Melink Intelli-Hood Controls User manual

Melink Corporation (513) 527-7020 www.melinkcorp.com

REFERENCE GUIDE

Rev. 1.6

Table of Contents

Section 1: Intelli-Hood Operation and Simplissimo Settings

Section 2: Troubleshooting/ Component Compatibility

Section 3: Drive Connections

Section 4: Drive Programming

Section 5: Helpful Phone Numbers and Contact Information

Section 1:

Intelli-Hood Operation and

Simplissimo Settings

Operation/Service Specifications for Melink Intelli-Hood Operator

1-1

KEYPAD OPERATION

•LIGHTS Button - Turns hood lights on and off if I/O board output is tied into the hood light circuit. Also

turns APU blowers on and off.

•FANS Button - Turns the fans on and off. Also turns APU blowers on and off.

•BYPASS Button - Turns fans on in bypass mode. If the processor is running, then the 7-segment

display will show a 'E' for bypass mode and the bar graph will show VFD speed at 100% (blinking).

Also turns on APU blowers.

•SELECT (up & down arrows)

oIn SETUP mode, this switch will scroll through main menu item numbers (0-9) on the seven-

segment display and scroll through the setup selections on the bar graph.

oIn normal operating mode, this switch will display scrolling temperatures a single time for each

hood on the bar graph; after which it displays scrolling % fan speeds.

•ENTER

oIn SETUP mode, this switch will validate a selection.

oIn normal operating mode, this switch will display average VFD speed on the bar graph.

•To enter SETUP mode, press both the SELECT key and the ENTER key for 10 seconds.

•To restore setup defaults:

oMust be in setup mode.

oMust be at the flashing '0'.

oPress and hold the SELECT key for 10 seconds.

oA 'd' will show on the 7-segment display.

oHold the SELECT key for another 10 seconds.

oDefault data will be stored.

o2 beeps

Operation/Service Specifications for Melink Intelli-Hood Operator

1-2

•To reset average VFD speeds:

oMust be in setup mode.

oMust be at the flashing '0'.

oPress and hold the ENTER key for 10 seconds.

oA 'r' will show on the 7-segment display.

oHold the ENTER key for another 10 seconds.

oAverage VFD speeds will be reset.

o2 beeps

•To lock programming:

oPress and hold the both the SELECT key and the ENTER key for 10 seconds.

oDisplay a flashing '0'.

oPress and hold the both the SELECT key and the ENTER key for 10 seconds.

oA 'L' will show on the 7-segment display

oPress ENTER to exit setup mode

•To unlock programming:

oPress and hold the both the SELECT key and the ENTER key for 10 seconds.

oDisplay 'L'.

oPress and hold the both the SELECT key and the ENTER key for 10 seconds.

oA flashing '0' will show on the 7-segment display

oPress ENTER to exit setup mode

•Program Editing While Locked:

oOnly temperature spans can be changed while programming is in the locked state.

oPress and hold the both the SELECT key and the ENTER key for 10 seconds.

oDisplay 'L'.

oPress the SELECT key. The 'L' display will change to '1' which signifies hood #1.

oTo select a different hood, press the SELECT key. The '1' display will change to '2' which

signifies hood #2. Press SELECT again to change to hood #3 and so on.

oTo edit the temperature span of a particular hood, press the ENTER key when the

appropriate hood number is displayed. The bar graph will light showing the current

temperature span setting. Use the SELECT key to scroll to a different span. Press ENTER

to store the new span. The display will revert back to hood selection.

oTo exit programming, use the SELECT key to scroll to display 'L'. Press ENTER to exit

programming.

•Summer/Winter (3 Gang Coverplates Only)

oThis switch will activate the external heat circuit when closed. It will turn off the external heat

circuit when open.

Operation/Service Specifications for Melink Intelli-Hood Operator

1-3

Simplissimo Settings

Hood Settings

Exhaust Temp Span - This sets up the temperature span for modulating VFD speed between its set

minimum and maximum based on temperature. The span has a low value of 75oF and a maximum of up

to 150oF. Auto Span automatically sets the temperature span based on average VFD speeds over

periods of approximately one day (starting with the 75-110 setting).

Min Speed - This sets up the minimum speed that the VFD will run. Min speed must be less than

maximum speed. DF means that when fans are turned on, the fans will run at 100% for 1 minute and

then return to their normal minimum speed. Maximum minimum speed is 80%.

Max Speed - This sets up the maximum speed that the VFD will run. Max speed must be greater than

minimum speed. Minimum maximum speed is 50%.

Exhaust Temp. Alarm #1 - This sets up the first temperature set point for the 24 VDC exhaust alarm.

Set pt #1 must be less than set pt #2. If the operator tries to set up a set pt #1 greater than or equal to set

pt #2, the error beep will sound. When the setpoint is reached, and the bar graph corresponding to the

hood in alarm will flash and 24Vdc will be sent to the corresponding I/O board terminals. If a setting with

the AUD prefix is selected, then when the hood's speed is being displayed on the bar graph and the

exhaust temperature exceeds the temperature set point #1, the keypad's beeper will sound. The keypad

will go through 12 iterations of beeping the beeper for the alarm.

Exhaust Temp. Alarm #2 - This sets up the second temperature set point for the auxillary 24 VDC

output. Set pt #2 must be greater than set pt #1. If the operator tries to set up a set pt #2 less than or

equal to set pt #1, the error beep will sound. When the setpoint is reached, 24Vdc will be sent to

corresponding I/O board terminals.

No. Hood Sensors - This sets up the number of temperature sensors and optics for the given hood. The

hood can have from 1 to 4 temperature sensors and 1 optics sensor; or it can have from 1 to 4

temperature sensors only; or it can have just 1 optic sensor. Optic Channel 1 is always allocated to Hood

1, Optic Channel 2 is always allocated to Hood 2, and so on. Temperature Channel 1 is always allocated

to Hood 1, Temperature Channel 2 is always allocated to Hood 2, and so on.

Note: It is typically not good practice to connect temperature sensors from different hoods together since

the signal is averaged across all sensors connected to that particular channel, potentially having a

detrimental effect on system response to heat.

Auto Fan On/Off – Sets fans to either turn on or off automatically based on either temperature or a

preset timer (turns fans off after set number of hours). In Heat 0 or Heat 5, system will resume typical

operation when exhaust air temperature of any hood is greater than or equal to 90oF. If exhaust air

temperature is less than or equal to 75oF, while the system is on, the either a signal for either 0% or 5%

will be sent to the VFD. If all hoods are at this level, the system will turn off. Note: when fan button is

pressed, there is a ten minute delay until the temperature sensor becomes active for auto on/off

operation.

Send 4-20mA / 0-10V - This sets up the channel for which the VFD is connected for this hood. If 0, then

there is no VFD for the hood. VFD 1 - VFD 4 are outputs on the master Autocal board. VFD 5 - VFD 8

are outputs on the slave Autocal board. If Multiple is selected, then the VFD signal will follow that of the

previous hood (e.g. If Hood 1 is set up with VFD 1 as the output to its exhaust fan, the Hood 2 may be set

to multiple to follow VFD 1 for the supply fan).

Short Cycle Hood Ratio - This sets up the short cycle hood ratio.

Operation/Service Specifications for Melink Intelli-Hood Operator

1-4

System Settings

Auxiliary VFD Output - This sets up how the signal is determined for the auxiliary VFD output.

•No - No auxiliary output

•Average - send the average of the used VFDs on board.

•Highest - send the highest of the used VFDs on board

•Lowest - send the lowest of the used VFDs on board

•VFD1 - send the same signal that is going to VFD 1

•VFD2 - send the same signal that is going to VFD 2

•VFD3 - send the same signal that is going to VFD 3

•VFD4 - send the same signal that is going to VFD 4

Auxiliary VFD Input - This sets up how the VFDs will respond to the auxiliary 4-20 mA VFD input.

•No - No auxiliary input

•Add - Add aux input to each VFD output

•Sub - Subtract aux input from each VFD output

•Average - Average aux input with each VFD output

Hang Time - Amount of time fans will be left at max speed and smoke alarm will be activated after

detection of smoke.

Relay Input - If #1 (No), then the remote input terminals are used for nothing. If #2 (Remote On/Off),

then the remote input terminals are used for remotely turning the fans on and off. If settings 3 through 5

(3 through 9 on V4.5 chips) are used, then the remote input terminals are used as inputs for a relay.

When this relay is closed then the minimum speed of 50%, 75%, 90%, etc. is used instead of the

minimum speed called out in hood menu #2. The external heat circuit is activated when the relay is

closed. When the relay is open then the minimum speed in hood menu #2 is used and the external heat

circuit is turned off.

Bypass Timer - If item 2 - 10 are selected this sets the bypass timeout. This sets the amount of time to

leave the system in bypass mode after the bypass switch on the front panel is pressed. The dipswitch on

the Autocal II board must be in the bypass timer position. Bypass mode can be turned off by pressing the

bypass switch again. If item 1 is selected then bypass mode can only be turned off by pressing the

bypass switch again.

Comfort Mode - When the comfort mode is enabled: if kitchen temperature is > 75 and outside

temperature < 75, then the VFD speed is increased up to max speed with a ramp of 1 minute. If the

kitchen temperature cools to < 70 or the outside temperature increases to >75, then reduce the VFD

speed back to automatic control. The kitchen and outside temperature sensors can be wired to the I/O

board terminal block (item #3) or to Temp #3 (kitchen) and Temp #4 (outside) (selection #4). Selection #1

and #2 will disable the comfort mode. Selection #2 will allow the MUA temperature sensor to be wired to

Temp #4 for short cycle hoods.

Miscellaneous - If item #1 is selected then there are no miscellaneous functions enabled.

•Win SB (item #2) - If kitchen temperature is less than or equal to 70, then the temperature

span automatically increases to the next higher range. If the kitchen temperature is greater

than 75, then the temperature span automatically revert back to original set point.

•Int Bar (item #3) - The bargraph displays the speed that the system is sending to the drive

instead of reading the speed from the drive. This will disable the VFD fault capability.

Alarm #2 Output - This sets up the function of the auxiliary 24 VDC output.

•Temp - Output is used as temperature set point #2 alarm.

•Smoke - Output is used as a smoke alarm.

•Starter - Output is used as control for a magnetic motor starter. The motor starter is turned

on if any of the exhaust temperatures exceed 90oF or smoke is detected or BYPASS mode is

Operation/Service Specifications for Melink Intelli-Hood Operator

1-5

selected with the processor running. It will be turned off if all of the exhaust temperatures fall

below 85oF or after the hang time on the optics has expired. The motor starter can also

operate in conjunction with the auto mode such that it turns on and off automatically with

either heat or turns off after a selected time interval, all hoods must turn off to turn off the

motor starter and one hood must turn on to turn on the motor starter.

•Damper - Output is used to control a damper. When the fans are turned on the damper turns

on. When the fans are turned off the damper is off.

•Kitch<68 - Output is used to control a MUA heat unit. When the kitchen temperature is less

than 60 F, the MUA heat unit is on. When the kitchen temperature is greater than 65 F, the

MUA heat unit is off.

•Mom Rel - Output is used to control a momentary relay. When the fans are turned off, the

relay output is turned on for 3 seconds and then turned off.

•Fault (V4.5 only) – Output is energized whenever a fault is displayed on the keypad. (Note:

enabling the internal bar setting will disable VFD faults)

Optics Alignment - This will be entered when the installer is aligning the optics sensors. When hood 1 is

selected, then the 7-segment display will show a "1" and the bar graph will display the strength of the

signal being read by optics channel #1. Each bar will represent a return voltage of 0.3VDC. Ideally,

adjust gain on optics to read between three and seven bars of strength. Aligning hoods 2 - 8 will work in

the same manner.

DISPLAY MODES

Setup Mode - Displays setup information as the user enters it. It will stay in this mode until setup mode is

ended.

Display Average VFD Speed (Left arrow key [ENTER] pressed while not in SETUP)

•Bar graph will display ‘exponential average’ VFD speed (blinking) for each hood.

•7-segment display will display hood number (non-blinking).

•After all hoods have been displayed, the overall average speed will be displayed. The 7-

segment display will show a 'o'.

•Average VFD speed will be scaled to display 0 to 100% with each LED representing 10%.

•After all average VFD speeds have been displayed, the display mode will revert back to

NORMAL MODE.

Display Temperature (Up & Down arrow key [SELECT] pressed while not in SETUP)

•Bar graph will display temperature (non-blinking) for each hood.

•7-segment display will display hood number (non-blinking).

•After all hoods have been displayed, the kitchen temperature will be displayed. The 7-

segment display will show a 'c'. The outside temperature will be displayed next. The 7-

segment display will show a 'o'.

•Temperature will be displayed with only one bar representing the temperature level.

•After all temperatures have been displayed, the display mode will revert back to NORMAL

MODE.

Operation/Service Specifications for Melink Intelli-Hood Operator

1-6

Bar Graph VFD Speed Exhaust Temp

V3.7-V4.4/V4.5 Kitchen Temp

(c) Outside Temp (o) Optics Align.

Top 91-100% 146+/150+ 96+ 91+ 2.71+V

81-90% 141-145/140-149 91-95 81-90 2.41V-2.7V

71-80% 136-140/130-139 86-90 71-80 2.11V-2.4V

61-70% 131-135/120-129 81-85 61-70 1.81V-2.1V

51-60% 126-130/110-119 76-80 51-60 1.51V-1.8V

41-50% 121-125/100-109 71-75 41-50 1.21V-1.5V

31-40% 116-120/90-99 66-70 31-40 0.91V-1.2V

21-30% 111-115/80-89 61-65 21-30 0.61V-0.9V

11-20% 106-110/70-79 56-60 11-20 0.31V-0.6V

Bottom 0-10% 100-105/60-69 50-55 0-10 0.00V-0.3V

Normal Display Mode

•Bar graph will display VFD speed (non-blinking) for each hood.

•7-segment display will display hood number (non-blinking).

•If there is a fault with the hood currently being displayed then the hood number will be

displayed on the 7-segment display (non-blinking), the fault(s) will be displayed on the bar

graph (non-blinking), and the fault led will be ON.

A Temperature fault will light the bottom LED of the bar graph.

A VFD fault will light the second LED of the bar graph.

There will be 3 beeps every hour as long as there is a fault on any hood.

•If the BYPASS switch is pressed, then the 7-segment display will display 'E' and bar graph

will display VFD speed (blinking).

•If the hood being displayed is causing an alarm condition (exhaust or smoke), then the bar

graph and the 7-segment display will be blinking.

•If a given hood's optic channel cannot be calibrated, then the clean LED will flash green/red.

Otherwise the clean LED will be green.

•VFD speed will be scaled to display 0 to 100% with each LED representing 10%.

Calibration

•Fans will calibrate when they are turned on or every 24 hours if fans are running at minimum

speed at that given time. If fans are not running at minimum speed at the time recalibration is

supposed to occur after 24 hours, then calibration will wait for a subsequent 24 hour time

when the fans are running at minimum speed. If fans cannot calibrate after 3 days in

succession, then the clean LED will blink red/green and the fans will go to 100% speed.

•If any given optics channel cannot calibrate, the VFD associated with that hood will run at

100% speed and flash the clean LED red/green when this hood's VFD speed is being

displayed.

0 -NA

9 - NA

8 - NA

7 - NA

6 - NA

5 - NA

4 - Average

3 - Subtract

2 - Add

1 - No

%

10 - NA

9 - NA

8 - VFD4

7 - VFD3

6 - VFD2

5 - VFD1

4 - Lowest

3 - Highest

2 - Average

1 - No %

%

10 - NA

9 - NA

8 - NA

7 - Mom Rel

6 - Kitch<68

5 - Damper

4 - Starter

3 - Smoke

2 - Temp

1 - No

%

%%

0 - 75% DF

9 - 50% DF

8 - 80%

7 - 70%

6 - 60%

5 - 50%

4 - 40%

3 - 30%

2 - 20%

1 - 10%

10 - NA

9 - NA

8 - NA

7 - NA

6 - Bio-Link

5 - Thermostat &90%

4 - Thermostat &75%

3 - Thermostat &50%

2 - Remote On/Off

1 - No

10 - NA

9 - NA

8 - NA

7 - NA

6 - NA

5 - NA

4 - Yes -Temp #3 & #4

3 - Yes -Term #6,7,8,9,10

2 - No - S.Cycle Temp #4

1 - No

10 - NA

9 - NA

8 - NA

7 - NA

6 - NA

0 - Exit

4 Hood 4 etc

3 - Hood 3

2 - Hood 2

1 - Hood 1

0 -NA

9 - NA

8 - NA

7 - 180 Sec

6 - 90 Sec

5 - 60 Sec

4 - 25 Sec

3 - 15 Sec

2 - 10 Sec

1 - 5 Sec

HOOD

%

0 - Exit to Main Menu

9 - Short Cycle Hood Ratio

8 - Send 4-20ma / 0-10v

7 - Auto Fan - On/Off

6 - No. Hood Sensors

5 - Exhaust Temp. Alarm #2

4 - Exhaust Temp. Alarm #1

3 - Max. Fan Speed

2 - Min. Fan Speed

1 - Exhaust Temp. Span 0 - NA

9 - NA

8 - Auto Span

7 - 75-150F

6 - 75-140F

5 - 75-130F

4 - 75-120F

3 - 75-110F

2 - 75-100F

1 - 75-90F

%

0 - Exit to Main Menu

9 - Optics Alignment Check

8 - Alarm #2 Output (24vdc)

7 - Miscellaneous

6 - Comfort Mode Sensors

5 - Bypass Timer

4 - Relay Input (Dry)

3 - Optics Hang Time

2 - 4-20 ma Aux Input

1 - 4-20ma / 0-10v Aux Out

0 - AUD350F

9 - AUD300F

8 - AUD250F

7 - AUD200F

6 - AUD150F

5 - 350F

4 - 300F

3 - 250F

2 - 200F

1 - 150F

0- 8 Hr

9 - 7 Hrs

8 - 6 Hrs

7 - 5 Hrs

6 - 4 Hrs

5 - 3 Hrs

4 - 2 Hrs

3 - 1 Hr

2 - 30 Min

1 - No

%

10 - NA

9 - NA

8 - NA

7 - NA

6 - NA

5 - NA

4 - NA

3 - Int Bar

2 - Win SB

1 - No

%

0 - NA

9 - NA

8 - 80%

7 - 70%

6 - 60%

5 - 50%

4 - 40%

3 - 30%

2 - 20%

1 - No

%

%

MELINK

Intelli-Hood Operator

TM

0 - Exit Setup

9 - System

8 - Hood 8

7 - Hood 7

6 - Hood 6

5 - Hood 5

4 - Hood 4

3 - Hood 3

2 - Hood 2

1 - Hood 1

Main Menu Hood Menu

Selections

S

IMPLISSIMO

TM

%%%

%

Default Values are Underlined 124

%

0 - No

9 - Multiple

8 - VFD 8

7 - VFD 7

6 - VFD 6

5 - VFD 5

4 - VFD 4

3 - VFD 3

2 - VFD 2

1 - VFD 1

8 %

0- 14 Hrs

9 -12 Hrs

8 -10 Hrs

7 -8 Hrs

6 -6 Hrs

5 -4 Hrs

4 -2 Hrs

3 -Heat 5

2 -Heat 0

1 - No

7%

0 - No

9 -1O

8 -4T1O

7 -3T1O

6 -2T1O

5 -1T1O

4 -4T

3 -3T

2 -2T

1 -1T

6%

0 -NA

9 -NA

8 -NA

7 -NA

6 -400F

5 -350F

4 -300F

3 -250F

2 -200F

1 -150F

5

1234

5

6

7

8

9

System Menu

0 -100%

9 - 90%

8 - 80%

7 - 70%

6 - 60%

5 - 50%

4 - NA

3 - NA

2 - NA

1 - NA

%3

9

99

9

Version 01.01.01

(V4.4 Software)

%

1-7

0 -NA

9 - NA

8 - NA

7 - NA

6 - NA

5 - NA

4 - Average

3 - Subtract

2 - Add

1 - No

%

10 - NA

9 - NA

8 - VFD4

7 - VFD3

6 - VFD2

5 - VFD1

4 - Lowest

3 - Highest

2 - Average

1 - No %

%

0 - NA

9 - NA

8 - Fault

7 - Mom Rel

6 - Kitch<68

5 - Damper

4 - Starter

3 - Smoke

2 - Temp

1 - No

%

%%

0 - 75% DF

9 - 50% DF

8 - 80%

7 - 70%

6 - 60%

5 - 50%

4 - 40%

3 - 30%

2 - 20%

1 - 10%

0 - NA

9 - Thermostat &90%

8 - Thermostat &80%

7 - Thermostat &75%

6 - Thermostat &70%

5 - Thermostat &65%

4 - Thermostat &60%

3 - Thermostat &50%

2 - Remote On/Off

1 - No

10 - NA

9 - NA

8 - NA

7 - NA

6 - NA

5 - NA

4 - Yes -Temp #3 & #4

3 - Yes -Term #6,7,8,9,10

2 - No - S.Cycle Temp #4

1 - No

10 - NA

9 - NA

8 - NA

7 - NA

6 - NA

0 - Exit

4 Hood 4 etc

3 - Hood 3

2 - Hood 2

1 - Hood 1

0 -NA

9 - NA

8 - NA

7 - 180 Sec

6 - 90 Sec

5 - 60 Sec

4 - 25 Sec

3 - 15 Sec

2 - 10 Sec

1 - 5 Sec

HOOD

%

0 - Exit to Main Menu

9 - Short Cycle Hood Ratio

8 - Send 4-20ma / 0-10v

7 - Auto Fan - On/Off

6 - No. Hood Sensors

5 - Exhaust Temp. Alarm #2

4 - Exhaust Temp. Alarm #1

3 - Max. Fan Speed

2 - Min. Fan Speed

1 - Exhaust Temp. Span 0 - NA

9 - NA

8 - Auto Span

7 - 75-150F

6 - 75-140F

5 - 75-130F

4 - 75-120F

3 - 75-110F

2 - 75-100F

1 - 75-90F

%

0 - Exit to Main Menu

9 - Optics Alignment Check

8 - 24 VDC Output #1

7 - Miscellaneous

6 - Comfort Mode Sensors

5 - Bypass Timer

4 - Relay Input (Dry)

3 - Optics Hang Time

2 - 4-20 ma Aux Input

1 - 4-20ma / 0-10v Aux Out

0 - AUD350F

9 - AUD300F

8 - AUD250F

7 - AUD200F

6 - AUD150F

5 - 350F

4 - 300F

3 - 250F

2 - 200F

1 - 150F

0- 8 Hr

9 - 7 Hrs

8 - 6 Hrs

7 - 5 Hrs

6 - 4 Hrs

5 - 3 Hrs

4 - 2 Hrs

3 - 1 Hr

2 - 30 Min

1 - No

%

10 - NA

9 - NA

8 - NA

7 - NA

6 - NA

5 - NA

4 - NA

3 - Int Bar

2 - Win SB

1 - No

%

0 - NA

9 - NA

8 - 80%

7 - 70%

6 - 60%

5 - 50%

4 - 40%

3 - 30%

2 - 20%

1 - No

%

%

MELINK

Intelli-Hood Operator

TM

0 - Exit Setup

9 - System

8 - Hood 8

7 - Hood 7

6 - Hood 6

5 - Hood 5

4 - Hood 4

3 - Hood 3

2 - Hood 2

1 - Hood 1

Main Menu Hood Menu

Selections

S

IMPLISSIMO

TM

%%%

%

Default Values are Underlined 124

%

0 - No

9 - Multiple

8 - VFD 8

7 - VFD 7

6 - VFD 6

5 - VFD 5

4 - VFD 4

3 - VFD 3

2 - VFD 2

1 - VFD 1

8 %

0- 14 Hrs

9 -12 Hrs

8 -10 Hrs

7 -8 Hrs

6 -6 Hrs

5 -4 Hrs

4 -2 Hrs

3 -Heat 5

2 -Heat 0

1 - No

7%

0 - No

9 -1O

8 -4T1O

7 -3T1O

6 -2T1O

5 -1T1O

4 -4T

3 -3T

2 -2T

1 -1T

6%

0 -NA

9 -NA

8 -NA

7 -NA

6 -400F

5 -350F

4 -300F

3 -250F

2 -200F

1 -150F

5

1234

5

6

7

8

9

System Menu

0 -100%

9 - 90%

8 - 80%

7 - 70%

6 - 60%

5 - 50%

4 - NA

3 - NA

2 - NA

1 - NA

%3

9

99

9

Version 02.00.00

(V4.5 Software)

%

1-8

Section 2:

Troubleshooting And Component

Compatibility

OPTICS FAULT

3RD LED

CLEAN

FAULT HOOD

%

KEYPAD SHOWS

3RD LED AND

FAULT LIGHT

8

ITEMS TO CHECK:

TEMP FAULT

1ST LED

DRIVE FAULT

2ND LED

a. Determine which hood is not working - refer to digit next to bar graph.

b. Determine fan speed by counting # of bars illuminated on bar graph, if any.

c. Push 100% bypass switch to see if all fans go to full speed.

d. Check if exhaust fan on roof is running.

- Check if fan disconnect switch is turned on.

- Check if fan belt is adjusted for proper tension and replace if necessary.

- Check if motor is functional and replace if necessary.

a. Press the 100% bypass switch to return to the ‘auto mode’.

a. Press fan switch on Keypad to see if Keypad activates.

b. Check for tripped breaker that feeds the I/O Processor.

c. Open I/O Processor panel to verify power LED is on.

d. Check for tripped breaker inside I/O Processor. Reset if necessary.

a. Press fan switch on Keypad to see if Keypad activates.

b. Check breakers for I/O Processor and exhaust fans.

c. Check display on Drives for a fault (ie.. OC1,OH2).

e. Press the Drive reset switch, or turn off breaker and turn back on after 30 sec.

f. Refer to Troubleshooting @ Drive Keypad on other side.

a. Determine which hood has a ‘temp fault’ - refer to the digit next to bar graph.

b. Check cable connections between each Temp Sensor and I/O Processor.

c. Check to see if resistance at Temp Sensor is about 100 Ohms.

d. Check Simplissimo hood menu #6 is set to correct number of Temp Sensors.

a. Determine which hood has a ‘drive fault’ - refer to the digit next to bar graph.

b. Check cable connections between each Drive and I/O Processor.

c. Check display on Drives for a fault (i.e..OC1.OH2).

d. Press Drive reset switch, or turn off breaker and turn back on after 30 sec.

e. Refer to Troubleshooting @ Drive Keypad on other side.

a. Determine which hood needs Optics cleaned - refer to digit next to bar graph

b. Remove Optic covers for that hood and clean lenses with a clean soft cloth.

c. Press the fan switch off… and on again to recalibrate the Optics.

a. Check for blockage of infrared beam, i.e. cleaning rag or fire suppression pipe.

b. Check ‘gain’ switch on Optic receiver board to verify proper hood length.

c. Check alignment of Optics in Simplissimo System Menu #9.

d. Check cable connections between Optics and I/O Processor.

… press the fan switch off and on again to recalibrate the Optics.

.

KEYPAD

APPEARS

NORMAL

BUT FANS

NOT RUNNING

KEYPAD IS

BLANK AND

FANS ARE

RUNNING

KEYPAD IS

BLANK AND

FANS ARE

NOT RUNNING

KEYPAD

DISPLAYS

“E” AND

BARGRAPH

FLASHING

PROBLEM:

CLEAN

FAULT HOOD

%

CLEAN

FAULT HOOD

%

HOOD

CLEAN

FAULT HOOD

%

CLEAN

FAULT HOOD

%

CLEAN

FAULT HOOD

%

CLEAN

FAULT HOOD

%

HOOD

KEYPAD SHOWS

1ST LED AND

FAULT LIGHT

KEYPAD SHOWS

2ND LED AND

FAULT LIGHT

4

1

5

HOOD

CLEAN

FAULT %

CLEAN

LIGHT

FLASHES

RED/GREEN

7

2

3

6

TROUBLESHOOTING

@ MELINK KEYPAD

MELINK

Intelli-Hood Operator

R

Rev. 10-01

2-1

PROBLEM: ITEMS TO CHECK:

F4,

Under Voltage

TROUBLESHOOTING

@ DRIVE KEYPAD

MELINK

Intelli-Hood Operator

R

Esc Sel

PROGRAM

REV

RUN

FWD

FAULT

VOLTS

AMPS

HERTZ

a. Check AC power input to drive for low voltage or line power interruption.

a. Check AC power input to drive for high line voltage . Assure deceleration

time is set at 60 sec.

a. Output current to motor exceeds limit set by parameter P033. Check motor

and fan for conditions that may cause excessive motor current.

b. Check for appropriate Start Boost (A084).

a. Check to see if cooling fan is running. If not, replace fan.

b. Check for blocked or dirty heat sink fins. Verify that ambient temperature is

not over 104deg. F.

a. The drive output current has exceeded the hardware current limit. Check to

see if the drive is sized properly for the motor.

b. Check for appropriate Start Boost (A084).

a. Check the motor and external wiring for a grounded condition.

a. Drive rating of 150% for 1 min. or 200% for 3 sec. has been exceeded.

Reduce load or extend Acceleration time.

a. Check wiring to RS485 port

b. Check wiring connections

c. Verify I/O Processor is operating properly

Under Voltage

Over Voltage

Motor Overload

Heatsink

Over Temp.

Hardware

Overcurrent

Communication

Loss

Ground Fault

Drive Overlaod

F5,

Over Voltage

F7,

Motor Overload

F8,

Heatsink

Over Temp.

F12,

Hardware

Over Current

F13,

Ground Fault

F64,

Drive Overload

F81,

Communication

Loss

2-2

PROBLEM: ITEMS TO CHECK:

a. Remove run command to Drive by turning off fan switch on Melink Keypad.

Green light on Drive that says RUN should go out. Press PRG/RESET

on drive to remove fault. Or, turn off breaker to drive and then back

on again after 30 sec.

b. If OC 1 still occurs check if motor circuit is shorted or grounded.

c. If OC 1 still occurs verify that program for torque boost is set for fan

application (consult with Melink on exact function # based on Drive type).

d. If OC 1 still occurs verify that program for acceleration is set for minimum of

5-10 seconds (consult with Melink on exact function # based on Drive type).

a. Remove run command to Drive by turning off fan switch on Melink Keypad.

Press PRG/RESET on Drive to remove fault. Or, turn off breaker to Drive and

then back on again after 30 sec.

b. If OC2 still occurs check if motor circuit is shorted or grounded.

c. If OC 2 still occurs verify that program for deceleration is set for minimum of 60

seconds (consult Melink on exact function # based on Drive type).

a. Remove run command to Drive by turning off fan switch on Melink Keypad.

Press PRG/RESET on Drive to remove fault. Or, turn off breaker to Drive and

then back on again after 30 sec.

b. If OC3 still occurs check if motor circuit is shorted or grounded.

c. If OC3 still occurs check if there is a load fluctuation being caused by bad

bearings and or unevenly balanced fan wheel.

a. Remove run command to drive by turning off fan switch on Melink Keypad.

Press PRG/RESET on drive to remove fault. Or, turn off breaker to drive and

then back on again after 30 sec.

b. If OU still occurs verify that the actual supply voltage to the Drive is within the

allowable rated voltage of the Drive.

a. Remove run command to drive by turning off fan switch on Melink Keypad.

Press PRG/RESET on drive to remove fault. Or, turn off breaker to drive and

then back on again after 30 sec.

b. If OH2 still occurs verify there is continuity between the THR and CM terminals.

A jumper or NC relay for the fire suppression system should be installed.

a. Remove run command to drive by turning off fan switch on Melink Keypad.

Press PRG/RESET on drive to remove fault. Or, turn off breaker to drive and

then back on again after 30 sec.

b. If OL still occurs verify that program for overload protection is set at the FLA

rating of the motor (consult Melink on exact function # based on Drive type).

OC 1,

over current

during

acceleration

OC 2,

over current

during

deceleration

OC 3,

over current

at constant

speed

OU,

over voltage

protection

OH2,

external

alarm

input

OL,

overload

protection

TROUBLESHOOTING

@ DRIVE KEYPAD

MELINK

Intelli-Hood Operator

R

PANEL

CONTROL PRG. MODE RUN

VA

HZ

r/sis s/sis

RUN

STOP

FUNC

DATA

P R G

RESET

2-3

Operation/Service Specifications for Melink Intelli-Hood Operator

2-4

Advanced Troubleshooting

This section will deal with phenomena that are not mentioned in the standard troubleshooting guide. The

following actions take a more subjective approach to the problems.

General Procedure For Isolating Bad Components

Temperature Sensors

•Verify correct number of sensors are programmed for the hood and that all plug-n-play

connections are secure.

•Ensure no “Y” cables are plugged in at the IOP. Plugging temperature “Y” cables in at the IOP

can cause erratic behavior due to the wiring used internally. Always plug these in at the sensor.

•Check resistance between Pin 1 and Pin 2 at the end of the cable plugged into the IOP.

Resistance value should be approximately 109Ωper sensor. If there is more than one sensor,

multiply 109Ωby the number of temperature sensors for that hood to get an approximate value.

oIf resistance is incorrect, check temperature probe and cable individually to determine

problem component and replace as necessary.

oIf issue is low resistance (i.e. approximately half to a third of expected value) and a “Y” is

being used, verify that a temperature “Y” is in place and not an APU “Y”. The APU “Y”

will put the resistances in parallel, effectively reducing it to the point that the system will

never operate at more than minimum speed on temperature.

•If temperature faults are still present after these checks, it is possible that the problem is coming

from the optic circuit (this has been known to happen in the past). To check for this condition,

eliminate any optics on non-calibrated channels in the Simplissimo programming as well as

disconnecting the cables from the IOP. If the system now runs fine, the culprit is probably in the

optics portion. If the system does not work, it is possibly a bad Autocal board that may need to

be replaced.

Optic Sensors

•Verify that the correct optic channels are programmed for the given system.

•Check optics alignment in Simplissimo System Menu #9.

oIf a strong signal is present (4-8 bars), verify that breaking the beam reduces the signal to

one bar.

oIf a weak signal (2-3 bars) or no signal (1 bar) is present, increase the gain setting on the

receiver.

•If system is running at full speed for no apparent reason, try re-calibrating the optics (turning

system on and off). Also try programming out the optics and re-testing the system.

oIf the system runs normally in temperature only, but at full speed with the optics then

check the voltage output from the receiver. There should be 1-2 volts (DC) between the

ground post on the Autocal board and the respective receiver points on the Autocal. The

test points are labeled RCV0 through RCV3 for channels 1 through 4 respectively. If the

voltage is below one volt with the gain setting at the appropriate level, the optic boards

will need to be replaced.

•If possible, switch optic boards from malfunctioning channel with boards from a working optic

channel. If the problem jumps with the optic boards, then the problem is with either the emitter or

receiver. If the problem does not move, then the optic boards are fine and more checks need to

be made:

oIf possible, try to isolate if the problem is in the cables by switching the optics “Y” (with all

existing cables attached) with a working channel. If the problem moves at this point, then

the problem can most likely be attributed to a bad cable. If the problem does not move at

this point then the Autocal board is probably malfunctioning and should be replaced.

oCheck cables: Use a “pigtail plug” (female plug with wires that can be twisted together for

a continuity check) to short two pins together and check for continuity at the other end of

the cable. Also check for shorts to other pins. The optic channel uses pins 1, 2, and 3 on

the 4-pin cables. Replace any bad cables and retest system.

Other Melink Control System manuals

Popular Control System manuals by other brands

DX Engineering

DX Engineering Top Ten Devices OPSWAPPER quick start guide

NAVIS

NAVIS NavDP 4000 Series Operation manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SLA3-ER Technical manual

ADB Safegate

ADB Safegate ACE2 user manual

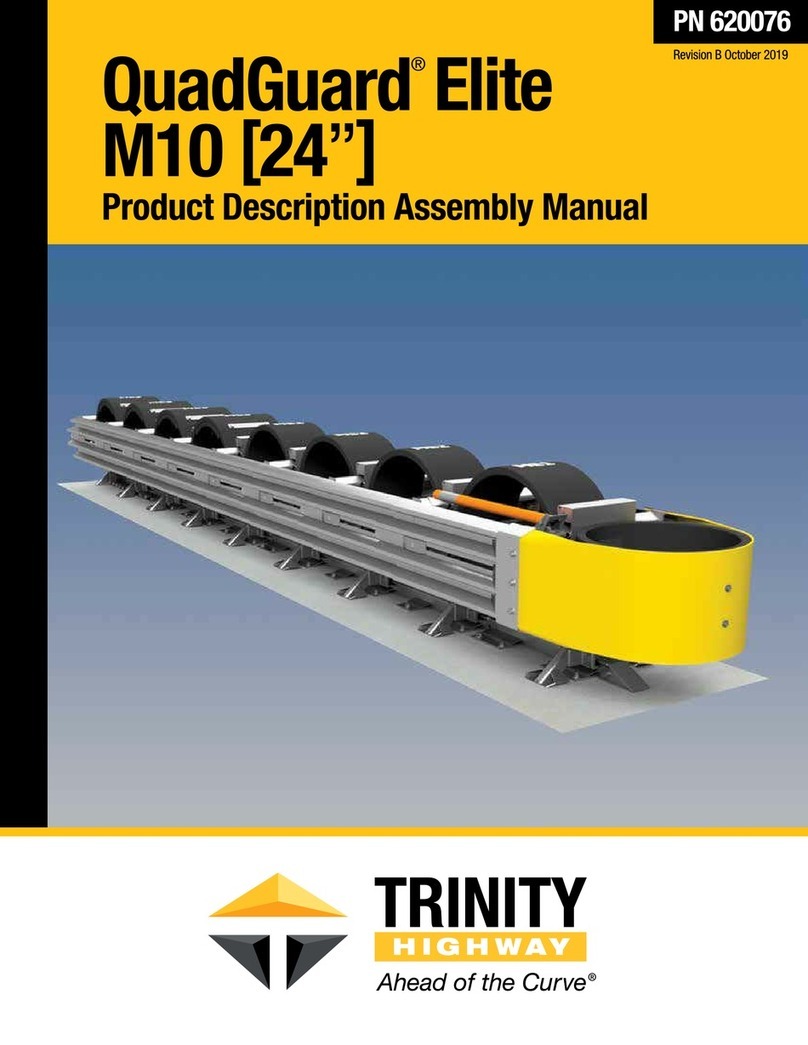

Trinity Highway

Trinity Highway QuadGuard Elite M10 Product Description Assembly Manual

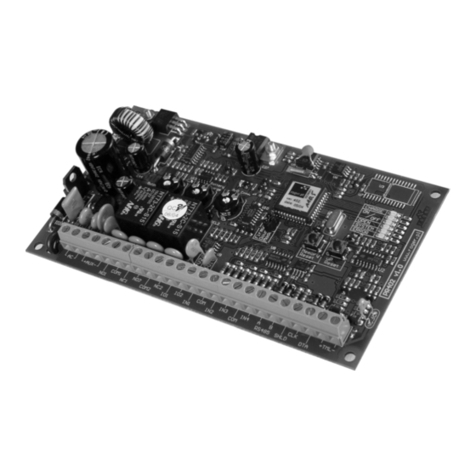

Roger

Roger CPR32-SE v2.0 operating manual

Extron electronics

Extron electronics TouchLink TLP Pro 520M user guide

Dill

Dill Retrofit TPMS manual

Hitachi

Hitachi YUTAKI ATW-YMM-01 Installation and operation manual

Condor

Condor 900 191 - V1.0 operating instructions

Carrier

Carrier ZONECC3ZAC01 Quick reference guide

Rise

Rise RANGER 500 installation manual