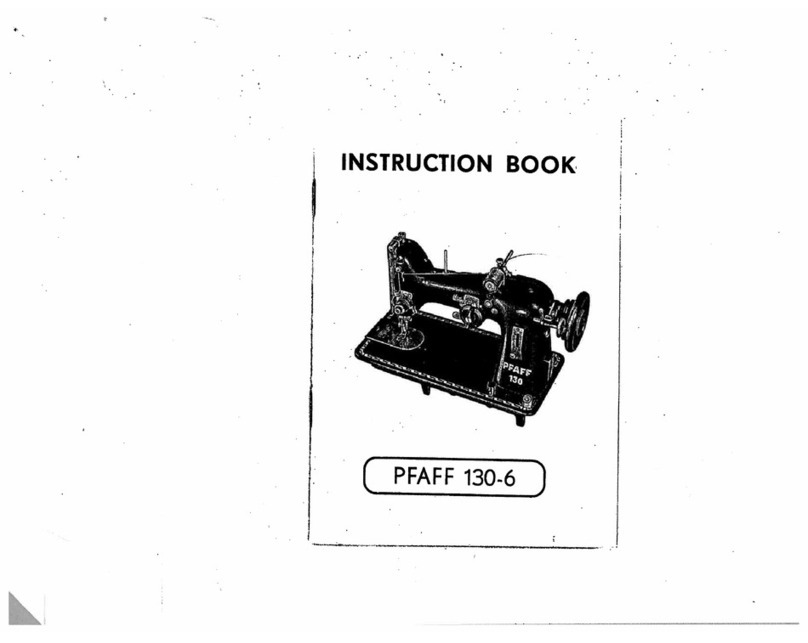

Meistergram M'100-JNS User manual

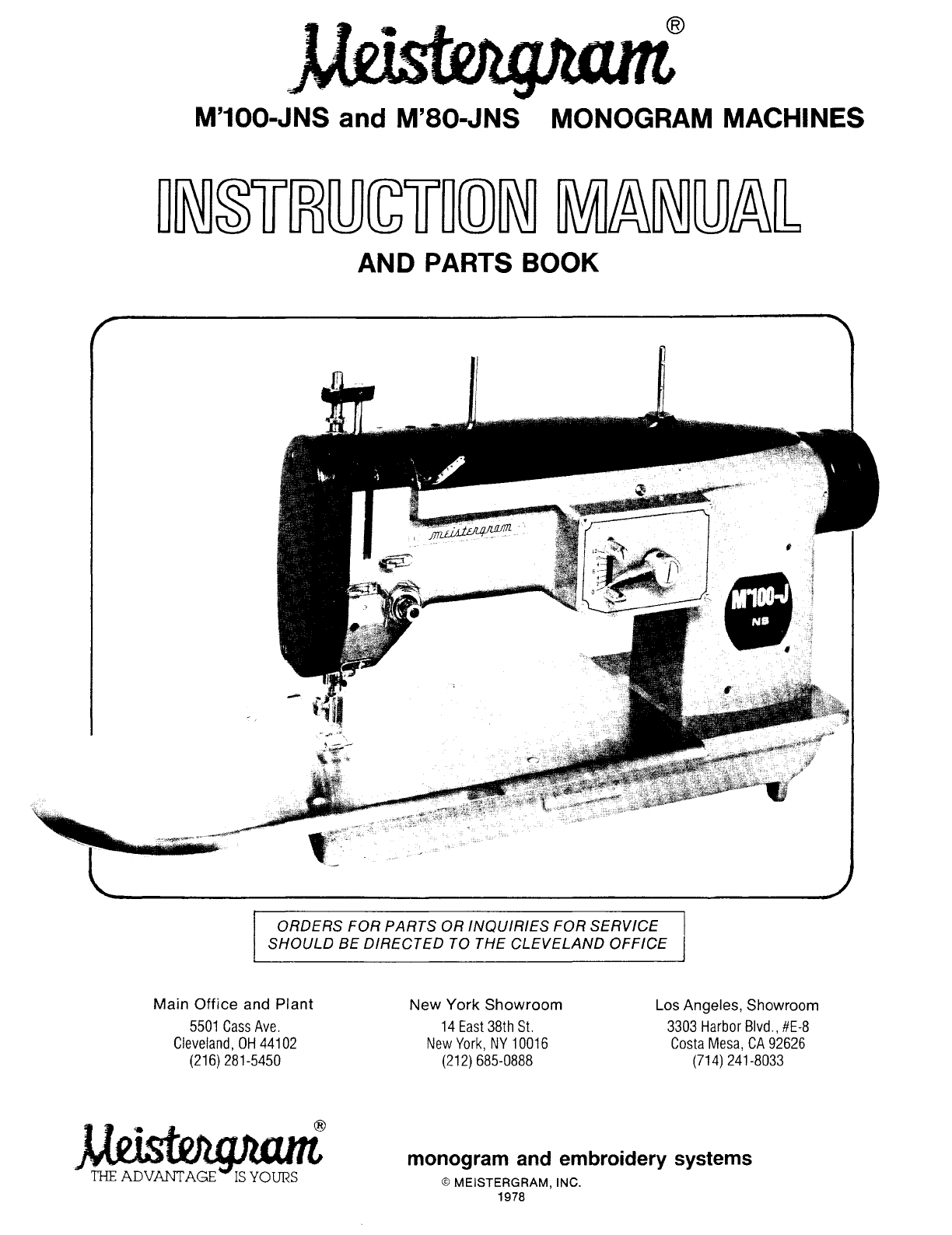

M'100-JNS and M'SO-JNS MONOGRAM MACHINES

AND PARTS BOOK

ORDERS FOR PARTS OR INQUIRIES FOR SERVICE

SHOULD

BE DIRECTED TO THE

CLEVELAND

OFFICE

Main

Office

and

Plant

5501

Cass

Ave.

Cleveland,

OH

441

02

(216)

281-5450

New

York

Showroom

14

East

38th

St.

New

York,

NY

10016

(212)

685-0888

Los Angeles, Showroom

3303

Harbor

Blvd.,

#E-8

Costa

Mesa,

CA

92626

(714)

241-8033

monogram and embroidery systems

© MEISTERGRAM, INC.

1978

From the library of: Superior Sewing Machine & Supply LLC

TABLE

OF

CONTENTS

Section I

M'1 00-JNS Machine Complete

....................................

.

M'100-JNS and M'80-JNS

Machine

Head

...........................

.

Threading

Machine

and Needles

..................................

.

Bobbin

Winder

Assembly and

Adjustment

..........................

.

Thread Types,

Adjusting

Upper

Thread Tension,

Tension Take-up

Spring

.......................................

.

Bobbin

Case Threading and

Adjustment

............................

.

Stitch

Width Control and

Adjustment

...............................

.

Presser Foot Assembly and

Adjustment

............................

.

Motor

and Clutch Assembly

......................................

.

Cleaning and Oiling

Machine

Head

................................

.

Timing

the

Hook

and Needle

......................................

.

Adjusting

Zigzag Mechanism

.....................................

.

M'100-JNS Pantograph Parts:

Hoop Arm Assembly

..........................................

.

Upper Pantograph Assembly

...................................

.

Lower Pantograph Assembly

...................................

.

Page No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14

Template

Holder

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pantograph

Instruction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15,

16, 17 &

18

Section II (see

front

page

of

this section

for

contents)

Instructions

as to

monogramming

and

basic

operation

of

equipment,

working

with

different

types

of

material and garments, cause and

correction

of

common

operating

problems.

Section Ill (see

front

page

of

this

section

for

contents)

Detailed parts listing

for

internal

components

of

the M'80-JNS and M'100-JNS

monogram machine head.

M' 80-JNS

with Supply Cabinet

and Panels

M' 100-JNS

with Panels

From the library of: Superior Sewing Machine & Supply LLC

eJ

~~~v

(:

~

~

\

1AV

~v

~·v

~V~'IfA~

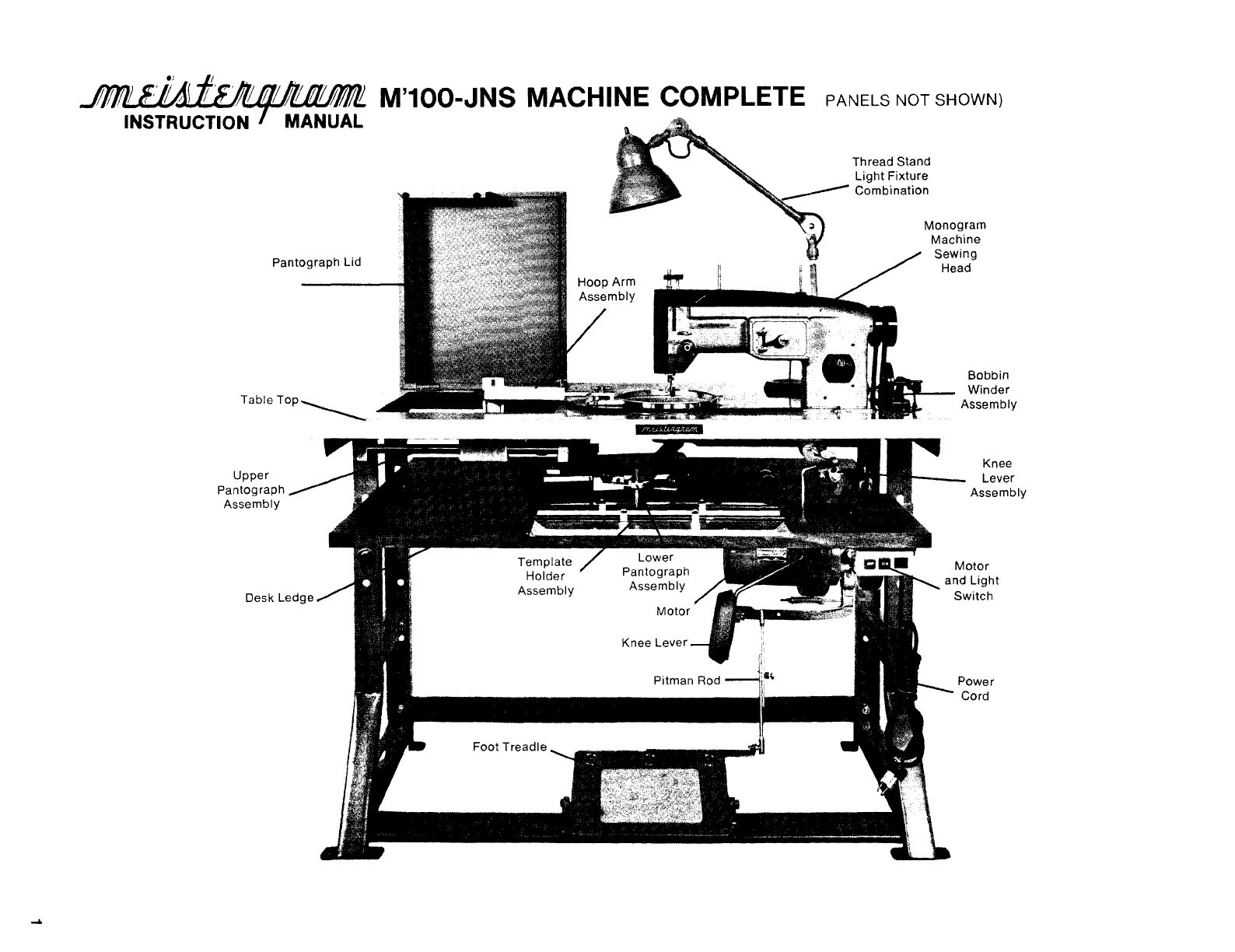

M'100-JNS MACHINE COMPLETE

PANELs

NOT

sHowN)

INSTRUCTION MANUAL

Pantograph Lid

Upper

Pantograph

Assembly

Thread Stand

Light

Fixture

Combination

Monogram

Machine

Sewing

Head

Bobbin

Winder

Assembly

Knee

Lever

Assembly

Motor

and Light

Switch

From the library of: Superior Sewing Machine & Supply LLC

l!~Y

~)I

(

·~~

11

~~~

?~~'!J~~

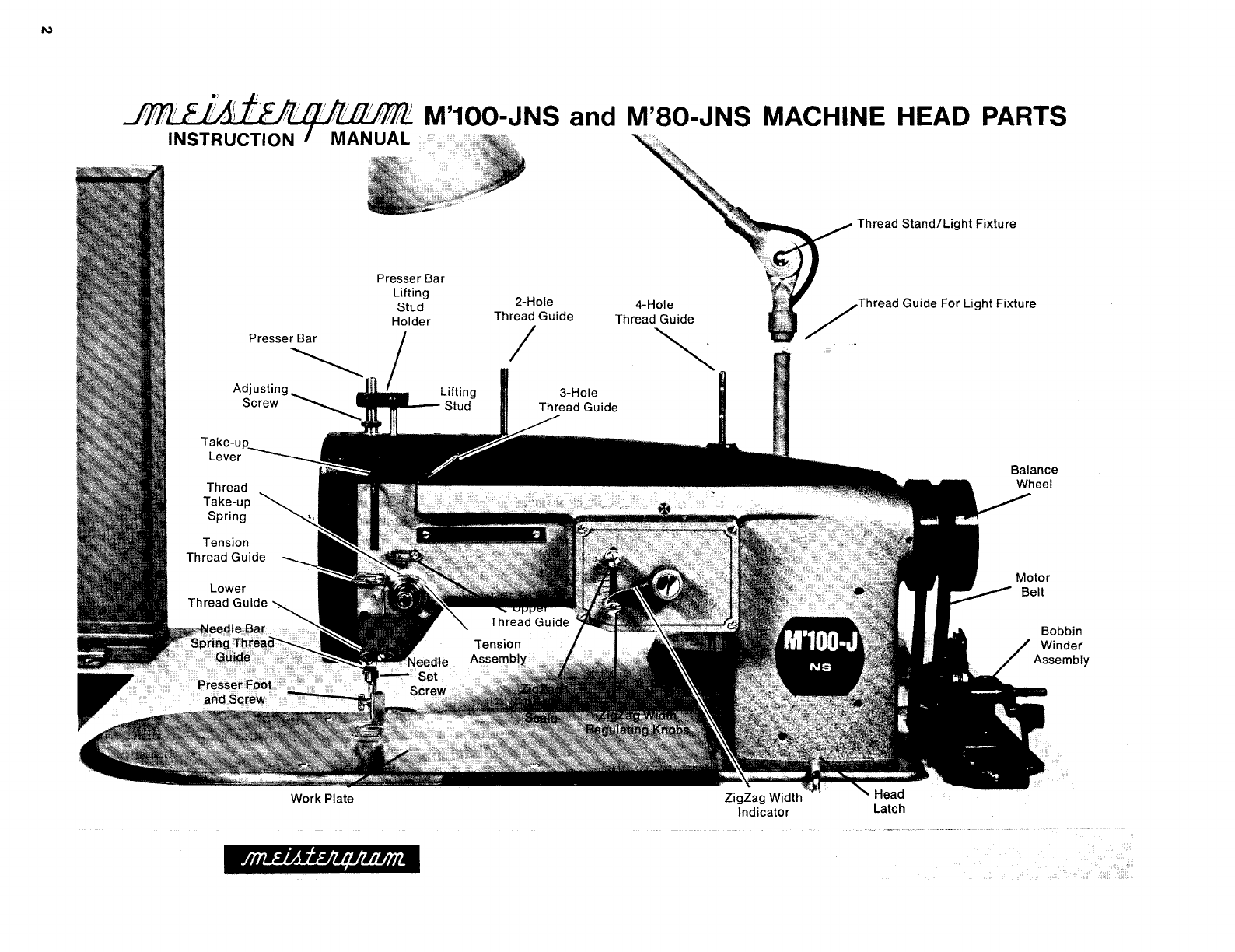

M'100-JNS and M'80-JNS MACHINE HEAD

PARTS

INSTRUCTION

Presser Bar

Tension

Thread Guide

~

2-Hole

Thread Guide

I 4-Hole

Thread Guide

~

Thread

Stand/Light

Fixture

/Thread

Guide For Light Fixture

Bobbin

Winder

Assembly

From the library of: Superior Sewing Machine & Supply LLC

6. Up to and

through

thread take-up lever.

7. Down

through

tension

thread

guide.

8.

Through

lower

thread

guide.

NEEDLES

Scarf

'],

_l~l~

(

,'

~

/)

,;',/

'/!

/V

~,V

~VJ0f~

~NSTRUCTION

MANUAL

THREADING MACHINE

2.

Through

three-holed

thread

guide

starting

with

top

hole

.c1nd

working

down,

back

to

front.

1.

Bring

thread from the

:hread

cone

up

through

thread

:;uide

located

on lamo stand.

~hen

through

the

4-hole

thread

guide

pm

located

on top

of

head, then

through

the

2-hole

:hread gu1de.

3.

Draw

thread

down

the

front

of the

machine

around

and

under

from

right

to

left

between

the

tension

discs.

5.

Under

tension

thread

guide

and

through

upper

thread

guide.

NEEDLES

It is very

important

that

the

proper

type

needle

be

used

with

your

M'80-JNS

or

M'1 00-JNS

machine.

These

needles

are

readily

available

from

Meistergram

in the

following

sizes: (The

numbers

in

parentheses

are

the

metric

equivalent)

#7 (60),

#9

(65),

#1

0 (70),

#11

(75), #12 (80}, #14 (90).

The size

of

the

needle

is

stamped

on the

shank

of

each

needle.

Sizes 10

or

11

will

work

well on

almost

all types and

thicknesses

of

material.

For

thin

or

sheer

material

a size 7

or

9 may

provide

better

results:

for

very

thick

material

a

size 12

or

14 may be required. However, when

switching

to

these

extreme

size

needles it may be

necessary

to

re-time the machine. (see

section

on

Timing)

Inserting Needle

1) Turn

balance

wheel

forward

until

needle

bar

is at

it's

highest

point. Loosen

screw

on needle

bar

and

insert

needle as

far

up

as

it

will

go.

2)

Be

sure

needle

eye and

long

groove

are

facing

forward

toward

operator.

The

scarf

should

be

facing

toward

the back.

3) Be

sure

needle

is

not

bent,

blunt

or

rough. Do

not

use

needle

size

any

larger

than

necessary

for

the

material

being

monogrammed.

3

From the library of: Superior Sewing Machine & Supply LLC

4

17.~/

,~~

/V

~r;

r;.Vr;l!J~~

INSTRUCTION MANUAL

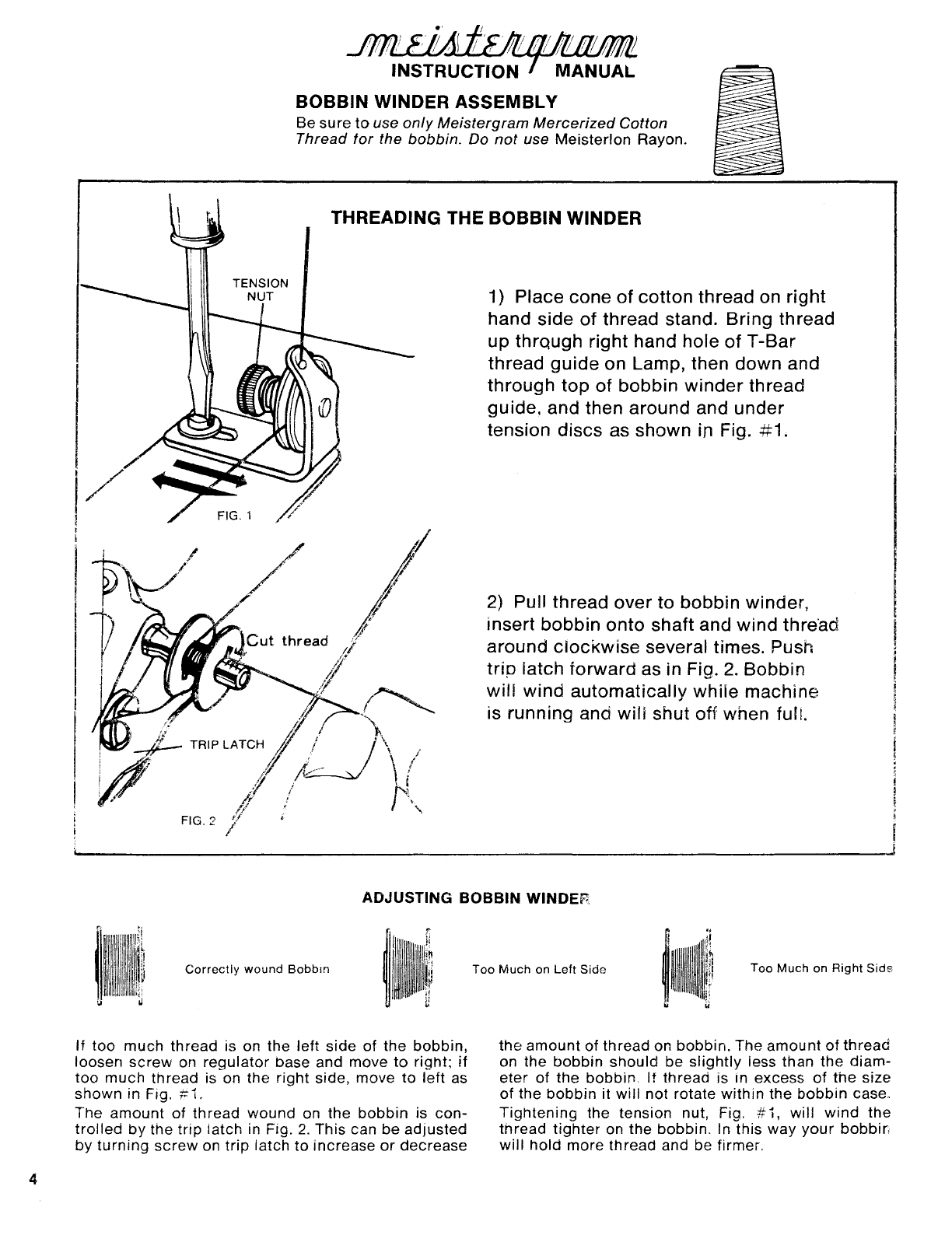

BOBBIN WINDER ASSEMBLY

Be

sure

to

use

only

Meistergram

Mercerized

Cotton

Thread

tor

the

bobbin.

Do

not

use

Meisterlon

Rayon.

THREADING THE BOBBIN WINDER

1) Place cone

of

cotton

thread on right

hand side

of

thread stand. Bring thread

up

thrqugh right hand hole

ofT-Bar

thread

guide

on Lamp, then down and

through

top

of

bobbin

winder

thread

guide. and then around and

under

tension discs as shown in Fig.

#1.

2) Pull thread

over

to

bobbin

winder,

insert

bobbin

onto

shaft and

wind

thre·ad

around

clockwise

several times. Push

trip

latch

forward

as in Fig.

2.

Bobbin

will

wind

automatically

while

machine

is running and

will

shut

off

when fulL

ADJUSTING BOBBIN WINDER

Correctly

wound

Bobbm

If

too

much

thread

is on

the

left

side

of

the

bobbin,

loosen

screw

on

regulator

base and

move

to

right;

if

too

much

thread

is on

the

right

side,

move

to

left

as

shown

in Fig.

#1.

The

amount

of

thread

wound

on

the

bobbin

is

con-

trolled

by

the

trip

latch

in Fig.

2.

This

can

be

adjusted

by

turning

screw

on

trip

latch

to

increase

or

decrease

Too

Much

on

Left

Side

Too

Much

on

Right

Side

the

amount

of

thread

on

bobbin.

The

amount

of

thread

on the

bobbin

should

be

slightly

iess

than

the

diam-

eter

of

the

bobbin,

If

thread

is

rn

excess

of

the

size

of

the

bobbin

it

will

not

rotate

within

the

bobbin

case.

Tightening

the

tension

nut, Fig. #

1,

will

wind

the

thread

tighter

on

the

bobbin.

In

this

way

your

bobbin

will

hold

more

thread

and be firmer,

From the library of: Superior Sewing Machine & Supply LLC

THREAD

Meistergram

threads

are

orepared

exclusively

for

use

with

our

high

speed

monogram

machines

and are

color

fast. Refer

to

Thread

Color

Cards

for

selection

and

be

sure

to

specify

"Meistergram

Gatton"

or

"Meisterlon

Rayon"

when

ordering.

;·v1eisterion

Silk-like

Rayon

-

approx.

5,500 yds.

Too

Thread-

use

either

cotton

or

rayon.

Bobbin

Thread-

use

onlv

cotton.

Fer

finer

appearance

use same

color

cotton

thread

in

bobbin

to

match

the

top

thread

being

used.

;,1eisteraram

Mercerized

Cotton~

approx.

12,000 yds.

ADJUSTING UPPER THREAD TENSION:

Correct

Tension

)p

Too

Loose

or

""'ottom

Too

Tight

Top

Too

Tight

or

)ttom

Too

Loose

The

upper

thread

tension and

bobbin

tension

can be

set

independently

of

each

other

and are

very

important

for

producing

proper

stitch

(see

section

on

Bobbin

Tension

and Case).

Tensions

should

be

set

so

that

on

the

back

of

the

monogram,

the

bobbin

stitch

is

about

1f3

of

the

width

of

the

top

zigzag

stitch.

Tension on the

top

thread

can be

adjusted

by

turning

the

tension

nut (A) in Fig.

1.

Ten-

sion

may

be

adjusted

for

variances

in

thread

and

material

being

embroidered.

If tension is

too

tight

it

may cause

thread

breakage,

puck-

ering

of

material,

the

bobbin

will

be

too

wide

on the

back

or

the

bobbin

may

pull

up

and

show

through

the

top

of

the

material. If ten-

sion

is

too

loose,

thread

may

loop

on

top

or

bottom

of

material,

embroidery

will

not

lay

smoothly

and

very

little

bobbin

will

show

on

back

of

monogram.

To

check

tension,

thread

the

machine

through

the

tension

assembly

and

take-up

lever.

Then

pull

on

thread

by

hand

to

feel the

amount

of

tension

and

adjust

accordingly.

Take-up

lever

should

be

at

its

highest

posi-

tion

when

doing

this.

FIG. 1

Adjusting

Top

Tension

Nut

TENSION TAKE-UP SPRING

(often referred to as

check

spring

or

thread

controller

spring)

Extending

from

behind

the

tension

discs

is

a

hooked

spring

called

the

tension

take-up

spring.

This

spring

pro-

vides

tension

on the

top

thread

until

the

needle

has

carried

it

down

to the material. It

may

be

necessary

to

adjust

the

tension

of

the

take-up

to

lighter

tension

on

thinner

material

and

tighter

tension

on

thicker

material.

~~~~n

TAKE-UP

SPRING

/~-

I

1(1

\

I

Ill

/-;~

]

1

I/

//

~~

/LIGHTER

j j ' FIG. 2

Insert

screwdriver

into

tension

stud

and

turn

slightly

as

shown

in Fig.

2.

This

will

wind

the

spring

tighter

or

make

it

looser

and

you

can

determine

the

amount

of

spring

pressure

by

pushing

it

with

your

finger.

If

tension

is

too

loose,

thread

will

loop

up

under

material

or

on

top.

if

too

tight

it

may

cause

the

stitches

to

skip.

CHANGING THE TAKE-UP SPRING:

If the

take-up

spring

breaks

or

becomes

too

worn

to

operate

properly

then the

spring

should

be replaced. First,

loosen set

screw

in the head

located

to the

right

on the

tension

assembly

and remove the assembly.

5

From the library of: Superior Sewing Machine & Supply LLC

6

TENSION

ADJUSTING SCREW

BOBBIN CASE

BOBBIN CASE

Raise needle bar to highest position.

To

remove the

bobbin

case,

tilt

back

the

machine

head

or

reach

under

the

machine. Open latch on case and remove both the case and

bobbin.

When the latch is open, the

bobbin

will be held in the

case; when latch is released

bobbin

drops

out.

THREADING BOBBIN CASE:

I

1.

Place

bobbin

into

case as shown.

2.

Guide thread

into

slot

on

top

of case.

3.

Pull thread

under

tension spring

and

wind

around

pig-tail thread

guide.

5.

Replacing Bobbin Case:

4.

Tension on the

bobbin

case can be adjusted

by

turning

tension screw.

Tension should be set

so that

slight

amount

of

pull is required

to

release thread.

Raise needle

bar

to

highest

position,

hold

latch on

case open

to

retain the bobbin,

tilt

bacK

machine

head

or

reach underneath

with

bobbin

case and insert on

shaft in the hook assembly. Release latch and press

bobbin

case

into

position so that you hear a

distinct

"click".

If you

do

not

hear

click,

remove case and

insert again. Be sure

that

several inches

of

bobbin

thread are hanging free from

bobbin

case.

NOTE: Make sure

bobbin

case

is

free

of

dirt

and

oil. Use

only

cotton

thread

in the

bobbin.

Do

not

use rayon.

From the library of: Superior Sewing Machine & Supply LLC

I ,

~...,.~"'-"11~'~(

·~~

~~

~~

~~~~~~

INSTRUCTION MANUAL

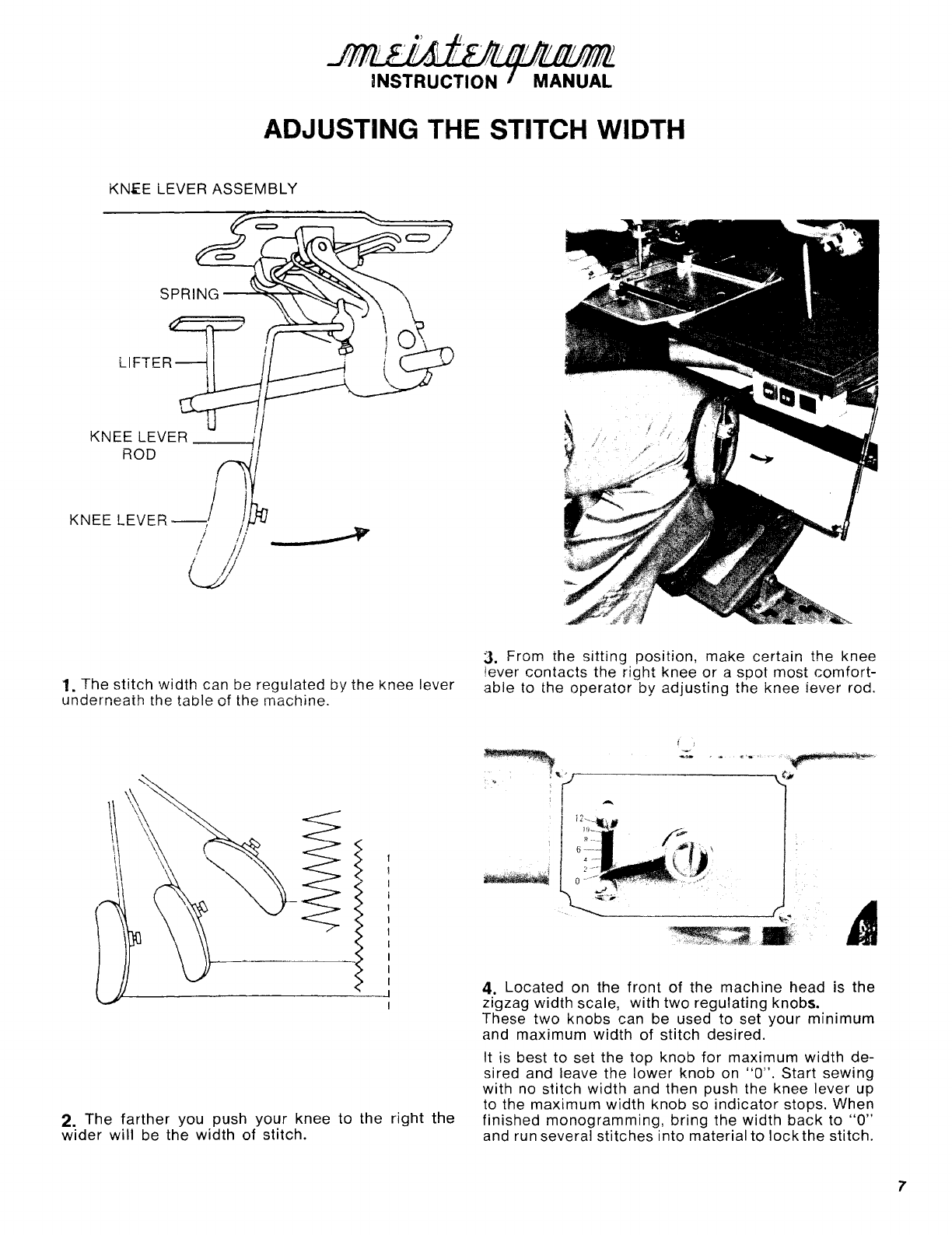

ADJUSTING THE STITCH WIDTH

KN~E

LEVER

ASSEMBLY

KNEE

LEVER

ROD

---~

1. The

stitch

width

can be regulated by the knee lever

underneath

the

table

of the machine.

3. From the

sitting

position,

make

certain the knee

lever

contacts

the

right

knee

or

a

spot

most

comfort-

able to the

operator

by

adjusting

the knee

lever

rod.

4.

Located

on the

front

of

the

machine

head is the

zigzag

width

scale, with

two

regulating

knobs.

These

two

knobs can be used to set

your

minimum

and

maximum

width

of

stitch

desired.

It is best to set the top knob

for

maximum

width

de-

sired and leave the

lower

knob on

"0".

Start

sewing

with no stitch

width

and then push the knee

lever

up

to the

maximum

width

knob so

indicator

stops. When

2.

The

farther

you push

your

knee

to

the

right

the finished

monogramming,

bring

the

width

back

to

"0"

wider

will

be the

width

of

stitch. and run several

stitches

into material to

lock

the

stitch.

7

From the library of: Superior Sewing Machine & Supply LLC

8

2~

Presser

Bar

Lifting---

Stud Holder

5.

Presser

Bar

Spring

6.

Guide Bracket

PRESSER FOOTASSEMBLY

ADJUSTING THE PRESSER FOOT

The

"jumping"

presser

foot

is an

exclu-

sive

design

found

only

on

Meistergram

monogram

machines. The

presser

foot

action

is

coordinated

with

the

move-

ment

of

the

needle

bar

so

that

the

foot

applies

pressure to the

material

during

stitching

and then releases

pressure

to

allow

movement

of

the material

after

the

needle

has

risen

clear

of

the

materiaL

To

adjust

the

presser

foot,

turn

the

balance

wheel

forward

so

that

the

needle

has

gone

into

the

material

and then has

just

come

out

of

the

material

on

the

upward

stroke.

At

this

point,

loosen

the

screw

holding

the

presser

toot

and posit1on

the

foot

so

that

it is

lightly

pressing

down

on the

material.

Tighten

the

screw.

The

presser

foot

should

be

adjusted

when

embroidering

different

thicknesses

of

material.

Oniy

slight

pressure

is

required

to

hold

the

material

as

the

needle

passes

up

through

it. If

too

much

pressure

is

used the

foot

will

bang

on the

work

plate.

The

foot

can

be raised

up

and

thus

disconnected

from

the

action

of

the

needle

movement

by

lifting

the

lever

on

the

back

of

the

head.

However,

you

should

not

operate

the

machine

with

the

foot

in

this

position

as

the

screw

on

the

needle

bar

may

hit

the

foot

and

bend

it. If you

wish to

operate

the

machine

with

the

presser

bar

up,

remove

the

presser

foot.

From the library of: Superior Sewing Machine & Supply LLC

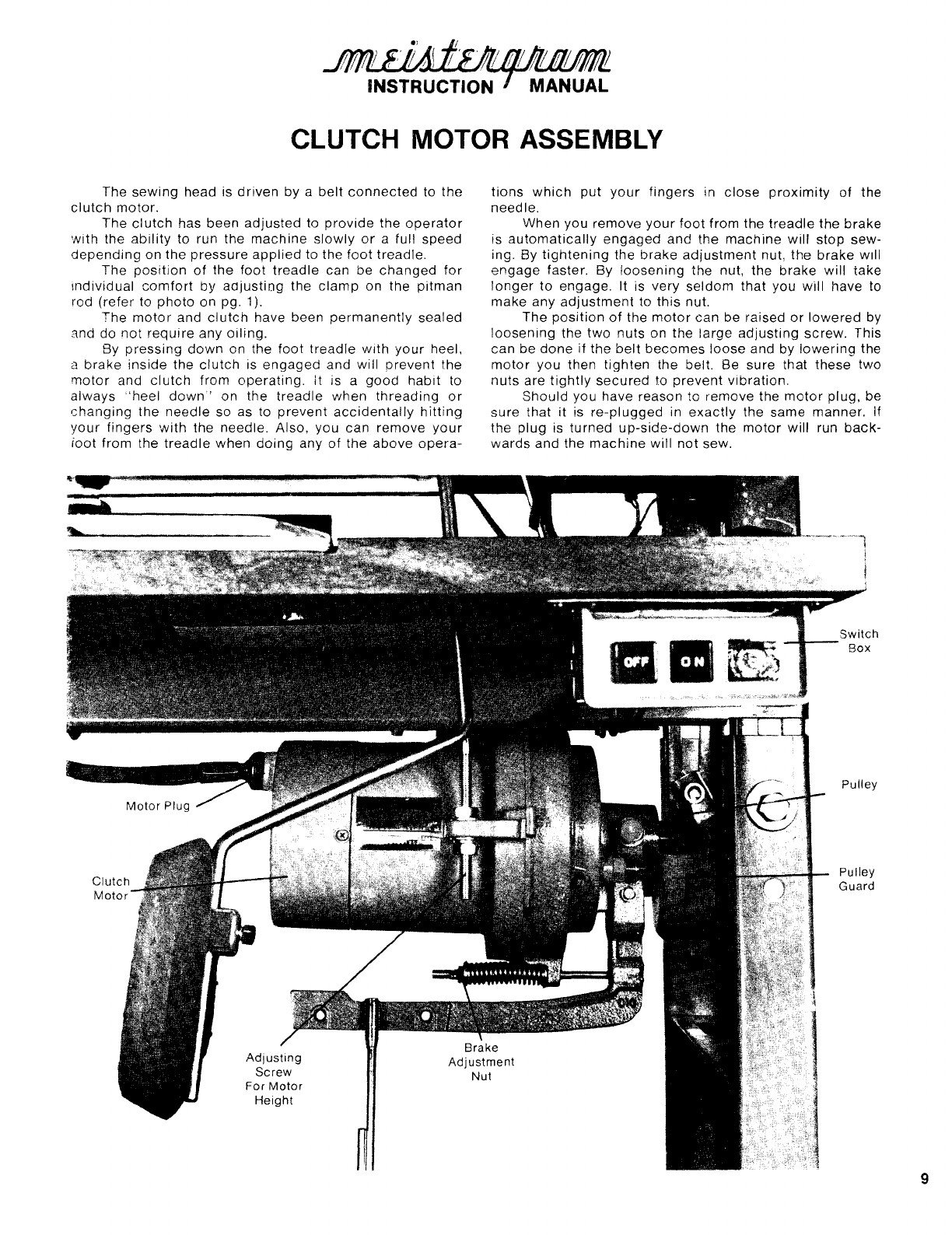

CLUTCH MOTOR ASSEMBLY

The

sewing

head is

driven

by a

belt

connected

to

the

clutch

motor.

The

clutch

has been

adjusted

to

provide

the

operator

with

the

ability

to run the

machine

slowly

or

a full

speed

depending

on

the

pressure

applied

to the

foot

treadle.

The

position

of

the

foot

treadle

can be

changed

for

mdividual

comfort

by

aajustiog

the

clamp

on

the

pitman

rod

(refer

to

photo

on pg. 1

).

The

motor

and

clutch

have been

permanently

sealed

and

do

not

require

any

oiling.

By

pressing

down

on the

foot

treadle

with

your

heel,

2

brake

inside

the

clutch

is

engaged

and

will

prevent

the

motor

and

clutch

from

operating.

It is a

good

habit

to

always

"heel

down"

on

the

treadle

when

threading

or

changing

the

needle

so as to

prevent

accidentally

hitting

your

fingers

with

the

needle.

Also, you can

remove

your

root

from

the

treadle

when

doing

any

of

the

above

opera-

tions

which

put

your

fingers

in

close

proximity

of

the

needle.

When you

remove

your

foot

from

the

treadle

the

brake

is

automatically

engaged

and

the

machine

will

stop

sew-

ing. By

tightening

the

brake

adjustment

nut,

the

brake

w11l

engage

faster. By

loosening

the

nut, the

brake

will

take

longer

to

engage.

It

is

very

seldom

that

you

will

have to

make

any

adjustment

to

this

nut.

The

position

of

the

motor

can be raised

or

lowered

by

loosening

the

two

nuts

on the

large

adjusting

screw.

This

can

be

done

if

the

belt

becomes

loose

and by

lowering

the

motor

you

then

tighten

the

belt. Be

sure

that

these

two

nuts

are

tightly

secured

to

prevent

vibration.

Should

you have reason

to

remove

the

motor

plug,

be

sure

that

it is

re-plugged

in

exactly

the same

manner.

lf

the

plug

is

turned

up-side-down

the

motor

will

run

back-

wards

and

the

machine

will

not

sew.

Pulley

Pulley

Guard

9

From the library of: Superior Sewing Machine & Supply LLC

10

CLEANING AND OILING

Like

any

other

piece

of

machinery

it

is very

important

to keep the head and ail moving parts cleaned and

lubricated.

located

under

the

top

cover

of

the machine are two

separate oil reservoirs. When you

first

receive

your

ma-

chine, remove the

top

cover

and then remove the

cover

plates

of

the reservoirs. Saturate the felt pads in each

reservoir

with

oil and replace the covers.

In

future

oilings

it

will

only

be necessary to fill the reservoirs by oiling

through

the

hole

in the

top

cover.

Located on the head you will find various

other

oil

holes. Oil holes are also located

under

the

work

plate. You

should

oil

each

of

these holes at least

twice

a week to keep

your

machine

running smoothly. If the machine is being

used

continuously

put a few

drops

of

oil in all oil holes

every day.

Oil machine at the end

of

the day and allow to sit over

night. Place a

piece

of cloth over

slot

on

work

plate to

prevent

oil from running into bobbin. Before sewing, wipe

excess oil from needle

bar

and presser bar. Run machine

without

thread

for

several minutes. Then sew

off

machine

with

cotton thread

which

will absorb oil

in

the hook. If oil

has accumulated in the hook, thread will bunch up on

back

of material. Excess oil in the

hook

should be wiped out.

Get in the

habit

of

cleaning the head every day.

Loosen the head clamp located on the table and

tilt

back

machine. With small brush, clean around the hook assem-

bly and shaft making sure

to

remove

lint

and thread. Even

a small piece

of

thread

caught

in the

hook

can jam

the

machine. Be sure to clean and oil the

hook

often.

Once

a week remove the top

cover

plate and the face

plate. Oil where indicated in photos below. Also, turn bal-

ance wheel by hand and oil all moving parts very lightly.

With a piece of cloth. remove excess oil that may have

accumulated in the bottom

of

the head.

Be sure to remove any thread that may have

accumu-

lated around the take-up lever assembly.

Meistergram Cotton thread will

produce

lint

rapidly so

be sure to clean around the needle

bar

and hook often.

Put one or two

drops

of oil

in

grooves

on side of hook assembly each

day.

For Efficient Operation of

Your

Machine

Use

Meistergram

Sewing Machine Oil.

From the library of: Superior Sewing Machine & Supply LLC

FIG. A

TIMING THE HOOK AND NEEDLE

FIG. B

0.1-

0.

OSmm

NEEDLE

EYE

FIG. E

0

A

common

problem

that

can

develop

with

the

sewing

operation

of

the

machine

is a

result

of

the

hook

and

needle

being

out

of

time

causing

the

stitches

to

skip

and

thread

or

needles to break.

These

machines

are

equipped

with

a full rotary

hook

which

picks

up

the

thread

from

the

needle

and passes it

completely

around

the

bobbin

case

allowing

time

for

the

tension

take..:up

spring

to

draw

up the

stitch

while

the

hook

is

making

the

second

revolution.

Stitching

problems

may be a

result

of

improper

or

faulty

thread, bent,

blunt

or

wrong

size needles,

needles

in

backwards

or

not

far

enough up

into

the

needle

bar, faulty

take-up

spring,

lack

of

or

too

much

oil in the

hook, faulty

bobbin

case

or

hook,

poorly

wound

bobbin,

nicks

or

scratches

on thread

guides

or

hook, material resting too

high

off

the

work

plate

or

presser

foot

incorrectly

adjusted.

Before

attempting

to re-time the machine,

check

the above items first.

TIMIN OCEDURE

(turn

off

machine

motor

before

proceeding

and

G PR :

press

down

on

foot

treadle

to

release

the

brake)

1)

First

remove

large

work

plate.

Use a

new

needle,

size

#1 0

or

#11

and

insert

prop-

erly

all

the

way

up

into

needle

bar,

with

long

groove

in

needle

facing

toward

you.

2)

Turn

balance

wheel

toward

you so

the

needle

is

going

straight

up

and

down

with

no

width

or

sideways

movement

and

check

to

see if

the

needle

is

entering

the

small

throat

plate

at the

center

of

the

slot. (if

the

width

indicator

is

on

"0"

but

your

needle

is

still

zigzaging,

refer

to

page

12

for

instructions

on

"Adjusting

ZigZag

Mechanism"

before

proceeding

any

further).

3) If

needle

is

not

entering

in

the

center

of

the

throat

plate,

correct

by

turning

eccentric

stud, fig.

C,

to

center

needle.

4) Raise

needle

to

highest

position

by

turning

balance

wheel

toward

you.

Remove

throat

plate

and

turn

balance

wheel

toward

you so

that

red

dot

on

machine

head

is

lined

up

with

red

dot

on

balance

wheel.

(fig. A).

At

this

point

the

needle

bar

is

at its

lowest

position.

The

needle

should

be as

low

as

possible

without

hitting

the

flat

part

of

the

bobbin

case.

To

adjust,

loosen

the

needle

bar

set

screw,

fig.

C,

and raise

or

lower

needle

bar

as

necessary.

To

check

height

of

needle,

press

knee

lever

so

indicator

is at

approximately

#11

or

#12

on

the

width

scale.

Turn

balance

wheel

toward

you so

that

needle

goes

all the

way

down

on

the

left

hand

side

of

the

zigzag.

You

will

then

be

able

to

see

how

close

the

needle

is

to

the

flat

part

of

the

bobbin

case, fig.

D,

and if

necessary

re-adjust

the

height

of

the

needle

bar

as

described

above.

5) Next,

with

the

needle

going

straight

up

and

down,

with

no

zigzag

width,

turn

balance

wheel

toward

you

to

line up red

dot

on

machine

head

with

green

dot

on

balance

wheel.

(fig. B).

At

this

position,

the

point

of

the

hook

should

be

at

the

center

of

the

needle

and

very

close

to

the

needle

without

touching

it. (fig. E & F).

6) If the

point

of

the

hook

is

not

at

the

center

of

the

needle

or

too

far

from

the

needle

to

pick

up

the

thread,

it is

necessary

to

change

the

position

of

the

hook

so

it

lines

up

properly

with

the

needle.

You

will

note

three

screws

behind

the

hook

which

hold

it

onto

the

shaft.

First

loosen

the

2

outer

screws,

then

loosen

the

middle

screw

enough

to

turn

the

hook

left

or

right

and

to

move

it

forward

or

backward

so

that

the

hook

point

can

be

positioned

properly

as in fig. E &

F.

Then

tighten

the

three

screws

securely.

7)

Now

that

the

timing

is

completed

it

should

be

checked

to

see

if

it is

proper.

Push

the

knee

lever

so

the

stitch

width

is at #11 and

turn

the

balance

wheel

toward

you

so

that

the

needle

is

rising

on

the

left

hand

side

of

the

zigzag

·and

meets

the

point

of

the

hook.

At

this

position

the

point

of

the

hook

should

be

just

above

the

eye

of

the

needle

and

close

to

the

needle

without

touching

it, as in fig. E &

F.

8)

If

the

timing

appears

to

be

correct,

replace

the

throat

plate

and

sew

on

the

machine

to

be

sure

it is

timed

properly.

If

when

sewing

the

stitches

still

"skip"

or

if

your

examination

in

#7

above

shows

that

the

timing

is

incorrect,

then

repeat

steps

#4,

5 & 6

to

re-time

the

machine.

Remember,

if

the

needle

bar

is

too

high

or

the

hook

point

is

too

far

from

the

needle,

the

machine

will

skip

stitches.

9) It

may

take

several

adustments

of

the

hook

and

needle

bar

to

achieve

the

proper

timing.

In

some

cases

it

is

necessary

to

set

the

hook

a

little

to

the

right

of

the

needle,

which

"slows"

the

hook,

or

to

set

the

hook

a

little

to

the

left

of

the

needle,

which

makes

the

hook

"fast"

in

order

to

achieve

proper

timing.

However,

this

should

not

be

done

until

you have

tried

the

proper

timing

sequence

as

outlined

above.

11

From the library of: Superior Sewing Machine & Supply LLC

12

ADJUSTING THE ZIGZAG STITCH WIDTH MECHANISM

(refer

to page 7 in this manual and

page

3

of

Section

3 in Parts List)

The

machine

is

designed

so

that

the

stitch

can be regu-

lated by

pressing

the

knee lever. In this

manner

the

stitch

can be as

narrow

as the

thread

itself

when

the

indicator

is

on

"0"

or

adjusted

up to

about

V2"

when the

indicator

is

on

"12".

If the zigzag

mechanism

is

not

operating

properly

check

for

these

problems

and

solutions:

1) Without pressing the knee lever the needle

is

still mak-

ing a zigzag stitch

refer

to

page

7 in this manual and

check

for

the

follow-

ing:

bottom

indicator

knob

is

not

at

lowest

position

...

return

spring

on knee

lever

assembly

is

dis-engaged

or

weak

...

the

I

ifter

on knee

lever

assembly

is set

too

high

and

is

pushing

up the

lifter

in the

machine

head

...

the

knee

lever

rod is

loose

or

in the

wrong

position.

If the

above

do

not

correct

the

problem,

remove

the

top

cover

of

the

machine

head and refer to

Section

3

of

the

Parts Manual

for

the

following

directions:

a.

make

sure

that

the

two

springs

#335 and #332 are

attached

to

the

machine

head as

indicated.

b.

check

I

ifting

rod #367 to be sure it is

not

bent

and

it

is

moving

freely.

c.

check

zigzag

regulator

#346

to

be

sure

it

is

not

loose.

To

do

this, remove

rear

oil

reservoir

#132 from head,

remove end

screw

#350,

loosen

two

screws

#348

and

loosen

bushing

screw

#345.

To

reach #345, push

knee

lever

which

will

then

expose

the

screw.

The

end

of

regulator

#346 is

now

exposed

in

the

indicator

#347. Use a

screwdriver

with

a

large

blade

and turn

regulator

#346 to the

right

to

tighten.

Tighten

bush-

ing

screw

#345, then

tighten

the

two

screws

#348

with

indicator

on

"0".

Put a

piece

of

paper

under

needle

and turn

balance

wheel

forward

by hand,

without

pushing

on knee lever. Needle

should

go up

and

down

in same

hole

in

paper

without

making

any

zigzag.

d.

if

the

needle

continues

to zigzag,

loosen

the

screws

#357 on

connector

#356.

Tap

the

connector

I

ightly

to

the

left,

tighten

one

of

the

screws

and

check

the

needle

in and

out

of

the paper. If the zigzag

con-

tinues,

adjust

the

connector

a Iittle

more

to the

left

or

right

as

required

and then

tighten

the

screws.

2) Indicator will not

go

all the way

up

the scale

a.

Check the knee

lever

rod to see

if it

is

positioned

properly

so as not to hit

the

table

top

or

the

desk

ledge

preventing

full movement.

b.

the

lifter

on the knee

lever

assembly

is

set

too

low

and

preventing

full

movement

of

the

knee lever. The

lifter

should

be

about

Va"

below

lifting

rod

roller

#371, when

indicator

is at

"0".

c.

check

lifting

crank

#359 by

loosening

two

screws

#360 and

position

crank

at

lowest

position

and

tighten

the

screws.

3) Indicator

is

not at

"0"

when needle

is

sewing straight

up

and down.

loosen

2

screws

#348

position

indicator

at

"0".

3.

ZIGZAG

WIDTH

REGULATING

MECHANISM

COMPONENTS

& PRESSER BAR

ASSEMBLY

365

!

c?ro

I

""'

I

J62

~·

368

~

370

•

.357

361

367

311

l--333

From the library of: Superior Sewing Machine & Supply LLC

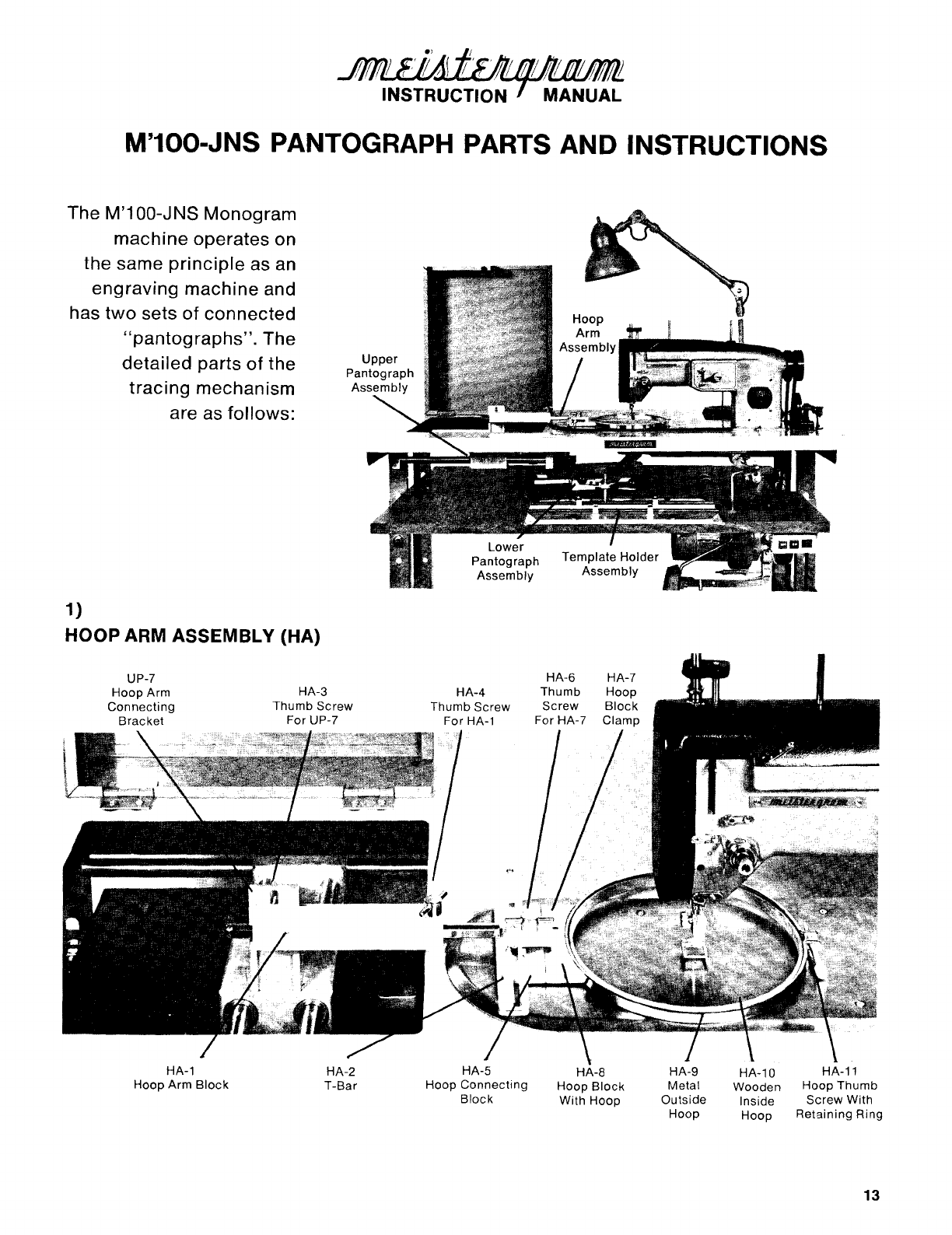

M'100-JNS PANTOGRAPH PARTS AND INSTRUCTIONS

The M'1 00-JNS Monogram

machine

operates on

the same

principle

as an

engraving machine and

has

two

sets

of

connected

"pantographs".

The

detailed parts

of

the

tracing

mechanism

are as

follows:

1)

HOOP ARM ASSEMBLY (HA)

HA-1

Hoop Arm

Block

HA-2

T-Bar HA-5

Hoop Connecting

Block

HA-8

Hoop

Block

With Hoop

HA-9

Metal

Outside

Hoop

HA-10 HA-11

Wooden Hoop Thumb

Inside Screw With

Hoop Retaining Ring

13

From the library of: Superior Sewing Machine & Supply LLC

14

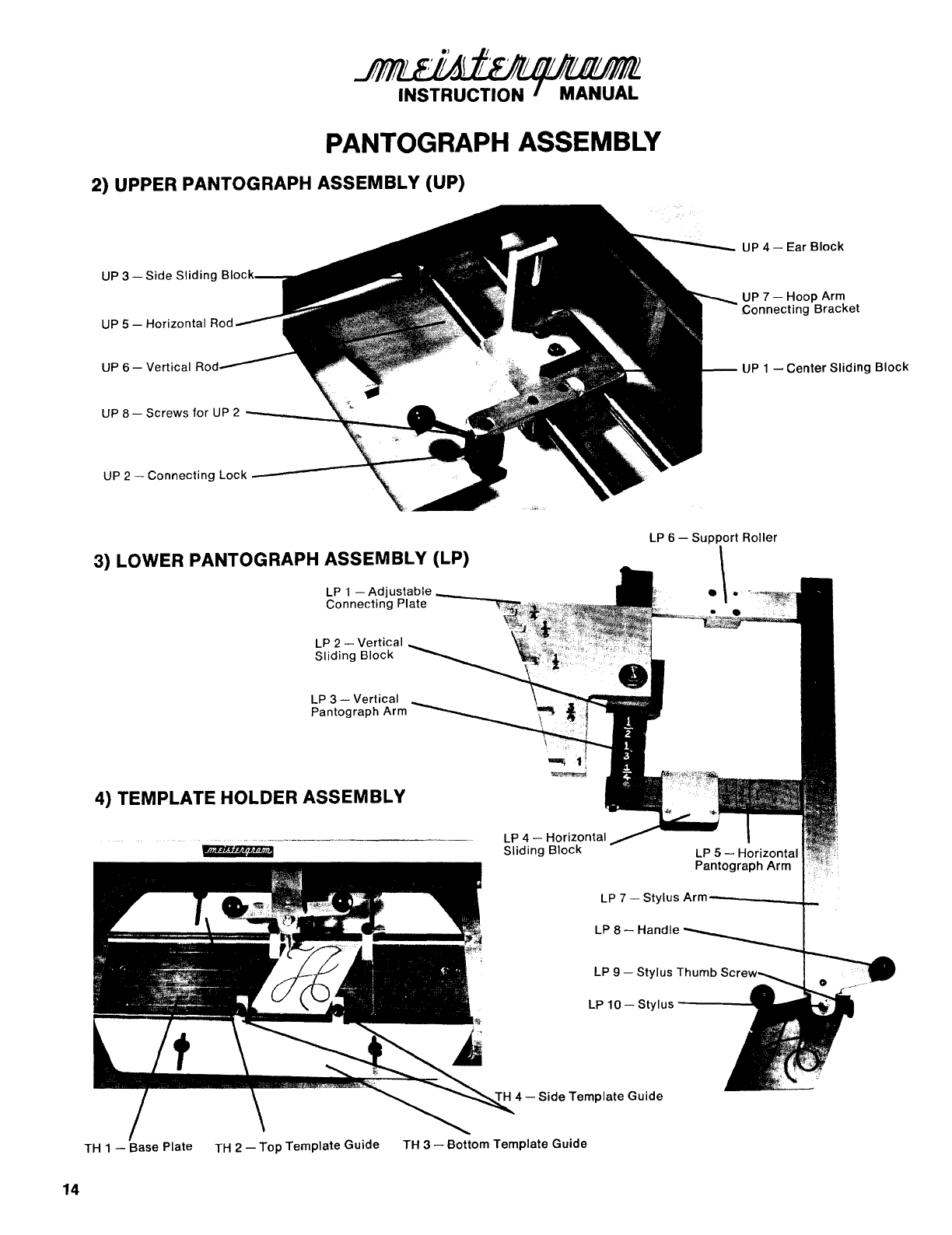

PANTOGRAPH ASSEMBLY

~UPPERPANTOGRAPHASSEMBLY(U~

UP

3-

Side

Sliding

Bloc

UP

6 - Vertical Rod

UP

8-

Screws

for

UP

2

UP

4-

Ear

Block

UP

7-

Hoop

Arm

Connecting

Bracket

UP

1

-Center

Sliding

Block

3) LOWER PANTOGRAPH ASSEMBLY (LP)

LP

6 -

su~C

Roller

LP

2-

Vertical

Sliding

Block

LP

3-

Vertical

Pantograph Arm

4) TEMPLATE HOLDER ASSEMBLY

LP

4 - Horizontal

Sliding

Block

LP

8-

Handle

LP

9-

Stylus Thumb S

4-

Side

Template

Guide

TH 1

-Base

Plate TH

2-

Top

Template

Guide

TH

3-

Bottom Template

Guide

From the library of: Superior Sewing Machine & Supply LLC

INSTRUCTIONS

M'100-J

PANTOGRAPH

ASSEMBLIES

refer

to

pages

12

&

13

1) HOOP

ARM

ASSEMBLY

(HA)

Install

Hoop

Arm

Assembly

by

attaching

HA

1

to

UP 7

with

thumb

screw

HA

3.

The

Hoop

Arm

provides

adjustment

in

three

different

directions:

a)

by

loosening

screw

HA

3,

the

assembly can be adjusted

up

or

down

for

various thicknesses

of

material.

Set

the

hoop

arm

so

that

the

block

on

the

hoop,

HA

8,

is

slightly

above

the

work

plate

when

the

material

is

in

the

hoop.

If

the

hoop

arm

is

too

low,

the

block

will

drag

on

the

plate.

If

too

high,

the

material

will

be

too

far

above

the

plate

and

not

allow

for

proper

stitching.

b)

by

loosening

thumb

screw

HA

4,

the

T-bar

can

be

adjusted

from

side

to

side

or

left

to

right.

This

enables

you

to

center

your

work

in

the

hoop,

or

in a

particular

area,

adjust

spacing

between

letters

and

to

make

monograms

vertically

or

diagonally.

Loosening

also enables

you

to

position

the

hoop

so

that

it

lies

flat

on

the

plate

and

is

not

tilted

toward

the

front

or

back.

c)

by

loosening

thumb

screw

HA

6,

the

hoop

can be

adjusted

from

front

to

back

which

enables

you

to

place

the

monograms

where

desired.

This

thumb

screw also enables

you

to

remove and

attach

the

hoop

to

the

clamp.

BE

SURE

THAT

ALL

SCREWS

ARE

SECURED

FIRMLY

TO

PREVENT

DISTORTED

MONOGRAMS

AND

IMPROPER

OPERATION

2) UPPER

PANTOGRAPH

ASSEMBLY

(UP)

The

Upper

Pantograph

acts

as

a

supporting

assembly between

the

Lower

Pantograph

and

the

Hoop

Arm

Assembly.

It's

smooth

sliding

action

is

possible

by

two

sets

of

rods and bearing-loaded

blocks.

The

Hoop

Arm

Assembly

is

to

be

connected

to

the

UP

on

part

UP

7.

The

Lower

Pantograph

is

to

be

connected

to

the

UP on

the

part

UP

2,

the

connecting

lock.

15

From the library of: Superior Sewing Machine & Supply LLC

16

There

are

two

sliding

blocks,

UP

3, and

into

each

block

is

inserted

the

ends

of

the

vertical

rods,

UP

6. These rods are secured

into

the

sliding

blocks

by

two

set screws,

located

on

the

bottom

of

each

block.

These set screws

must

be secure

to

keep

the

vertical

rods

from

moving

and causing

distortion

or

double

lines

in

the

monogram.

Be sure

to

check these screws,

to

make sure

they

have

not

loosened,

with

the

small allen

wrench

included

in

your

tool

kit.

Keep

both

sets

of

rods cleaned and

lightly

oiled.

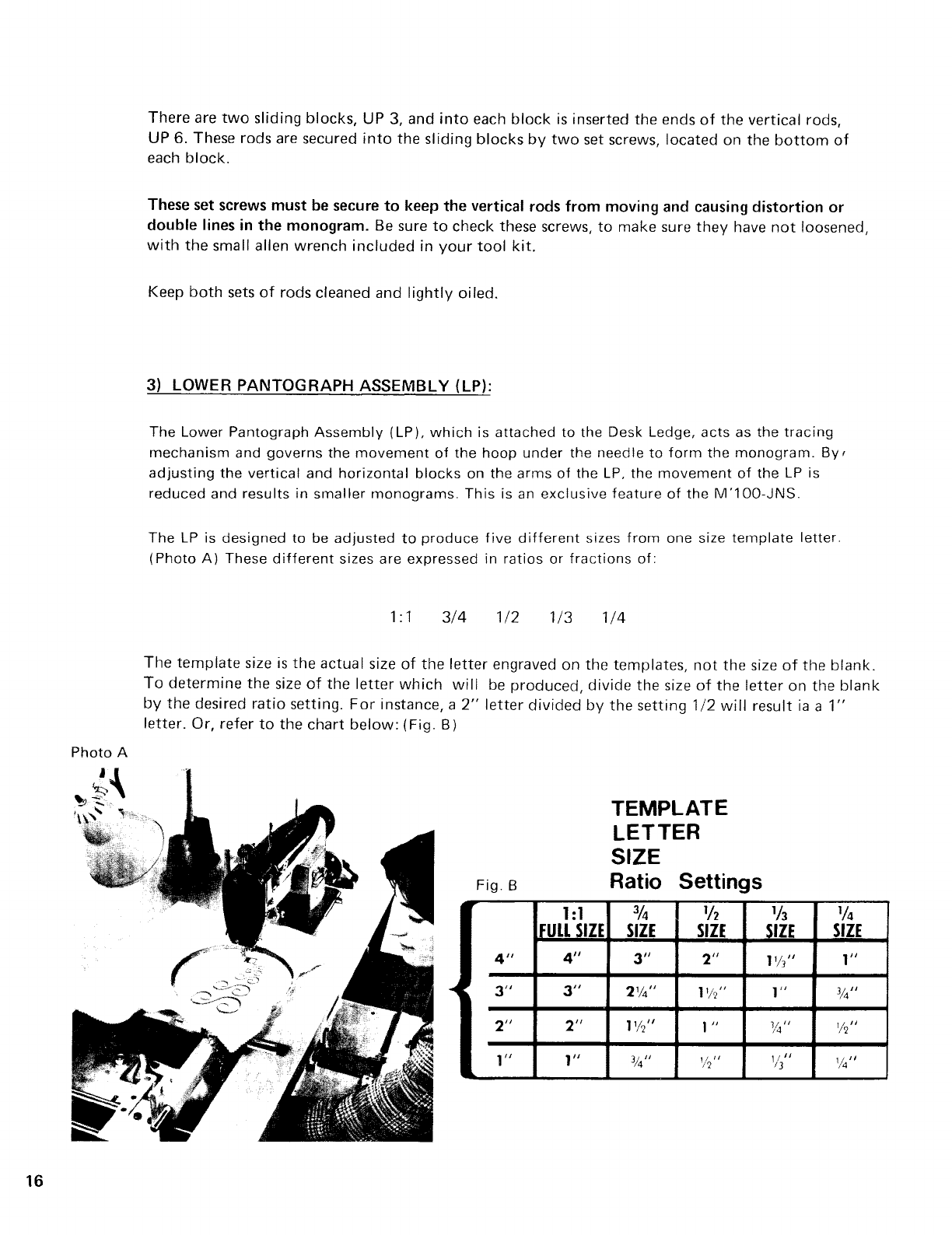

3) LOWER

PANTOGRAPH

ASSEMBLY

(LP):

The Lower Pantograph

Assembly

(LP).

which

is attached to the Desk Ledge, acts

as

the

tracing

mechanism and governs the

movement

of

the hoop under the needle to

form

the monogram.

By'

adjusting

the vertical and horizontal

blocks

on the arms

of

the

LP,

the

movement

of

the

LP

is

reduced and results in

smaller

monograms.

This

is

an

exclusive feature

of

the

M'100-JNS.

The

LP

is designed to be adjusted

to

produce

five

different

sizes

from

one size

template

letter.

(Photo A) These

different

sizes are expressed in ratios or

fractions

of:

1:1

3/4

1/2 1/3

1/4

The

template

size

is

the

actual

size

of

the

letter

engraved

on

the

templates,

not

the

size

of

the

blank.

To

determine

the

size

of

the

letter

which

will

be

produced,

divide

the

size

of

the

letter

on

the

blank

by

the

desired

ratio

setting.

For

instance, a

2"

letter

divided

by

the

setting

1/2

will

result

ia

a

1"

letter.

Or,

refer

to

the

chart

below:

(Fig. B)

Fig. B

1:1

lEULL

SIZE

4"

4"

~

3"

311

2"

211

1"

111

TEMPLATE

LETTER

SIZE

Ratio

Settings

3

/4

1f2

SIZE

SIZE

3"

2"

21//'

11/r;"

11/c/'

1

II

%"

1f'2''

lfl 1

/4

_S_IZE

SIZE

11//'

111

1"

%11

%"

1/'211

1I

11

13

1/4''

From the library of: Superior Sewing Machine & Supply LLC

(Lower

Pantograph

Assembly

continued)

You

will

find

these

ratio

settings

marked

on

the

adjustable

connecting

plate

(

LP

1),

the

vertical

arm

(

LP

3),

and

the

horizonta

I

arm

(

LP

5).

To

produce

different

size

letters

from

one

template,

you

must

change

the

ratio

settings

on

the

machine.

Follow

these steps

in

the

order

listed:

(Photo

C Pg.

18)

1)

Under

the

lid

on

the

table

top

is

the

Upper

Pantograph

Assembly.

Attached

to

the

large

center

sliding

block

(UP

1)

is

the

Connecting

Lock

(UP 2).

This

lock

is

connected

to

the

Adjustable

Connecting

Plate

(LP

1

).

Hold

the

plate

with

one hand and

turn

the

lock

handle

counter-clockwise,toward

the

back

of

the

machine,

to

loosen

the

lock.

Then,

push

the

lock

over

toward

the

left,

out

of

the

adjustable plate.

(PhotoDPg.18)

2) Grasp

the

connecting

plate

with

the

left

hand, and move

to

the

desired setting,

while

holding

the

horizontal

arm (LP 5)

stationary

with

the

right

hand.

The

adjustable

plate

is

attached

to

the

vertical

sliding

block

(

LP

2).

This

block

will

move along

the

arm

and

lock

at

each

ratio

setting.

The

front

edge

of

the

vertical

block

should be lined

up

with

the

ratio

setting

desired,

which

is

stamped on

the

vertical

arm.

(Photo

E Pg. 1

8)

3) Grasp

the

horizontal

pantograph

arm

(LP

5}

at

both

ends and push

horizontally,

to

the

left

or

right,

so

that

the

desired

ratio

setting lines

up

with

the

right

hand side

of

the

horizontal

block

(

LP

4).

The

horizontal

arm

has

the

same

ratio

settings

as

the

vertical

arm.

{Photo

C Pg.

18)

4)

Bring

the

connecting

lock

over

to

the

adjustable

plate

and

insert

lock

into

same

ratio

setting

slot

as

the

two

arms are set at.

Tighten

lock

very

securely,

by

turning

clockwise,

toward

front

of

the

machine.

IMPORTANT:

Be

sure

that

the

horizontal

arm,

vertical

arm

and

connecting

lock

are all located

at

the

same

ratio

setting.

If

one

of

these

three

settings are

not

the

same

it

will

result

in

a

distorted

monogram.

Be

sure

the

connecting

lock

is

secured

tightly

to

prevent

movement

of

the

plate,

when

locked,

or

this

will

also cause

distortion

of

the

monogram.

The

plate should swing

freely

when

not

connected

to

the

lock.

The

movement

of

the

vertical and

horizontal

sliding

blocks

is

governed

by

spring pressure

on

a

pin

inside each

block

(LP 2 and LP 4). These

pins

have been set

at

the

factory

prior

to

shipment,

however,

if

the

blocks

are

too

tight

to

move easily

or

too

loose

during

monogramming,

adjust

the

set screws

with

the

large allen

wrench

in

the

tool

kit.

Be

sure

that

all parts

of

the

Lower

Pantograph are

kept

clean and

lightly

oiled.

17

From the library of: Superior Sewing Machine & Supply LLC

18

4)

TEMPLATE

HOLDER

ASSEMBLV: (TH)

The

adjustable

Template

Holder

is

designed

to

hold

various styles and sizes

of

templates

and

locks

them

in

position

with

two

large guides

at

top

and

bottom

and

four

small side guides.

The

screws should be

tightened

enough

to

secure

the

templates

from

moving

but

undue

pressure

should

not

be required

to

loosen

them.

A series

of

holes are

provided

for

the

screws

for

the

large guides

which

will

enable

you

to

place

the

guides

to

accommodate

various size templates.

It

is

not

necessary

to

remove screws;

just

loosen

and slide

the

guides back and replace templates.

Templates: These are made

of

a very

tough

bakelite

and

will

provide

long

life.

For

smooth

movement

of

the

stylus,

use

graphite

or

soft

lead pencil in all grooves on

template

or

stylus

will

drag.

(Photo

C)

(Photo

D)

(Photo

E)

From the library of: Superior Sewing Machine & Supply LLC

This manual suits for next models

1

Table of contents

Other Meistergram Sewing Machine manuals