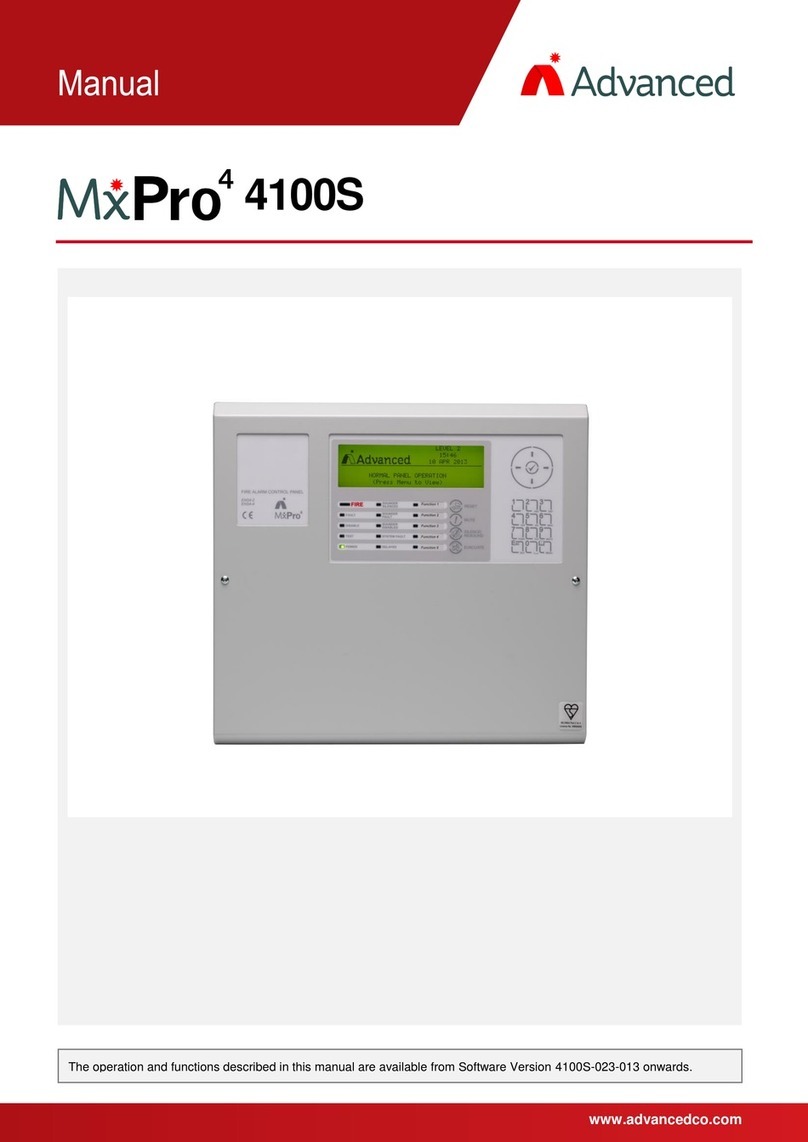

Advanced Mx-5101xR User manual

www.advancedco.com

5000 Series Rack Panels

The operation and functions described in this manual are available from Software Version Mx5000-050-04 onwards.

www.advancedco.com

Specifications & Ordering:

Models, Sales Order Parts:

Mx-5101xR Panel 1-LP Module 6U

Mx-5201xR –Mx-5202xR Panel 2-LP Module 6U

Mx-5401xR –Mx-5404xR Panel 4-LP Module 6U

* Add suffix (x): N for Nittan and V for Argus Vega

Mxp-514 AC Filter Card Kit

Mxm-510-16U Enclosure IP55 16U

Mxm-510-20U Enclosure IP55 20U

Mxm-510-KL Optional CAM Key-Lock kit for outer door

Mxm-510-BS Enclosure Battery Shelf (7Ah/18Ah)

Mxm-510-BS1 Enclosure Battery Shelf Lower (25Ah)

Mxm-510-CP Enclosure Chassis Plate

Mxm-511-XX Enclosure –Blanking Plates –XX = 1U, 2U, 4U, 6U

Mxm-512 Enclosure –LED Mounting Plate 4U

Mxm-513-BB Enclosure –Utility Module 6U –Back Box

Mxm-513-D1 Enclosure –Utility Module 6U –Blank Door

Mxm-513-D2 Enclosure –Utility Module 6U –Door with LED Aperture

Mxm-513-D3 Enclosure –Utility Module 6U –Door with Aperture

Mxm-513-FP Enclosure –Utility Module 6U –Fascia Plate Blank

Mxm-513-MF Enclosure –Utility Module 6U –Switch / LED Mounting Frame

Mxm-513-BP Enclosure –Utility Module 6U –Switch / LED Blanking Plate

Mxm-514-BB Enclosure –Utility Module 8U –Back Box

Mxm-514-D1 Enclosure –Utility Module 8U –Door with Aperture

Mxm-514-FP Enclosure –Utility Module 8U –Fascia Plate Blank

Mxm-515-6U Enclosure –Utility Chassis Plate 6U

Mxm-515-8U Enclosure –Utility Chassis Plate 8U

Mxm-534 Loop Card Vibration Support Plate

Applications / Limitations:

Enclosure solutions requiring rack mounting arrangement and increased IP rating.

With the MXM-510-KL fitted the IP rating of the enclosure is IP44.

Fit the MXM-534 when the panel module is mounted in large floor mounting rack enclosures.

Compatibility:

5000 Series panels, power supplies, peripheral bus modules and network peripherals.

www.advancedco.com

3

Table of Contents Page

1INTRODUCTION.............................................................................................................................................4

1.1 STANDARDS.............................................................................................................................................4

1.2 CAUTIONS AND WARNINGS .......................................................................................................................5

1.3 DESCRIPTION ...........................................................................................................................................5

1.3.1 5000R Series .....................................................................................................................................5

1.3.2 5000VR Series...................................................................................................................................5

1.4 EN54 FUNCTIONS ....................................................................................................................................5

1.5 INSTALLATION APPROVALS.......................................................................................................................6

1.5.1 Fire System Installations....................................................................................................................6

1.5.2 Wiring Regulations.............................................................................................................................6

2INSTALLATION..............................................................................................................................................7

2.1 IDENTIFICATION OF PARTS ........................................................................................................................7

2.2 MECHANICAL SPECIFICATIONS..................................................................................................................8

2.2.1 Enclosure –16U ................................................................................................................................8

2.2.2 Enclosure –Other Sizes....................................................................................................................9

2.2.3 Enclosure –Commercial....................................................................................................................9

2.2.4 Battery Gas Venting...........................................................................................................................9

2.2.5 Battery Shelf / Chassis Plate / DIN Rail.............................................................................................9

2.2.5.1 MXM-510-BS: ..........................................................................................................................................9

2.2.5.2 MXM-510-BS1: ........................................................................................................................................9

2.2.5.3 MXM-510-CP:........................................................................................................................................10

2.2.5.4 DIN-RAIL: ..............................................................................................................................................10

2.3 MODULES...............................................................................................................................................11

2.3.1 Panel Module...................................................................................................................................11

2.3.1.1 Wiring.....................................................................................................................................................12

2.3.2 LED Modules....................................................................................................................................14

2.3.3 Utility Module –6U...........................................................................................................................15

2.3.3.1 Chassis..................................................................................................................................................15

2.3.3.2 Door Options..........................................................................................................................................17

2.3.4 Utility Module –8U...........................................................................................................................19

2.3.4.1 Chassis –6U .........................................................................................................................................19

2.3.4.2 Chassis –8U .........................................................................................................................................20

2.3.4.3 Mimic Door.............................................................................................................................................21

2.3.5 AC Filter Card ..................................................................................................................................22

www.advancedco.com

4

1 Introduction

1.1 Standards

Advanced Electronics Ltd declares that the products identified below conform to the essential requirements

specified in the Construction Products Directive 89/106/EEC:

0786-CPD-20952

EN54-2: 1997 +A1:2006

Control and indicating equipment for fire detection and fire

alarm systems for buildings

Provided options:

- Outputs to Fire Alarm Devices

- Output to Fire Routing Equipment

- Output to Fire Protection Equipment

- Output to Fault Routing Equipment

- Investigation Delays to Outputs

- Dependency on more than one alarm signal

- Fault Signals from Points

- Disablement of Points

- Alarm Counter

- Test Condition

- Standardised Input / Output

EN54-4: 1997 +A1:2002 +A2:2006

Power supply equipment for fire detection and fire alarm

systems for buildings

Mx-5100R, Mx-5200R, Mx-5400R

Mx-5100VR, Mx-5200VR, Mx-5400VR

In addition, the products comply with the following:

Low Voltage Directive 2006/95/EC

BS EN60950-1: 2006 Safety of information technology equipment

Electromagnetic Compatibility Directive 2004/108/EC

BS EN55022: 1998 Emissions, Class B

BS EN50130-4: 1996 +A2: 2003 Immunity, Product Family Standard

www.advancedco.com

5

1.2 Cautions and Warnings

STOP

BEFORE INSTALLATION –Refer To the Ratings shown on the label inside

the product and to the ‘Specifications Chart’ in this document.

Please read this manual carefully. If you are unclear on any point DO NOT

proceed. Contact the manufacturer or supplier for clarification and guidance.

Only Trained service personnel should undertake the Installation,

Programming and Maintenance of this equipment.

This product has been designed to comply with the requirements of the Low

Voltage Safety and the EMC Directives. Failure to follow the installation

instructions may compromise its adherence to these standards.

ATTENTION

OBS ER VE PR ECA UTIO NS

FO R H AND LING

EL ECT RO S TA TIC

SE NSITIV E DEV IC ES

This equipment is constructed with static sensitive components. Observe anti-

static precautions at all times when handling printed circuit boards. Wear an

anti-static earth strap connected to panel enclosure earth point. Before installing

or removing any printed circuit boards remove all sources of power (mains and

battery).

1.3 Description

The 5000R Series is a modular assembly rack mount version of the 5000 Series of Fire Alarm Control panels.

The panels and peripheral devices are housed in dedicated module assemblies designed to be installed into

standard 19” rack mount enclosures.

Enclosures are provided in different sizes to IP55 rating (IP30 with outer glass door open). In addition, the

module assemblies can be mounted into commercial rack mount enclosures.

This manual covers the installation of the rack mount 5000R, 5000VR Series Fire Alarm Control Panel

assemblies and enclosures only. For all other information:

Refer to Product Manual (Document No. 680-165) for all other information on installation and programming

of the panel.

Refer to the User Manual (Document No. 680-166) for details of how to operate the panel.

Refer to the appropriate protocol application note for further and specific information for each protocol.

Refer to individual power supply module, peripheral bus module or network peripheral module

documentation for detailed information on these items.

1.3.1 5000R Series

The 5100R is a Single Loop, Analogue Addressable Fire Alarm Control Panel.

The 5200R is a Two Loop, Analogue Addressable Fire Alarm Control Panel.

The 5400R is a Multiple Loop, Analogue Addressable Fire Alarm Control Panel with provision for up to four

loops.

All above models are designed for use with the Apollo (Discovery, Explorer, XP95 and Series 90) and Hochiki

(ESP).

1.3.2 5000VR Series

The 5100VR is a Single Loop, Analogue Addressable Fire Alarm Control Panel.

The 5200VR is a Two Loop, Analogue Addressable Fire Alarm Control Panel.

The 5400VR is a Multiple Loop, Analogue Addressable Fire Alarm Control Panel with provision for up to four

loops.

All above models are designed for use with the Advanced (AV) fire detection devices.

1.4 EN54 Functions

The EN54 functions and options with requirements are identical to standard 5000 Series Panels. Refer to the

Product Manual (Document No. 680-165) for information.

www.advancedco.com

6

1.5 Installation Approvals

1.5.1 Fire System Installations

The panel must be installed and configured for operation in accordance with these instructions and the

applicable code of practice or national standard regulations for fire systems installation (for example BS5839-1:

2002) appropriate to the country and location of the installation.

1.5.2 Wiring Regulations

The panel and system must be installed in accordance with these instructions and the applicable wiring codes

and regulations (for example BS7671) appropriate to the country and location of the installation.

www.advancedco.com

7

2 Installation

2.1 Identification of Parts

The following diagram shows the major parts of the panels for the 16U enclosure.

Alternative enclosure sizes follow the same general arrangement.

The standard enclosures offer ingress protection to category IP55 with the outer door closed. Internal ingress

protection (with the door open) is to category IP30.

For full details of each individual model refer the separate sections in this manual.

Visual indicators can be seen through the glass panel. The outer door is not locked to provide access to Level 1

and Level 2 controls.

An optional key-lock is available for critical installations

1

.

1

This means, however, that the panel will not fulfil all of the requirements of EN54-2 at Level 1 –in this case, the connection of a remote

terminal (5030) will fulfil all indication and control requirements.

Back Box

1U Blank Plate

1U Blank Plate

Blank Plates or

optional modules

Glazed Outer Door

Control Panel

Key Lock

CAM Lock

Optional key lock is

available

www.advancedco.com

8

2.2 Mechanical Specifications

Item

Specification Details

MXM-510-16U

MXM-510-20U

Dimensions (H x W x D)

730 x 535 x 230

910 x 535 x 230

Weight

22 Kg

25 Kg

IP Rating (Door Closed)

IP55

IP55

IP Rating (Door Open)

IP30

IP30

2.2.1 Enclosure –16U

The diagram below shows the overall dimensions and fixing points for the 16U enclosure.

Optional battery shelves can be fitted in the back box at the positions indicated for batteries (7Ah or 18Ah).

Alternatively, batteries can be mounted in the bottom of the enclosure. Larger batteries (up to 45Ah) must be

mounted in the bottom of the enclosure and can be fitted behind Zone LED modules or blanking plates.

Mount the enclosure on the wall using fixing hardware suitable for the size and weight of the complete

enclosure.

2

The fixing holes are fitted with plugs. To maintain the IP rating, only remove the required plugs and then fit the

supplied sealing washers to the fixing screws.

Knockouts are provided in the top (44), rear (20) and bottom (44) of the enclosure. To maintain the IP rating,

only remove sufficient knockouts for the required cabling and use 20mm cable glands with IP55 rating or better.

If a knockout is removed in error and unused, fit a 20mm sealing plug.

2

Depending on the optional modules fitted, the weight of the complete panel(not including the weight of batteries)can be > 40kg. Including

45Ah batteries, the weight can be > 70kg.

www.advancedco.com

9

2.2.2 Enclosure –Other Sizes

Other wall mount enclosure sizes are available in height increments of 4U (178mm). Fixings point positions are

adjusted accordingly.

2.2.3 Enclosure –Commercial

All of the modules may be housed in any commercially available 19” rack mount enclosure (e.g. SAREL or

RITTAL)

3

. This manual does not provide any information on these enclosures but the information provided will

assist and guide the installation of the modules in these enclosures.

The following are recommended:

SAREL –Spacial S3D wall mount enclosures

(500H x 500W x 200D up to 1000H x 800W x 250D)

RITTAL –TS8 Baying System floor mount enclosures

(1400H x 600W x 500D up to 2000H x 800W x 600D)

The enclosures should be fitted with a glass door option for viewing of Level 1 indications.

2.2.4 Battery Gas Venting

The charging of batteries can result in the release of flammable gases (hydrogen). To prevent a build up of

potentially hazardous gases in a sealed or semi-sealed enclosure, the enclosure should be fitted with a vent

suitable for the IP rating required.

2.2.5 Battery Shelf / Chassis Plate / DIN Rail

2.2.5.1 MXM-510-BS:

Up to two battery shelves can be fitted for mounting of 7Ah or 18Ah batteries. The shelves rest on the side wall

flanges and are secured with three M4 nuts and washers and fit behind panel and utility panel modules. Order

these items separately.

2.2.5.2 MXM-510-BS1:

A battery shelf can be located and secured with four M4 nuts and washers to the bottom of the enclosure whilst

maintaining access to the bottom 20mm knockouts. The shelf will accept up to 2x 25Ah batteries. Field wiring

cables can be routed behind the battery shelf. Order this item separately.

NOTE: If using the top knockouts, batteries up to 45Ah can be located directly in the bottom of the enclosure.

3

For compliance with the requirements of EN54-2 and EN54-4 the commercial enclosure and internal arrangement must follow the

instructions in this manual and must continue to meet an IP30 ingress protection rating with the outer door in both open and closed

positions. If the panel door is lockable, the panel will not fulfil all of the requirements of EN54-2 at Level 1 –in this case, the connection of a

remote terminal (5030) will fulfil all indication and control requirements.

www.advancedco.com

10

2.2.5.3 MXM-510-CP:

A chassis plate can be fitted and secured to the rear wall using six M4 nuts and washers and utilises the same

fixing points as the battery shelves. Order this item separately.

If fitted, batteries must be located in the bottom of the enclosure with or without MXM-510-BS1.

The chassis plate provides mounting positions for up to eight peripheral bus modules or up to six peripheral bus

modules and a power supply (MXS-050 or MXS-051).

Fixed stand-off pillars are provided for six of the peripheral bus modules. The modules can be mounted directly

to these stand-off pillars using the M3 screws supplied with the module.

Separate M-F pillars are supplied with the chassis plate for mounting the further two peripheral bus modules.

Screw these M3 pillars into the captive nuts on the chassis plate and then mount and affix the modules using

the M3 screws supplied with the module.

The PSE module fits directly the chassis plate and is fixed using four M3 screws.

Fit the terminal block to the chassis plate using the two supplied M3x14 screws and affix the integral earth lead

to the stud using the supplied M4 Nuts and Washers.

Affix the supplied warning label to the right of the terminal block.

The incoming AC cables can be tied down to the chassis using one of the supplied cable ties.

2.2.5.4 DIN-RAIL:

M4 Fixing points are provided for up to two DIN Rail sections. Three fixings per rail give options for 200mm,

270mm or 450mm long rails.

If fitted, batteries must be located in the bottom of the enclosure with or without MXM-510-BS1.

PSE

PBUS Module

PBUS Module

PBUS Module

PBUS Module

PBUS Module

PBUS Module

PBUS Module

PBUS Module

www.advancedco.com

11

2.3 Modules

2.3.1 Panel Module

The Panel Module comprises metalwork and electronics. The metalwork is designed to accommodate the

standard common 5000 Series Base Card and Display Card chassis assemblies.

The Panel Module is supplied in a 6U High rack mount enclosure chassis. The depth of the back box is 125

mm. The panel module weight is 6 kg.

The door is securely locked using the standard Advanced Electronics Ltd panel key. The internal arrangement

of the panel module is shown in the following diagram.

The enclosure comprises the standard 5000 panel chassis and display plate assemblies. Up to one peripheral

bus or expansion bus module can be mounted on the chassis plate to the left of the base card. Standard printer

and key-switch options can be mounted to the display plate –refer to main panel manual for details.

www.advancedco.com

12

When the panel module is mounted in large

floor standing rack enclosures, fit the MXM-

MXM-534 loop card support plate as shown

opposite.

Remove the three screws fixing the display

card and replace with the supplied pillars.

Mount the plate onto the pillars and fix in place

using the supplied screws.

2.3.1.1 Wiring

Cable entry holes are provided for installation wiring –two on the right hand side for AC Supply and Battery

Supply –one on the left for internal wiring. Also on the left (top) is a U channel cut-out for routing field wiring to

the side frame of the enclosure.

Cable tie anchor points are provided at strategic locations to tie down the wiring.

Refer to the wiring section of the product manual 680-165 for full information. The AC Supply and Battery

Supply connections are re-iterated below for reference.

2.3.1.1.1 AC Supply

Route the high voltage mains AC wiring into the

enclosure at the upper right corner only. Keep the

AC wiring away from the circuit boards and all

other wiring.

The mains input connector is shown in the

diagram below. Note the positions of the earth,

neutral and live terminal connections. These are

clearly marked on the label next to the connector.

The connector block contains an integral fuse

holder.

FU SE

Brown

Green

LIVE

EARTH

NEUTRA L

Panel W iring

Blue

3.15A

AC Mains terminations

The fuse is rated as follows:

T 3.15A H 250V

Replace with correct rating and specification only.

Must be

earthed

The panels must be connected to

the supply earth through the power

cable.

Secure the mains input wiring by tie wrap as close

to the terminal block as possible.

Connect the Control Panel to the mains supply via

a readily accessible disconnect-device (Isolation

Switch) and suitable earth fault protection

incorporated in the building installation wiring. The

Mains cable should be 0.75mm2cable rated at

250V and fused via a 5A anti-surge fuse.

NOTE: If two or more power supplies are installed

then an MXP-514 AC Filter card kit must be

installed in the back box. Refer to Section 2.3.5 for

more details.

M3 Pillars

MXM-534 Plate

Order separately

www.advancedco.com

13

2.3.1.1.2 Battery

The batteries must be located on the battery shelf behind the module or in the bottom of the enclosure. Fit the

Mxp-501 Battery Remote Temperature Sensor to ensure that the batteries are charged at the correct voltage.

Plug the Mxp-501 into the connector and route the sensor cable along with the battery leads. Use the supplied

tie-wraps to tie the sensor cable to the battery leads so that the encapsulated sensor is located close to the

batteries. The sensor cable is 500mm in length.

NOTE: If the base card is not fitted with either a jumper or a remote temperature sensor the panel will indicate a

charger failure condition. Ensure that the jumper is replaced if the remote sensor is removed / not used.

WARNING: HIGH VOLTAGE INSIDE

DO NOT REMOVE COVER

No Serviceable Parts Inside

Jumper –centre two pins

Battery Leads

Sensor

www.advancedco.com

14

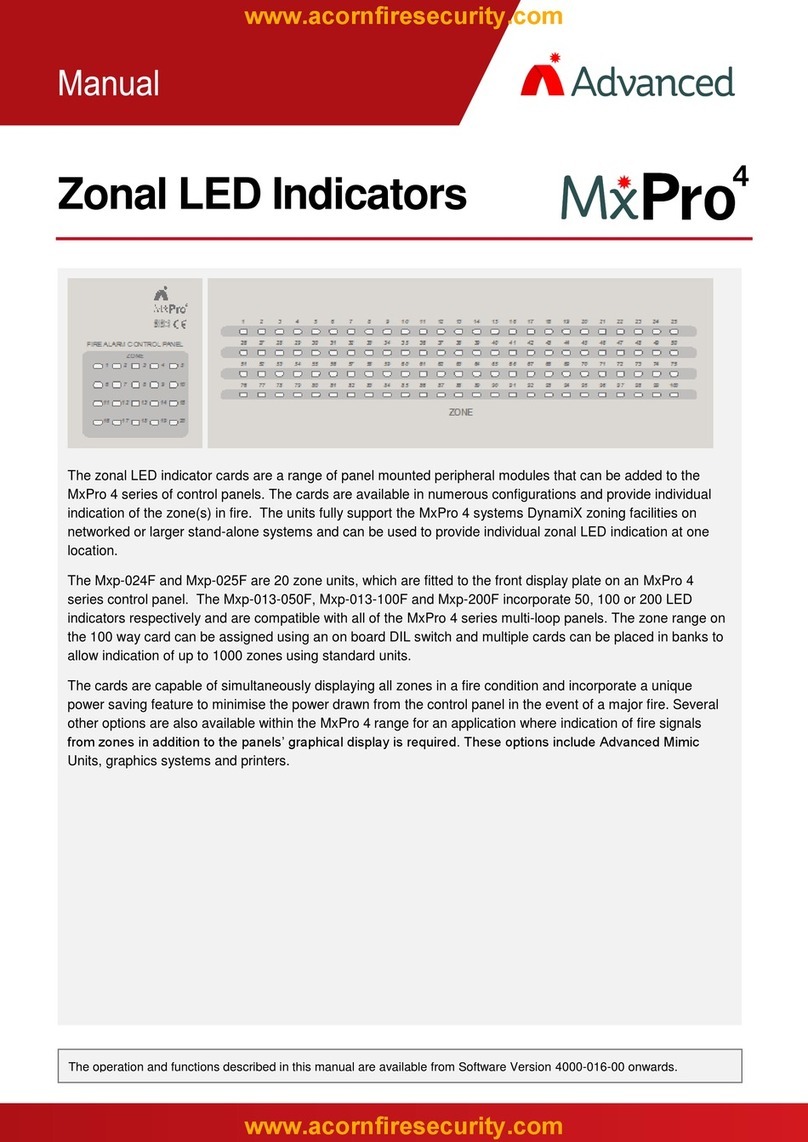

2.3.2 LED Modules

LED Indicator Modules are available with 50 (Column), 100 or 200 LED indicators. All Modules are 4U in height

(see also 6U Utility Module for additional mounting options). Order the required LED Module and the 4U

Mounting Plate separately.

A Panel can support up to 250 LED

indicators in total (or one 200 LED

module). An example (50 LED column

format) is shown opposite.

The Zone LED chassis plate is mounted

onto the 19” mounting frame using 4x M4

Nuts and washers.

Connect the ribbon cable to the display

card. Route the cable through the lower

hole in the left hand side of the panel

module enclosure and connect to the input connector (top) of the first LED module. Use the long ribbon cable

supplied with the 4U mounting plate instead of the cable supplied with the LED Module. Use the short ribbon

cable to connect between modules.

Connect the supplied ribbon cables between the modules.

Connect the earth lead fitted on each 19” 4U mounting frame

to the nearest suitable earth point in the enclosure.

Up to 5 modules

(250 LED)

100-LED Modules

50-LED (Column) Modules

200-LED Module

www.advancedco.com

15

2.3.3 Utility Module –6U

The Utility Module comprises of the same metalwork assembly as the Panel Module.

Alternative doors are available and must be specified separately. All doors are securely locked using the

standard Advanced Electronics Ltd panel key. The weight is 4-6 kg depending on modules fitted.

The module accommodates a standard 6U utility chassis plate to which power supplies, peripheral bus cards

and network peripherals may be fitted.

2.3.3.1 Chassis

The utility chassis plate can accept the following module types:

1x PSE Module (Mxs-049, Mxs-050 or Mxs-051) and

1x Mxp-510 BMS Interface

4

or 1x Mxp-554 ipGateway or 2x standard peripheral bus modules or 2x Mxp-539

Mimic Interface Modules

OR

1x Mxp-510 BMS Interface or 1x Mxp-554 ipGateway and 1x standard peripheral bus module

OR

2x Mxp-539 Mimic Interface Modules and 1x standard peripheral bus modules

OR

3x standard peripheral bus modules

4

Mxp-020 and Mxp-045 modules can also be fitted in this one location.

Chassis

Plate

Order

separately

AC Terminal Block

and cable (supplied

with PSU module)

Earth Stud

Back Box

Order

separately

www.advancedco.com

16

2.3.3.1.1 Modules

Screw the M3 Pillars supplied with the chassis plate into the required mounting holes. Fit the module to the

pillars with the supplied M3 Screws.

2.3.3.1.2 PSE

The PSE modules fit directly the chassis plate and are fixed using four M3 screws. Fit the Mxs-049 to the upper

four holes and fit the Mxs-050 and Mxs-051 to the outer four holes.

Fit the terminal block to the enclosure using the two supplied M3 Screws and affix the integral earth lead to the

stud using the supplied M4 Nuts and Washers.

Affix the supplied warning label to the right of the terminal block.

The incoming AC cables can be tied down to the enclosure using one of the supplied cable ties.

PSE

MXP-539

MXP-510/MXP-554

MXP-539

PBUS Module

PBUS Module

PBUS Module

www.advancedco.com

17

2.3.3.2 Door Options

The following door options are available (all diagrams show the rear view of the door). Order the required door

and associated metal parts separately. Mount the door to the back box and secure the hinge using the supplied

M4 Nuts, Plain and Spring Washers supplied.

2.3.3.2.1 Blank Door Option

The utility enclosure can be simply fitted with a blank door to provide secure (key cam lock) access to the

internal modules.

2.3.3.2.2 Zone LED Door Option

Any of the Zone LED option cards can also be fitted to the 6U Utility Module.

Route the ribbon cable from the panel display card

through the lower hole in the left hand side of the panel

module enclosure. Route the cable through the lower

hole in the left hand side of the utility module enclosure

and connect to the input connector (top) of the first LED

module.

Refer to the LED section for further details.

2.3.3.2.3 Switch / LED Door Option

This option comprises of the standard panel module door fitted with a mounting frame to accept up to two Mxp-

538 Switch / LED cards.

Mount the Mxp-538 module on the four fixing studs of the mounting frame.

Fit a blanking plate to the second aperture if unused.

Refer to the data sheet supplied with

the Mxp-538 for full wiring information.

Hinge (Common to all doors)

Affix with the supplied nuts

and washers to the three

studs on the back box.

Hinge

Mxp-538

Positions

Mounting

Frame

Order

separately

Blanking

Plate

Order separately

if required

www.advancedco.com

18

2.3.3.2.4 Small Mimic Door Option

This option consists of the standard 6U panel door (with aperture) and a fascia plate. The fascia plate can be

drilled and screen printing for the required graphic indicator diagram.

Mimic area = 350 W x 180 H

Up to two Mxp-539 Input / Output Cards are required to be mounted to the chassis. LED and Switch options

required are available.

Up to 48 (96) LED indicators and 16 (32) Switches can be driven by one (or two) Mxp-539 modules.

Hinge

Fascia

Plate

Order

separately

www.advancedco.com

19

2.3.4 Utility Module –8U

The large Utility Module is of similar construction but 8U in height. The module accommodates either the

standard 6U or large 8U utility chassis plates. The weight is 5-8 kg depending on modules fitted.

The main use of the large utility enclosure is for graphical mimic indicator panels. The blank plate in the door

can be removed so that it can be drilled and screen printed as required for fitting of switches and LED

indicators.

2.3.4.1 Chassis –6U

The 6U Chassis can be fitted –refer to previous section for full details.

Up to 7Ah batteries can be installed in the 8U Utility Module if the 6U Chassis is employed. Otherwise, batteries

can be mounted in the bottom of the enclosure or on the battery shelf.

Chassis Plate

Order separately

AC Terminal Block

and cable (supplied

with PSU module)

Earth Stud

Back Box

Order

separately

www.advancedco.com

20

2.3.4.2 Chassis –8U

The utility chassis plate can accept the following module types:

1x PSE Module (Mxs-049, Mxs-050 or Mxs-051) and

1x Mxp-510 BMS Interface

5

or 1x Mxp-554 ipGateway and up to 2x Mxp-539 Mimic Interface Modules

OR

1x PSE Module (Mxs-049, Mxs-050 or Mxs-051) and

Up to 4x Mxp-539 Mimic Interface Modules (Up to 192 LED and up to 64 Switches)

5

Mxp-020 and Mxp-045 modules can also be fitted in this one location. An additional Mxs-027 can be also be fitted to provide a further 100

LED outputs.

PSE

MXP-539

MXP-510/MXP-554

or Mxp-020/045

MXP-539

MXP-539

MXP-539

Mxs-027

LED Extender

Chassis Plate

Order separately

AC Terminal Block

and cable (supplied

with PSU module)

Earth Stud

Cable tie anchor

points for DC

power wiring

Cable clip positions

This manual suits for next models

4

Table of contents

Other Advanced Control Panel manuals

Advanced

Advanced ExGo Series User manual

Advanced

Advanced MxPro4 Series User manual

Advanced

Advanced MxPro 5 Installation and operating instructions

Advanced

Advanced MxPro 4 4100S User manual

Advanced

Advanced Lux Intelligent LX-9400 User manual

Advanced

Advanced Quick Zone XL Guide

Advanced

Advanced MxPro4 Series User manual

Advanced

Advanced Mx Pro 4 User manual

Advanced

Advanced LIFELINE Px-100 User manual

Advanced

Advanced Ex-3001 User manual