TFP480

Page 2 of 12

Warnings

General

The RAPID RESPONSE Residential Dry

Pipe System described herein must be

installed and maintained by qualified

personnel in compliance with this doc-

ument, and with the applicable stan-

dards of the National Fire Protection

Association, in addition to the require-

ments of any other authorities having

jurisdiction. Failure to do so may impair

the performance of this device.

Owner Responsibility

Owners are responsible for maintain-

ing their fire protection system and

devices in proper operating condition

and in compliance with all applicable

standards and requirements. The in-

stalling contractor or sprinkler manu-

facturer should be contacted with any

questions.

Do NOT Disconnect Batteries or Turn

Off AC Power to Quiet Unwanted

Alarms.

The Model RCP-1 Panel will not oper-

ate (that is, release water or energize

alarms) if AC power is not connect-

ed, has failed, or has been interrupt-

ed for any reason AND the battery is

disconnected, drained, or improperly

connected.

Household Fire Alarm System

The use of an automatic sprinkler sys-

tem does not allow for omission of a

“Household Fire Alarm System” in-

stalled per NFPA 72. The Model RCP-1

Panel is not intended to be used as part

of a “Household Fire Alarm System”.

Electrical Hazard

Disconnect electrical field power when

making any internal adjustments or re-

pairs. Failure to do so may result in per-

sonal injury. Servicing should be per-

formed by qualified personnel.

Static Hazard

Static electricity can damage com-

ponents. Therefore, qualified person-

nel must be grounded before opening

components, installing components,

and prior to installation. Keep compo-

nents wrapped in anti-static material at

all times.

Radio Frequency Energy

This equipment generates, uses, and

can radiate radio frequency energy,

and if not installed and used in accor-

dance with this technical data sheet,

may cause interference to radio com-

munications. This equipment has been

tested and found to comply with the

limits for a Class A computing device

pursuant to Subpart J of Part 15 of FCC

Rules, that are designed to provide rea-

sonable protection against such inter-

ference when operated in a commer-

cial environment. However, operation

of this equipment in a residential area

may cause interference, in which case

the user, at their own expense, will be

required to take whatever measure may

be required to correct the interference.

System Re-Acceptance Test

To ensure proper operation, this prod-

uct must be retested by qualified per-

sonnel in accordance with the Care and

Maintenance section after any modifi-

cation, repair, or adjustment. Retesting

is required to assure that the system is

operating as intended.

Technical

Data

Approvals

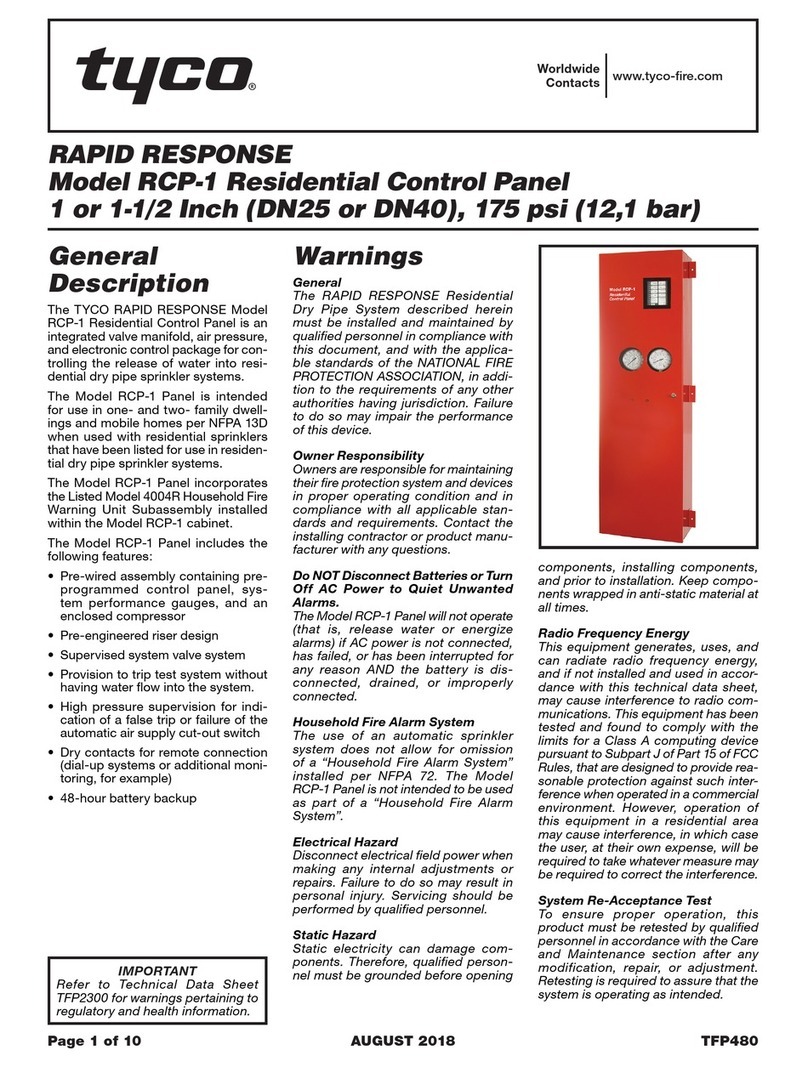

The Model RCP-1 Residential Con-

trol Panel is UL Listed for use in res-

idential dry pipe sprinkler systems

installed in one and two-family dwell-

ings and mobile homes per NFPA 13D

when installed in accordance with this

document.

The Model 4004R Household Fire

Warning Unit Subassembly (Electronic

Control) installed within the Model RCP-

1 cabinet is UL and C-UL Listed.

Maximum Water Pressure

175 psi (12,1 bar)

Friction Loss

Refer to Graph A on Page 3.

Input Voltage

120 VAC, 60 Hz, 4 A

Battery Backup

Two 8.0 amp-hour 12 VDC batteries in

series provides a minimum of 48 hours

of standby and a minimum of 15 min-

utes of alarm/system release. The 15

minutes of alarm/system release pro-

vides a 150% safety factor as com-

pared to the 10-minute requirement of

NFPA 13D.

The battery size is pre-calculated

based on a maximum 1A rating for

NAC1 (Notication Appliance Circuit

-Horns), and a maximum 0.25A rating

for auxiliary devices. The battery back-

up does not provide power to the air

compressor in the event of primary 120

VAC power failure.

Battery Charger

Backup batteries provide a 48-hour

standby and 15-minute alarm/system

release. Batteries automatically re-

charge within 24 hours.

Depleted Battery Operation

The system monitors the battery volt-

age and indicates a trouble status when

the battery is outside its normal range.

There are two battery trouble levels:

Low Battery and Depleted Battery.

When Low Battery is detected, the sys-

tem sounds the tone-alert (piezo) and

ashes the trouble LED. The event must

be accepted by pressing the ACCEPT

SIGNAL KEY. If discharge continues

further, and the batteries reach the de-

pleted state, once again the tone-alert

activates and the trouble LED ashes.

Initiating Device Circuit (IDCs)

IDC1 is internally wired to the system’s

low pressure switch, and no other de-

vices are to be connected to IDC1.

IDC2, IDC3, and IDC4 are spares and

are not to be utilized.

Notification Appliance Circuit

(NACs)

NAC1 is rated at 1 A. NAC2 is a spare

and is not to be utilized.

Notification Appliances

NFPA 13D does not require the instal-

lation of a waterow alarm (notication

appliance device).

If needed, notication appliances can

be installed to indicate release of the

Model RCP-1 Panel.

When installed, notication appliances

must be installed in accordance with

the applicable requirements of NFPA

72. Per the requirements of NFPA 72,

re warning equipment for dwelling

units shall provide a sound that is au-

dible in all occupiable dwelling areas.

Auxiliary Device Power Supply

The Auxiliary Device Power Supply is

rated at 0.25A. If desired and where

the system is not otherwise monitored

by a central control station, the Auxil-

iary Device Power Supply can be used

to power a remote visual signal of an

alarm, supervisory, or trouble condition

through use of the relay contacts (Figure

5). This arrangement is especially con-

venient when the Model RCP-1 Panel is

located in an area where its Tone Alert

is not readily heard or the Operator In-

terface is not readily apparent. The cir-

cuitry, while operable by battery backup,

is not a supervised circuit.

LED/Keypad Operator Interface

•

Red Alarm LED for IDC1 and to indi-

cate system release.

•

Yellow Trouble LEDs for each IDC,

NAC, RAC, and SPM.

•

Dedicated Alarm Silence, Superviso-

ry, and Earth Fault Trouble LEDs.

• Green LED for AC Power ON.

•

KEYs for Accept, Silence, and Reset.