Menards PERFORMAX AntFi X60-2 User manual

06/2020© 2020 Menard, Inc., Eau Claire, WI 54703

To Reduce The Risk Of Injury, User Must Read And

Understand Operator’s Manual. Save These Instructions For Future Reference.

OPERATOR’S MANUAL

242-1487

CAUTION:

Auto-Darkening

Welding Helmet

Customer Service: 1-855-692-6872 Distributed by Menard, Inc. Eau Claire, WI 54703

Page 1

Page 4

Page 5

Page 6

Page 6

Page 7

Page 7

Page 7

Page 8

Page 8

Page 10

TABLE OF CONTENTS

SAFETY SYMBOLS

TECHNICAL SPECIFICATIONS

OVERVIEW

OPERATION

SELECT THE SHADE NUMBER

SELECT DELAY TIME

SELECT SENSITIVITY

PRE-WELDING CHECK & BATTERY TESTING

RECOMMENDED SETTINGS

MAINTENANCE

INSERT THE MAGNIFYING LENS

Page 10

INSPECTION

Page 1

SAFETY SYMBOLS

Indicates a potentially hazardous situation that, if not avoided, COULD result

in death or serious injury.

WARNING:

Indicates an imminently hazardous situation that, if not avoided, WILL result

in death or serious injury.

DANGER:

Indicates a potentially hazardous situation that, if not avoided, MAY result in

minor or moderate injury.

CAUTION:

Indicates important information, which if not followed, MAY cause damage to

equipment.

NOTICE:

Read and understand this entire instruction manual before attempting to assemble,install, operate

or maintain this tool. Failure to comply with the instructions may result in serious personal injury

and/or property damage!

The following signal words are used to emphasize safety warnings that must be followed when

using this tool:

IMPORTANT SAFETY INSTRUCTIONS

FUMES AND GASES can be hazardous !

Welding produces fumes and gases that are hazardous to your health.

• Keep your head out of the fumes. Do not breathe in the fumes.

• If inside, ventilate the area and/or use exhaust at the arc to remove welding

fumes and gases.

• If ventilation is poor, use an approved air-supplied respirator.

• Read the manufacturer’ s instructions for metals, consumables, coatings, cleaners, and

degreasers.

• Work in a confined space only if it is well ventilated, or while wearing an air-supplied respirator.

Always have a trained watchperson nearby. Welding fumes and gases can displace air and

lower the oxygen level causing injury or death. Be sure the breathing air is safe.

• Do not weld in locations near degreasing cleaning, or spraying operations. The heat and rays

of the arc can react with vapors to form highly toxic and irritating gases.

• Do not weld on coated metals, such as galvanized, lead, or cadmium plated steel, unless the

coating is removed from the weld area, the area is well ventilated, and if necessary, while

wearing an air-supplied respirator.The coatings and any metals containing these elements can

give off toxic fumes if welded.

SAFETY SYMBOLS

HOT PARTS can cause severe burns !

• Never touch hot parts bare handed.

• Allow adequate cooling period before touching work piece.

NOISE can damage hearing !

• Noise from some processes or equipment can damage hearing.

• Wear approved ear protection if noise level is high.

FLYING METAL can injure eyes !

• Wear ANSI approved safety glasses with side shields under your welding

helmet.

• Welding, chipping, wire brushing, and grinding cause sparks and flying metal.

As welds cool, they can throw off slag.

GENERAL INFORMATION

Auto-Darkening Welding Helmet does not

protect against severe impact hazards, such

as fractured grinding wheels or abrasive

discs,explosive devices or corrosive

liquids.Machine guards or eye splash

protection must be used when these hazards

are present.

The auto-darkening welding filters are

designed for Arc welding or cutting

applications.The unit is suitable for all Arc

welding processes such as MIG,MAG,

TIG,SMAW,Plasma Arc,and Carbon

Arc.

This auto-darkening welding helmet is not

recommended for "overhead" welding

applications,laser welding or Iaser cutting

applications.

In the event of electronic failure, the welder

remains protected against UV and IR

radiation according to shade 13.

The auto-darkening welding filter should

always be used with original inner and outer

cover lenses.

The manufacturer is not responsible for any

failure due to modifications to the welding

filter or the use of the filter from any other

manufacturer's helmet.

Page 2 Page 3

SAFETY SYMBOLS

Never look at arc welding without proper eye protection. Arc rays from the

welding process produce intense visible and invisible (ultraviolet and infrared)

rays that can burn eyes and Skin, Hot sparks fly off from the weld and can burn

eyes and skin.

Wear a welding helmet fitted with a proper shade of filter to protect your

face and eyes when welding or watching.

• Wear approved safety glasses with side shields under your helmet.

• Use protective screens or barriers to protect others from flash and glare, warn others in the area

not to watch the arc.

• Wear protective clothing made from durable, flame resistant materials, leather welding gloves

and full foot protection.

• Always keep a fire extinguisher readily available and watch for fire.

• Protect yourself and others from flying sparks and hot metal.

• Do not weld where flying sparks can strike flammable material.

• Remove all flammable materials from the welding area. If this is not possible, tightly cover them

with approved covers.

• Be alert that welding sparks and hot materials from welding can easily go through small cracks

and openings to adjacent areas.

• Be aware that welding on a ceiling ,floor, bulkhead, or partition can cause fire on the hidden

side.

• Do not weld on closed containers such as tanks, drums, or pipes; unless they are properly

prepared according to AWS F4.1 standards.

• Connect work cable to the work as close to the welding area as practical to prevent welding

current from traveling long, possibly unknown paths and causing electric shock and fire

hazards.

• Never use arc welder to thaw frozen pipes.

• Remove electrode from holder when not in use.

• Wear oil-free protective garments such as leather gloves, heavy shirt, trousers with no cuffs,

high shoes, and a cap.

• Remove any combustibles, such as butane lighters or matches, from yourself and the

surroundings near the welding location before doing any welding.

• Welding or cutting equipment produces fumes or gases which contain chemicals known to the

State of California to cause birth defects and, in some cases, cancer. (California Health & Safety

Code Section 25249.5 et seq.)

California Proposition 65 Warnings !

ARC RAYS can burn eyes !

Welding on closed containers, such as tanks, drums, or pipes, can cause

them to explode.Sparks can fly off from the welding arc. The flying sparks,

hot work piece, and hot equipment can cause fires and burns, Accidental

contact of electrode to metal objects can cause sparks, explosion,

overheating,or fire. Check and be sure the area is sale before doing any

welding.

WELDING can cause fire or explosion !

TECHNICAL SPECIFICATIONS TECHNICAL SPECIFICATIONS

OVERVIEW

WARNING:

NOTICE:

MARKING EXPLAINED

This is a sample of EN379 marking only. For the product you are

using, please refer to the marking information on the filter.

ADF Model

Viewing Area

Cartridge Size

Light State

Optical Specifications

Dark State

UV/IR Protection

Sensors

Grinding

Battery Type

Sensitivity Control

Solar Cell

Delay Control

TIG Rating

Operation Temperature

Storage Temperature

Standards Compliance

Weight

Inner cover lens

Outer cover lens

AntFi X60-2

98mm x44mm/3.86" x1.73"

110 x90 x9mm /4.33" x3.54" x0.35"

Shade DIN 4

1/1/1/2

Variable Shade 5~9/9~13

Permanent Shade DIN 13

Shade DIN 4

2 xCR 2032 ( Replaceable)

Knob Adjustable

Yes

0.1-1.0 Seconds Continuously Adjustable

-5°C to +55°C (23° F to 131° F)

-20°C to +70°C (-4° F to 158° F)

4

>2Amp

ANSI Z87.1-2015 & CSA Z94.3-2015

& CE EN379:2009-07

18.20oz/516g

99.3 x 45.4 x 1mm/3.91"x1.79"x0.04"

137.5x121x1mm/5.41"x4.76"x0.04"

• Inspect all parts for signs of wear or damage. Any scratched or cracked parts should be

replaced prior to use.

• When stored in extremely cold temperature, the helmet should be warmed up to ambient

temperature before welding.

• SKIN CONTACT ALLERGIC ALERT! Extra protections must be taken if individuals are

allergic to plastic or other materials that his/her skin may be in contact with when using

this product.

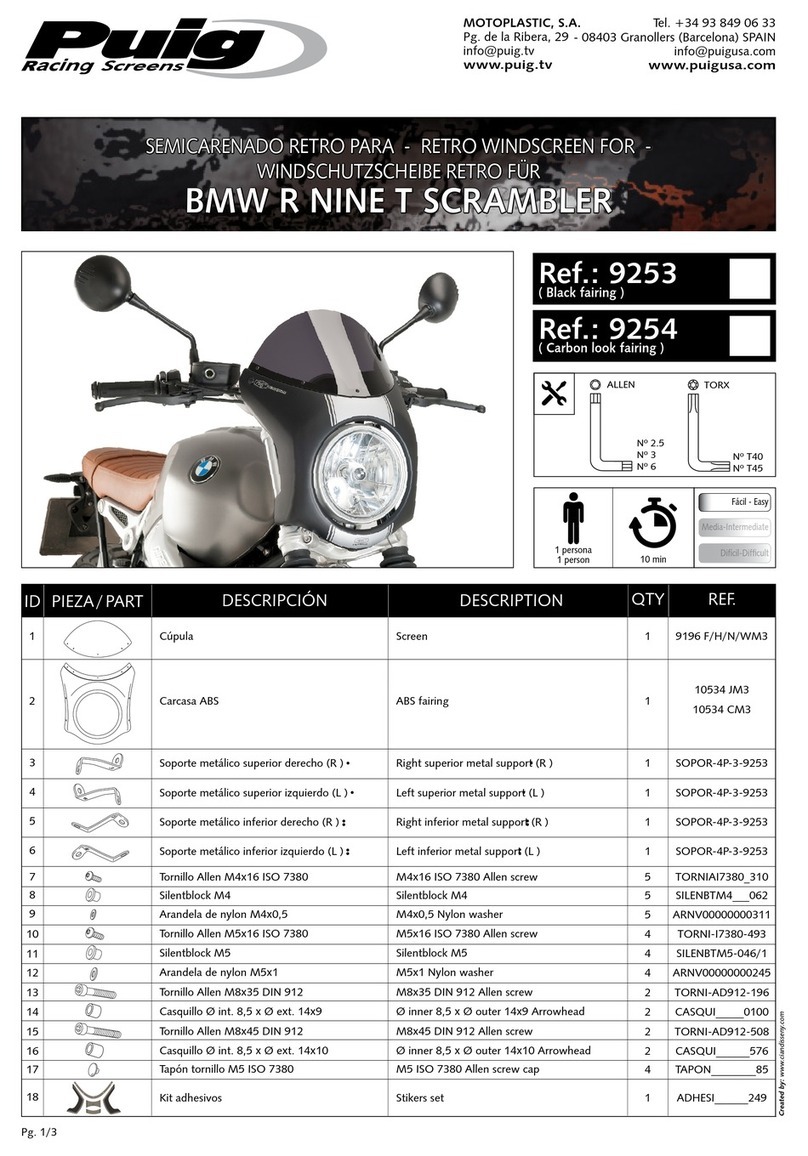

PARTS LIST

• NEVER place the helmet on a hot surface.

• NEVER open or tamper with the filter cartridge

• Not for Overhead welding without extra protection..

Page 4 Page 5

4 / 5 -9 / 9-13 AT 1 / 1 / 1 / 2 / 379 CE

Light shade

Dark shades

Identification of the manufacturer

Optical class

Diffusion of light class

Variation in luminous transmittance class

Angle dependency class

Number of the standard

Optical Specifications

Standards

Model

S/N:XXXXXXXXXXXXXAXXX

Serial number

1

Helmet Shell

2

Adjustable Knob

3

Front Cover Lens

4

Cartridge

5

Inside Cover Lens

6

Lens Retaining

Frame

8

Adjustable Headband

7

Lock Switch

OPERATION SELECT DELAY TIME

SELECT SENSITIVITY

RECOMMENDED SETTINGS

WARNING:

ADJUST THE WELDING HELMET

ACCORDING TO YOUR

INDIVIDUAL REQUIREMENTS.

ON/OFF

The solar unit automatically switches ON

when exposed to light.

SELECT THE SHADE NUMBER

1)Welding control

Two ranges of shade numbers, "5-9" and

"9-13" are available in the dark state(Fig.4).

2)Grinding control

The arrow on the knob indicates the shade

setting.

Set the adjustable knob to "Grind" position

for grinding application.

The headband should be adjusted both in

circumference and height.

The angle between the face and the helmet is

recommended to be adjusted to 10°-12°

(Fig.1).

ADJUST HEADBAND PER

PERSONAL PREFERENCE.

Use the ratcheting knob on the headband to

adjust width.

Loosen or tighten the top strap to adjust

headband height. Make sure that the helmet

fits firmly on your head(Fig.3).

This welding helmet is featured with

continuously adjustable delay time control.

The lens will lighten in 0.1 to 1.0 seconds

upon ambient temperature and shade

setting. By turning the DELAY knob (Fig.5)

clockwise, the delay time will increase from

0.1 seconds to 1.0 seconds.

Turn Knob counter-clockwise for tack

welding or production welding with short

welds.

Turn Knob clockwise for welding at high

amperage where there is an after glow from

the welding

This welding helmet is featured with

continuously adjustable sensitivity control

knob. Sensitivity is a setting of how sensitive

this helmet is responding to the welding arc.

Turn knob clockwise to increase the

sensitivity (Fig.6).

Scenario may need to increase:

1) Low amperage welding

2) Used for DC TIG welding

Turn knob counter-clockwise to decrease the

sensitivity (Fig.6).

Scenario may need to decrease:

1) High ambient light

2) Interference exists

Make sure that the adjustment knob is on the

"5-9" or "9-13" position before starting to

weld.

WARNING:

MAKE SURE TO RESET the knob back to

"5-9" or "9-13" position after grinding.

Adjust helmet’s headband stop to get desired

viewing angle(Fig.2).

Fig.1

Fig.3 Fig.5

Fig.6

Fig.2

9

876 10

Shade 8

Shade 5

Shade 9 Shade 10

Shade 11 Shade 12 Shade 13 Shade 14 Shade 15

Shade 11 Shade 12 Shade 13 Shade 14

Shade 12 Shade 14

Shade 15

Shade 11

Shade 13Shade 12Shade 11Shade 10 Shade 14

REFERENCE ANSI Z49.1-2005

Page 6 Page 7

Fig.4

Adjustment

Knob

Adjust sensitivity setting to properly

condition according to the application

and the environment.

PRE-WELDING CHECK & BATTERY TESTING

MAINTENANCE

MAINTENANCE

CAUTION:

WARNING:

The following procedures should be followed

to perform this testing:

1) Make sure there is enough ambient light to

trigger the auto darkening lens on.

2) Make sure that the adjustment knob is on

the "5-9/9-13" position .

3) Press and hold on the "Batt" button(Fig7)

for 1-2 seconds:

If the LED (Fig.7) is ON, and the lens is

darken as per shade setting, the helmet is

functioning properly.

If the LED is NOT ON when procedures

above are followed, battery replacement is

required.

If the LED is ON and LCD is not darkening as

per shade setting, the auto darkening lens

may be Defective

Always test the auto darkening lens before

welding.

REPLACEMENT OF BATTERIES

1)Detach the auto darkening filter from the

helmet shield (Refer to REPLACEMENT OF

WELDING FILTER)

2)Carefully open the battery compartments.

3)Put the new batteries into the

compartments. (Fig.8)

4)Snap the compartments back into the filter.

5)Install the filter back onto the helmet shield.

REPLACEMENT OF EXTERIOR

COVER LENS

Remove the front lens by pulling out the

retaining frame by move the lock switch from

the helmet (Fig.9).

REPLACEMENT OF WELDING

FILTER

Insert tabs of the front lens retaining frame

under the two slots of the back lens retaining

frame. Push the two corners on front lens

retaining frame until it snaps into place

(Fig.13).

Insert tabs of the back lens retaining frame

under the two slots of the helmet. Push the

lock switch until it snaps into right place.

(Fig.14).

REPLACEMENT OF INNER

COVER LENS

Detach the auto darkening filter from the

helmet shield (Refer to REPLACEMENT OF

WELDING FILTER).

Lift up one edge of the inner cover lens and

pull the cover lens away from the filter

(Fig.11).

Detach the cartridge from the shield and put

it aside. Remove the old lens cover.

Remove the protect film on the new lens

cover. Put the new lens cover back onto the

shield(Fig10).

Ensure the front cover lens is mounted

before using and the protective film on the

lens cover is removed.

Ensure that the lens is clean and there is no

dirt or spatter covering the 4 sensors at the

front of the filter cartridge.

Fig.7

Fig.8

Fig.9

Fig.10 Fig.12

Fig.11

NOTICE:

Always change both of the batteries when

renewing them.

NEVER put used batteries into house hold

waste.

Please always have used batteries recycled

properly.

Page 8 Page 9

Remove protective film on the new inner

lens cover, feed one side of the lens cover

(Fig.12) onto lens retaining slots on the filter,

then push it slightly all the way until the

whole lens cover is snapped on properly.

Fig.13

Fig.14

+

+

CR2032CR2032

NOTES

Page 10 Page 11

INSERT THE MAGNIFYING LENS

INSPECTION

WARNING:

1.Carefully inspect your Auto-Darkening

Welding Filter regularly.

2. Cracked, pitted or scratched filter glass or

cover lenses reduced vision will seriously

impair protection.

3.Worn parts should be replaced immediately

to avoid injury to the eyes.

CLEANING AND DISINFECTION

Clean the helmet with mild soap and

lukewarm water.

Clean the welding filter with a clean lint-free

tissue or cloth.

DO NOT immerse in water.

DO NOT use solvents.

TROUBLE SHOOTING

AUTO DARKENING FILTER DOES NOT

DARKEN OR FLICKER

-Check the lens cover for dirt and spatter that

may be blocking the arc sensors.

-The sensors are dirty, wipe them clean with

a soft lint-free cloth.

-Check the sensitivity setting

recommendations and increase the

sensitivity if possible.

-Increasing lens delay 0.1-0.3 second may

also reduce flickering.

-Check batteries and verify that they are in

good condition and installed properly.

-Battery terminals and the contact surface of

the filter are dirty or oxidized(clean both) .

-Shade adjustment knob is on "GRIND"

position, set helmet on “WELD” and/or proper

shade from “5-13”.

THE LENS STAYS DARK AFTER THE

WELD ARC IS EXTINGUISHED, OR THE

AUTO-LENS STAYS DARK WHEN NO

ARC IS PRESENT.

-Fine-tune the sensitivity setting in small

increments. In extreme light conditions, it

may be necessary to reduce the surrounding

light levels

SLOW SWITCHING

-The operating temperature is too low,

don’ t use at temperatures of below -5 ° C

(+23° F).

POOR VISION

-The cover lens and the filter cartridge is

dirty or damaged, clean the dirty

components and replace the damaged ones.

-Ensure ambient light is not too low.

-Ensure the shade number is correct and

adjust accordingly.

IRREGULAR DARKENING

-Headband has been set unevenly so the

distance between the eyes and the lens is

different from the left to the right side.

If the described malfunctions cannot be

solved, stop using the helmet immediately

and contact the nearest distributor.

Fig.15

1)Magnifying lens is sold separately.

2)Insert the magnifying lens into the slot from

the bottom to the top(Fig.15).

SAVE YOUR RECEIPTS

THIS WARRANTY IS VOID WITHOUT THEM

2-YEAR LIMITED WARRANTY

WARRANTY

Page 13

NOTES

Page 12

Auto-Darkening Welding Helmet

The welding helmets are warranted against defects in materials and workmanship for a

period of two (2) years from date of purchase.

This warranty is limited to the repair or replacement of items which are not in compliance

with this warranty. This warranty does not extend to any item subject to unauthorized

repair, alteration, tampering, improper storage or operation, inadequate maintenance,

accident, misuse, abuse or negligent handling. This warranty is not transferrable from the

original purchaser to any subsequent purchaser.

Seller shall in no event be liable or responsible for any injury, damage or loss resulting

either directly or indirectly from, the use or misuse of this product.

This limited warranty is the exclusive remedy of purchaser and the sole obligation of

Seller in connection with any claim, whether in contract,negligence, strict liability, tort or

otherwise.

Do not use these items unless you are trained and experienced in the proper use and

maintenance. Please read the instruction manual carefully to avoid certain situations

which may void this limited warranty.

Customer Service: 1-855-692-6872

Distributed by Menard, Inc. Eau Claire, WI 54703

Table of contents

Popular Motorcycle Accessories manuals by other brands

MSA

MSA V-Gard H1 operating manual

Evotech Performance

Evotech Performance SUZUKI GSXR1000 Tail Tidy installation instructions

KettenMax

KettenMax Classic instruction manual

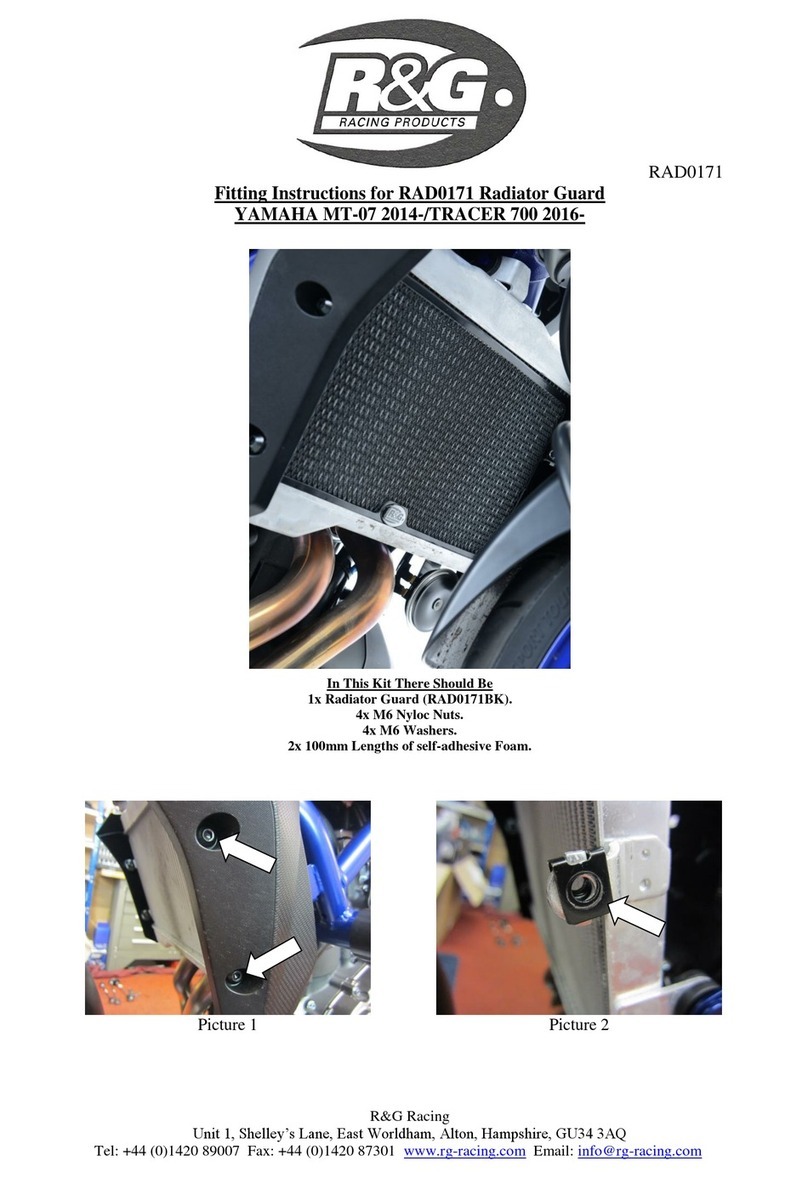

R&G

R&G RAD0171 Fitting instructions

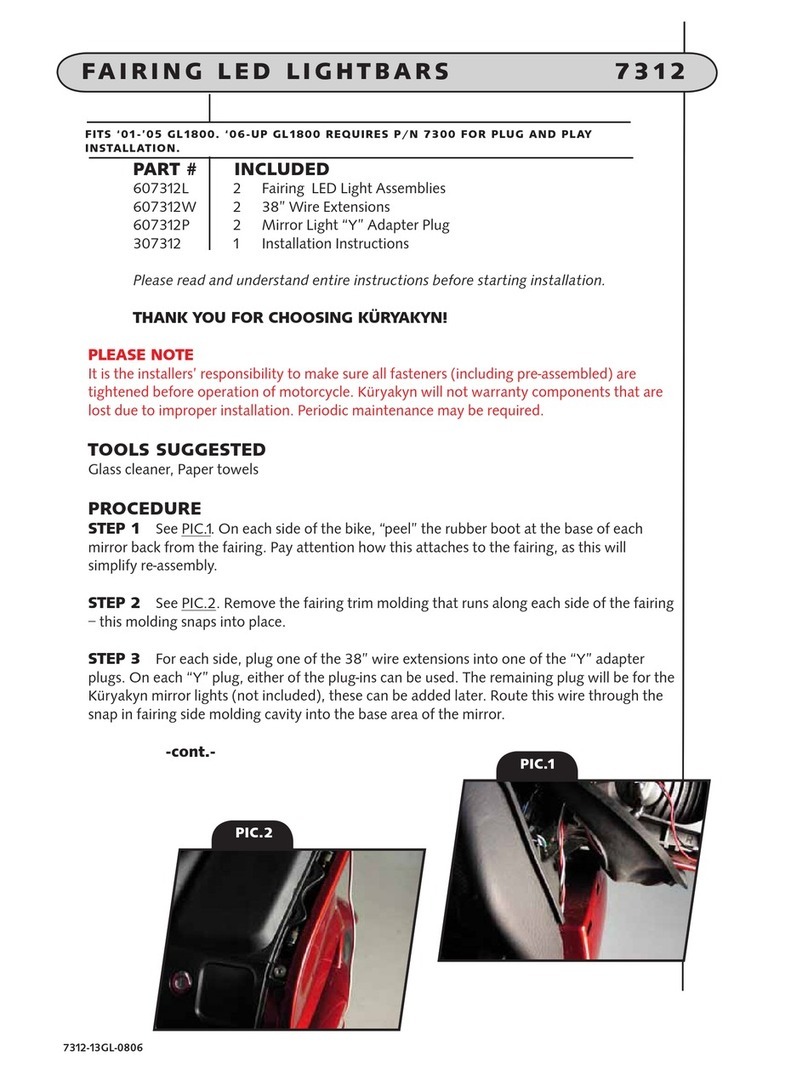

Kuryakyn

Kuryakyn 7312 quick start guide

hepco & becker

hepco & becker Lock-it 506012-5 quick start guide