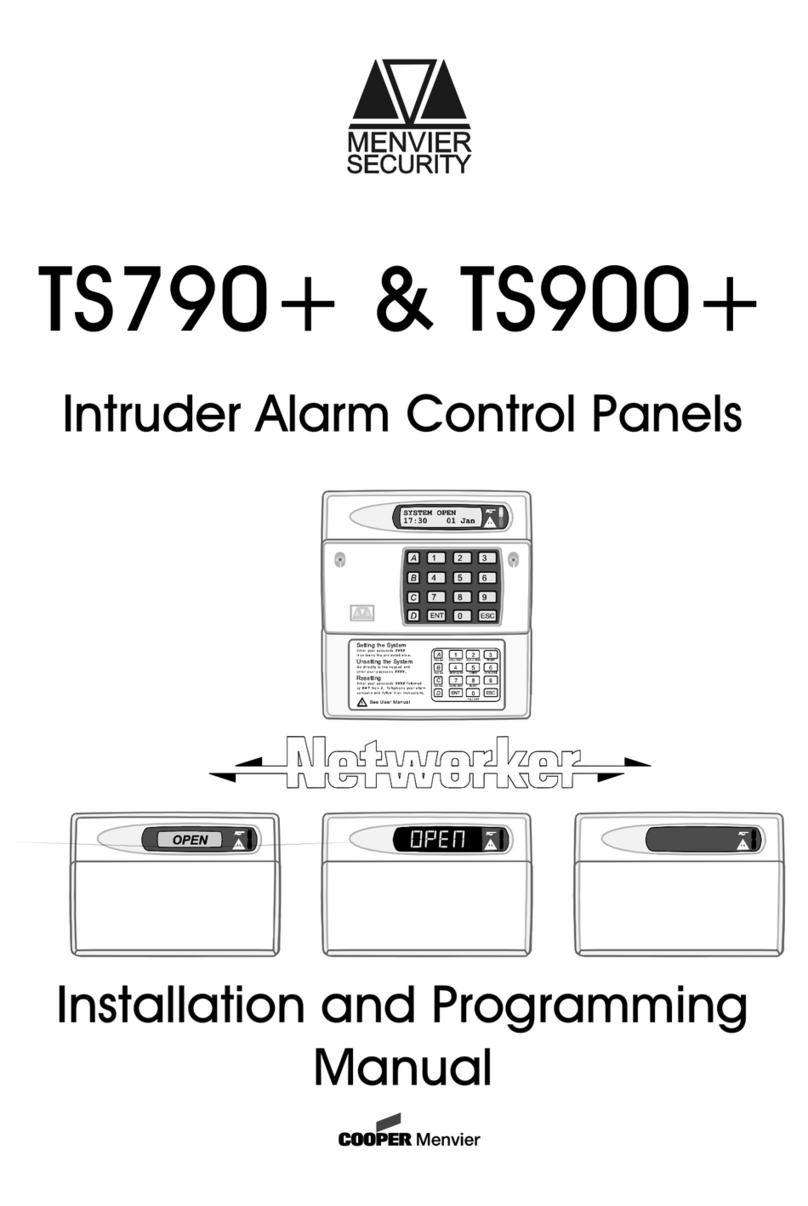

Menvier Security TS690 Assembly instructions

TS690 & TS690ID

Intruder Alarm Control Panels

Installation & Programming

Manual

_

~

Engineers menu 2

Select option :-

_

~

OPEN

_

~

Engineers menu 2

Select option :-

_

~

_

~

OPEN

1A

D

C

B

23

7

6

5

4

89

0

ENT ESC

_

~

SYSTEM OPEN

17:30 01 Jan

SIL EN TZONE OMIT

CHIMENEW COD E 24 H r O MIT

WALK TESTBELLTESTPart Set

Part Set

Part Set

RE SET

1

A

B

C

D

23

456

7

ENT ESC

8

0

9

Se tt ing th e S yst em

Enter your passcode XXXX

th en lea v e the p ro tec te d a rea.

Unsetting the System

Go directly to the keypad and

en ter you r p as scod e XXXX .

Resetting

Enter your passcode XXXX followed

by EN T then 3. Te l eph on e you r a l arm

com pan y and follo w th eir instr uct ions .

!

See User Manual

FULL S ET

Contents

Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . 4

Remote Keypads . . . . . . . . . . . . . . . . . . . . . 4

32 Character LCD (NETLCD) . . . . . . . . . . . 4

8 Character Starburst (NETSTAR) . . . . . . . . 4

4 Character LED (NETLED) . . . . . . . . . . . . . 4

Remote Arming Station (NETARM) . . . . . . . 4

TS700 LEC. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Architecture . . . . . . . . . . . . . . . . . . . 5

Specifications. . . . . . . . . . . . . . . . . . . . . . . . 6

Control Panel . . . . . . . . . . . . . . . . . . . . . . 6

LCD Remote Keypad . . . . . . . . . . . . . . . . 6

Starburst Remote Keypad. . . . . . . . . . . . . 6

LED Remote Keypad . . . . . . . . . . . . . . . . 6

Arming Station . . . . . . . . . . . . . . . . . . . . . 6

TS700 LEC . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Installation

Cable Routing . . . . . . . . . . . . . . . . . . . . . . . 7

Remote/LEC Network Wiring . . . . . . . . . . . . . 7

ID Loop Wiring (TS690ID Only) . . . . . . . . . . . . 8

Cabling Requirements . . . . . . . . . . . . . . . 8

Control Panel Installation . . . . . . . . . . . . . . . 9

Control Panel PCB Layout. . . . . . . . . . . . . . . 10

Connection Terminals & Indicators. . . . . . . . 11

Mains Connection . . . . . . . . . . . . . . . . . . . . 12

Battery Connection . . . . . . . . . . . . . . . . . . . 12

Remote Keypads . . . . . . . . . . . . . . . . . . . . . 12

NETLCD Remote Keypad . . . . . . . . . . . . . 12

NETSTAR Remote Keypad . . . . . . . . . . . . . 12

NETLED Remote Keypad . . . . . . . . . . . . . . 12

NETARM Remote Arming Station . . . . . . . . 12

PCB Layouts & Connections . . . . . . . . . . . 12

Installation Procedure. . . . . . . . . . . . . . . . 13

Keypad Loudspeaker Connections . . . . . 14

Engineer’s Keypad . . . . . . . . . . . . . . . . . . . . 14

TS700 LEC Installation . . . . . . . . . . . . . . . . . . 14

Wiring Detection Circuits . . . . . . . . . . . . . . . 15

Double Pole . . . . . . . . . . . . . . . . . . . . . . . 15

End Of Line . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring ID Biscuits . . . . . . . . . . . . . . . . . . . . . . 16

Biscuit Connections . . . . . . . . . . . . . . . . . 16

Wiring A Biscuit to a PIR . . . . . . . . . . . . . . . 16

Wiring a Biscuit to a Panic Button . . . . . . . 17

Wiring a Biscuit to a Smoke Detector . . . . 17

External Sounder Connections . . . . . . . . . . . 17

Auxiliary Tamper . . . . . . . . . . . . . . . . . . . . . . 17

Extension Loudspeakers . . . . . . . . . . . . . . . . 18

Digicom/RedCARE Installation . . . . . . . . . . . 18

DC6 Digi-Modem Installation . . . . . . . . . . . . 18

Regulatory Requirements . . . . . . . . . . . . . 18

Application . . . . . . . . . . . . . . . . . . . . . . . . 19

Approval. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connections. . . . . . . . . . . . . . . . . . . . . . . 19

Installation. . . . . . . . . . . . . . . . . . . . . . . . . 20

DC54 & DC58M Installation . . . . . . . . . . . . . 20

Connecting a Printer . . . . . . . . . . . . . . . . . . 21

Using the DATAC / RS232 Printer . . . . . . . . 21

Using the CPA6 Printer. . . . . . . . . . . . . . . . 21

Programmable Outputs . . . . . . . . . . . . . . . . 21

Control Panel Outputs. . . . . . . . . . . . . . . . 21

Remote Keypads & TS700.LECs . . . . . . . . 21

Pre Power-Up Checks . . . . . . . . . . . . . . . . . . 22

ID Cable Checks (TS690ID Only) . . . . . . . . . . 22

Initial Power-Up . . . . . . . . . . . . . . . . . . . . . . . 23

Power-Up Checks . . . . . . . . . . . . . . . . . . . . . 23

NVM Defaults . . . . . . . . . . . . . . . . . . . . . . . . 24

Engineer’s Menu 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 25

Menu contents . . . . . . . . . . . . . . . . . . . . . 25

Panel Outputs. . . . . . . . . . . . . . . . . . . . . . . . 26

Digicom Outputs . . . . . . . . . . . . . . . . . . . . . 26

Digicom Channels . . . . . . . . . . . . . . . . . . . 26

Programmable Output Types . . . . . . . . . . . . 26

Program Circuits . . . . . . . . . . . . . . . . . . . . . . 29

Circuit Types . . . . . . . . . . . . . . . . . . . . . . . 29

Circuit Attributes . . . . . . . . . . . . . . . . . . . . 29

System Timers . . . . . . . . . . . . . . . . . . . . . . . . 31

Setting Modes . . . . . . . . . . . . . . . . . . . . . . . 33

Do System Print. . . . . . . . . . . . . . . . . . . . . . . 34

Remote Reset Algorithm. . . . . . . . . . . . . . . . 34

Configuration . . . . . . . . . . . . . . . . . . . . . . . . 34

Go to User Menu 1 . . . . . . . . . . . . . . . . . . . . 37

Add/Clear ID Devices (TS690ID) . . . . . . . . . . 37

2

TS690 & TS690ID Installation Manual

Clear & Relearn ID Devices . . . . . . . . . . . 37

Add ID Devices. . . . . . . . . . . . . . . . . . . . . 37

Display Codes . . . . . . . . . . . . . . . . . . . . . 37

Slow Scan Mode. . . . . . . . . . . . . . . . . . . . 37

View Location Text (LCD Only). . . . . . . . . . . . 38

Re-Map ID Devices (TS690ID) . . . . . . . . . . . . 38

Relearn Hardware. . . . . . . . . . . . . . . . . . . . . 38

Engineer's Menu 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 39

Menu Contents. . . . . . . . . . . . . . . . . . . . . 39

View Circuits . . . . . . . . . . . . . . . . . . . . . . . . . 40

Set System Time . . . . . . . . . . . . . . . . . . . . . . 40

Set System Date . . . . . . . . . . . . . . . . . . . . . . 40

Change Passcode . . . . . . . . . . . . . . . . . . . . 41

Chime Circuits . . . . . . . . . . . . . . . . . . . . . . . 41

Alter Shunt Group . . . . . . . . . . . . . . . . . . . . . 41

Print System Log . . . . . . . . . . . . . . . . . . . . . . 41

Configure Part Sets . . . . . . . . . . . . . . . . . . . . 42

View System Log. . . . . . . . . . . . . . . . . . . . . . 42

Log Event Codes . . . . . . . . . . . . . . . . . . . . . 43

Log Event Codes . . . . . . . . . . . . . . . . . . . . . 44

Reset User Code 1 . . . . . . . . . . . . . . . . . . . . 44

Start Call Back . . . . . . . . . . . . . . . . . . . . . . . 44

Custom Text Menu (LCD Only) . . . . . . . . . . . 45

Circuit Text . . . . . . . . . . . . . . . . . . . . . . . . 45

Banner Message. . . . . . . . . . . . . . . . . . . . 45

Location Text . . . . . . . . . . . . . . . . . . . . . . 45

Modem Options. . . . . . . . . . . . . . . . . . . . . . 45

Call Back No.1 . . . . . . . . . . . . . . . . . . . . . 45

Call Back No.2 . . . . . . . . . . . . . . . . . . . . . 45

Call Back No.3 . . . . . . . . . . . . . . . . . . . . . 45

Modem Password. . . . . . . . . . . . . . . . . . . 46

Modem Site No. . . . . . . . . . . . . . . . . . . . . 46

Program Digicom . . . . . . . . . . . . . . . . . . . 46

Digicom Tests . . . . . . . . . . . . . . . . . . . . . . 47

Reset Digi-Modem . . . . . . . . . . . . . . . . . . 47

Text Editing Keys . . . . . . . . . . . . . . . . . . . . . . 48

Cursor Types . . . . . . . . . . . . . . . . . . . . . . . 48

Common Key Sequences . . . . . . . . . . . . 48

Displaying Text on a Starburst . . . . . . . . . . 48

Appendices

Point ID Extended Reporting . . . . . . . . . . . . . 49

Resetting the Engineers passcode . . . . . . . . 49

Part-Set Application Example . . . . . . . . . . . . 51

Alarm Abort & Confirmation . . . . . . . . . . . . . 51

Alarm Abort Operation . . . . . . . . . . . . . . . 51

Sequential Confirmation Operation . . . . . 51

Setup New Users . . . . . . . . . . . . . . . . . . . . . . 52

User Types . . . . . . . . . . . . . . . . . . . . . . . . . 52

Software History. . . . . . . . . . . . . . . . . . . . . . . 53

Version 1.0 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 1.2 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 1.3 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 1.4 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 2.0 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 2.1 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 2.4 . . . . . . . . . . . . . . . . . . . . . . . . 53

Version 4.0 . . . . . . . . . . . . . . . . . . . . . . . . 53

Quick Reference Engineers Menus. . . . . . . . 54

Quick Reference User Menus . . . . . . . . . . . . 56

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3

TS690 & TS690ID Installation Manual

Overview

Introduction

The TS690 range of alarm control systems have

been designed to suit small to medium installation

sites. The TS690 system can monitor 6 zones locally

and up to 8 zones via remote keypads or LECs. All

zones can be wired either as double pole or end

of line. The TS690ID system can monitor up to 30

zones via ID biscuits and 8 conventional zones via

remote keypads or LECs.

Both systems feature local “downloading" via a

DCI link and PC, or remote “downloading” via a

plug-on digi-modem (DC6) and PC.

Control Panel

The control panel is the controlling unit for the

system, it has a power supply and connections for

a standby battery. It has the following facilities:

l6 programmable detection circuits (TS690

only)

lDetector loop for connecting up to 30

programmable ID biscuits (TS690ID only)

lBell and strobe outputs

l3 programmable outputs (1 x Voltage free

contacts and 2 high current transistorised)

l5 programmable digicom/RedCARE outputs

lA connector for a plug-on digi-Modem (DC6)

lExtension loudspeaker output

lAll system program information and the 700

event log is stored in a removable non-volatile

memory (NVM)

l15 user codes + engineer's code

l7.0Ah battery capacity

Remote Keypads

Up to 4 remote keypads can be connected to the

control panel. Each remote keypad has two

detection circuits and a single switched -ve

output. All remote keypads have “Power LED” and

a programmable “Function LED” (the “Function

LED” may be programmed as “Fault” or “Area Set”

etc.). There are four types of remote keypads that

can be used:

32 Character LCD (NETLCD)

The NETLCD remote keypad has a backlit 32

character super-twist Liquid Crystal Display (LCD)

and a backlit tactile rubber keypad. When using

the LCD Keypads the text for user codes, part

setting modes and circuit identification can be

programmed to make the operation and

programming of the system easier.

8 Character Starburst (NETSTAR)

The NETSTAR remote keypad has a backlit 8

character starburst display (LCD) and a backlit

tactile rubber keypad.

4 Character LED (NETLED)

The NETLED remote keypad has a 4 character LED

display and backlit tactile rubber keypad. When

using the LED remote keypads, text cannot be

programmed but all other system functions are

available.

Remote Arming Station (NETARM)

The NETARM remote arming keypad does not

have a display and can only be used for setting,

part setting and unsetting of the system.

TS700 LEC

The Local Expansion Card (LEC) provides two

programmable detection circuits and one

programmable output.

4

Overview TS690 & TS690ID Installation Manual

System Architecture

5

TS690 & TS690ID Installation Manual Overview

Printer

Printer

Speaker

Speaker

Aux 12V

Aux 12V

DCI Connection

DCI Connection

Bell output

Bell output

Strobe

Strobe

output

output

Digi outputs 1- 5

Digi outputs 1- 5

Outputs 1- 3

Outputs 1- 3

30 ID zones

Biscuit

1

Biscuit

30

Remote

Network

Remote

Network

TS690

Number of Zones = 8 to 14

Number of Zones = 2 to 38

DC6

Digi Modem

(Optional)

TS690ID

DC6

Digi Modem

(Optional)

I.D. Loop

6 Zones

(DP / EOL)

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

2 Zones

(DP / EOL)

1Output

Remote

Keypad

or LEC

Figure 1. TS690 & TS690ID System Architecture

Specifications

Control Panel

Part No.: TS690 - 6 to 14 zones

TS690M - with DC6 modem

TS690ID - 2 to 38 zones

TS690IDM - with DC6 modem

Input Supply: 230V ±10% 50Hz

Current: 110mA (normal)

250mA (alarm) with speaker

Power Supply: 1.5A

Standby Battery: 7.0Ah

Outputs 1-3: 1 = Voltage free changeover

2 = Switched -ve @500mA

3 = Switched +ve @500mA

Digi Outputs 1-5: +ve removed

Source 5mA in 12V condition

Sink 100mA in 0V condition

Speaker Output: 16 Ohms

Bell Trigger: Switched -ve @500mA

Strobe Trigger: Switched -ve @500mA

Dimensions: 384(W) x 312(H) x 95(D) mm

Material: 1.2mm mild steel

Weight: 4.9 Kg

Environment: -10 to 55°C

LCD Remote Keypad

Part No.: NETLCD

Display: 32 character Liquid Crystal

Green power LED

Red function LED

Current: 50mA (normal) 60mA (alarm)

Zones: 2

Output: Switched -ve @100mA

Dimensions: 150(W) x 104(H) x 30(D) mm

Material: 3mm Polycarbonate

Weight: 282g

Environment: -10 to 55°C

Starburst Remote Keypad

Part No.: NETSTAR

Display: 8 character Liquid Crystal

Green power LED

Red function LED

Current: 50mA (normal) 60mA (alarm)

Zones: 2

Output: Switched -ve @100mA

Dimensions: 150(W) x 104(H) x 30(D) mm

Material: 3mm Polycarbonate

Weight: 263g

Environment: -10 to 55°C

LED Remote Keypad

Part No.: NETLED

Display: 4 character seven segment

Green power LED

Red function LED

Current: 60mA (normal) 70mA (alarm)

Zones: 2

Output: Switched -ve @100mA

Dimensions: 150(W) x 104(H) x 30(D) mm

Material: 3mm Polycarbonate

Weight: 254g

Environment: -10 to 55°C

Arming Station

Part No.: NETARM

Display: Green power LED

Red function LED

Current: 30mA (normal) 40mA (alarm)

Zones: 2

Output: Switched -ve @100mA

Dimensions: 150(W) x 104(H) x 30(D) mm

Material: 3mm Polycarbonate

Weight: 254g

Environment: -10 to 55°C

TS700 LEC

Part No.: TS700.LEC

Current: 30mA (normal) 40mA (alarm)

Zones: 2

Output: Switched -ve @100mA

Dimensions: 142(W) x 82(H) x 36(D) mm

Material: 3mm Polycarbonate

Weight: 213g

Environment: -10 to 55°C

6

Overview TS690 & TS690ID Installation Manual

System Installation

Cable Routing

When installing cables, the following should be

noted:

+

Ensure that all Network and detection

circuit cables are kept clear of mains

supply cables, telephone cables, R.F.

cables and cables supplying bells or

sounders.

+

Screened cable may prove necessary if

the Network or ID loop is run adjacent to

cables that produce R.F. or are switching

high current loads, e.g., mains, telephone,

computer etc.

+

Mains power supply cables to the system

must be connected to an un-switched

fused spur that cannot be accidentally

switched off. The mains cable must enter

the housing via its own cable entry point.

+

In larger installations it may prove

necessary to fit remote power supplies to

overcome excessive voltage drops in the

cable runs.

Remote/LEC Network Wiring

The Remote Network connections are used for

connecting either remote keypads or LECs. Each

device has 5 connection terminals and therefore

a 6 core cable is required for interconnection. It is

recommended that the spare core is doubled up

with the [B] connection as this will help reduce

voltage drop on long cable runs.

Devices can be individually connected back to

the control panel (star connection) or looped

together (daisy-chain connection). Which ever

method of connection is used the distance to the

furthest device from the control panel must not

exceed 100 metres.

Power for detectors are provided by the [A] and [B]

terminals (see figure 2).

7

TS690 & TS690ID Installation Manual System Installation

Remote

Network

Spare Core

Control Panel

Power for

detectors

Power for

detectors

Power for

detectors

Power for

detectors

I/D=2I/D=1 I/D=3 I/D=4

Remote

Keypad

or LEC

ABCDE

Remote

Keypad

or LEC

ABCDE

Remote

Keypad

or LEC

ABCDE

Remote

Keypad

or LEC

ABCDE

A

B

C

D

E

100m (Max.)

+ + + +

Figure 2. TS690 & TS690ID Remote Network Wiring

ID Loop Wiring (TS690ID Only)

Each ID device is connected across a two-wire ID

loop. Apart from observing the correct polarity,

any wiring configuration can be used, as shown in

the figure below.

Cabling Requirements

The ID loop can be wired using standard 4 core

cable, this allows 2 cores to be used for the ID

devices and 2 cores for supplying 12V power for

PIR's etc.

The number of devices permitted per cable run is

governed by the resistance of the cable used.

Standard 4 core alarm cable (7/0.2mm) has a

resistance of approximately 8 Ohms per 100

metres and as a guide the maximum number of

devices that can be connected at the END of a

single cable run is as follows:

No of Biscuits at

end of cable

Max Cable

Distance (m)

Max. cable loss

resistance, ends

shorted at panel

30 40m 6 Ohms

15 68m 11 Ohms

7 107m 17 Ohms

3 150m 24 Ohms

If a different type of cable is used, the distances

should be recalculated. e.g., if 7/0.4mm cable is

used, a single run of 80 metres would support 30

devices on the end as the resistance of the cable

is halved.

When installing the ID loop wiring It is usually more

practical to run several cables from the control

panel to the different areas of protection. This

effectively reduces any distance problems and

makes fault finding much easier.

To reduce the likelihood of induced interference

and wherever possible, cables should not be

positioned along side mains power, telephone or

other data transmission cables, or run within the

same ducting or trunking as any other cables.

The wiring for remote keypads and internal

sounders (loudspeakers) should not be

connected in the same multi-core as the ID loop.

+

Included in the spares pack is a 47nF

capacitor. Although not necessary for

correct operation of the system, it will

improve the system noise immunity if

connected across the ID loop at one of the

devices furthest from the control panel.

8

System Installation TS690 & TS690ID Installation Manual

TS690ID +

ID

LOOP

-

01 02 03 04 05

10 09 08 0712 11

14

13

06

Figure 3. ID Detector Loop Wiring

Control Panel Installation

Proceed as follows:

1. Open the control panel by removing two

screws from the front cover. Remove the cover

and disconnect the earth bonding cable from

the spade connection near the transformer.

2. Note the position of the cable entries as

follows:

(a) Ten 20mm cable entries for detection,

alarm and remote keypad cables.

(b) A 20mm cable entry for mains (240V)

below the mains input terminal block.

+

The mains cable must enter the control

panel through its own cable entry and

must not be mixed with other cables.

3. Hold the control panel back box in the

required position and mark the centre of the

middle fixing position. Remove the back box,

drill and plug the hole.

4. Screw a No 10 screw into the plugged hole.

Reposition the back box and mark the

remaining two securing holes. Remove the

back box, drill and plug the holes.

5. Reposition the back box and pass all cables

into the base via the appropriate cable entries,

remembering to fit grommets where

necessary.

6. Secure the back box using not less than 30mm

x No 10 screws through the three securing

holes.

7. If required install and connect the following:

(a) Stand alone digicom or RedCARE STU.

(b) Printer type DATAC or serial RS232 via a

printer adapter (MPA/DCI).

(c) Relay module type RM.3A.

+

When replacing the cover, always

ensure that the earth bonding lead is

connected to the spade connection on

the transformer.

9

TS690 & TS690ID Installation Manual System Installation

Mains

Transformer

Spade connection

for earth lead to

front cover

Mains Cable

Entry

Fused Terminal

Block 315mA

Printed Circuit Board

(PCB)

Battery

Position

Figure 4. TS690 & TS690ID Control Panel Layout

Control Panel PCB Layout

10

System Installation TS690 & TS690ID Installation Manual

PRINTER

REMOTE KEYPAD

JP3

DIGI-MODEM

PLUG ON DIGI MODEM

JP4

FACTORY

RESET

Auxiliary 12V (SELV)

Remote

keypad

Network

connections

(SELV)

Programmable

Detection

Circuits 1 - 6

(SELV)

(Only Fitted on

TS690)

Aux 12V

&

I.D. Loop

(SELV)

(Only Fitted on

TS690ID)

Digicom Outputs

Programmable @ 100mA

(SELV)

Auxiliary Tamper (SELV)

Extension loudspeaker

(SELV)

External sounder

connections

(SELV)

21V A.C. from mains

transformer

(SELV)

Telephone connections

(TNV)

Panel Outputs

O/P 1 = Change over contacts

O/P 2 = Switched -ve @ 500mA

O/P 3 = Switched +ve @ 500mA

(SELV)

Z1 Z2 Z3 Z4 Z5 Z6

AUX

0V 12V

T1 T2 T3 T4 T5 T6

ID LOOP

+-

CIRCUIT 1 CIRCUIT 2 CIRCUIT 3 CIRCUIT 4 CIRCUIT 5 CIRCUIT 6

JP5

SPEAKER

VOLUME

DC6 Digi-modem

(Only fitted on the TS690M & TS690IDM)

V

NVM

AUX BELL

1 AMP

1 AMP

BATT

FAULT

POWER

ON

TRG

-

STB

-

TR- H/O

-

H/O

+

SPK

+

AUX

TAMP

LINE

FLT

+

REM

RESET

-

1234

DIGITAL COMMUNICATOR

5AUX

A

REMOTE NETWORK

BCDE

+3 -2

OUTPUT 1

OUTPUTS

N/O N/CCOM

0V 12V

A.C.A.C.

AB

1 AMP

JP1

JP2

ENGINEERS REMOTE

U3

+

DC

PWR

FS1

FS2

VR2

FS3

LED1

LED2

B1 A1

Figure 5. TS690 & TS690ID Main PCB

Connection Terminals & Indicators

Connection terminals on the TS690 / TS690ID are

described as ether “Safety Extra-Low Voltage”

(SELV) circuits or “Telecommunication Network

Voltages” (TNV) circuits. Figure 5 shows the two

types of circuits.

JP1 PRINTER

This 6-pin plug is used for connecting to

either a CPA6.P printer or a standard RS232

printer via the MPA/DCI printer adapter.

JP2 ENGINEERS REMOTE

An Engineers remote keypad may be

temporarily connected to this 6-pin plug to

allow programming and testing to be

carried out at the control panel.

JP3 DIGI-MODEM

The DCI lead connects to this plug when

using the Lineload software via a P.C. for

direct communication with the control

panel. A DC54, DC58 or DC58M can also

be connected to this plug if the DC6 is NOT

being used.

JP4 PLUG ON DIGI MODEM (DC6)

The plug-on digi-modem plugs directly onto

these pins. The DC6 is a 8 channel digital

communicator and V21 modem. The DC6

is required when using the downloading

feature. The TS690M and TS690IDM are

supplied with the DC6 already pre-fitted.

JP5 FACTORY RESET

If these pins are shorted during power-up all

system parameters are reset to their factory

default settings. If the engineer’s passcode

is lost or forgotten it can be reset to 1234

without losing any other program data. The

procedure for resetting the engineer’s

passcode is described on page 49.

VR2 SPEAKER VOLUME

When an extension loudspeaker is

connected to the control panel terminals

the volume of the advisory tones may be

adjusted using this control.

+

Alarm tones are always at full volume.

U3 NVM

A removable nonvolatile memory (NVM)

device that stores all system program

parameters and the 700 log events.

LED1 BATT FAULT

If the system battery is incorrectly

connected to the control panel or the

battery voltage is below 4 Volts, then the

“BATT FAULT” LED will light. The fault LED will

only extinguish when the battery has been

correctly connected or replaced, as

appropriate.

LED2 POWER ON

This LED indicates that the system power

(mains or battery) is healthy.

V SYSTEM CURRENT CONSUMPTION

The system current consumption may be

calculated by measuring the Voltage

across this test point on the main PCB. Using

a Voltmeter set to a low Voltage range

measure the Voltage across the test point

and multiply the reading by 10 to give the

Total system current consumption i.e., a

reading of 70mV = 700mA.

FS1 BELL

This 1 Amp fuse protects the supply to the

external sounder/bell. The fuse is in-line with

the [H/O+] terminal connection.

FS2 AUXILIARY

This 1 Amp fuse protects the auxiliary supply

output. The fuse is in-line with the [AUX. 12V]

terminal connections.

FS3 REMOTE KEYPAD

This 1 Amp fuse protects the supply to the

remote network. The fuse is in-line with the [A]

terminal connection.

ID LOOP (TS690ID Only)

These two terminals are used for connecting

ID devices.

+

The ID Loop has electronic short circuit

protection, therefore no fuse is fitted to

protect it. In the event that the ID Loop

is shorted the system will indicate a

short circuit condition and will revert to

normal when the short is removed.

11

TS690 & TS690ID Installation Manual System Installation

Mains Connection

The mains supply is connected to a 3 way “Euro

Type” fused terminal block, which is fitted with a

315mA fuse. All electrical connections should be

carried out by a qualified electrician and must

comply with the current IEE regulations.

+

To comply with European regulations the

supply should be fed from a readily

accessible disconnect device, e.g.

un-switched fused spur fitted.

+

When making mains connections it should

be ensured that if the cable slips in such a

way as to place a strain on the conductors,

the protective earthing conductor will be

the last to take the strain.

Battery Connection

A 7Ah battery must be fitted to the system to allow

it to function during a mains fail condition. The

TS690 & TS690ID is equipped with a “Battery

Protection” circuit so that if a battery is accidentally

reverse connected or its voltage is below 4V, the

“BATT FAULT” LED lights. To clear the fault simply

reconnect or replace the battery as appropriate.

Remote Keypads

Four types of remote keypads can be used on the

system, however, only the NETLCD remote keypad

can be used for programming text information.

Any combination of remote keypad can be used

on the same system, if desired.

NETLCD Remote Keypad

The NETLCD remote keypad has a 32 character

backlit Liquid Crystal Display (LCD)

NETSTAR Remote Keypad

The NETSTAR remote keypad has a 8 character

backlit Starburst Liquid Crystal Display (LCD).

NETLED Remote Keypad

The NETLED remote keypad has a 4 character LED

display.

NETARM Remote Arming Station

The NETARM remote arming station does not have

a display, therefore it is designed to only be used

where setting, part setting and unsetting of the

system is required.

PCB Layouts & Connections

Detection Circuits.

Each remote keypad has two

programmable detection circuits.

Loudspeaker Volume.

For adjusting the volume of a speaker wired

to the remote keypad (NETLCD only).

LED Mimic.

If this jumper link is set to the “enabled”

position, the red () LED on the keypad will

be “ON” when the keypad output is active.

Remote I/D.

Used to select the remote keypads address.

(ENG = Engineer).

Ward Sounder Control.

If this jumper link is set to the “disabled”

position, the remote keypad sounder will

follow the control panel speaker output. If

this link is set to “enabled”, the remote

keypad sounder will only activate when the

panel speaker and the output on the

remote keypad are active at the same time.

Loudspeaker Output.

This terminal can be connected to a single

16 Ohm Loudspeaker (NETLCD only).

Network Connections & O/P.

Terminals A to E are used to connect the

remote keypad to the control panel

network. The O/P terminal is the

programmable output.

12

System Installation TS690 & TS690ID Installation Manual

L

E

N

To transformer

FUSE 315mA

Figure 6. Mains Supply Connections

Tamper Switch.

Remote Keypad case tamper

ENT Key Disable.

If the “ENT” key is enabled the remote keypad can

be used to set/unset and access all user menus. If

the “ENT” key is disabled the remote keypad can

only be used to set and unset the system.

Installation Procedure.

+

Always ensure that all power (mains and

battery) is removed before making any

connections to the remote keypad.

1. Separate the cover and base by using a

screwdriver to push 2 of the clips (top or

bottom) inward from the base indents, then lift

the cover assembly, noting that the PCB is fixed

to the under side of the cover.

2. Hold the base in position (keyhole to the top)

and mark the three securing holes, drill and

plug the wall as required. Pass all the cables

into the base via the cable entry points as

appropriate and secure the base to the wall.

3. Connect “Remote Network” and detection

circuit cables to the appropriate terminals.

4. Set the I/D selector jumper link to the required

position:

TS690

I/D Selector Circuit A Circuit B Panel

Output

107085

209106

311127

413148

ENG/NULL N/A N/A N/A

TS690ID

I/D Selector Circuit A Circuit B Panel

Output

131325

233346

335367

437388

ENG/NULL N/A N/A N/A

lNo two remote keypads or LECs should

have the same I/D.

lIf the I/D is set to “ENG” the remote keypad

will function as an Engineer’s keypad

allowing it to be plugged onto the control

panel so that system programming and

testing can be carried out, see Engineer’s

Keypad.

13

TS690 & TS690ID Installation Manual System Installation

I/D

Selector

REMOTE

I/D

LED MIMIC

ENT KEY

DISABLED

1

2

3

4

ENG

WARD SOUNDER

CONTROL

ABCDE SPK

+

1 2

3

5

4

67

89

Display Module

O/P

-

Figure 7.NETLCD, NETLED & NETARM PCB Layout

I/D

Selector

REMOTE

I/D

LED MIMIC

ENT KEY

DISABLED

1

2

3

4

ENG

WARD SOUNDER

CONTROL

4

5

Display Module

31

89 7

ABCDEO/P

-

Figure 8.NETSTAR PCB Layout

5. Set the “ENT KEY DISABLE” jumper link to the

required position.

6. Set the “WARD SOUNDER CONTROL” jumper link

to the required position.

7. Finally clip the remote keypad cover onto the

base being careful not to trap any cables or to

obstruct the tamper switch.

Keypad Loudspeaker Connections

A single 16 Ohm loudspeaker may be wired to the

keypad if required. This loudspeaker will follow the

existing keypad sounder and its volume level can

be adjusted by the speaker volume pot (VR1).

+

The speaker output and volume pot are

only available on the NETLCD keypad.

Engineer’s Keypad

Normally all system programming will be carried

out from one of the installed remote keypads,

however sometimes it may be more convenient

to program the system at the control panel. This

can be achieved by using an “Engineers Keypad”

which is temporarily plugged on to the control

panel (JP2). To convert a standard remote keypad

to an “Engineers Keypad” an Engineer’s interface

lead is required which can be obtained from your

supplier (P/No. NETEKI).

TS700 LEC Installation

The TS700 LEC (Local Expansion Card) is

connected to the “Remote Network” and provides

two additional programmable detection circuits

and a programmable output. The “Remote

Network” may have up to three LECs connected,

as the system will always require at least one

remote keypad.

+

Always ensure that all power (mains and

battery) is removed before making any

connections to the LEC..

1. Remove the cover from the base and carefully

remove the PCB.

2. If the LEC is being fitted inside the control panel

you may remove the LEC PCB from its base

and secure it to base of the control panel using

self adhesive feet. If required, the tamper

switch may also be disabled by fitting the

jumper link across JP2, see Figure 10.

3. If the LEC is being fitted outside the control

panel, hold the base in position and mark the

two securing holes. Drill and plug the wall, then

pass all cables into the base via the cable

entry points. Secure the base to the wall using

the appropriate fixing screws.

14

System Installation TS690 & TS690ID Installation Manual

1x16Ohm

Loudspeaker

ABCDE SPK

+

O/P

-

Figure 9. NETLCD Speaker Connections

Control Panel

To TS900

Remote

Keypad

A (Red)

A

AUX

12V 0V

ENGINEERS REMOTE

JP2

C (Yellow)

B

B(Black)

C

D(White)

D

E(Blue)

E

7 Way 0.1" Molex

connector

Figure 10. Engineer’s Keypad Connection

Network

connections

Programmable

output

switched -ve

@100mA

Tamper switch

Fit jumper-link to

disable tamper switch

CABLE ENTRY

CABLE ENTRY

Programmable

detection circuits

I/D selector

CCT B

ED

CB

LEC I/D

A

12 34

NULL

JP2

TAMPER = JP2 NOT FITTED

NO TAMPER = JP2 FITTED

CCT A

TA

TB ZA

ZB

O/P

Figure 11. TS700.LEC Layout

4. Connect “Remote Network” cables and

detection circuit cables to the appropriate

terminals, see Figure 10

5. Set the I/D selector jumper link to the required

position:

TS690

I/D Selector Circuit A Circuit B Panel

Output

107085

209106

311127

413148

ENG/NULL N/A N/A N/A

TS690ID

I/D Selector Circuit A Circuit B Panel

Output

131325

233346

335367

436388

ENG/NULL N/A N/A N/A

lNo two LECs or remote keypads should

have the same I/D.

lDO NOT set the I/D selector to the “NULL”

position.

6. Finally clip the LEC cover onto the base being

careful not to trap any cables or to obstruct the

tamper switch.

Wiring Detection Circuits

All detection circuits may be wired as “End Of Line”

(EOL) or “Double Pole” (DP). Both methods can be

used on the same equipment.

Double Pole

The DP method requires the following:

lThe detector alarm and tamper contacts are

connected to the zone and tamper terminals

respectively.

lThe combined alarm and tamper loop

resistance must be less than 100 Ohms.

lThe maximum number of detection devices

allowed in a circuit is ten.

lNormally open devices such as pressure pads

and exit terminator buttons are connected

between the zone and tamper terminals.

lIf the detection circuit is not used links can be

fitted across the zone and tamper loops or

programmed as Not Used.

End Of Line

The EOL method requires the following:

lThe detector alarm contacts must have a 4K7

shunt resistor fitted.

lA 2K2 End of Line (EOL) resistor must be fitted at

the point in the circuit furthest from the control

panel.

lLoop resistance with the EOL resistor shorted

must be less than 100 Ohms.

lThe maximum number of detection devices

allowed in a circuit is ten.

lNormally open devices such as pressure pads

and exit terminator buttons are connected

across outer terminals

lIf the detection circuit is not used links can be

fitted across the zone and tamper loops or

programmed as Not Used.

15

TS690 & TS690ID Installation Manual System Installation

Alarm

Tamper

CIRCUIT A

ZA

TA

CIRCUIT A

ZA

TA

CIRCUIT A

ZA

TA

Alarm

Tamper

Max. 10 devices per circuit

Wiring N.O. devices (Exit Terminators)

Alarm

Tamper

500 metres or 100 Ohms

Figure 12. Double Pole Wiring

Wiring ID Biscuits

Each ID biscuit is identified by its own number, 01

to 30 and contains its own internal sensor which is

continuously monitored by the two-wire ID Loop.

The figure below shows the basic connections to

the biscuit using a tamper and alarm contacts.

When the tamper switch is opened, the ID biscuit

becomes off line and a tamper alarm is

generated by the control panel. If the alarm

contacts are opened the biscuit's internal sensor

changes state and the control panel will see this as

an active condition and will respond as

appropriate.

Biscuit Connections

The figure below shows an ID wired biscuit the

connection are as follows:

Yellow Wire ID Loop +

Blue Wire ID Loop -

White Wire Alarm switch wire

Wiring A Biscuit to a PIR

The figure below shows typical wiring configuration

for a standard PIR.

16

System Installation TS690 & TS690ID Installation Manual

500 metres or 100 Ohms

Alarm

Alarm

Tamper

Max. 10 devices per circuit

Wiring N.O. devices (Exit Terminators)

Tamper

4K7 = Yellow, Violet, Red

2K2 = Red, Red, Red

Alarm

Tamper

4K7

4K7

4K7

2K2

2K2

2K2

CIRCUIT B

ZB

TB

CIRCUIT B

ZB

TB

CIRCUIT B

ZB

TB

Figure 13. End of Line Wiring

ID Biscuit

Alarm Contact

s

Tamper Switch

ID Loop +

ID Loop -

WhiteYellow

Blue

Figure 14. ID Wiring

01

Blue wire (ID LOOP -)

Yellow wire (ID LOOP +) White wire (alarm switch)

Biscuit Number

Figure 15. A Wired ID Biscuit

+-TAMPER ALARM

From Panel To next detector

Red

Black

Yellow

Blue

Red

Black

Yellow

Blue

White

Blue

Yellow

Figure 16. Wiring a Biscuit to a PIR

Wiring a Biscuit to a Panic Button

The figure below shows typical wiring configuration

for a standard panic button.

Wiring a Biscuit to a Smoke Detector

The figure below shows typical wiring configuration

for a standard 12V smoke detector.

External Sounder Connections

The following terminals have been provided to

allow connections to an external sounder:

H/O - This is used to provide a permanent -ve

hold off to external sounders, strobes etc.

H/O + This is used to provide a permanent +ve

hold off to external sounders, strobes etc.

It is protected by a 1 Amp fuse (Bell 12V).

TR - This is the negative tamper return

connection from the siren or bell.

STB - This is the strobe output which will switch to

0V on alarm and is rated at 500mA.

Connect the other side of the strobe to the

H/O +.

TRG - This is the bell trigger output which can be

programmed for SAB or SCB operation, as

follows:

SAB: TRG - will switch to 0V on alarm and

will provide a maximum of 500mA.

SCB: TRG - will provide a negative hold

off (500mA), which is removed on alarm.

Auxiliary Tamper

These two terminals provide tamper protection to

auxiliary devices such as power supplies,

extension loudspeakers etc. If they are not used

they must be linked out.

17

TS690 & TS690ID Installation Manual System Installation

Blue

Yellow

Yellow

White

Blue

Figure 17. Wiring a Biscuit to a Panic Button

+- SPARE ALARM

Red

Black

Yellow

Blue

White

Blue

Yellow

Figure 18. Wiring a Biscuit to a Smoke Detector

Typical

External Sounder

Control

Panel

H/O + 12V +

H/O - 0V

Tamper In

TR -

STB - Tamper Out

TRG - Strobe +ve

Strobe -ve

Trigger -ve

Figure 19. External Sounder Connections

Extension Loudspeakers

Up to two extension loudspeakers can be

connected across the [SPK+] and [H/O-] terminals

on the control panel PCB. The volume for the

loudspeaker is controlled by VR1 “Speaker

Volume”.

Digicom/RedCARE Installation

A stand alone digital communicator, RedCARE

STU or Paknet interface card can be connected to

the control panel using the following connections:

Digicom Outputs 1 to 5

These are the programmable digicom output

connections. They are normally at +12V and

switch to 0V when active. The outputs can be

inverted so that they switch from 0V to +12V when

active, see System Configuration on page 34.

Each output will source 5mA in the +12V condition

and sink 100mA in the 0V condition.

+DC POWER

This provides the +12V power to the digicom. This

output is un-fused and therefore should only be

used if the digicom is fitted inside the control

panel. The 0V supply for the digicom/STU can be

picked up from any of the auxiliary 0V terminals.

LINE FLT

When this input is switched to +12V, a “Line Fault”

condition is generated. A “Line Fault” condition In

the unset mode will cause a “Chime” type tone to

be generated every minute, which can be

silenced by entering any valid passcode. A “Line

Fault” condition In the set mode will cancel the

“Bell Delay”.

REM RESET

If the system is programmed for “Engineer Reset”,

then after a full alarm the system will require

resetting, normally this is done by the engineer or

coded remote reset. Applying a -ve to this input

terminal will cause the system to reset after a full

alarm. This input could be connected to the

“Control” output on a RedCARE STU so that the

Alarm Receiving Centre can poll the STU and thus

reset the panel.

DC6 Digi-Modem Installation

A plug-on digi-modem DC6 can be fitted inside

the control panel to allow remote interrogation

and programming via a personal computer (PC).

It will also function as a standard digital

communicator. Before attempting to install the

DC6, the installer must be aware of the following:

Regulatory Requirements

The DC6 digi-modem must be installed by an

electrically competent person.

18

System Installation TS690 & TS690ID Installation Manual

1 x 16 Ohm Loudspeaker

2 x 16 Ohm Loudspeakers

SPK+

H/O -

SPK+

H/O -

Figure 20. Loudspeaker Connections

Control

Panel

3GSTU

1

1

+DC POWER

Program

As:-

Open (036)

Alarm (005)

PA (006)

Fire (007)

LINE FLT

AUX 0V

2

2

3

3

4

4

5

TB1

Channel Inputs are

Programmed as

Positive Removed

TB2 TB3

TB4

Control

Line

Fault RPS

5

67

0V

NO NO NO

NC NC NC

8CC

C

A+ A+ A+ A+ V+

REM RESET

Figure 21. 3GSTU RedCARE Connections

Application

The DC6 digital communicator/modem is suitable

for connection to the following types of telephone

line:

lDirect exchange lines (PSTN) supporting DTMF

(Tone dialling) or Loop Disconnect (Pulse

Dialling).

lPABX exchanges (with or without secondary

proceed indication).

+

The DC6 is only approved for use with

compatible PABXs. Correct operation in all

circumstances is not guaranteed.

+

The DC6 is fully compatible with BT Network

services.

+

Only control panels fitted with V2.0 or later

software, or DC6’s fitted with V1.17 or later

software are compatible with Call Minder

and Call Divert services. For full details on

compatibility refer to Technical Bulletin

002/04/98 or contact Technical Support.

Approval

The DC6 digital communicator/modem is not

suitable for connection as an extension to a pay

phone or 1+1 carrier systems. The DC6 digital

communicator/modem is approved for the

following usage:

lAutomatic call initialisation

lOperation in absence of proceed indication

lMultiple repeat attempts

lModem

Usage other than the approved usage or failure to

comply with the installation and programming

instructions may invalidate any approval given to

the apparatus.

Connections

Connection terminals on the DC6 are described

as "Telecommunications Network Voltage" circuits

(TNV).

+

It is important that the installer ensures that

TNV connections are only connected to

the PSTN and SELV circuits are only

connected to other circuits designated as

SELV circuits.

+

Please ensure that cabling to the

telephone line connections (TNV) are

routed well away from the detection

circuitry (SELV) and the cabling to the

detection circuitry (SELV) are routed well

away from the telephone circuitry (TNV).

+

Interconnection circuits should be such

that the equipment continues to comply

with the requirements of 4.2 of EN 41003 for

TNV circuits and 2.3 of EN 60950 for SELV

circuits, after making connections

between circuits.

19

TS690 & TS690ID Installation Manual System Installation

Telephone cable

Type 1/0.5mm CW130

8

A = 5 - White/Blue ring

B = 2 - Blue/White ring

NOTE

The A1 and B1 telephone connections are not

used on the UK version of the DC6.

6

5

4

ABB1A1

Status

LED

Plug onto

JP4

Telephone Line

Connections

(TNV)

Mounting Pilar

Holes

Mounting Pilar

Holes

3

2

1

Figure 22. DC6 Connections

Installation

+

For your safety, installation of the DC6

MUST be carried out in the sequence

shown below:

1. Ensure that all power is removed from the

system i.e. mains supply and standby battery.

2. Remove the DC6 from its packaging and fit

the plastic mounting pillars into the 4 holes

provided.

3. Align the DC6 with the connector JP4 on the

main PCB and push firmly into place.

4. Connections to the telephone network must

be made via a NET master socket (Line Box).

5. Using the cable type 1/0.5mm CW1308, strip

back 5mm of the required cores and feed into

the control panel though the appropriate

cable entry. Keep all telephone cables at least

5mm away from other alarm cables.

6. Connect the two telephone cables to the

terminal blocks A and B, see figure 22.

7. Remove the two screws from the BT master

jack socket and remove the bottom section

from the master jack.

8. Connect the cable from A and B terminals on

the DC6 to the BT master jack terminals, see

figure 22.

9. A special insertion tool will be required to

connect the cable to the master jack, this is

available from RS Components (Part No.

470-487).

10.Replace the bottom section of the master jack

socket and replace the two screws.

11.Re-apply power to the control panel.

12.The DC6 must now be programmed, refer to

"Modem Options” on page 45.

13.Each channel can be tested using the

Digicom Test routine, see page 47.

14.Finally replace and secure the cover on the

control panel.

DC54 & DC58M Installation

A plug-on digital communicator DC54, DC58 or

DC58M may be fitted inside the control panel to

allow alarm status information to be transferred to

a dedicated central station. The unit should be

fitted in accordance with the installation

instructions supplied with it and connected to the

control panel plug DIGI-MODEM (JP3) using the

lead provided with the unit. The NVM within the will

need to be programmed using an engineer’s

keypad or PP5.

+

The control panel can only support one

plug-on Digi-Modem either the DC6 or

DC54/58M. Do not connect both types to

same control panel.

20

System Installation TS690 & TS690ID Installation Manual

Connect to JP3

DIGI-MODEM

Plug-on digicom / digi-modem

A

B

BC

B.T. master jack ( Type NTE5

user accessible connections )

A(5) = White / Blue ring

BC(3) = Orange / White ring

B(2) = Blue / White ring

Telephone cable

(Type 1/0.5mm CW1308)

6

5

4

3

2

1

Figure 23. DC54/DC58 Connections

Other manuals for TS690

3

This manual suits for next models

1

Table of contents

Other Menvier Security Control Panel manuals

Menvier Security

Menvier Security TS690 Assembly instructions

Menvier Security

Menvier Security TS2500 User manual

Menvier Security

Menvier Security TS400 Installation manual

Menvier Security

Menvier Security TS590 Assembly instructions

Menvier Security

Menvier Security TSD402 Operation manual

Menvier Security

Menvier Security TSD402 User manual

Menvier Security

Menvier Security TS690 Assembly instructions

Menvier Security

Menvier Security TS700 Installation manual

Menvier Security

Menvier Security TS510 User manual

Menvier Security

Menvier Security TS690 User manual