Menvier Security TS510 User manual

TS510

INTRUDER ALARM CONTROL PANEL

INSTALLATION

MANUAL

Menvier Security Ltd., Hither Green, Clevedon, Avon BS21 6XU

Tel: 0275 870078, Fax: 0275 343453, Tlx: 44782

CONTENTS

SPECIFICATION ........................................................................................ 1

INTRODUCTION ........................................................................................ 1

PRE-INSTALLATION PANEL TEST.......................................................... 2

INSTALLING THE PANEL ......................................................................... 2

SYSTEM WIRING....................................................................................... 3

REMOTE KEYPAD..................................................................................... 6

DIGITAL COMMUNICATOR ...................................................................... 6

PROGRAMMING........................................................................................ 9

DEFAULTS................................................................................................. 9

Complete the programming and zone reference records,leave these with

the control panel for future reference. Complete the Zone Location

Record at the back of the user manual, and leave it with the customer.

Fully train the customer in the use of the system, as this will save much

wasted time later on in answering simple questions over the telephone.

COPYRIGHT: All rights reserved. No part of the information

contained in this document may be reproduced or

copied by any means without the written permission

of Menvier Security.

Pt No B.18783 Drg No 33:0919:00.Iss 04.Doc 01

© Menvier Security Ltd. 1993

Issue 4: June 93 Page 1

SPECIFICATION

5 Programmable Zones with individual Tamper circuits, plus Fixed PA, Exit Terminator and

programmable Keyswitch/Final Exit circuit.

Outputs for Bell, Strobe, 16Loudspeaker and two programmable outputs.

Optional Remote Keypad (4 max).

Plug-on digicom DC3, or plug-on interface (TS510.IF) for connection to digicoms (eg DC28,

Redcare STU, Paknet etc.)

Conforms to BS4737: Part 1: 1986

INPUT VOLTAGE 240V ±10% 50Hz

PANEL DC CURRENT 30mA, 100mA in alarm

REM DC CURRENT10mA

CURRENT AVAILABLE 750mA MAX (AUX + BELL CURRENT)

BATTERY CAPACITY 12V, 2.6/3.2AHr (batteries not supplied)

DIMENSIONS W x H x D Weight

Panel 260 x 213 x 85mm 1.5Kg

Remote Keypad 125 x 127 x 32mm 200g

ENVIRONMENT 0-55C (INDOORS)

INTRODUCTION

This Installation Manual is intended to help you install the TS510 as quickly and easily as

possible. It is therefore very important to read the manual thoroughly

before

starting any

work. This is particularly significant if it is your first TS510 installation.

If you have installed a TS510 before then you may wish to turn straight to the Quick

Reference Guide (Page 8) to refresh your memory.

Figure1- TS510 ASSEMBLY LAYOUT

Page 2 Issue 4: June 93

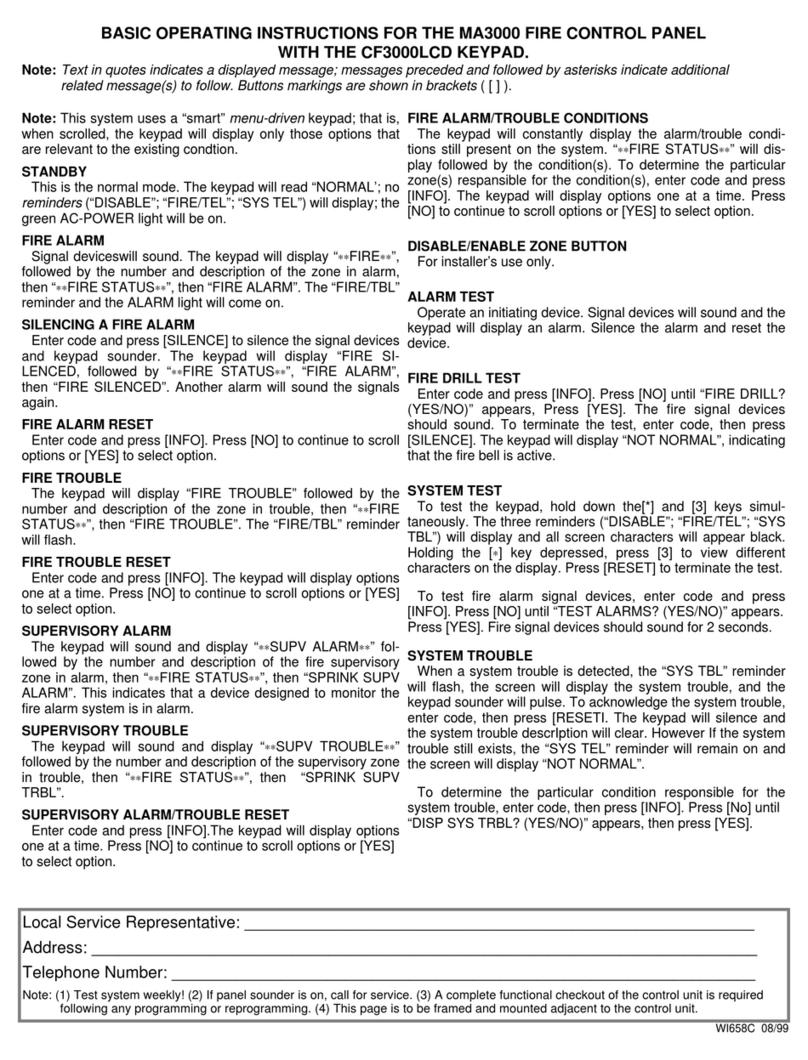

PRE-INSTALLATION PANEL TEST (OPTIONAL)

1 Unpack the TS510, remove the two screws from the front of the panel and lift away

the left hand cover. Disconnect the transformer leads, release the clip near the top of

the PCB and then carefully remove the complete right hand cover assembly.

CAUTION: Do not touch the surface of the PCB as this may cause static damage

to the product.

2 Connect the mains supply to the fused terminal block using a suitable cable, and then

replace the right hand cover assembly ensuring that it is securely clipped in place and

the transformer leads are reconnected. Check that all the ZONE and TAMPER

terminal blocks are correctly linked out, then replace the left hand cover. (The battery

is not necessary at this stage)

3 Switch on the power and enter the default user code, [5678]. The [UNSET] LED will

flash and, after 5 seconds, the setting sequence will begin. Wait until the exit tone

ceases and a two tone confirmation signal is heard. The panel is now SET and the

[UNSET] LED is out.

4 With the panel still in the SET condition, remove the left hand cover thereby releasing

the tamper switch. Ensure that the sounder operates at full volume.

5 With the left hand cover still removed, enter [5678] to unset the panel ([UNSET] LED

on), and check that the [TAMPER] LED flashes.

Successful completion of this procedure indicates that the panel is working correctly and is

ready to install. If unsuccessful, switch off and re-apply the mains (ensuring that the Exit

Terminator is linked out to reset the system to factory defaults. Repeat the procedure and if

still unsuccessful contact your supplier.

INSTALLING THE PANEL

NOTE. THE PANEL MUST ONLY BE CONNECTED TO THE MAINS

VIA AN UNSWITCHED FUSED SPUR.

Remove the two screws from the front of the panel and carefully lift away the left hand cover.

Disconnect the transformer leads, release the clip near the top of the PCB and then remove

the complete right hand cover assembly. CAUTION: Do not touch the surface of the PCB

as this may cause static damage to the product.

Place the base on the wall where it is required and mark the screw positions. Remove the

base, then drill and plug the wall. Fix the base to the wall.

Connect the mains to the fused (160mA) terminal block in the panel, then replace the right

hand cover assembly remembering to reconnect the transformer leads. The panel is now

ready to wire and programme.

NOTE: When connecting the battery, if the red LED near to the

AUX fuse is illuminated, then the battery has been incorrectly

connected or the battery voltage is below 8 Volts. Disconnect the

battery and reconnect correctly, on reconnecting the battery the

LED will switch off.

Issue 4: June 93 Page 3

SYSTEM WIRING

All ZONE and TAMPER inputs are linked out prior to despatch from the factory. Remove

these links from those zones which are to be used, but leave the links in unused zones. The

EXIT TERMINATOR link MUST BE REMOVED even if this facility is not used, otherwise all

programmed information will be lost on total power loss (mains and battery).

WHEN PLANNING AND INSTALLING THE WIRING:-

1Ensure that the mains cable, circuit cables and telecom cables are kept separate, and

that mains cable enters the housing as near to the fused terminal block as possible.

2Ensure that the circuit, tamper and remote keypad cables are not routed adjacent to

AC or RF cabling and are not run in multicore cables with bells or sounders.

3Insulation testing should only be carried out when the cable under test is disconnected

from electronic circuitry at both ends.

Figure2- SAMPLE Wiring Diagram (showing Double Pole and End Of Line Resistor wiring)

Page 4 Issue 4: June 93

AC IN: These are connected to the mains transformer via the two AC leads, (their

polarity is not critical).

AUX +/-: These provide auxiliary power for PIRs and other devices within the protected

area. The system current consumption can be determined by measuring the

voltage across the two test pads located between the terminal blocks for circuit

1 and circuit 2. Multiply the reading by 10 (eg. 30mV 300mA, 75mV

750mA) to give the current reading. The output is protected by a 1A fuse [FS1],

located near the terminal blocks (see Fig 1). Failure of [FS1] is indicated as a

tamper.

NOTE: THE TOTAL POWER CONSUMPTION MUST NOT EXCEED 750mA.

CIRCUITS 1-5: The zones can be wired using any combination of two different zone wiring

methods, called DOUBLE POLE (4 wire) or END OF LINE RESISTOR (2 wire).

- DOUBLE POLE: This is the conventional wiring method using

two wires for the alarm loop (wired across the [ZONE] terminal

blocks) and two for the tamper loop (wired across the [TAMP]

terminal blocks) (see Fig 2).

- END OF LINE RESISTORS: This method uses resistors on the

detection circuit, one (4K7) fitted across

each

alarm contact and

the other (2K2) in series with the loop at the furthest point (End

of Line). The 2 wires are connected between the outer terminal

blocks of the [ZONE] & [TAMP] connections, (see Fig 2).

The maximum number of detection devices connected to any zone is ten.

EXIT

TERM: This feature is required in some Police force areas and consists of a normally

open" push button positioned outside the last exit, used to finalise the setting

procedure. The Exit Terminator may be used with Timed Exit (when the

system will set within 5 seconds of pressing the button) or Last Exit setting

procedures (the button must be pressed after the Final Exit has been

operated), and can be programmed to Chime thereby acting as a door bell

when the system is unset. (See PROGRAMMING).

If shorted on power up, the panel will "factory reset", i.e. the factory default

settings will be loaded and any previously programmed data will be lost. The

Exit Terminator uses a single conventional wiring loop (i.e. no resistors) and

tamper protection is provided by the Aux Tamper loop, (see Fig 2).

KEY SW/F.EXIT This input can have one of two functions depending on how the system is

programmed:

KEYSWITCH - A "normally open" keyswitch can be connected to the control panel for

setting, part setting and unsetting the system. When the system is unset,

operating the switch will initiate the setting sequence and, when Set, the same

action unsets the system. Any combination of keyswitch or keypad can be used

in the setting/unsetting sequence; for example the system could be set using

the keyswitch and then unset via the keypad or visa versa. To determine the

operation of the keyswitch ,see PROGRAMMING.

The keyswitch may be of either the spring return momentary action type, or a

standard keyswitch with the key captive in the closed position.

Issue 4: June 93 Page 5

SYSTEM WIRING (Cont.)

FINAL EXIT - The KEY SW/F.EXIT input can be alternatively used as a Final Exit zone, if so

programmed, thus providing a sixth zone.

The KEY SW/F.EXIT input uses a single conventional wiring loop, and the

tamper protection is provided by the Aux Tamper loop, (see Fig 2).

P./A. When activated, the PA (Personal Attack) zone causes a full alarm from the

panel and may also cause the external sounders to be activated. The PA zone

uses a single conventional wiring loop (i.e. no resistors) and tamper protection

is provided by the Aux Tamper loop, (see Fig 2)

AUX TAMPER These provide tamper protection for the P.A. and any other devices

connected to the control panel, (see Fig 2).

If 2 or more tamper circuits are to

be connected to

[AUX TAMP],

they must be wired in series.

NOTE: IF THE MAINS IS OFF AND THE BATTERY VOLTAGE

DROPS BELOW 10.5V, A TAMPER CONDITION WILL BE

GENERATED.

BELL TR- This provides the bell tamper return signal for the external sounder (bell or

siren) via a -ve return signal.

O/P 1 & O/P 2 These are programmable outputs which are +ve applied and can be selected

as any one of the following .

SW12V: Activates when the system sets, and de-activates on entry

or

on

alarm to activate latch indicators on movement detectors.

DETECTOR RESET: Normally active, and de-activates when a passcode is

entered whilst the system is unset to reset latched detectors.

WALK TEST (Output 1): Activates whilst the system is in walk test mode to

enable the walk test LED on movement detectors.

ALARM(Output 1): Activates when a full alarm condition is detected.

P.A.(Output 2): Activates when a P.A. alarm condition is detected.

FAULT (Output 2): Activates when a circuit is active during the exit period.

+VE H/O This is used to provide the +ve hold off to external sounders, strobes etc. It is

protected by a 1A fuse [FS2], (see Fig 1). To gain access to FS2, remove the

left hand cover and the fuse will be seen below the NOVRAM.

NOTE: THE TOTAL POWER CONSUMPTION OF THE SYSTEM

MUST NOT EXCEED 750mA.

H/O- This connection is used to provide -ve hold off to external sounders etc.

STB- This is a -ve applied output that can draw up to 250mA to drive strobes etc. It

switches on with the bell, and off when the panel is reset. Additionally, the

strobe will operate if the system fails to set during exit.

TRG- This is a -ve applied output which can draw up to 500mA to drive external

sounders. It switches on when the bell delay time expires, and off when the bell

duration time expires, or when a passcode is entered.

L/S+ This output will drive a 16(minimum) loudspeaker connected across L/S+ and

-VE H/O. The volume control is located above FS1 and allows adjustment of

the Entry /Exit and Chime tones (see Fig 1).

Page 6 Issue 4: June 93

REMOTE KEYPAD

The option of up to 4 remote keypads (order code: TS510.REM) are supplied with an

interface which plugs onto the main panel PCB. The connections from the panel to the

Remote Keypad require a five core cable (max length 50m).

Assuming that the control panel covers have been removed, the cable is in place and

that the mains supply and backup battery have been disconnected, installation is as

follows:

Connect the cable to the interface connections A, B, C etc. and then carefully locate

the interface in the slot at the bottom of the panel PCB (see Fig 3). Replace the right

hand cover assembly.

Separate the remote keypad cover assembly from the base by releasing the clips on

the top and bottom of the housing. Place the base on the wall where it is required and

mark the screw positions. Remove the base then drill and plug the wall. Fix the base

to the wall.

Taking care not to damage the PCB assembly, connect the terminal blocks on the

remote keypad to the cable, ensuring that the connections through to the control panel

interface card are A to A, B to B etc.

Carefully re-attach the front cover assembly to the base ensuring that the cable is

clear of the spring on the tamper switch, and the cover is securely clipped to the base.

Finally re-connect the mains supply and test the operation of the remote keypad.

If more than 1 remote keypads are to be used, connections may be in a star or daisy

chain configuration.

DIGITAL COMMUNICATOR

The DC3 is an 8 channel plug-on digital communicator specifically designed to operate with

Menvier control panels, and is supplied with a lead for connection directly onto the main

panel PCB. The unit has its own installation and programming instructions which must be

referred to before proceeding with installation. The digital communicator is mounted behind

the right hand lid assembly as appropriate.

CAUTION: The mains supply and backup battery must be disconnected before connecting

the DC3 to the main PCB.

Other communication devices such as the DC28 Digicom, RedCARE STU, Paknet Interface

Card etc. may be connected to the TS510 by using an optional interface card (TS510.IF).

This is also supplied with its own installation instructions which should be referred to before

proceeding with installation. Fig. 4 shows the TS510.IF connections when plugged onto the

TS510 PCB.

Issue 4: June 93 Page 7

Fit the DC3 connector to the TS510 plug as shown.

Fig 3 - DC3 and TS510.REM Connections

Fit the TS510.IF to the panel plug taking care to ensure that

correct alignment is made and that no pins are visible.

Fig 4 - TS510.IF and TS510.REM Connection

Page 8 Issue 4: June 93

QUICK REFERENCE GUIDE

FS1 (AUX 12V) FUSE = 1A

FS2 (BELL 12V) FUSE = 1A

MAINS FUSE = 160mA

OPTIONS 1

61 Bell duration

(20 mins)

62 Bell delay time

(0 mins)

63 Signalling options

ZONE LED 1 2 3 4 5

On for:

Bell= SAB No Abort Audible PA

PA audible on L.F.

Not used

Off for: Bell= SCB Abort Silent PA PA silent on L.F. OFF

64 Signalling of fire

On for: Unset Partset A Partset B

Full Set

Not used

65 Output 1

On for:

Walk test

SW12V Dtr reset Alarm Not used

66 Output 2

On for: Fault

SW12V

Dtr reset PA Not used

67 Keyswitch operation

On for:

Full set

Part set A Part set B Final Exit Not used

68 Event log; Press 1 for newest event, 2 for oldest etc. Press 0 to exit

69 Setting options

On for: Set allowed

with mains

failure

Rising Entry

and Exit

tones

Set allowed

with line fault Not used Not used

Off for:

Set

disallowed

with mains

failure

Continuous

Entry and

Exit tones

Set

disallowed

with line

fault

Not used Not used

9 Options 2

On for: ET/FE Silent F.Exit set E.T. enabled Engr reset

3 rearms

Off for:

ET/FE

Chimes

Timed set E.T. disabled User reset

0 rearms

Issue 4: June 93 Page 9

PROGRAMMING

The TS510 is very easy to program, using a combination of simple keystrokes, lights and

sounds. Additionally, there are two ways to speed up the process even further; 1) fill in the

programming record before you start, and 2) use the Default Settings where they coincide

with your own requirements. These are factory programmed and appear when the mains

supply is first connected to the panel.

In order to save your programmed information the

Exit Terminator link MUST be removed as otherwise any subsequent interruption to

the mains supply will reset the panel to the Default Settings.

After each programming step has been successfully completed a two tone confirmation tone

will sound indicating that the panel has accepted the current information and is ready to

accept the next instruction. For some functions the tone is automatic (eg. setting timers) but

for other functions it is given after pressing [0]. To assist programming, a [FUNCTION] LED

is provided which indicates the next keypress is to be a number (off) or a function (on).

The programming instructions should be left with the TS510 for future reference. They

assume that you have entered the Engineer Code (default setting = 1234) and the

[CALL ENGR] LED is lit indicating that the system is in the Engineer's Menu. The key

functions now change to those shown on the Quick Reference Guide. If any other LED is also

lit this shows which circuit created the last full alarm condition, (i.e. it acts as an automatic 1

event memory log). If the [CALL ENGR] LED is flashing at this stage, the last alarm

activation occurred whilst a line fault was present.

It is not necessary to programme the options in numerical order.

DEFAULTS

ENGINEER CODE = 1234 OPTIONS 1:

MASTER USER CODE = 5678 Bell output is SAB

LAST EXIT ZONE = ZONE 1 Alarm cleared on reset

ACCESS ZONE = ZONE 2 Audible P.A.

EXIT TIME = 30 SEC P.A. audible in line fault

ENTRY TIME = 30 SEC Fire output signals during Full Set

only

BELL DURATION = 20 MIN Output 1 is WALK TEST

BELL DELAY = 0 MIN Output 2 is SW12V

REMOTE RESET REF = 004 KEY SW/F.EXIT input is full set keyswitch

Set inhibited on mains fail

OPTIONS 2:

Exit Terminator chimes

Exit terminator disabled

Timed exit set

Auto rearm

User reset

NOTE:

IF THE EXIT TERMINATOR IS CLOSED AT POWER-UP,

ALL INFORMATION WILL BE RESET TO

THE DEFAULTS.

TS510

PROGRAMMING GUIDE AND SYSTEM RECORDS

COMPLETE FORM USING BOXES PROVIDED AND LEAVE

WITH THE CONTROL PANEL FOR FUTURE REFERENCE

ENTER ENGINEER CODE AND THE [CALL ENGR] LED WILL ILLUMINATE TOGETHER WITH

THAT OF THE ZONE WHICH CREATED THE LAST ALARM. IF THE [CALL ENGR] LED

FLASHES, THE LAST ALARM OCCURRED WITH A LINE FAULT PRESENT. OPTION

DEFAULTS ARE SHOWN IN BOLD.

To programme any of the zones (1 to 5) as standard NIGHT circuits, simply ensure that they are

not programmed as Last Exit, Access or Fire.

To program any of the zones (1 to 5) as LAST EXIT circuits, press [1].

If any of the Zone LEDs

are ON, then these are already programmed with this option

. To change zones simply enter the

zone number, which will toggle the zone LED on/off. Once the setting is correct press [0] (END) and

listen for the confirmation tone.

LED 1 2 3 4 5

LAST EXIT

ON

/ OFF ON / OFF ON / OFF ON / OFF ON / OFF

DEFAULT = ZONE 1 ONLY

To program any of the zones (1 to 5) as ACCESS circuits, press [2].

If any of the Zone LEDs are

ON, then these are already programmed with this option

. To change zones simply enter the zone

number, which will toggle the zone LED on/off. Once the setting is correct press [0] (END) and

listen for the confirmation tone.

LED 1 2 3 4 5

ACCESS ON / OFF

ON

/ OFF ON / OFF ON / OFF ON / OFF

DEFAULT = ZONE 2 ONLY

To program any of the zones (1 to 5) as FIRE circuits, press [3].

If any of the Zone LEDs are ON,

then these are already programmed with this option

. To change zones simply enter the zone

number, which will toggle the zone LED on/off. Once the setting is correct press [0] (END) and

listen for the confirmation tone.

LED 1 2 3 4 5

FIRE ON / OFF ON / OFF ON / OFF ON / OFF ON / OFF

NO DEFAULT ZONES

EXIT TIME:Press [4] and 3 zone LEDs will light, indicating that a 3 digit exit time (in secs) is

required. Once complete the confirmation tone will be heard. eg. for 30 secs, enter 030

EXIT TIME s

DEFAULT = 030 SECS

ENTRY TIME:Press [5] and 3 zone LEDs will light, indicating that a 3 digit entry time (in secs) is

required. Once complete the confirmation tone will be heard. eg. for 30 secs, enter 030

ENTRY TIME s

DEFAULT = 030 SECS

BELL DURATION: Press [6] [1] and 3 zone LEDs will light, indicating that a 3 digit bell duration

time (in mins) is required. Once complete, the confirmation tone will be heard. eg. for 20 mins,

enter 020 BELL DUR. m

DEFAULT = 020 MINS

BELL DELAY:Press [6] [2] and 3 zone LEDs will light, indicating that a 3 digit bell delay time (in

mins) is required. Once complete the confirmation tone will be heard. eg. for 5 mins, enter 005

BELL DELAY m

DEFAULT = 000 MINS

SIGNALLING OPTIONS:Press [6] [3] and combination of zone LEDs will light, each

showing a different setup:

LED 1 2 3 4 5

ON BELL IS SAB NO ALARM

ABORT AUDIBLE PA PA AUDIBLE

ON L.F. NOT USED

OFF BELL IS SCB ALARM ABORT SILENT PA PA SILENT ON

L.F. NOT USED

SIGNALLING OF FIRE:Press [6] [4] combination of zone LEDs will light, each showing a

different setup:

LED 1 2 3 4 5

ON = FIRE

SIGNALLED

IN:

UNSET PARTSET A PARTSET B

FULL SET

NOT USED

ON / OFF ON / OFF ON / OFF ON / OFF NOT USED

OUTPUT 1:Press [6] [5] and one of the following LEDs will light, showing which function is

indicated by Output 1:

LED 1 2 3 4 5

ON FOR:

WALK

TEST

SW12V DTR RESET ALARM NOT USED

ON / OFF ON / OFF ON / OFF ON / OFF NOT USED

OUTPUT 2:Press [6] [6] and one of the following LEDs will light, showing which function is

indicated by Output 2:

LED 1 2 3 4 5

ON FOR: FAULT SW12V DTR RESET PA NOT USED

ON / OFF ON / OFF ON / OFF ON / OFF NOT USED

KEYSWITCH/FINAL EXIT:Press [6] [7] and one of the following LEDs will light, showing

how the keyswitch input will operate.

LED 1 2 3 4 5

ON

FOR:

FULL SET

PARTSET A PARTSET B FINAL EXIT NOT USED

ON / OFF ON / OFF ON / OFF ON / OFF NOT USED

VIEW EVENT LOG:Pressing [6] [8] will allow the event log to be viewed. Pressing [8] displays

the last event whilst pressing numbers other than [9] and [0] displays earlier events in order, with [1]

being the oldest event. To exit the routine, press [0].

SYSTEM SET WITH MAINS FAIL: Press [6] [9] to select the system setting options.

LED 1 2 3 4 5

ON FOR: SET ALLOWED

WITH MAINS

FAILURE

RISING ENTRY

AND EXIT

TONES

SET ALLOWS

WITH LINE

FAULT

NOT USED NOT USED

OFF FOR:

SET

DISALLOWED

WITH MAINS

FAILURE

CONTINUOUS

ENTRY AND

EXIT TONES

SET

DISALLOWED

WITH LINE

FAULT

NOT USED NOT USED

ENGINEER CODE:Press [7] and 4 zone LEDs will light indicating that a 4 digit engineer code

is required. Once entered, re-enter the code for confirmation and listen for the confirmation tone.

ENGR CODE

DEFAULT = 1234

REMOTE RESET CODE:Press [8] and 3 zone LEDs will light, indicating that a 3 digit code

must be entered. Enter your code and listen for the confirmation tone.

RESET NO. DEFAULT = 004

OPTIONS:Press [9] and a combination of zone LEDs will light, each showing a different setup.

To change any option, simply enter the number for the options required. Once the settings are

correct, press [0] and listen for the confirmation tone.

LED 1 2 3 4 5

ON FOR: ET/F EXIT

SILENT FINAL EXIT

SET E.T.

ENABLED ENGINEER

RESET

3 REARMS

OFF FOR:

ET /F EXIT

CHIMES TIMED EXIT E.T.

DISABLED USER

RESET

0 REARMS

NOTE: Whilst in engineer mode, tampers are inhibited. To monitor tampers return the panel

to the UNSET condition.

Other manuals for TS510

1

Table of contents

Other Menvier Security Control Panel manuals

Menvier Security

Menvier Security TS690 User manual

Menvier Security

Menvier Security TS690 Assembly instructions

Menvier Security

Menvier Security TS400 Installation manual

Menvier Security

Menvier Security TS690 Assembly instructions

Menvier Security

Menvier Security TS590 Assembly instructions

Menvier Security

Menvier Security TSD402 User manual

Menvier Security

Menvier Security TS690 Assembly instructions

Menvier Security

Menvier Security TS400 User manual

Menvier Security

Menvier Security TS700 Installation manual

Menvier Security

Menvier Security TS2500 User manual