

Pistons, piston rods and cylinder heads must

be removed before welding is carried out in the

inner fork.

Applies only to: KOOI-REACHFORKS® type RGE and RGEN;

When surface A (dark grey, integrated wear plate) is

worn to the extent that it is level with or below surface

B (light grey), then the sleeve (2) must be replaced. If

there are signs of wear in the lower side of the sleeve (2)

then it must be replaced. See point 4 of the Maintenance

Schedule.

Wear Plate Welding Data:

• Process: MAG (135), 210A, 28 VDC

• Weld type: llet weld a4, 1 layer

• Cleaning: brush

• Wire: 1 mm, EN 12534 / Mn3Ni1CrMo

• Shielding gas: 80% Ar / 20% CO2, 15-16 L/min

• Weld in wear-plate grooves

8

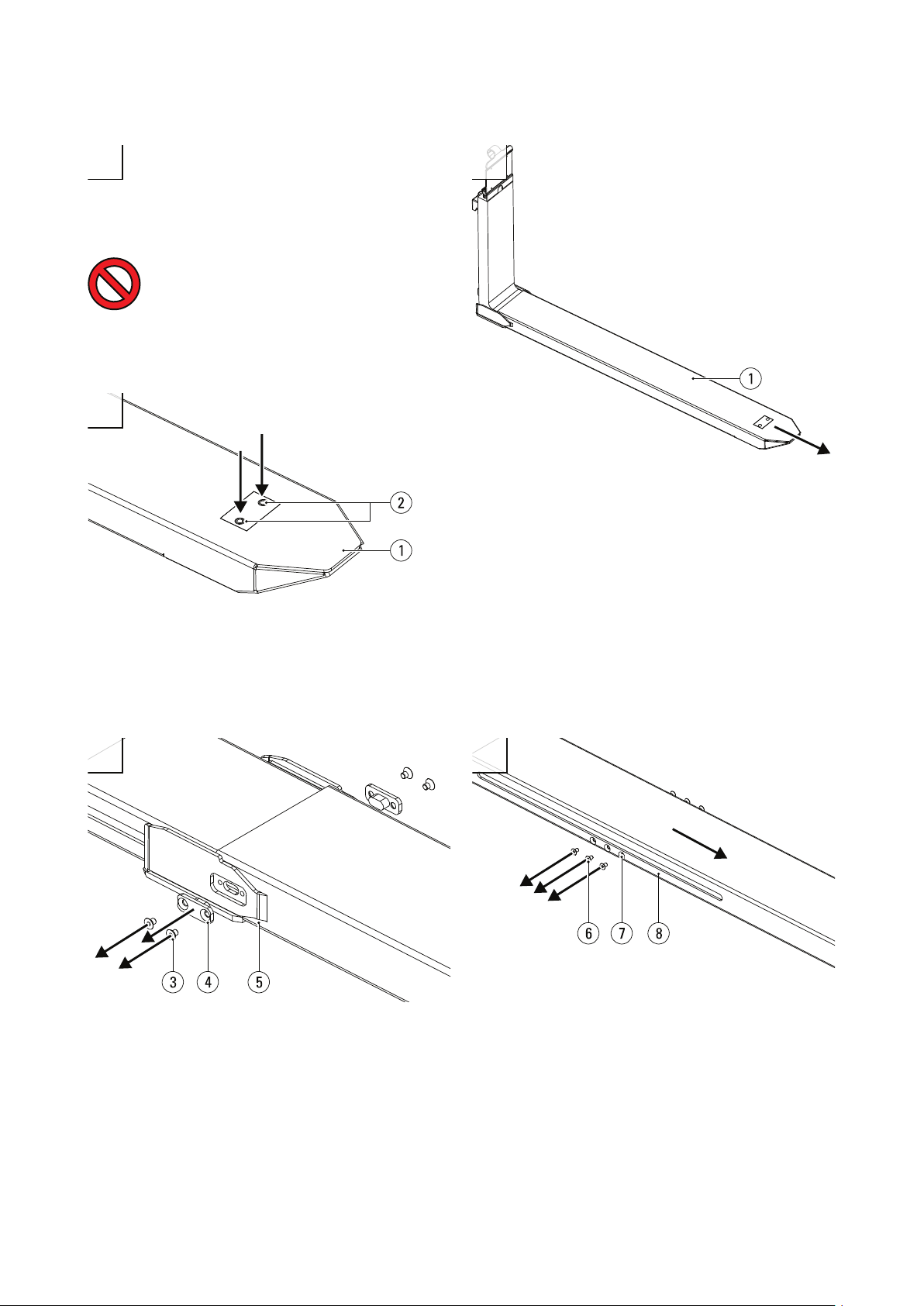

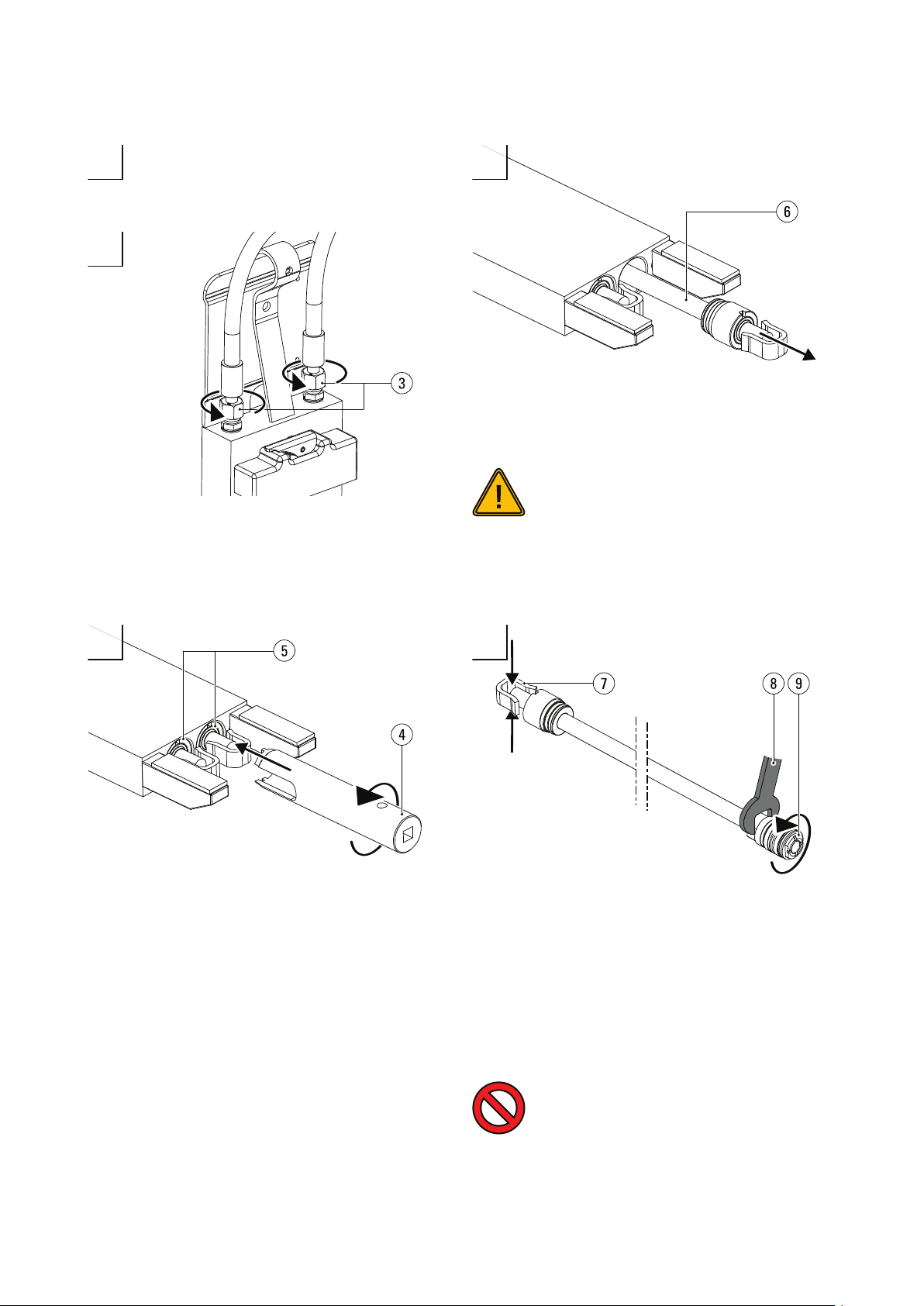

1

2

3

Instructions for Replacement of Sleeve

2a 3a

Position the KOOI-REACHFORKS® at hip height,

tilt the mast of the forklift slightly forward and

remover the key from the ignition switch of the

forklift.

Warning:

Do not carry out maintenance work on the

KOOI-REACHFORKS® whilst there is pressure

in the hydraulic system (remove key from forklift

ignition switch).

Applies only to: KOOI-REACHFORKS® type TRG2;

Unscrew the screws (3) and remove the stops (4) from the

outer sleeve (5) (on both sides of the sleeve).

Tools required: Allen key 4.

Pull the sleeve (1) off the fork.

Tap the spring pins (2) out of the sleeve (1).

Tools required: Hammer, punch10

Applies only to: KOOI-REACHFORKS® type TRG2;

Unscrew the screws (6) (on both sides) from the stops (7)

and remove the inner sleeve.

Tools required: Allen key 4.

9

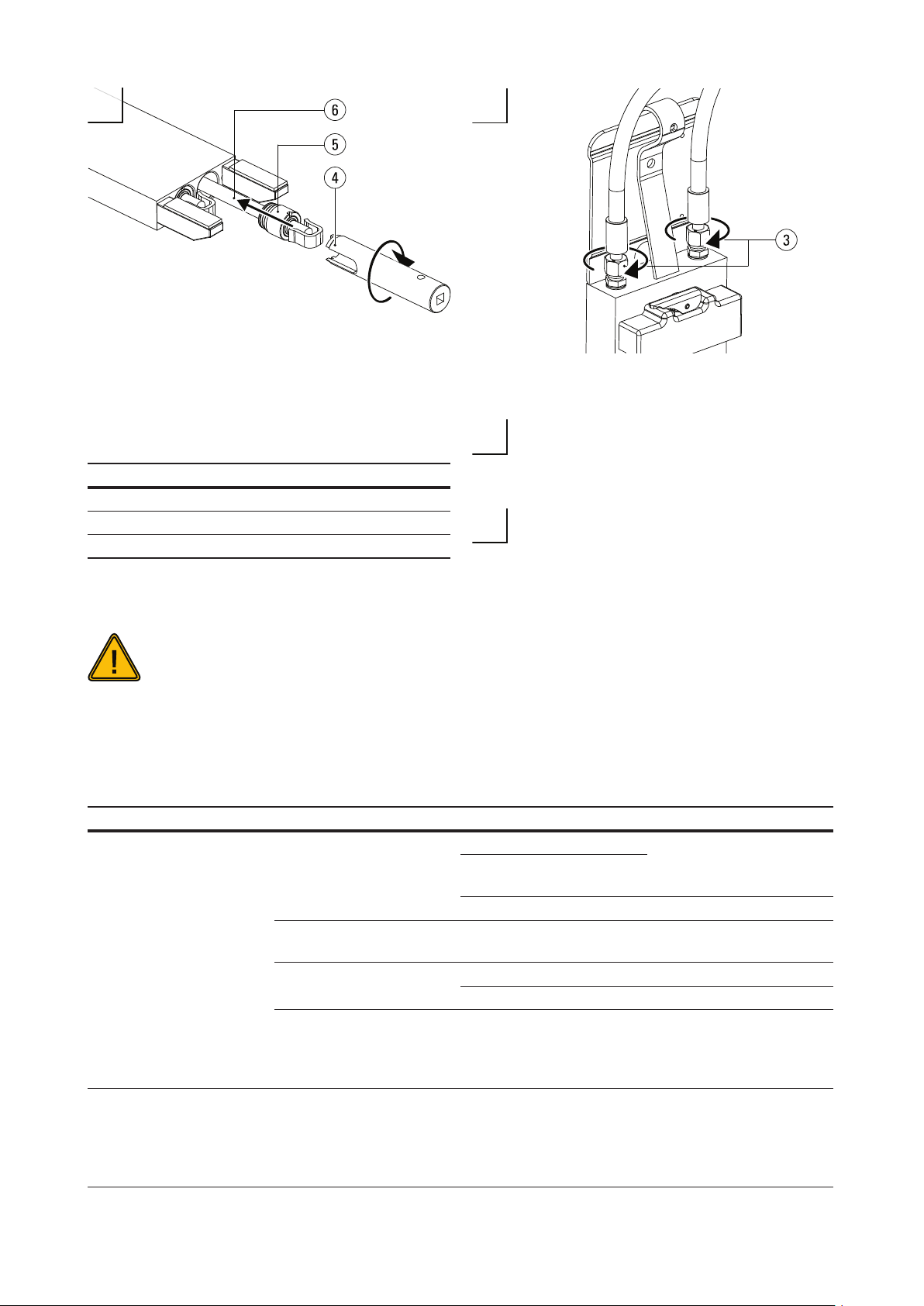

4

54a

5a

Tap the spring pin(s) (2) into the (new) sleeve (1).

Caution:

Ensure that the holes in the sleeve (1) are aligned

with the opening in the bracket(s) that are

welded onto the piston rod(s). DO NOT tap the

spring pin onto the bracket or piston rod!

Tools required: Hammer.

Slide the (new) sleeve (1) over the fork.

Applies only to: KOOI-REACHFORKS® type TRG2;

Slide the (new) inner sleeve (8) onto the fork. Tighten the

screws (6) (on both sides in the stops (7). Lock the screws

(6) with Loctite 2701.

Tools required: Allen key 4, Loctite 2701.

Applies only to: KOOI-REACHFORKS® type TRG2;

Place the stops (4) in the outer sleeve (5). Tighten the

screws (3) (on both sides od the sleeve). Lock the screws

(3) with Loctite 2701.

Tools required: Allen key 4, Loctite 2701.

1See www.loctite.com

10

1

2

3

4

5

Follow steps 1 to 3 in chapter on ‘Instructions for

Replacement of Sleeve’.

Replacement of Hydraulic Parts

Loosen the hose connectors (3) slightly so that the pistons

do not create a vacuum when removing the hydraulic

parts.

Tools required: Open-ended spanner 22.

Place a drip tray below the fork. Unscrew the cylinder

head(s) (5) using a cylinder head spanner (4) and a

ratchet.

Tools required: Cylinder head spanner, 1/2’’ ratchet.

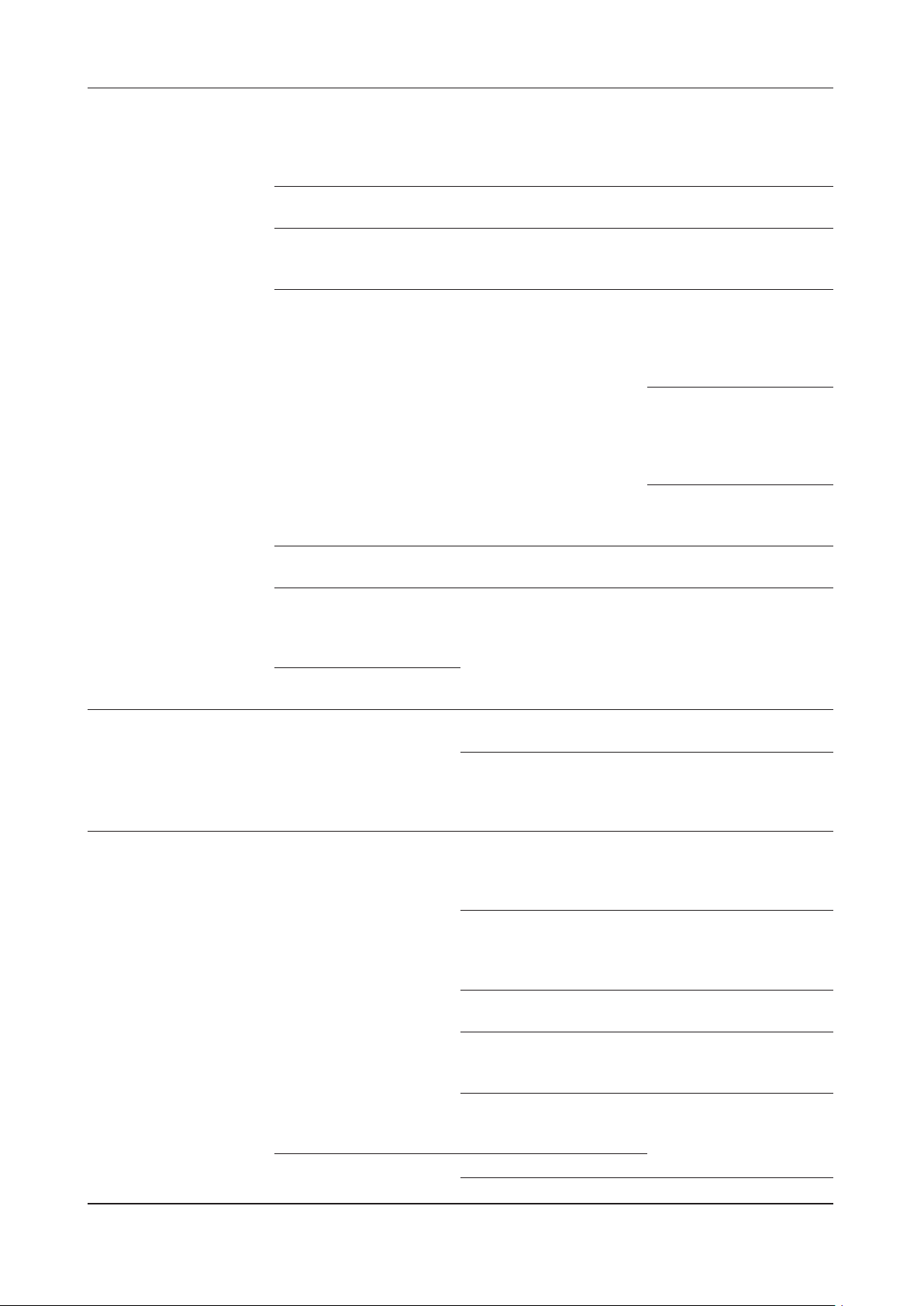

*Cylinder head spanners are only available from Meijer

Handling Solutions B.V. (Art. Nº RE0058034).

Pull the entire hydraulics set (6) consisting of the piston,

cylinder head and piston rod out of the fork.

Caution:

Take care with the surface of the piston rod.

Even minor damage to surface can cause leaks.

Clamp the piston rod at the rod end (7), not on the piston

rod itself to prevent damage (see step 4 in this chapter).

Use a size 24 (8) open-ended spanner to loosen the piston

(9). If the piston cannot be loosened, heat the piston with

a burner.

Tools required: Open-ended spanner 24, clamp.

Note: When heating the piston with a burner, it must be re-

placed due to the damage to the seals caused by heating.

Warning:

Do not use a burner in an area not equipped/in-

tended for his purpose because of re hazard.

11

6

7

8

9

When piston (9) is removed, the cylinder head (5) can be

removed, should it need to be replaced.

Remove remaining adhesive residue from the piston rod

thread (10), then clean the piston rod and thread (10) using

Loctite 70631.

Tools required: Loctite 70631.

Slide the (new) cylinder head (5) onto the piston rod (10).

Caution:

Do not damage the cylinder head seals (5) during

assembly as this can result in leakage. Pay par-

ticular attention when the sliding cylinder head

(5) over the thread (10) of the piston rod.

Apply Loctite 270 to the thread (10) of the piston rod 1.

Clamp the piston rod at the rod end (7), not on the piston

rod itself to prevent damage (see step 4 in this chapter).

Clean the piston thread with Loctite 70631. Use a torque

wrench 24 (11) to tighten the piston (9) onto the piston rod

(10) to a torque of 100 Nm.

Tools required: Loctite 2701, Loctite 70631, torque wrench

24.

12

10 11

12

13

Smear Copaslip2onto the thread of the cylinder head (5).

Line up the hydraulic set (6) with the cylinder and use a

hammer to tap it carefully into the bore. Screw the cylin-

der head tight using the cylinder head spanner (4) and a

torque wrench. See table below for torque values.

Tools required: Hammer, Copaslip2, cylinder head span-

ner*, 1/2” ratchet.

*Cylinder head spanners are only available from Meijer

Handling Solutions B.V. (Art. Nº RE0058034).

Caution:

Do not damage the piston or cylinder head seals

during assembly as this can result in leakage.

Follow steps 4 to 5 in chapter on ‘Instructions for

Replacement of Sleeve’.

Screw the hose connectors (3) tight.

Tools required: Open-ended spanner 22.

Finally, follow step 5 of the chapter on ‘Assem-

bly’.

1See www.loctite.com

2See www.kroon-oil.com

Troubleshooting

Observation Symptom Possible Cause Possible Solution

Oil leak

Oil leak between cylinder

head and piston rod

Bent piston rod Replace piston rod and

cylinder head

Scratched/damaged piston

rod

Leaking piston seal Replace cylinder head

Oil leak between cylinder

head and fork blade. Leaking O-Ring Replace cylinder head

Oil leak at connector Leaking copper ring Replace copper ring

Loose connector Tighten connector

Forks leaking oil One or both KOOI-REACH-

FORKS® are cracked

Remove KOOI-REACH-

FORKS® from carriage

immediately and contact

supplier.

Forks not moving in unison

Right sleeve extends faster

than left one. When the

right-hand fork has reached

its limit, the left one stops

approx. half way.

The left and right KOOI-

REACHFORKS® have been

mounted the wrong way

round

Swap the left and right

KOOI-REACHFORKS®

around and connect the

hoses correctly

Cylinder diameter (mm) Torque (Nm)

30 60

35 80

40 90

13

Forks not moving in unison

The left sleeve reaches its

end position rst. When the

left sleeve is at its end posi-

tion, the right one reaches

3/4 of its stroke

KOOI-REACHFORKS® have

been connected the wrong

way round

Connect the KOOI-REACH-

FORKS® as indicated in the

instructions in the chapter

on ‘Assembly’

Sleeves not moving in

unison A piston seal is leaking Replace the piston with the

leaking seal

Left or right sleeve extends

without operating lever be-

ing used.

Air in hydraulic system Follow step 5 of the chapter

on ‘Assembly’

Difference in stroke length

becomes increasingly great

and one sleeve fails to

retract fully.

Pistons cannot return to

their rear position meaning

the KOOI-REACHFORKS®

hydraulic system cannot be

ushed and reset

Slide the sleeves in fully

and operate the lever for

another 30 sec. (in the same

direction as when retract-

ing)

Check that the rear of the

sleeve(s) does not come

into contact with the car-

riage plate. If so, please

contact your supplier

Dismantle sleeves and

remove any dirt that has ac-

cumulated in the front ends.

One or both sleeves move

without being operated

Leak in the forklift’s control

valve Inform your forklift supplier.

One sleeve remains station-

ary when retracting and

then suddenly retracts

quickly Spring pin(s) broken Replace the spring pin(s)

One of the sleeves fails to

retract

Difference in length be-

tween the sleeves Stroke length difference

Piston rods are not same

length.

Please contact your sup-

plier.

Loose piston

Dismantle outer fork,

remove hydraulic set from

fork and tighten piston (100

Nm)

Difference in height be-

tween forks

One fork point hangs lower

than the other

One of the KOOI-REACH-

FORKS® has been perma-

nently deformed as a result

of overloading.

Remove KOOI-REACH-

FORKS® from carriage

immediately and contact

supplier

One of the KOOI-REACH-

FORKS® is not hanging on

the carriage plate

Hang the KOOI-REACH-

FORK® properly onto the

carriage plate (check lock-

ing mechanism)

Carriage plate is not com-

pletely horizontal

Please do contact your

forklift truck supplier.

The forks do not match

(forks belong to different

sets)

Check serial Nºs.

Wear strips on one KOOI-

REACHFORK® are more

worn than the other Replace wear strips

Excessive play between

fork blade and sleeve

Wear strips worn out

Sleeves worn out Replace sleeves

14

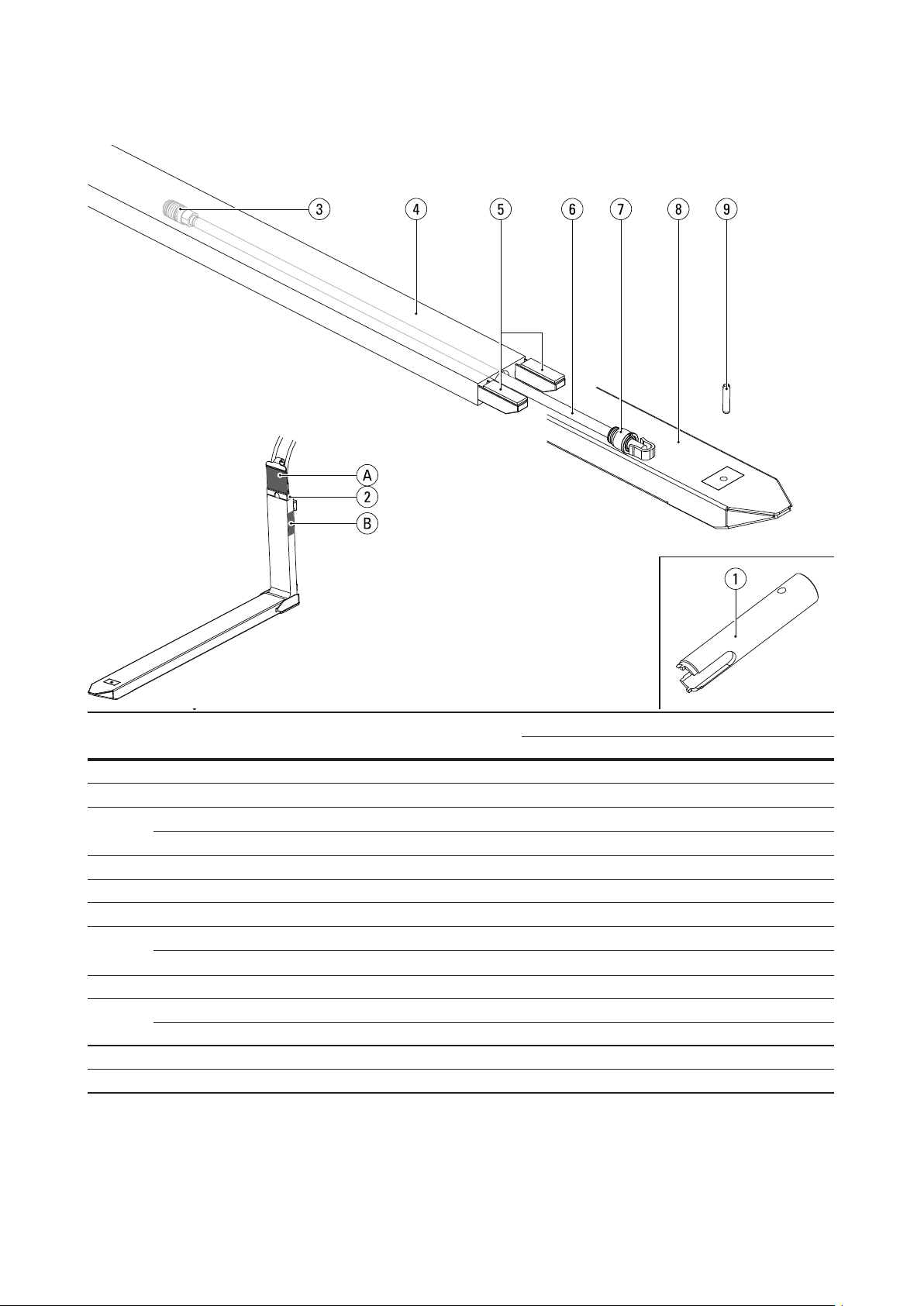

Replacement parts list RG2, RGN2

Pos. Nº Description Article Nº Number of parts per set and type of forks

RG2-20 RG2-30 RGN2-30 RGN2-35

1 Cylinder head spanner1RE0058034 - - - -

2 Straight male coupling 12L RE2017001 4 4 4 4

3Piston30 (for piston rod18)2RE2008009 1 1 1 1

Piston35 (for piston rod18)3RE2008011 1 1 1 1

4 Inner fork 42 2 2 2

5 Wear strip PA6 RE0020000 4 4 4 4

6Piston rod 18 42 2 2 2

7Cylinder Head30 (for piston rod18)2RE2009002 1 1 1 1

Cylinder Head35 (for piston rod18)3RE2009003 1 1 1 1

8 Sleeve 42 2 2 2

9 Spring pin 55 mm RE0033015 2 2 - -

Spring pin 65 mm RE0033014 - - 2 2

A Type plate

B Engraved type information and serial number

1Available separately from KOOI-REACHFORKS® supplier, is not supplied a standard with KOOI-REACHFORKS®.

2Parts from left fork

3Parts from right fork.

4Article Nº depending on specic model. Please provide serial number when ordering.

15

Replacement parts list TFG2

Pos. Nº Description Article Nº Number of parts per set and type of forks

TFG2-20

1 Cylinder head spanner1RE0058034 -

2 Straight male coupling 12L RE2017001 4

3Piston35 (for piston rod20)2RE2008011 1

Piston40 (for piston rod20)3RE2008014 1

4 Inner fork 42

5 Wear strip PA6 RE0020000 4

6Piston rod 20 42

7Cylinder Head35 (for piston rod20)2RE2009004 1

Cylinder Head40 (for piston rod20)3RE2009006 1

8 Sleeve 42

9 Spring pin 65 mm RE0033015 2

A Type plate

B Engraved type information and serial number

1Available separately from KOOI-REACHFORKS® supplier, is not supplied a standard with KOOI-REACHFORKS®.

2Parts from left fork

3Parts from right fork.

4Article Nº depending on specic model. Please provide serial number when ordering.

16

Replacement parts list RG4

Pos. Nº Description Article Nº Number of parts per set and type of forks

RG4-25 RG4-35 RG4-45 RG4-58

1 Cylinder head spanner1RE0058034 - - - -

2 Straight male coupling 12L RE2017001 4 4 4 4

3Piston30 (for piston rod18)2RE2008009 1 1 1 1

Piston30 (for piston rod18)2RE2008010 1 1 1 1

Piston35 (for piston rod18)3RE2008011 1 1 1 1

Piston35 (for piston rod18)3RE2008012 1 1 1 1

4 Inner fork 42 2 2 2

5 Wear strip PA6 RE0020000 4 4 - -

Wear strip AMPCO RE0020001 - - 4 4

6Piston rod 18 44 4 4 4

7Cylinder Head30 (for piston rod18)2RE2009002 2 2 2 2

Cylinder Head35 (for piston rod18)3RE2009003 2 2 2 2

8 Sleeve 42 2 2 2

9 Spring pin 55 mm RE0033015 4 4 4 -

Spring pin 65 mm RE0033014 - - - 4

A Type plate

B Engraved type information and serial number

1Available separately from KOOI-REACHFORKS® supplier, is not supplied a standard with KOOI-REACHFORKS®.

2Parts from left fork

3Parts from right fork.

4Article Nº depending on specic model. Please provide serial number when ordering.

18

Replacement parts list RG4

Pos. Nº Description Article Nº Number of parts per set and type of forks

RG4-77 RG4-105

1 Cylinder head spanner1RE0058034 - -

2 Straight male coupling 12L RE2017001 4 4

3Piston35 (for piston rod20)2RE2008011 1 1

Piston35 (for piston rod20)2RE2008012 1 1

Piston40 (for piston rod20)3RE2008014 1 1

Piston40 (for piston rod20)3RE2008015 1 1

4 Inner fork 42 2

5 Wear strip AMPCO RE0020001 4 4

6Piston rod 20 44 4

7Cylinder Head35 (for piston rod20)2RE2009004 2 2

Cylinder Head40 (for piston rod20)3RE2009006 2 2

8 Sleeve 42 2

9 Spring pin 65 mm RE0033014 4 -

Spring pin 75 mm RE0033023 - 4

A Type plate

B Engraved type information and serial number

1Available separately from KOOI-REACHFORKS® supplier, is not supplied a standard with KOOI-REACHFORKS®.

2Parts from left fork

3Parts from right fork.

4Article Nº depending on specic model. Please provide serial number when ordering.

20

Replacement parts list RG8

Pos. Nº Description Article Nº Number of parts per set and type of forks

RG8-90 RG8-116 RG8-154 RG8-210

1 Cylinder head spanner1RE0058034 - - - -

2 Straight male coupling 12L RE2017001 8 8 8 8

3Piston30 (for piston rod18)2RE2008009 4 4 - -

Piston30 (for piston rod18)2RE2008010 4 4 - -

Piston35 (for piston rod18)3RE2008011 4 4 - -

Piston35 (for piston rod18)3RE2008012 4 4 - -

Piston35 (for piston rod20)2RE2008011 - - 4 4

Piston35 (for piston rod20)2RE2008012 - - 4 4

Piston40 (for piston rod20)3RE2008014 - - 4 4

Piston40 (for piston rod20)3RE2008015 - - 4 4

4 Inner fork 42 2 2 2

5 Wear strip AMPCO RE0020001 8 8 8 8

6Piston rod 18 48 8 - -

Piston rod 20 4- - 8 8

7Cylinder Head30 (for piston rod18)2RE2009002 8 8 - -

Cylinder Head35 (for piston rod18)3RE2009003 8 8 - -

Cylinder Head35 (for piston rod20)2RE2009004 - - 8 8

Cylinder Head40 (for piston rod20)3RE2009006 - - 8 8

8 Sleeve 42 2 2 2

This manual suits for next models

9

Table of contents

Other Meijer Forklift manuals