Table of contents

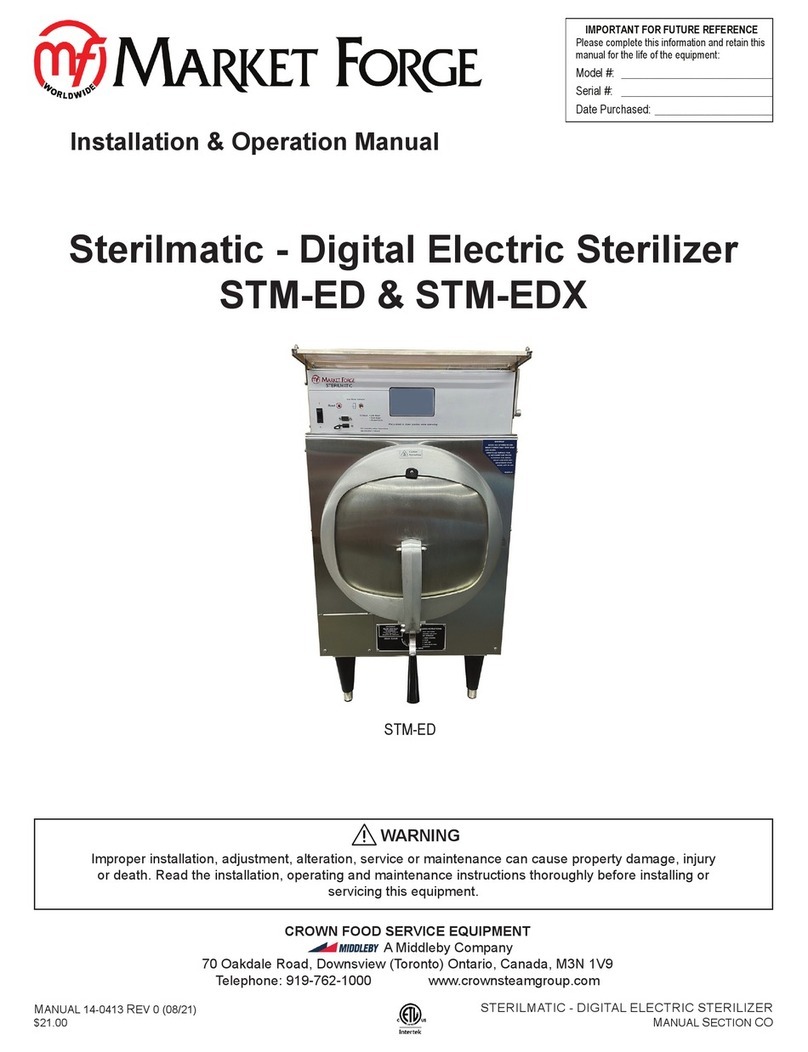

Chapter 1 – Device description....................... 8

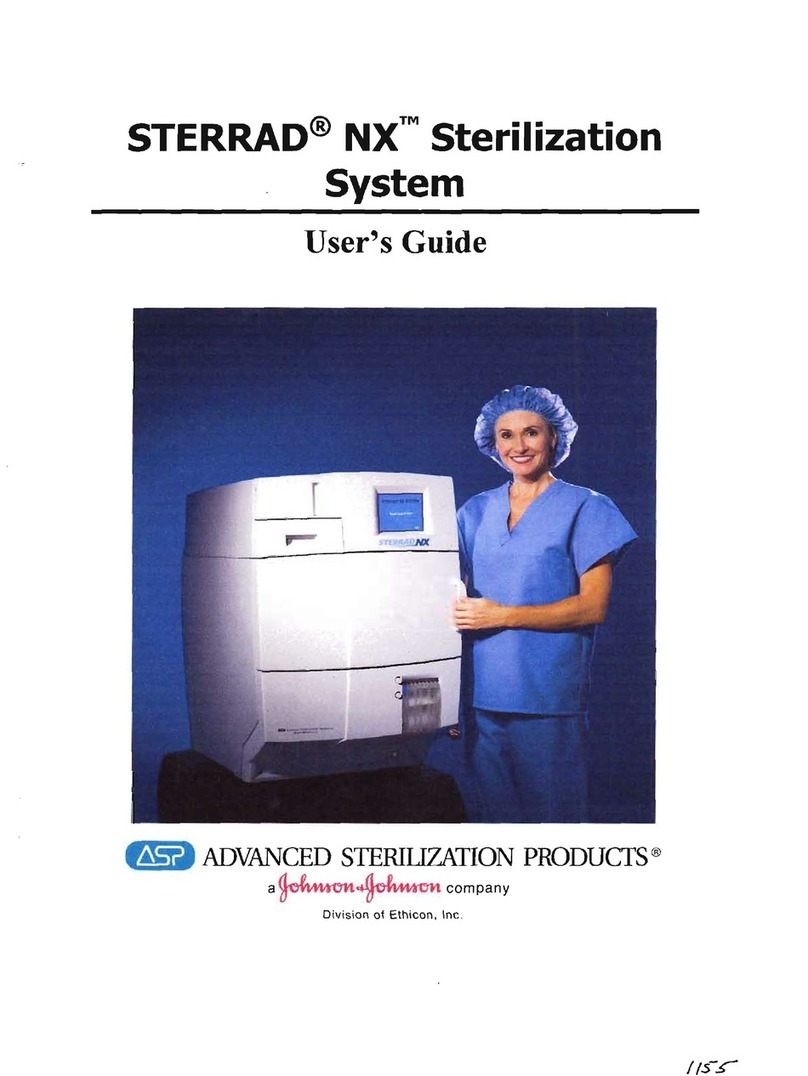

Intended Use ................................................................8

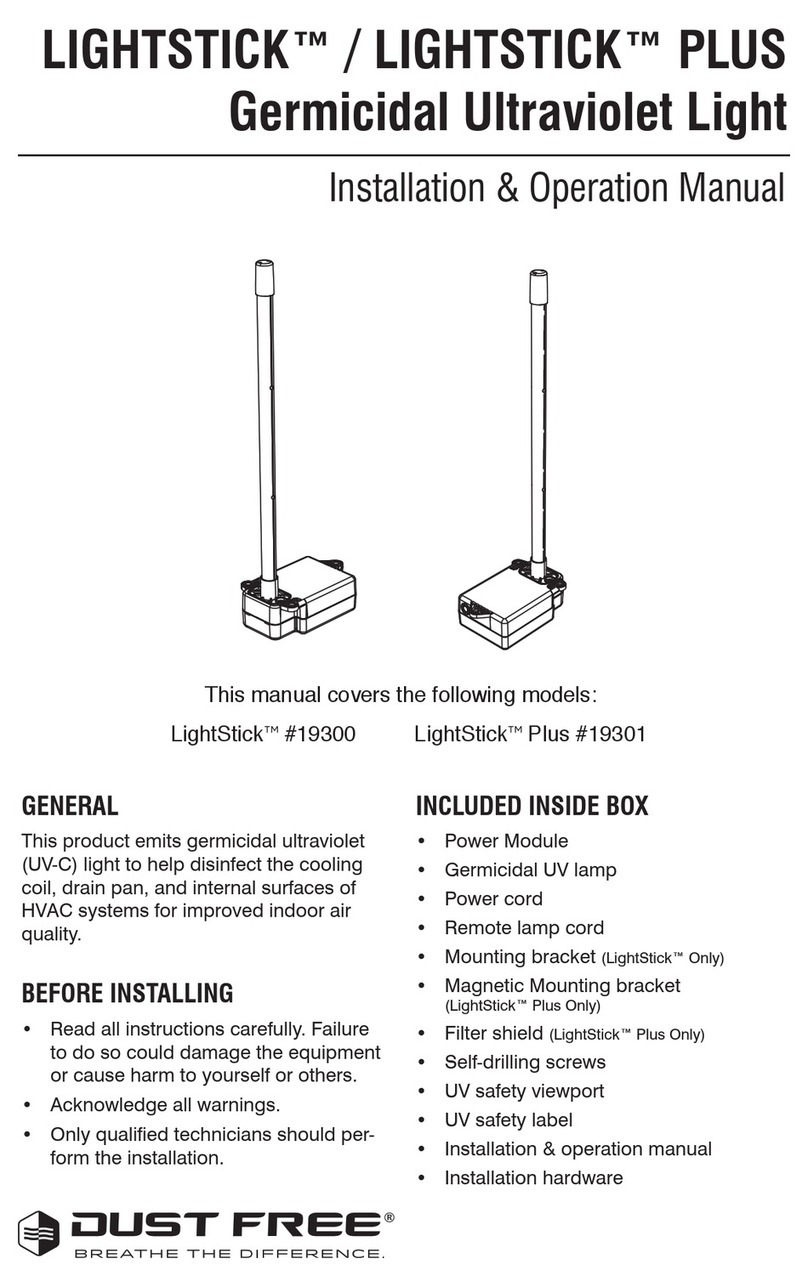

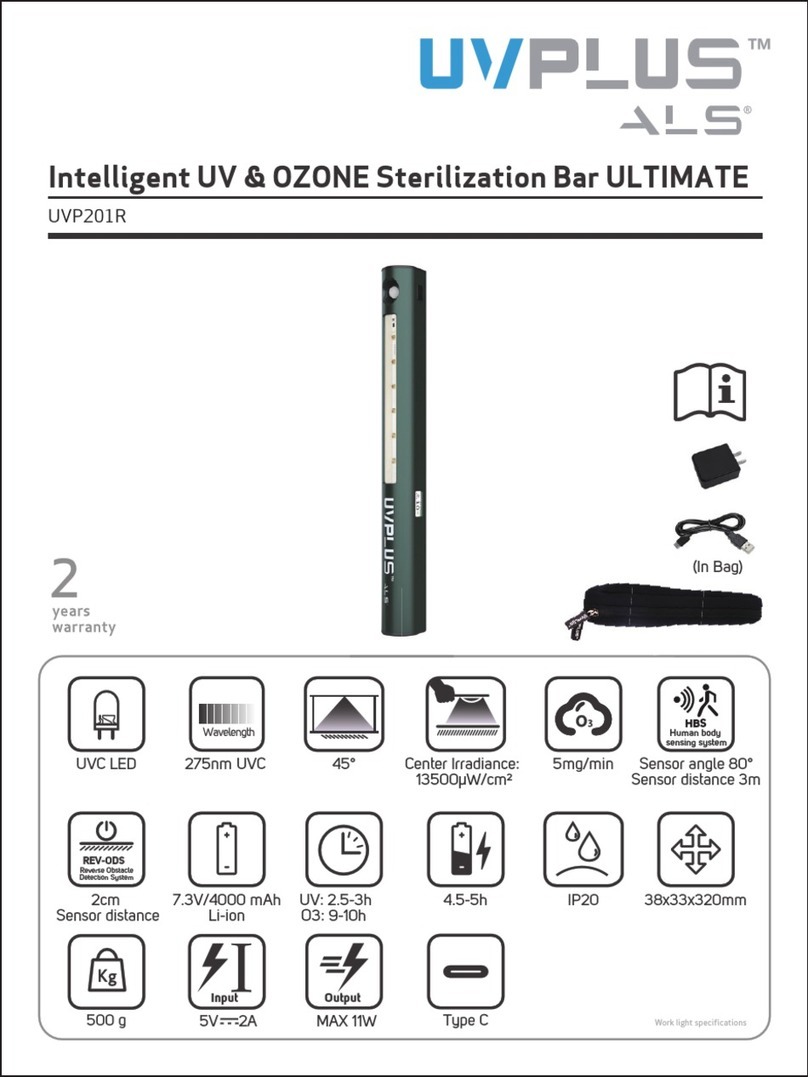

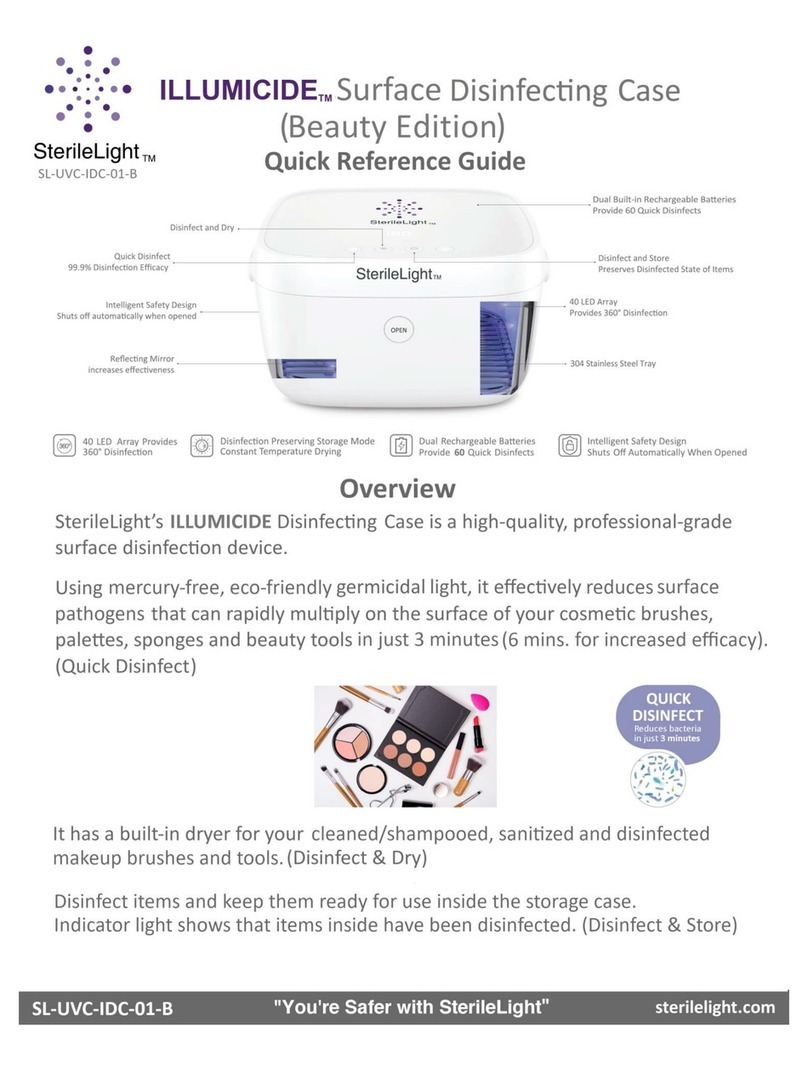

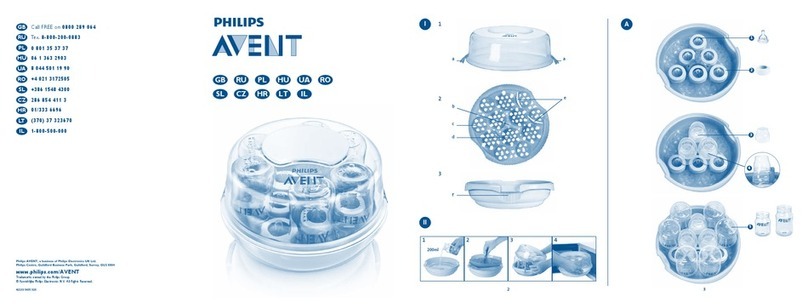

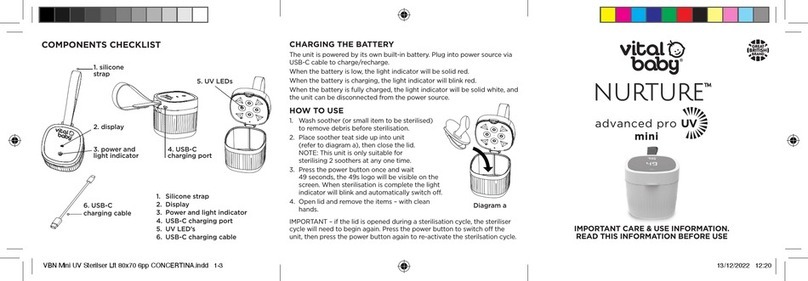

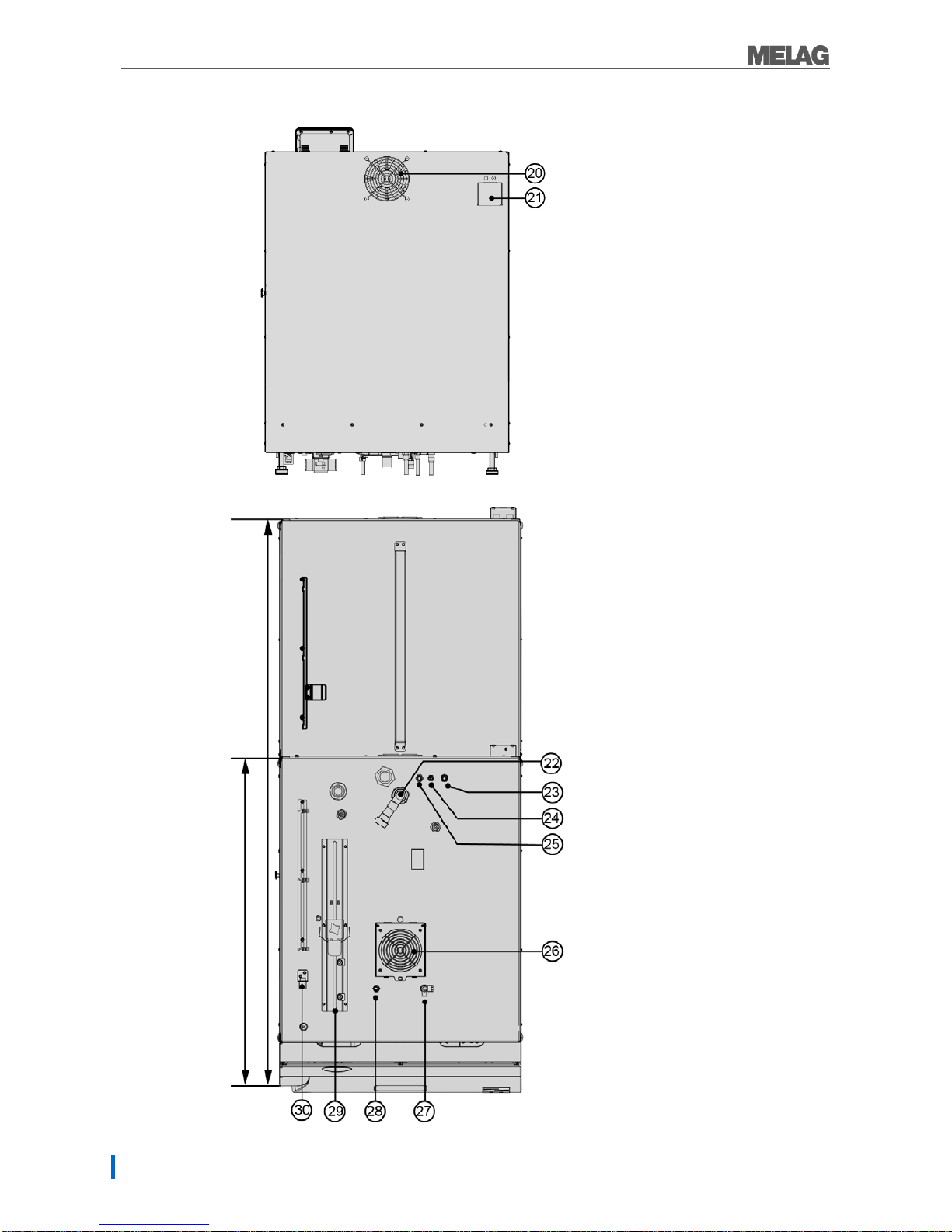

Views of the device.......................................................9

Colour-Touch Display.................................................11

Load mount.................................................................13

Chapter 2 – First steps.................................. 14

Preconditions for commissioning................................14

Record of installation and set-up................................14

Providing feed water...................................................14

Tap water supply ........................................................14

Switch on the autoclave..............................................15

Opening and closing the door.....................................15

Chapter 3 – Loading the steam sterilizer ...... 17

Preparing the sterilization material .............................17

Loading the autoclave ................................................18

Chapter 4 – Sterilizing................................... 22

Important information regarding routine operation......22

Selecting the program ................................................23

Starting the program...................................................25

Sterilization phase is ended........................................26

Drying phase ..............................................................27

Program is ended .......................................................27

Manual program abort ................................................27

The clearance process ...............................................28

Removing the sterilized equipment.............................29

Storing sterile instruments..........................................30

Chapter 5 – Logging ..................................... 31

Batch documentation..................................................31

Output media..............................................................31

Outputting logs immediately and automatically...........35

Subsequent log output................................................36

Determining the log format .........................................37

Finding a log...............................................................39

Reading logs correctly................................................39

Chapter 6 – Settings..................................... 41

Logging.......................................................................41

User administration.....................................................41

Additional drying.........................................................43

Date and time .............................................................43

Light intensity..............................................................44

Volume .......................................................................44

Key tones....................................................................44

Screensaver ...............................................................45

Intelligent drying .........................................................46

Label printer................................................................46

Log printer..................................................................47

Touch sensitivity ........................................................48

Energy-saving mode..................................................49

Chapter 7 – Functional Checks..................... 50

Vacuum test...............................................................50

Bowie & Dick test.......................................................50

Helix test body system MELAcontrol/MELAcontrol

PRO .........................................................................51

Checking the quality of the feed water.......................51

Validation ...................................................................51

Renewed Qualification (revalidation) .........................51

Chapter 8 – Maintenance.............................. 52

Cleaning.....................................................................52

Avoiding staining........................................................53

Greasing the door spindle..........................................53

Changing the filter on the housing fan........................53

Maintenance ..............................................................53

Chapter 9 – Operating Pauses ..................... 54

Frequency of sterilization ...........................................54

Pause times ...............................................................54

Decommissioning.......................................................54

Transport....................................................................54

Emptying the double-jacket steam generator.............55

Recommissioning after relocation..............................55

Chapter 10 – Description of function............. 56

The sterilization procedure.........................................56

Type of the feed water supply....................................56

Internal process monitoring........................................56

Emergency shut-down ...............................................56

Program sequence.....................................................57

Chapter 11 – Malfunctions............................ 58

Before you call customer service ...............................58

Opening the door manually........................................62

Glossary........................................................ 63

Technical Data.............................................. 65

Appendix A – Accessories............................ 67