Contents

Contents

Chapter 1 – Performance Specification.............. 7

Proper use.............................................................. 7

User benefit ............................................................ 7

Overview of sterilization programs.......................... 9

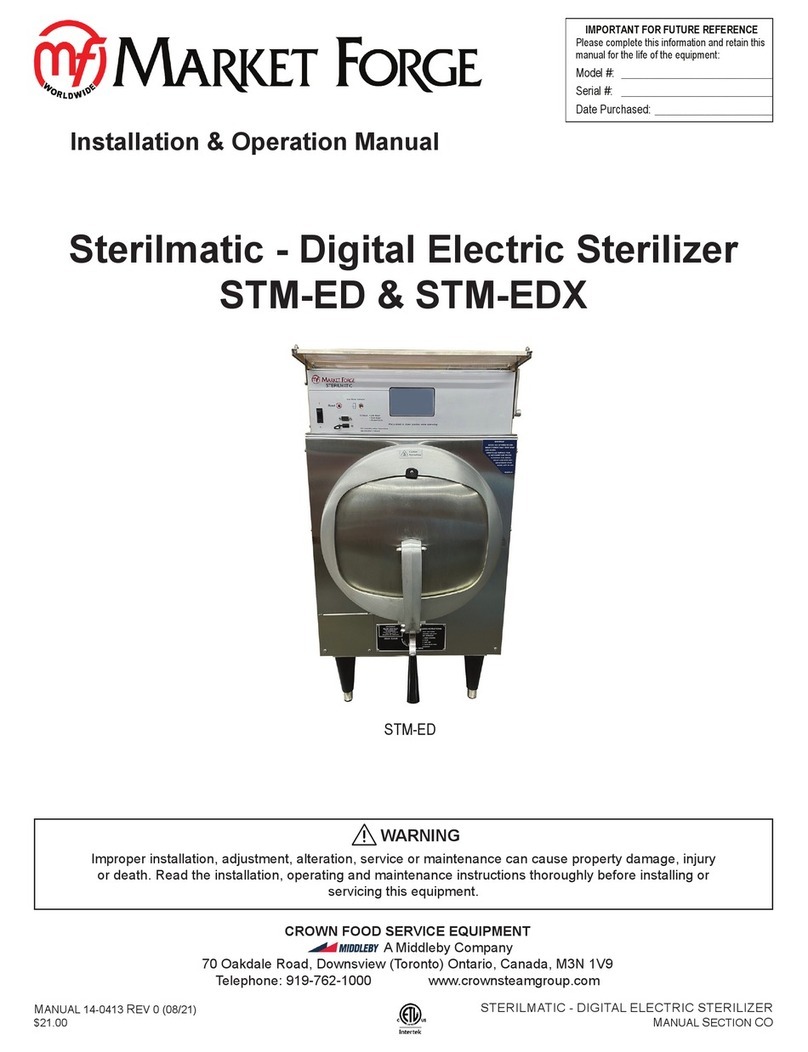

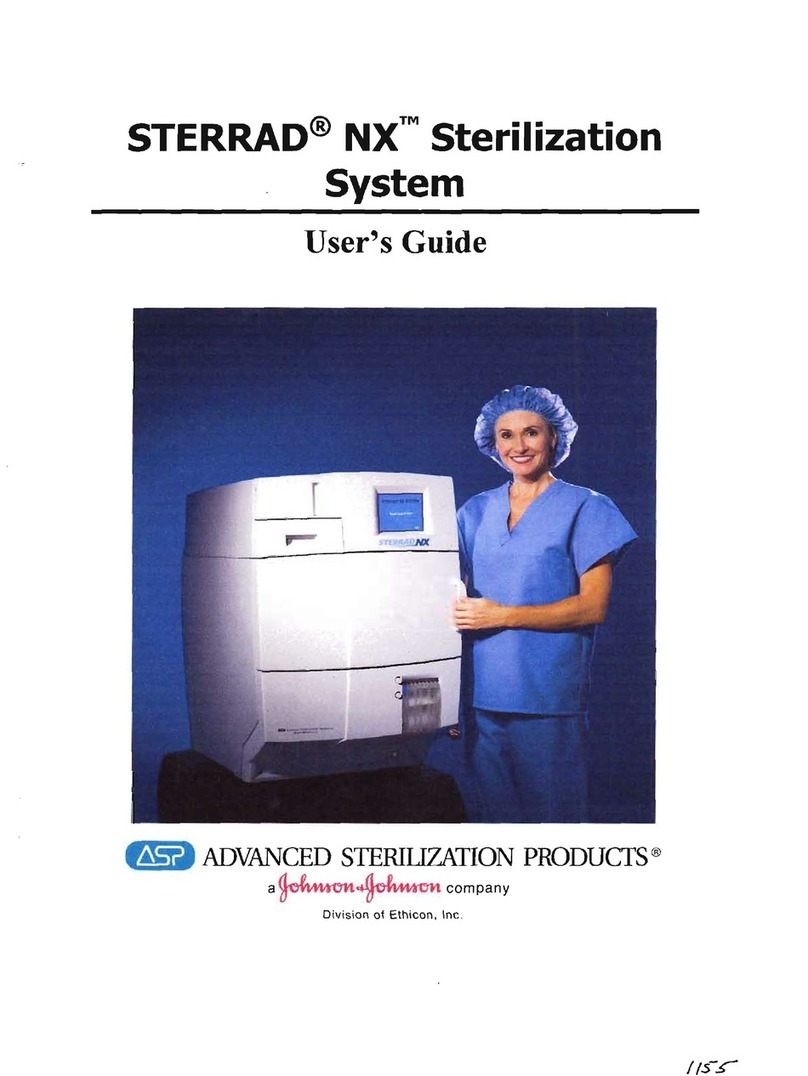

Chapter 2 – Device Description......................... 10

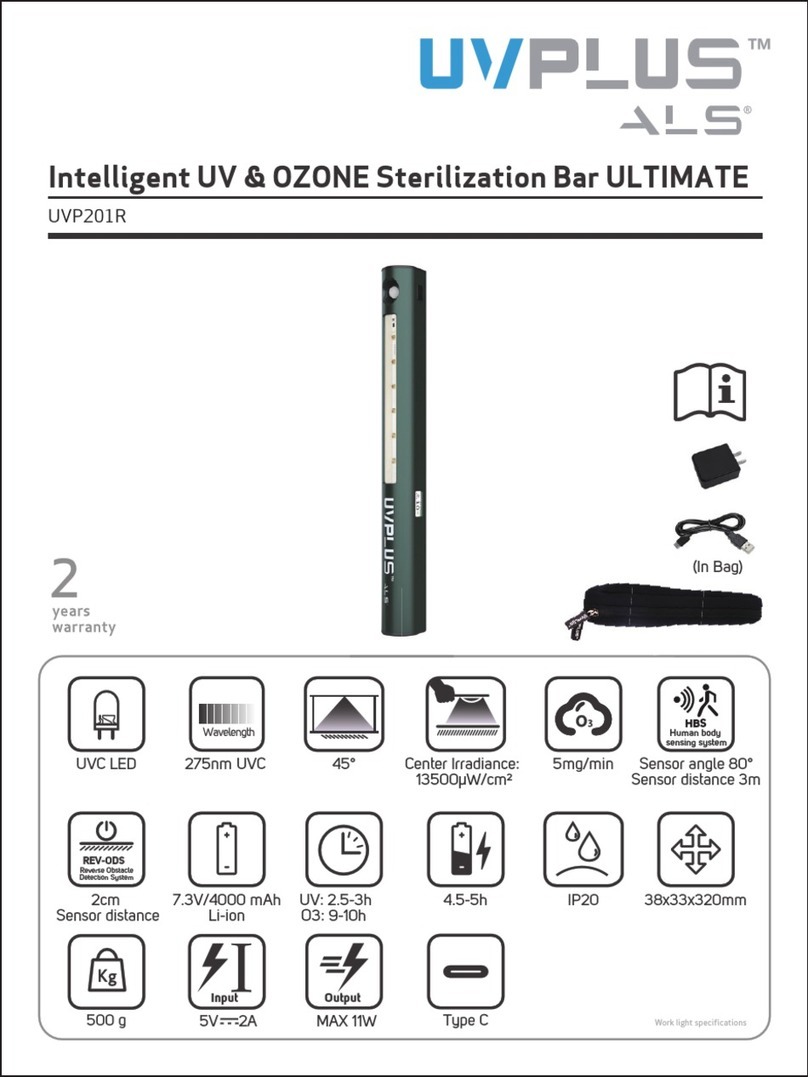

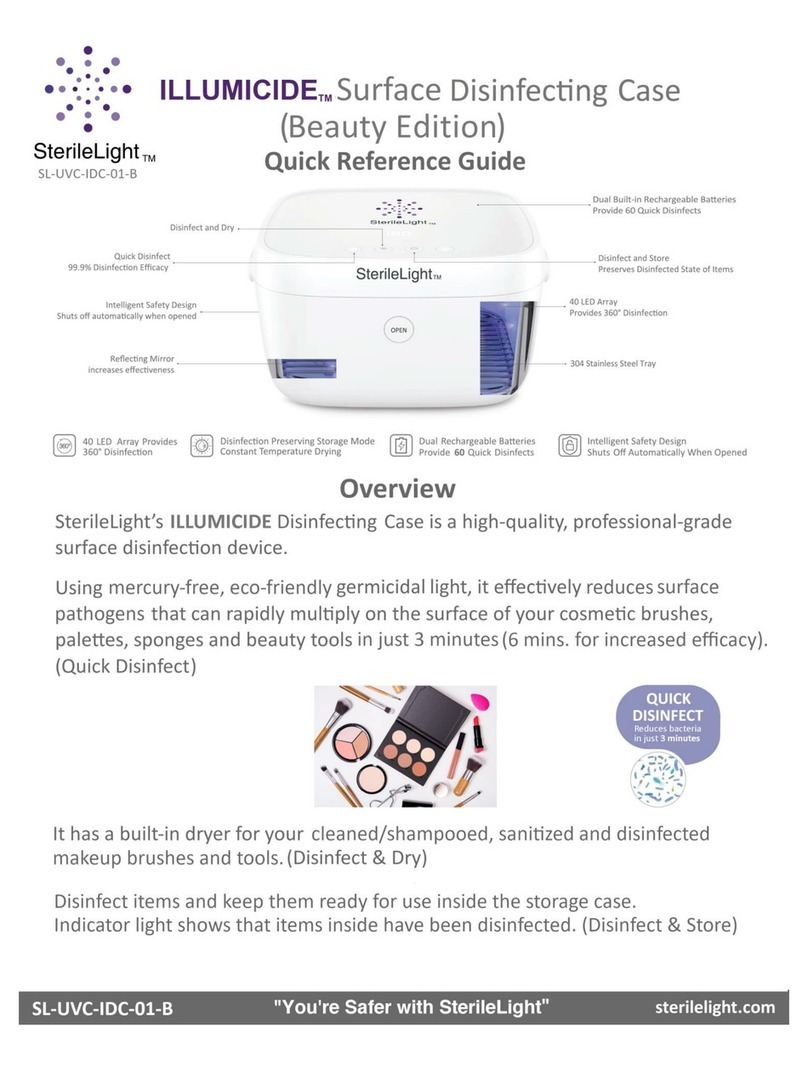

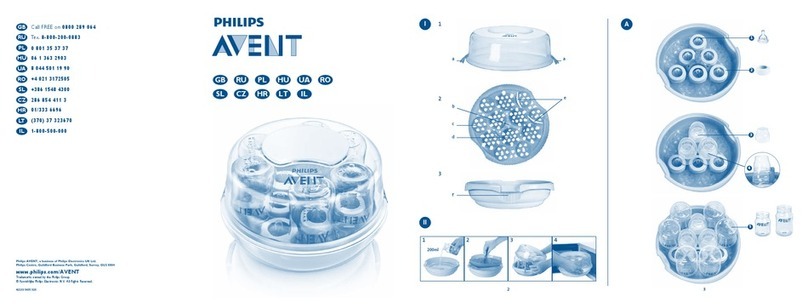

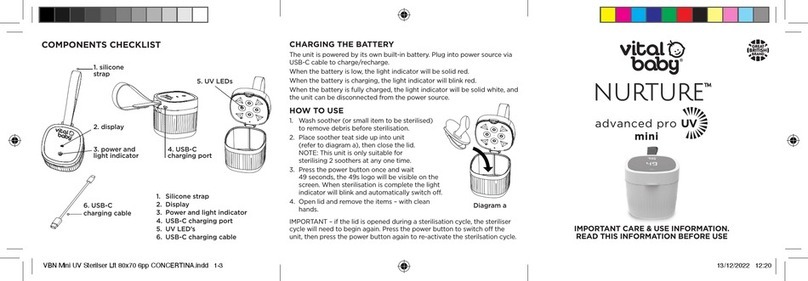

Scope of delivery.................................................. 10

Device views......................................................... 11

Effective capacity.................................................. 12

Mountings for the load .......................................... 12

Control panel ........................................................ 13

Supply with feed water ......................................... 13

Supply with cooling water ..................................... 14

Chapter 3 – Initial start-up ................................. 15

Conditions for setting up, installing and starting up

............................................................................. 15

Set-up location requirements................................ 15

Connections required ........................................... 16

Prerequisites for initial start-up ............................. 18

Record of installation and setting up..................... 18

Switch on steam sterilizer..................................... 18

Chapter 4 – Sterilization..................................... 19

Create prerequisites ............................................. 19

Prepare items to be sterilized ............................... 19

Load the steam sterilizer ...................................... 21

Close the door ...................................................... 23

Select program ..................................................... 23

Select automatic pre-heating................................ 24

Select additional drying ........................................ 25

Start program........................................................ 25

Program is running ............................................... 25

Manually terminate program................................. 26

Sterilization phase is finished ............................... 27

Drying phase ........................................................ 28

Program is finished............................................... 28

Display batch number........................................... 28

Remove sterilized items ....................................... 29

Storage of sterilized items .................................... 29

Chapter 5 – Logging........................................... 30

Batch documentation............................................ 30

Set date and time ................................................. 31

Use printer as output medium............................... 31

Employing MELAflash as output medium ............. 33

MELAnet Box as output medium .......................... 33

Computer as output medium ................................ 33

Automatic immediate log output ........................... 34

Output the logs subsequently ............................... 34

Display protocol memory ...................................... 36

Read log files correctly ......................................... 36

Chapter 6 – Maintenance ................................... 38

Cleaning ............................................................... 38

Avoid formation of spots ....................................... 39

Use qualitatively high-grade feed water................ 39

Replacing the door seal........................................ 40

Aligning the door seal sealing lip .......................... 40

Changing the sterile filter...................................... 41

Cleaning the filter in the chamber......................... 43

Maintenance......................................................... 43

Chapter 7 – Operating pauses........................... 44

Sterilization frequency .......................................... 44

Pause times.......................................................... 44

Shut-down ............................................................ 45

Transport .............................................................. 45

Re-startup after change of locality........................ 45

Chapter 8 – Function test................................... 46

Automatic function test ......................................... 46

Manual function test ............................................. 46

Testing in daily operation...................................... 47

Vacuum test.......................................................... 47

Bowie & Dick test.................................................. 47

Helix test body system MELAcontrol /PRO........... 48

Display water quality............................................. 48

Chapter 9 – Errors .............................................. 49

A warning is not an error ...................................... 49

Warning messages............................................... 49

Error message ...................................................... 49

Before you call...................................................... 50

No display on the screen ...................................... 56

Too large feed water consumption ....................... 56

Bad drying results................................................. 56

Glossary .............................................................. 57

Technical Data .................................................... 60

Appendix A – Accessories................................. 61