Merck EMD Millipore NovAseptic User manual

Installation and User

Guide

NovAseptic®GMP ATEX Mixer

NovAseptic and the Vibrant M are trademarks of Merck KGaA, Darmstadt, Germany or its aliates. All other trademarks are the

property of their respective owners. Detailed information on trademarks is available via publicly accessible resources. © 2008-

2018 Merck KGaA, Darmstadt, Germany and/or its aliates. All Rights Reserved.

00105442PU Rev 5 02/2018

2 Installation and User Guide

Contents

Installation Note ......................................................................................... 5

Operator and Equipment Safety .................................................................... 6

Labeling .................................................................................................... 7

NovAseptic®GMP ATEX Mixer Components ..................................................... 8

Mixing Head (AX#/12#) ........................................................................ 8

Male Bearing (AX#/24#) ....................................................................... 8

Tank Plate (AX#/33) ............................................................................ 8

Drive Unit (AX#/41-E#) ........................................................................ 8

Required Tools ..................................................................................... 9

Optional Equipment .............................................................................. 9

Installation and

Operating Parameters ................................................................................. 9

Noise Level and Vibrations ..................................................................... 9

Installation .............................................................................................. 10

Male Bearing Installation ..................................................................... 10

Mixing Head Installation ...................................................................... 11

Drive Unit Installation ......................................................................... 11

Electrical Installation .......................................................................... 13

Operation ................................................................................................ 15

Starting the Mixer .............................................................................. 15

Operating Notes ................................................................................. 16

Disassembly ...................................................................................... 16

Storage ............................................................................................. 16

Recycle and Disposal .......................................................................... 16

Cleaning and Sterilizing Procedures ............................................................. 17

Cleaning in Place (CIP) ........................................................................ 17

Sterilizing in Place (SIP) ...................................................................... 17

Installation ATEX Checklist ......................................................................... 19

Install the Male Bearing ...................................................................... 19

Install the Mixing Head ....................................................................... 19

Before Installing the Drive Unit ............................................................ 19

Install the Drive Unit – GMP 50 ATEX, GMP 100 ATEX, GMP 500 ATEX ........ 19

Install the Drive Unit – GMP 1000 ATEX and GMP 2000 ATEX .................... 20

Install the Drive Unit – GMP 5000 ATEX, GMP 10000 ATEX,

GMP 20000 ATEX ................................................................................ 20

Before Installing the Electrical Components ............................................ 20

Install the AC Motor ............................................................................ 20

Install the Revolution Counter .............................................................. 20

Install the VFD System ........................................................................ 21

Commissioning ......................................................................................... 22

Valid Regulations ................................................................................ 22

Installation Qualication Checklist ............................................................... 23

Installation Qualication ..................................................................... 23

Maintenance Checklist ............................................................................... 25

Spare Parts .............................................................................................. 27

Troubleshooting ........................................................................................ 28

Standard Warranty ................................................................................... 30

NovAseptic® GMP ATEX Mixer 3

4 Installation and User Guide

Installation Note

The ATEX mixer is designed for operation in the classification noted on the product label.

The mixer must be in good working order before operating.

Before using the mixer, ensure the following:

• The tank plate is installed properly on the tank and concentricity and alignment have been

verified to prevent any contact between the mixing head, outer rotor and tank plate. If the

tank plate is warped during welding or not aligned properly with the tank surface, remove and

discard it and replace it with a new tank plate. The tank plate cannot be repaired if damaged.

• Verify that the mixer drive unit is in proper working order prior to attaching to the tank plate.

If the drive unit has been dropped, check for damage. After installation, verify that the mixer

drive is properly mounted to the tank plate. If there is any damage to the drive unit, ensure it is

repaired before using.

• If, when dropped, the outer magnet was damaged or the outer magnet drive shaft is bent,

attach the drive unit to the tank plate and manually check to determine if there is any contact

between the outer magnet and tank plate. If there is any contact, do not operate the mixer and

have it repaired prior to use.

NovAseptic® GMP ATEX Mixer 5

Operator and Equipment Safety

All installers and operators of the equipment must read and understand this

installation and user manual before using this equipment. Failure to follow operating

and installation instructions could result in operator injury or damage to the

equipment.

Any attempt to use the NovAseptic® GMP ATEX Mixer equipment in a manner not

specified in this manual may result in damage to the equipment, voiding of product

warranty, and possible operator injury.

Any of the following can damage the mixer: external load, reaction forces, torque,

corrosion, erosion, fatigue and the decomposition of unstable liquids.

Prior to operation, the equipment must be fully assembled according to the

instructions in this manual.

Use appropriate personal protective equipment and eye protection when operating the

equipment.

Protect drive unit against dust.

The drive unit may be heavy. Use appropriate equipment to avoid injury.

Do not install components close to rotating parts of the GMP ATEX Mixer.

During mixing operations, mixer parts may become hot to the touch.

Do not insert fingers into equipment; pinching may occur.

Do not run with an empty vessel.

Check that all components in the mixer are of correct size.

Handle the mixing head and male bearing with care; bearing material is hard and

brittle.

The mixing head must always be completely submerged.

System must be properly grounded.

To eliminate any risk of electrostatic charges in ATEX IIC environments, clean the

surface of the Drive Unit using only a damp cloth.

Tachometer must be connected to an intrinsically safe barrier.

The mixer must be operated with a variable frequency drive.

Check the magnetic parts of the GMP ATEX Mixer regularly for foreign materials.

Ensure that the process fluid does not contain magnetic particles.

Keep electrically controlled medical devices and magnetically stored media away from

magnetic parts of the GMP ATEX mixer.

Follow Ex regulations applicable to the GMP ATEX mixer.

6 Installation and User Guide

Labeling

Part No: AX20/33

GMP2000 Tank Plate 316L/1.4435, ATEX

JAD00388ID No:

Millipore SAS, 67120 Dachstein, France

www.millipore.com

NovAseptic Mixer

2009/26Production year/week :

DNV-2003-OSL-ATEX-0227X

0081 II 1/2 GD c T4

Figure 1: Product label

Number Description

10081 – LCIE. Notified body identification number.

2II – The mixer is classified for explosion group IIC.

3

1/2 – Category 1/2. The mixer parts inside the vessel can be used in

zone 0, 1, 2, 20, 21, 22 and the outside parts in zone 1, 2, 21, 22:

Category Zone Explanation

10 (gases) Flammable material present continuously or for long periods.

20 (dusts)

21 (gases) Flammable material present occasionally in normal operation.

21 (dusts)

32 (gases) Flammable material present in abnormal conditions for short

periods.

22 (dusts)

4

GD – Category GD is intended for use in hazardous areas, in which explosive gases

and dust are present.

G – Category G is intended for use in hazardous areas, in which explosive gases are

present.

D – Category D is intended for use in hazardous areas, in which explosive dust are

present.

5

c – Constructual safety. A type of ignition protection in which constructional measures

are applied so as to protect against the possibility of ignition from hot surfaces, sparks

and adiabatic compression generated by moving parts. For further information read EN

13463-5.

6

T4 – Maximum Design temperature: T4 (135 °C) [275 °F]. The mixer can be used in

temperatures T1-T4.

0 °C (32 °F) ≤ Ta ≤ +40 °C (104 °F ) The ambient temperature must not exceed 40 °C

(104 °F).

®

1

2

3456

NovAseptic®GMP ATEX Mixer 7

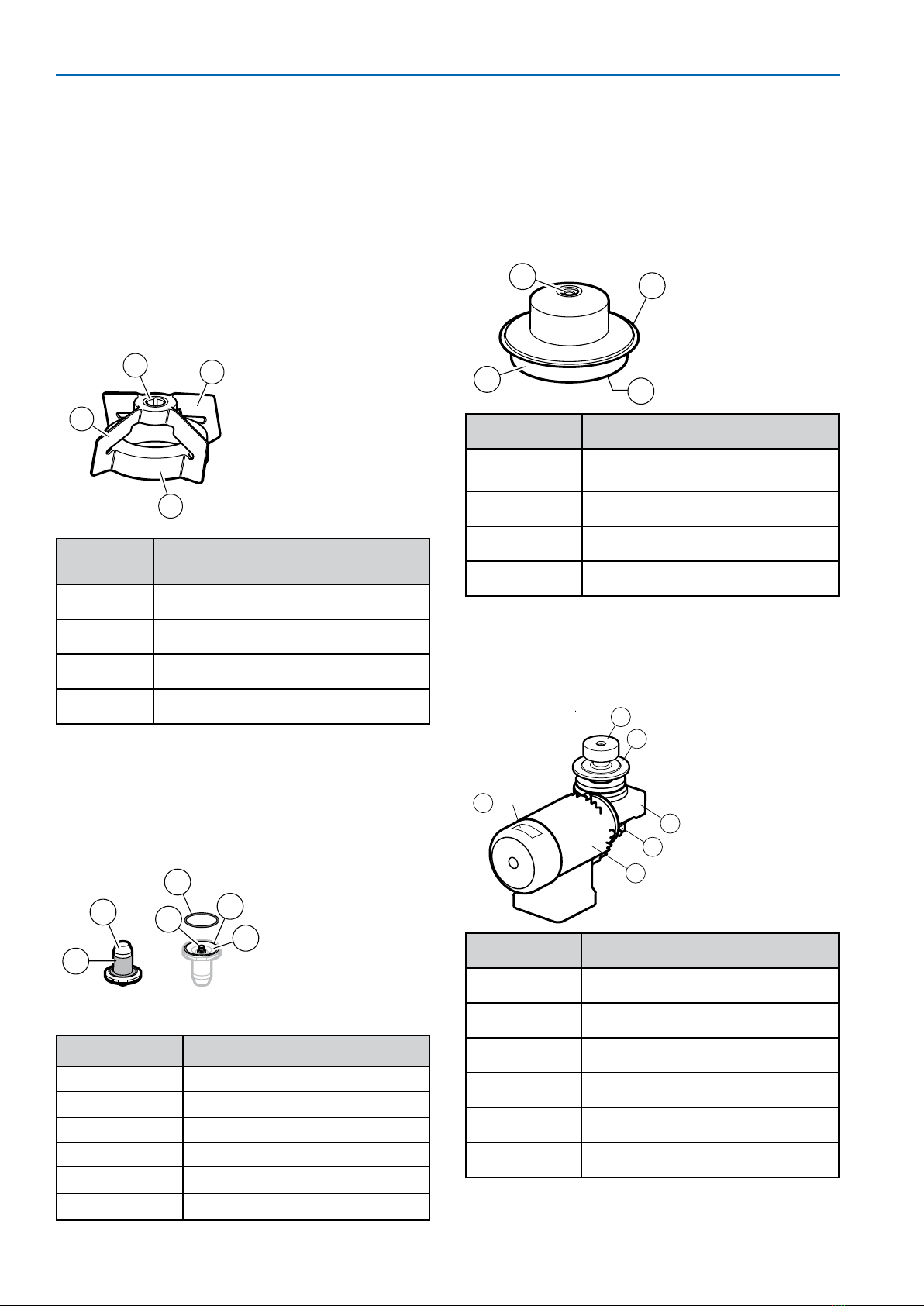

NovAseptic®GMP ATEX

Mixer Components

Catalog numbers and specifications for the

components listed here can be found on the

appropriate specification sheet.

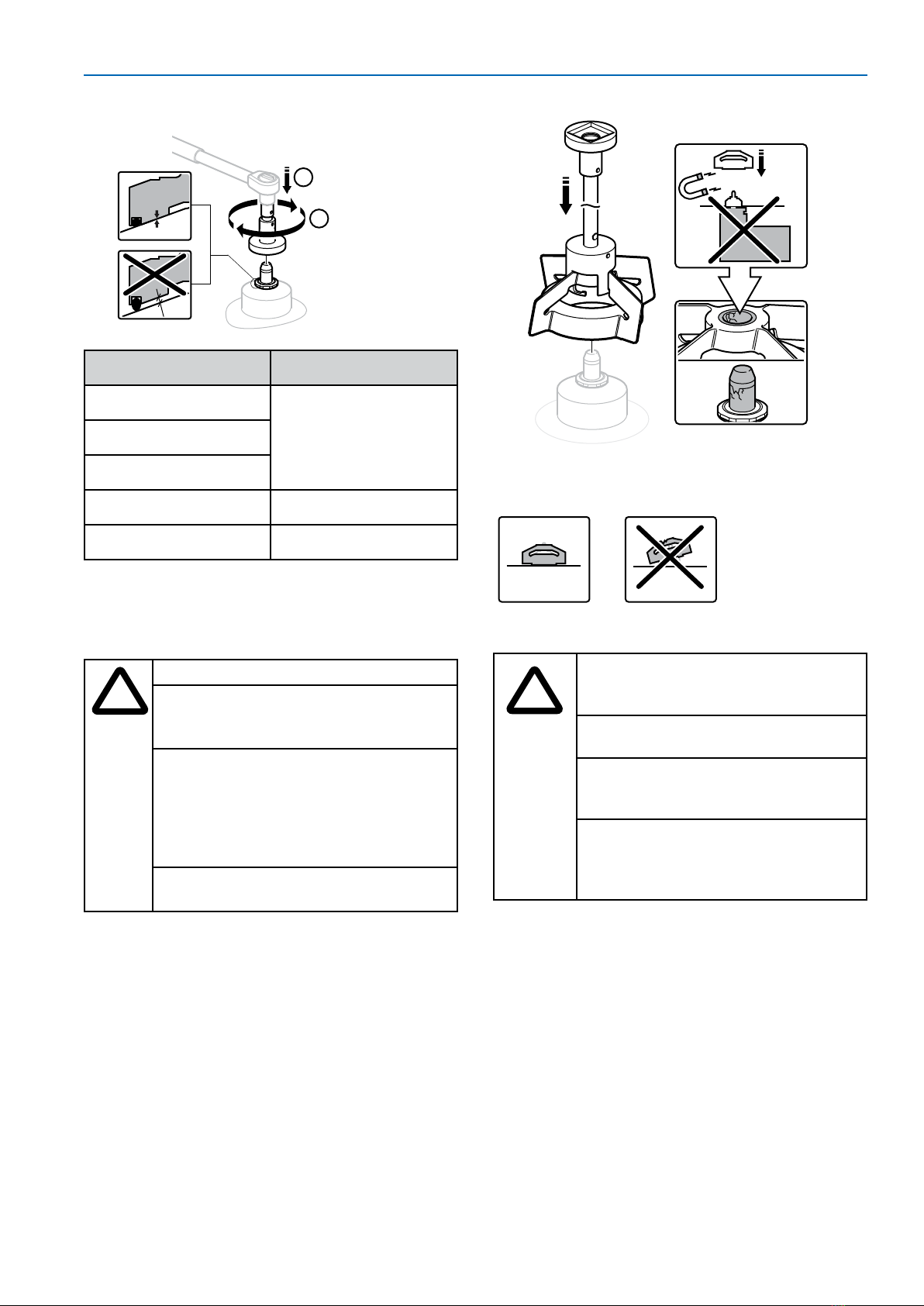

Mixing Head (AX#/12#)

Handle the mixing head with care. The bearing

material is hard and brittle. Keep the magnetic body

away from any particles that may adhere to it.

xxxxxxx

3

4

2

1

Key

Number Description

1 Magnetic body

2 Wings

3 Silicone carbide female bearing

4 Serial number

Male Bearing (AX#/24#)

The male bearing keeps the mixing head in a

correct position; it mounts on the tank plate

inside vessel.

x

x

x

x

x

x

x

5

9

6

8

10

7

Key Number Description

5 Stainless steel support

6Silicone carbide bearing

7 Connection thread

8Groove

9O-ring

10 Serial number

Tank Plate (AX#/33)

Each tank plate is marked with the serial

number and a mill stamp that corresponds to

its heat number. The tank plate is welded onto

the vessel and is considered an integrated part

of the vessel. The tank plate must comply with

your local pressure vessel code.

11 12

14

13

Welded tank plate

Key Number Description

11 Male bearing connection

thread

12 Welding edge

13 Drive unit connection flange

14 Serial number

Drive Unit (AX#/41-E#)

The drive unit delivers the rotating torque to

the mixing head and is mounted on the outside

of the vessel.

21

16

17

18

19

20

x

x

x

x

x

x

Key Number Description

16 Magnetic outer drive head

17 Tank plate connection flange

18 Gearbox unit

19 Revolution counter

20 Motor

21 Serial number label

8 Installation and User Guide

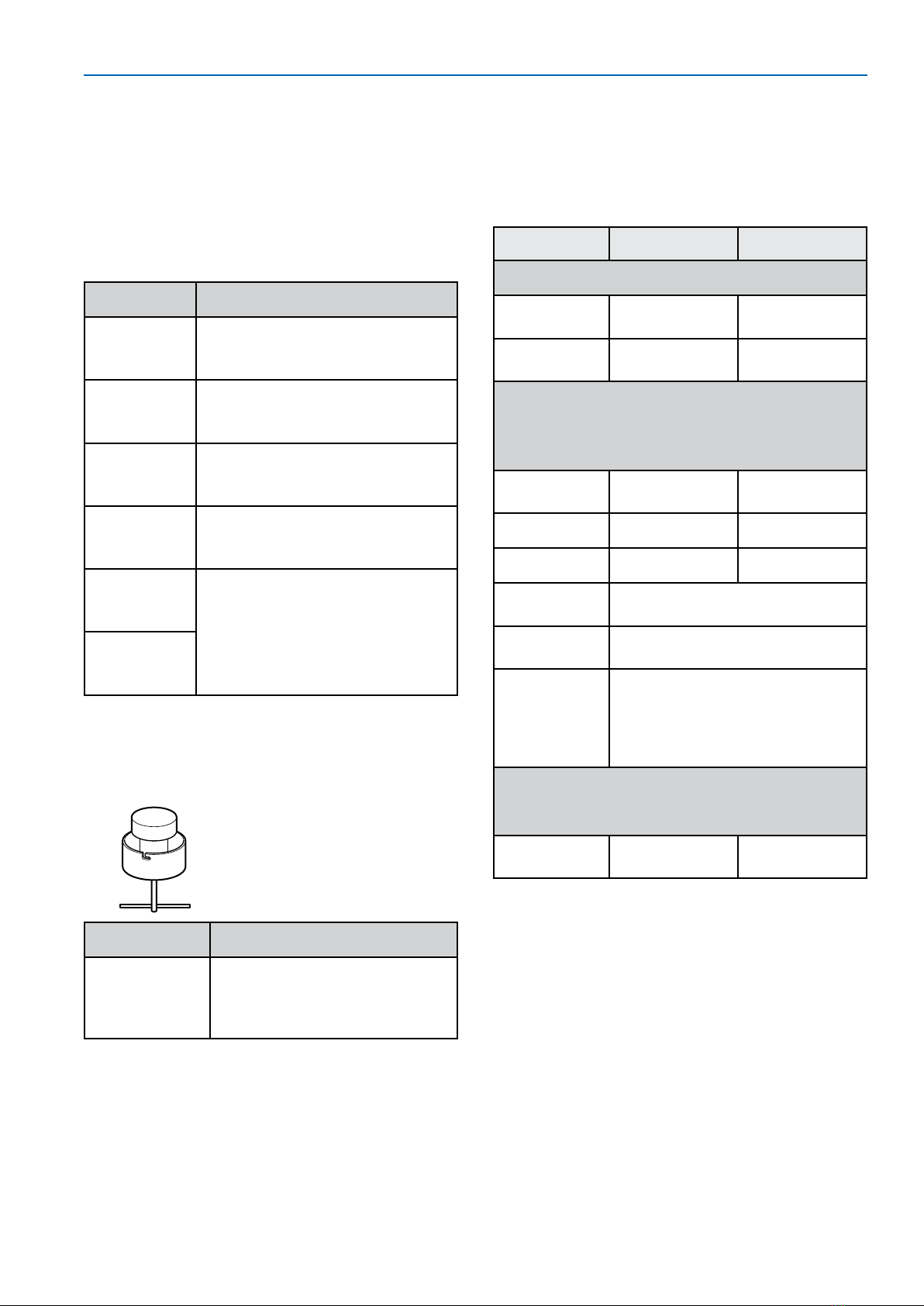

Required Tools

The following tools are required for installation

of the NovAseptic® GMP ATEX Mixer. The

tools (shown below) are not included with

the mixer and are available from your local

representative. Component catalog numbers

and specifications can be found on our web

site.

Description Purpose

NovAseptic®

Gauges 1

and 2

Checks the tank plate

deformation.

Multi tool

(GT#/25)

Installation tool for mixing

head and male bearing for use

in small vessels.

Tightening

tool

(GT#/26)

Installation tool for male

bearing.

Heatsink

tank plate

(G94-#)

Attached to the tank plate

during welding to prevent

deformation.

NovAseptic®

gauge 1

(G91-#) For verification of geometry

after welding.

NovAseptic®

gauge 2

(G92-#)

Optional Equipment

Catalog numbers and specifications for the

component shown here can be found at www.

millipore.com.

Description Purpose

Mixing head

attractor

(GT#/AW)

Keeps the mixing head in

place when vessel is moved.

Replaces the drive unit during

transport.

Installation and

Operating Parameters

Please refer to the appropriate product

specification sheet for more information.

Parameter Minimum Maximum

Tank Plate

Temperature -80 °C

(-112 °F)

200 °C

(392 °F)

Pressure -1 barg

(-14.5 psig)

10 barg

(145 psig)

Mixing Head, Male Bearing, and Tank

Plate

Defines the operating parameters inside the

vessel

Temperature 5 °C (41 °F) 135 °C

(275 °F)

pH 1 14

Viscosity 1 cP 800 cP

Media Media may not contain

magnetic particles.

Rotation

speed

See Product Specification

Sheet.

Minimum

acceleration

and

deacceleration

time

Five seconds (specific to each

application; set accordingly).

Drive Unit

Defines the operating parameters outside the

vessel

Ambient

temperature 0 °C (32 °F) 40 °C (104 °F)

Noise Level and Vibrations

Motor noise levels are measured according to

ISO®1680 standard, and are within maximum

levels specified by standards IEC 60034-9.

Vibration falls under standard class N, as

specified by standard IEC 60034-14.

The noise level and vibration of the motor

installed in the tank must be evaluated before

the complete installation is declared compliant

with appropriate equipment directives.

NovAseptic®GMP ATEX Mixer 9

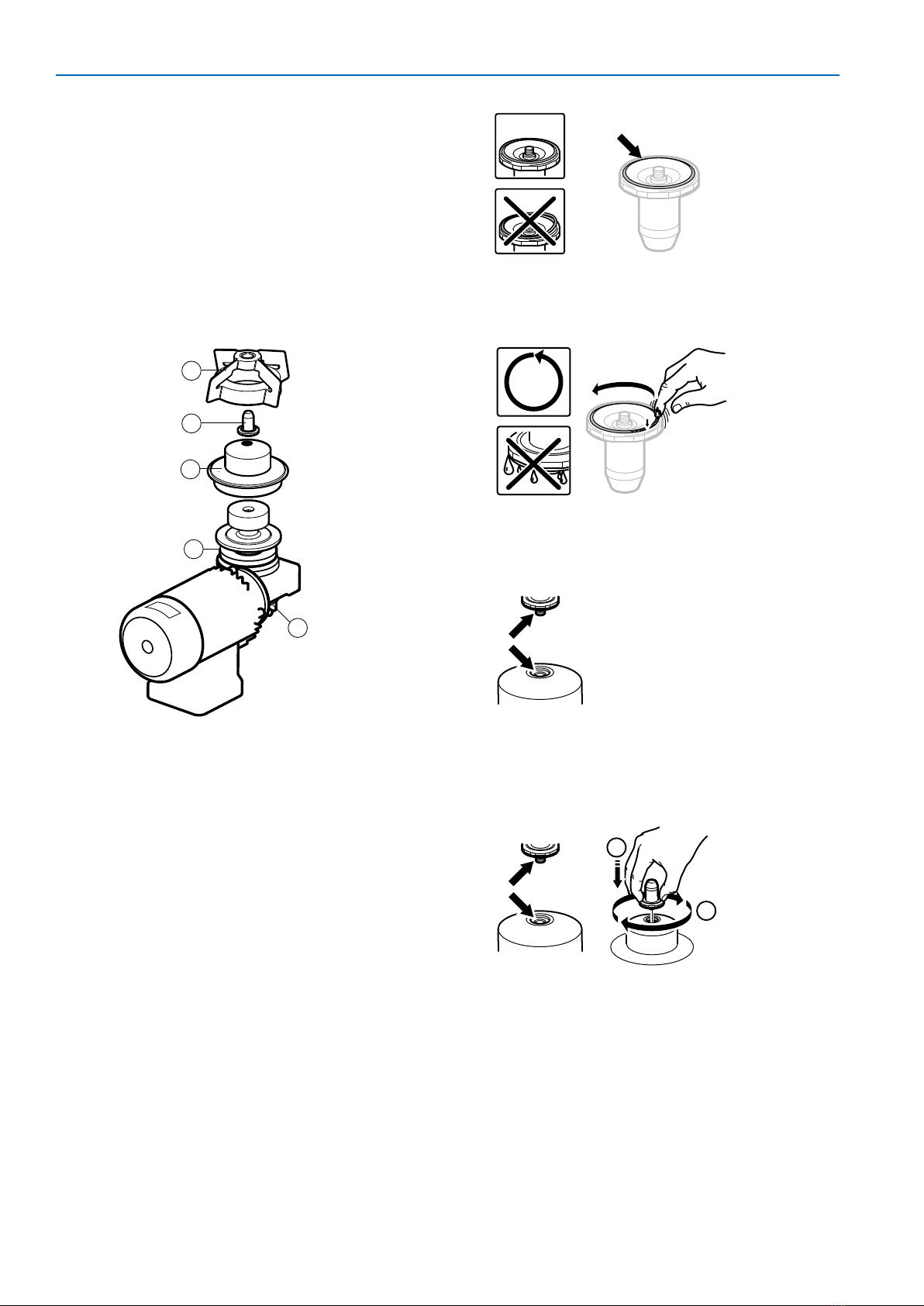

Installation

Use the Installation Checklist and the

Installation Qualification Checklist (in this

manual) as guides for installing the mixer and

initiating use. Use the Maintenance Checklist

as a guide for follow up care of the mixer.

For welding of the Tank Plate use GMP ATEX

Welding Instructions.

Install the GMP ATEX Mixer components in the

following order:

4

x

x

x

x

x

x

5

2

1

3

1. Tank plate

2. Male bearing

3. Mixing head

4. Drive unit

5. Revolution counter

Male Bearing Installation

See NovAseptic® Mixer Male Bearing

Installation Guide 00101868PU for additional

information.

• The vessel must be clean and completely

dry inside.

• Do not use grip tools on bearing surfaces.

• Follow all local safety codes before entering

the vessel.

• Handle the male bearing with care.

Mounting the Male Bearing

1. Ensure proper position of the O-ring on the

male bearing.

2. For minimal friction, lubricate the visible

part of the O-ring with a small amount of

purified water.

H2O

360°

3. Remove the protective cap. Ensure that the thread

connection in the tank plate and male bearing are

clean, dry, and free from foreign material.

1

2

4. Tighten the male bearing clockwise by hand

into the thread of the tank plate, making

sure that it is aligned with the center line of

the tank plate.

1

2

5. Position the male bearing in the appropriate

tightening tool or multi-tool with a torque

wrench. Ensure that the tool fits the nut.

Tighten the bearing to metal-to-metal

contact by applying recommended torque

according to table below.

Important: Ensure metal-to-metal contact

by applying recommended torque in table

below. If bearing is not installed properly it

may come off.

10 Installation and User Guide

3

4

Catalog Number Torque

AX05/24#

6 Nm (4.4 Lbft)AX1/24#

AX510/24#

AX20/24# 13 Nm (9.6 Lbft)

AX50200/24# 30 Nm (22.1 Lbft)

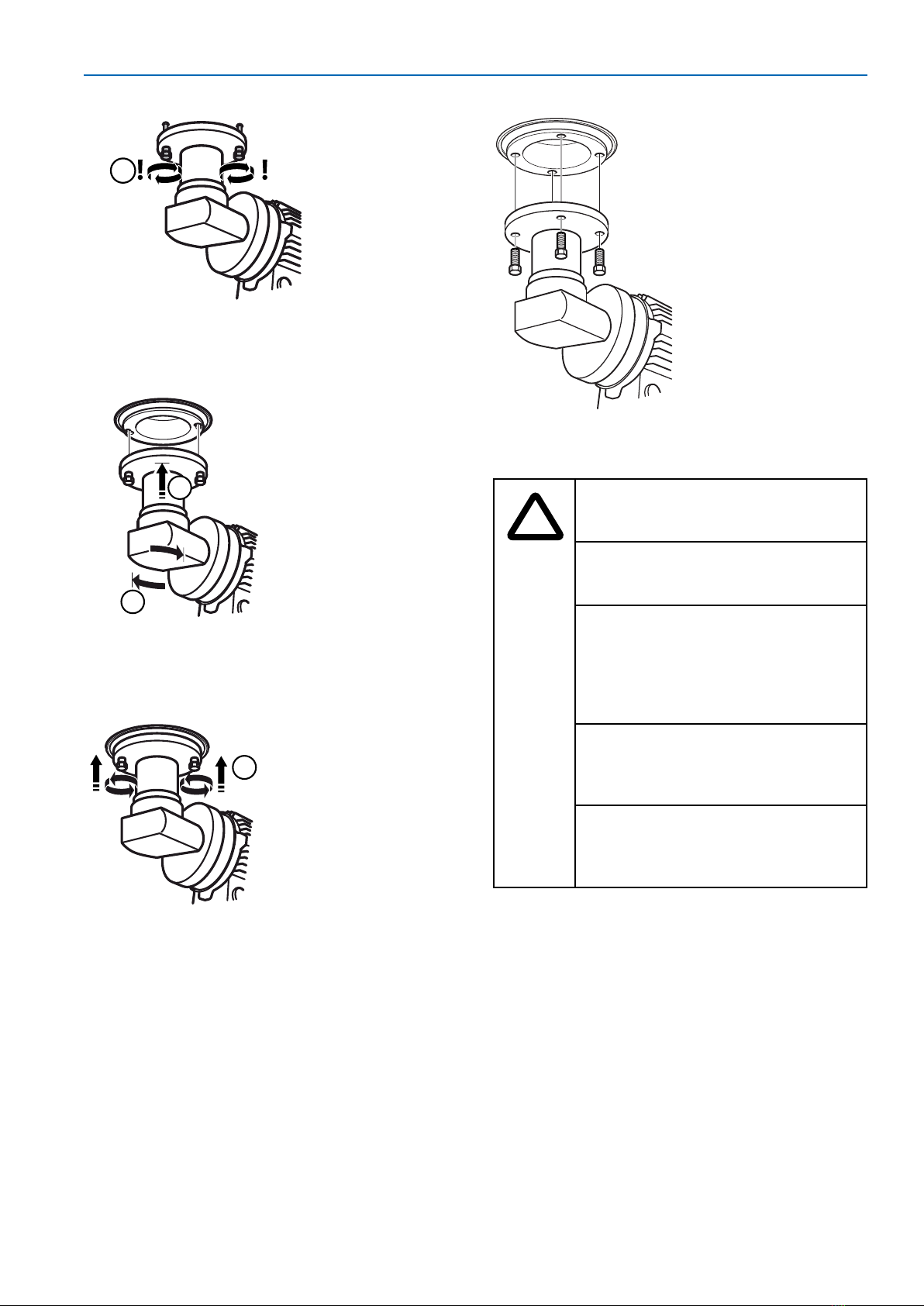

Mixing Head Installation

See NovAseptic® GMP Mixing Head Installation

Guide 00101868PU for additional information.

!

Handle the mixing head with care.

Use extreme care when mounting

the mixing head on to the male

bearing; mixer bearings are brittle.

Do not mount the drive unit before

installing the mixing head. The

powerful magnetic force between

the mixing head and the outer drive

head may cause severe damage to

bearings as well as personal injury.

Follow all local safety codes before

entering the vessel.

1. Remove any foreign magnetic particles

from the mixing head.

If the mixing head must be placed on a

table, place the female bearing downward

to prevent magnetic particles from

adhering to the magnetic surface of the

mixing head.

2. Remove the drive unit.

3. Install the mixing head using the multi-tool.

Mixing head sizes GMP 5 000–20 000ATEX

must be installed by hand.

4. Carefully position the mixing head by

turning it while lowering it onto the male

bearing.

Align the mixing head with the tank plate.

Ensure that the mixing head rotates smoothly.

Drive Unit Installation

!

The drive unit may be heavy. Use

appropriate equipment to avoid

injury.

Never use the drive unit without a

frequency converter.

See the Electrical Installation

section of this user guide for

electrical information.

To eliminate any risk of electrostatic

charges in ATEX IIC environments,

clean the surface of the Drive Unit

using only a damp cloth.

Before installation

• Ensure that all incoming power is equipped

with an emergency stop and an on/off

switch that can be locked in both positions.

• Ensure that the motor cables are shielded

(to avoid disturbance).

• Ensure that the drive unit is properly

grounded.

• Ensure that the electric cables are long

enough so that the drive unit can be

disassembled and removed from the vessel.

• The mixing head must be covered with

liquid before starting the unit.

NovAseptic® GMP ATEX Mixer 11

• Store the motor in an area which is humid

and weather proof. Ensure that motor is

on a stable surface to prevent falling or

vibration.

• Remove the transport collar before

installing the motor.

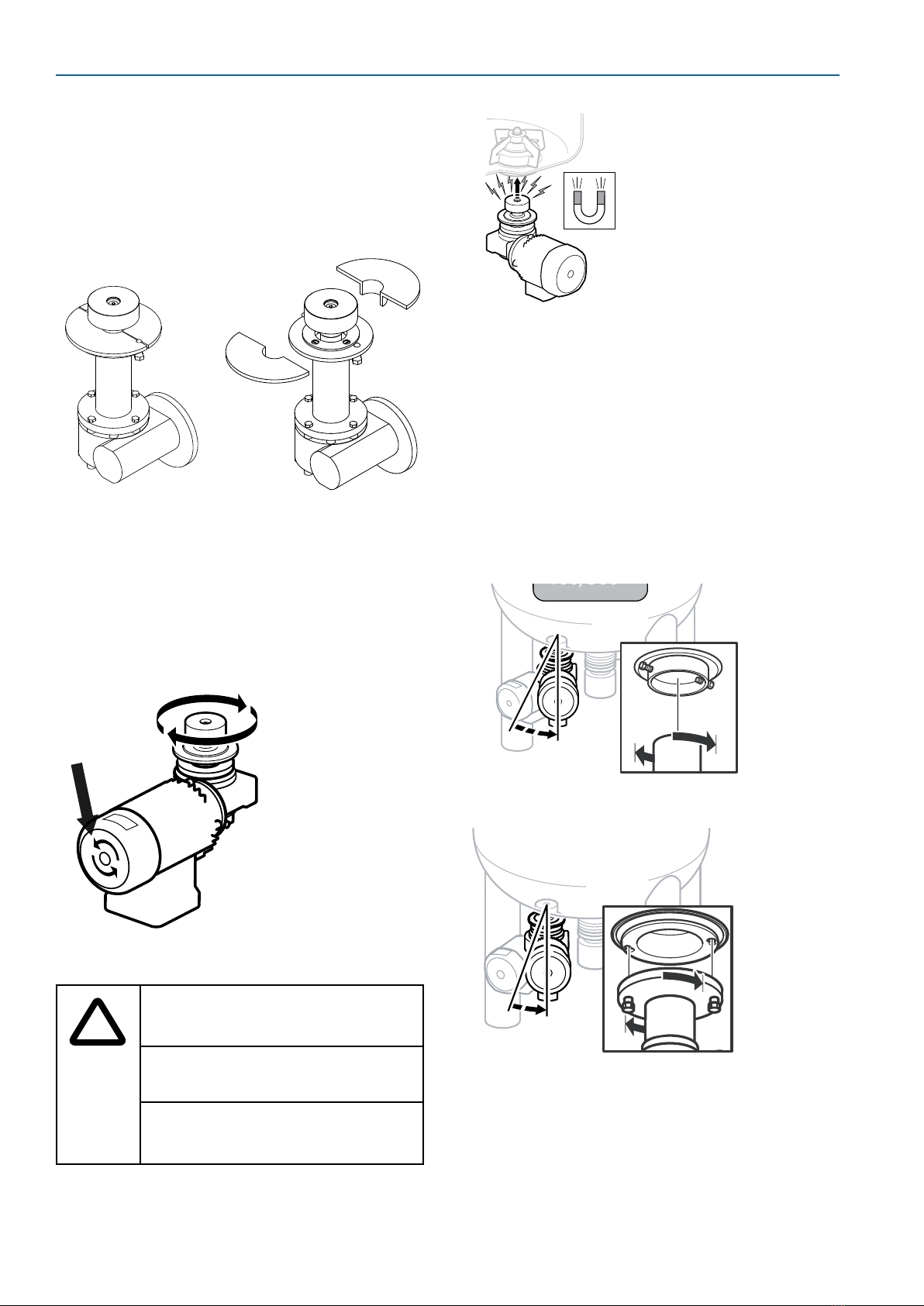

Check Direction of Rotation

Turn on the motor. Verify that the outer drive

head rotates clockwise and the fan rotates

counterclockwise.

A sticker on the motor indicates the correct

rotation direction of the fan.

Mounting the Drive Unit

!

Handle the drive unit with caution

to avoid personal injury and

damage to the equipment.

Do not make any adjustments to

screws and bolts.

There is a powerful magnetic

force between the mixing head

and the outer drive head.

Mount the drive unit onto the vessel following

the instructions for the appropriate mixer size:

GMP 50 ATEX, GMP 100 ATEX and GMP

500 ATEX

1. Install the drive unit into the tank plate.

Put the two studs on the tank plate into the

slots on the drive unit.

2. Turn the drive unit clockwise (view from

below) to the stop position, approximately

15º.

3. Tighten the two nuts with a wrench.

15°

GMP 50,

100, 500

GMP 1000 ATEX and GMP 2000 ATEX

10°

1. Tighten the screws (1) clockwise (view

from below).

12 Installation and User Guide

1

2. Install the drive unit onto the tank plate.

Insert the locking screws into the two oval

holes in the tank plate (2).

310°

2

3. Turn the drive unit clockwise (3) (shown

from below) to the stop position,

approximately 10º .

4

4. Tighten the two screws counterclockwise

(4) (shown from below) with a wrench.

GMP 5000 ATEX, GMP 10000 ATEX and

GMP 20000 ATEX

1. Install the drive unit onto the tank plate.

Align the four holes in the drive unit to the

threaded holes in the tank plate.

2. Screw the four bolts into the tank plate and

tighten them with a wrench.

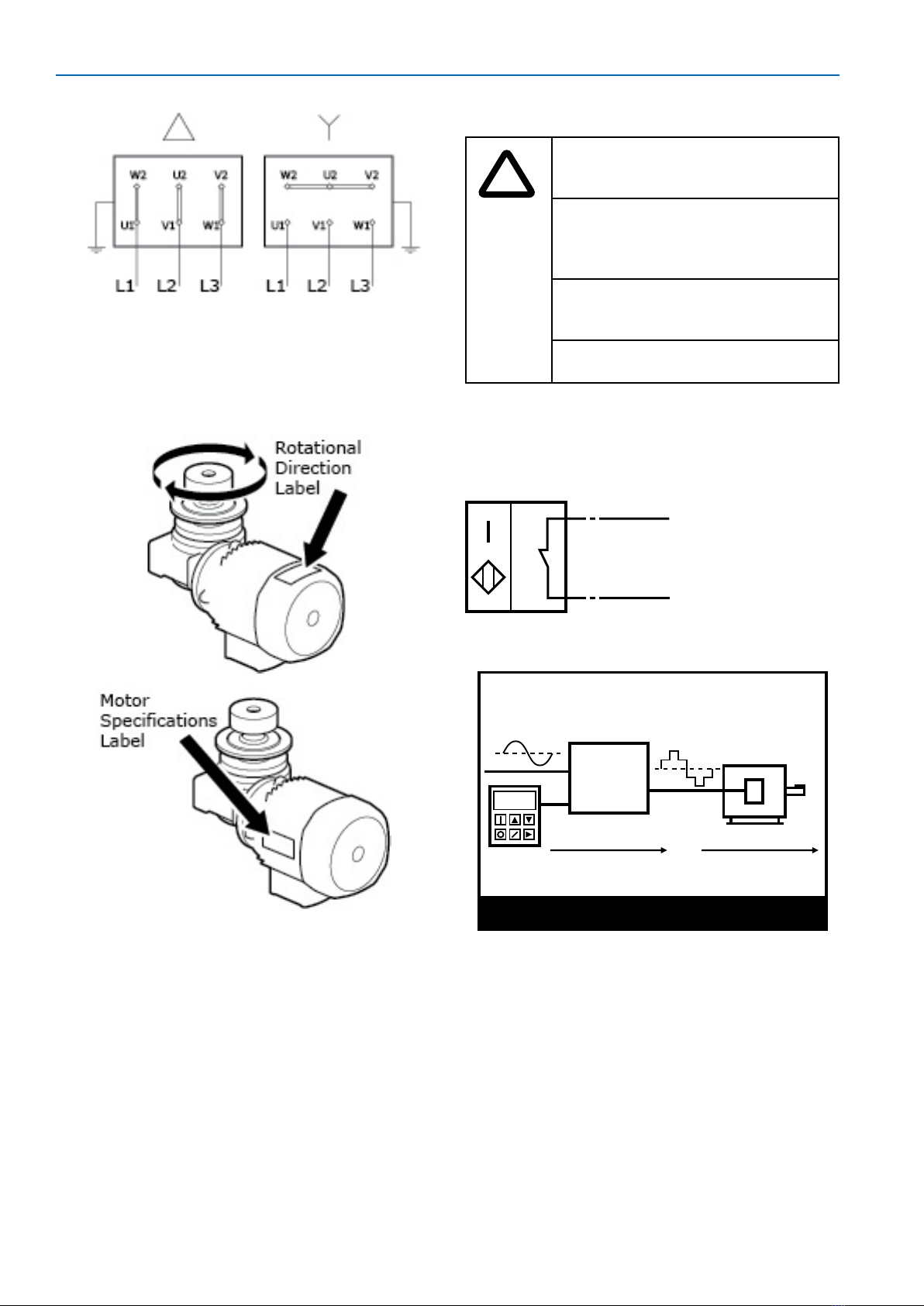

Electrical Installation

!

The mixer must be operated with

a variable frequency drive to

function properly.

Drive units require a frequency

converter for 3-phase AC motor

speed control.

The electrical components,

including the variable frequency

drive, must be installed by an

authorized electrician trained

according to European directive

1999/92/CE.

When working on live drive

controllers, prevent accidents

by observing applicable national

regulations.

The red plugs must be replaced

with ATEX cable connectors

(cable glands) by an ATEX trained

operator.

NOTE

Electrical installations for these

products are regulated by EN 60079-14

for gas and dust.

AC Motor Installation

The AC motor in the standard NovAseptic®GMP

ATEX Mixer is three-phase.

1. Connect the drive unit according to the

Variable Frequency Drive (VFD) system

specifications. The drive unit can be Y- or

∆-connected, depending on the supply

voltage from the variable frequency drive.

NovAseptic® GMP ATEX Mixer 13

2. Ensure that the supply voltage and

overload protection are set according to

the motor specification data. Ensure that

the electrical cover and the conduit entries

are properly in place. Check that the outer

drive head rotates clockwise.

Drive Unit Thermistor

All standard NovAseptic® GMP ATEX drive units are

equipped with two positive temperature coefficient

(PTC) thermistor probes. EMD Millipore recommends

installation of the probes. Thermistor protection

units continuously monitor the temperature of the

motor through a probe embedded in the motor

windings. If the nominal operating temperature of

the probe is reached, a rapid increase in resistance

is converted into a switching function. This can be

used to switch off the motor or to signal a fault.

Accidental breaks in the supply circuits of the

thermistors are also detected.

Motor current higher than recommended could

cause damage to the bearings through decoupling

of the mixing head.

Revolution Counter

!

Observe laws, regulations and/or

standards governing the use, or

intended use, of this equipment.

Any alteration of this equipment

from factory specification may

cause unsafe conditions and will

void the product warranty.

The tachometer must be

connected to an intrinsically safe

barrier.

Do not damage the sensor.

Connection

Connect the socket using the following electric

scheme.

N/N0

1/BN

2/BU

L+

L-

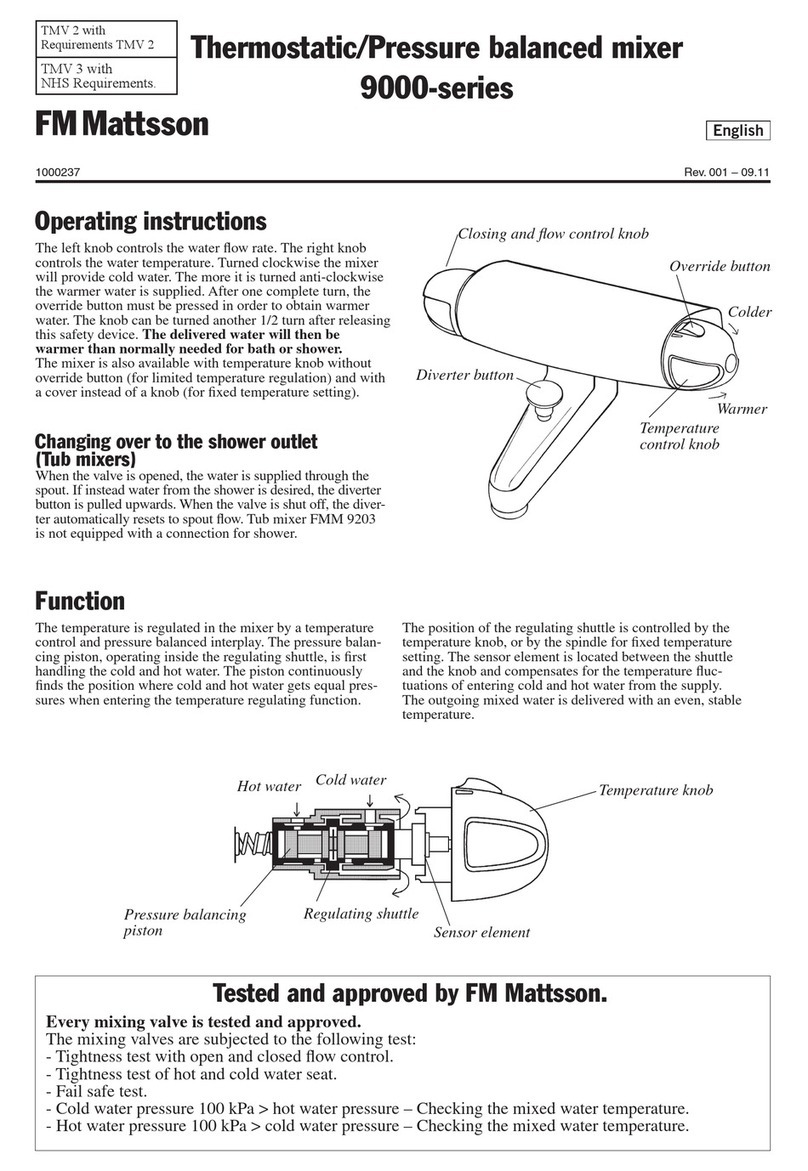

Variable-Frequency Drive

Sine Wave

Power

Operator

Interface

VDF System

Power Conversion

Variable

Frequency

Power

Variable

Frequency

Controller

Mechanical

Power

AC Motor

1540

Power Conversion

A variable-frequency, adjustable-speed drive

(VFD) controls the rotational speed of an

alternating current (AC) electric motor by

controlling the frequency of the electrical power

supplied to the motor. VFDs are also known as

adjustable-frequency drives (AFD), variable

speed drives (VSD), AC drives and inverter

drives.

When starting a motor, a VFD initially applies a

low frequency and voltage to the motor.

A VFD increases the applied frequency and

voltage at a controlled rate and accelerates the

load without drawing excessive current.

14 Installation and User Guide

NOTE

Consult the parameter settings and

circuit and terminal diagrams before

installing the control cabinet.

Validate the current media and

process conditions. If the production

conditions are in any way altered after

commissioning of the mixer, a new

validation must be performed.

Validate the possible minimum and

maximum operating speed for each

process.

Catalog

Number

Design Speed (rpm)

NOTE: Design Speed is the

Mechanical Limit

AX05/41 50 – 400

AX1/41 50 – 400

AX5/41 50 – 400

AX10/41 50 – 400

AX20/41 50 – 400

AX50/41 50 – 400

AX100/41 50 – 400

AX200/41 35 – 280

!

Set VFD unit to 100% nominal

power (kW) and current (A) of the

motor rating.

Excess force may cause magnetic

decoupling.

Electric motors (and VFD system

parts, i.e. sensors) when working

with driven equipment are capable

of causing an explosion in an

explosive atmosphere. Consider

this when selecting parts for the

system in ATEX environment.

Operation

!

Ensure that the installation has

been performed correctly and

that the parameters are correctly

programmed.

Ensure that no one is working

inside the vessel.

Ensure that a sufficient level of

liquid covers the mixing head

and the male bearing to ensure

sufficient lubrication of the

bearing.

The mixing head must be covered with

liquid during operation with explosive

media.

Never work close to the drive unit

while it is connected to its driving

source. Keep away from moving

parts.

Regulate speed, acceleration, and

deacceleration carefully to avoid

magnetic decoupling.

Stop the mixer immediately if any

signs of malfunction, abnormal

noise, or smell occurs.

Do not exceed operation

temperature of 135 ºC (275 ºF)

inside vessel.

Use extra precaution because of

pressure buildup when the mixer is

running at high speed and:

• with hot WFI

• at atmospheric pressure

• during or after steam

sterilization

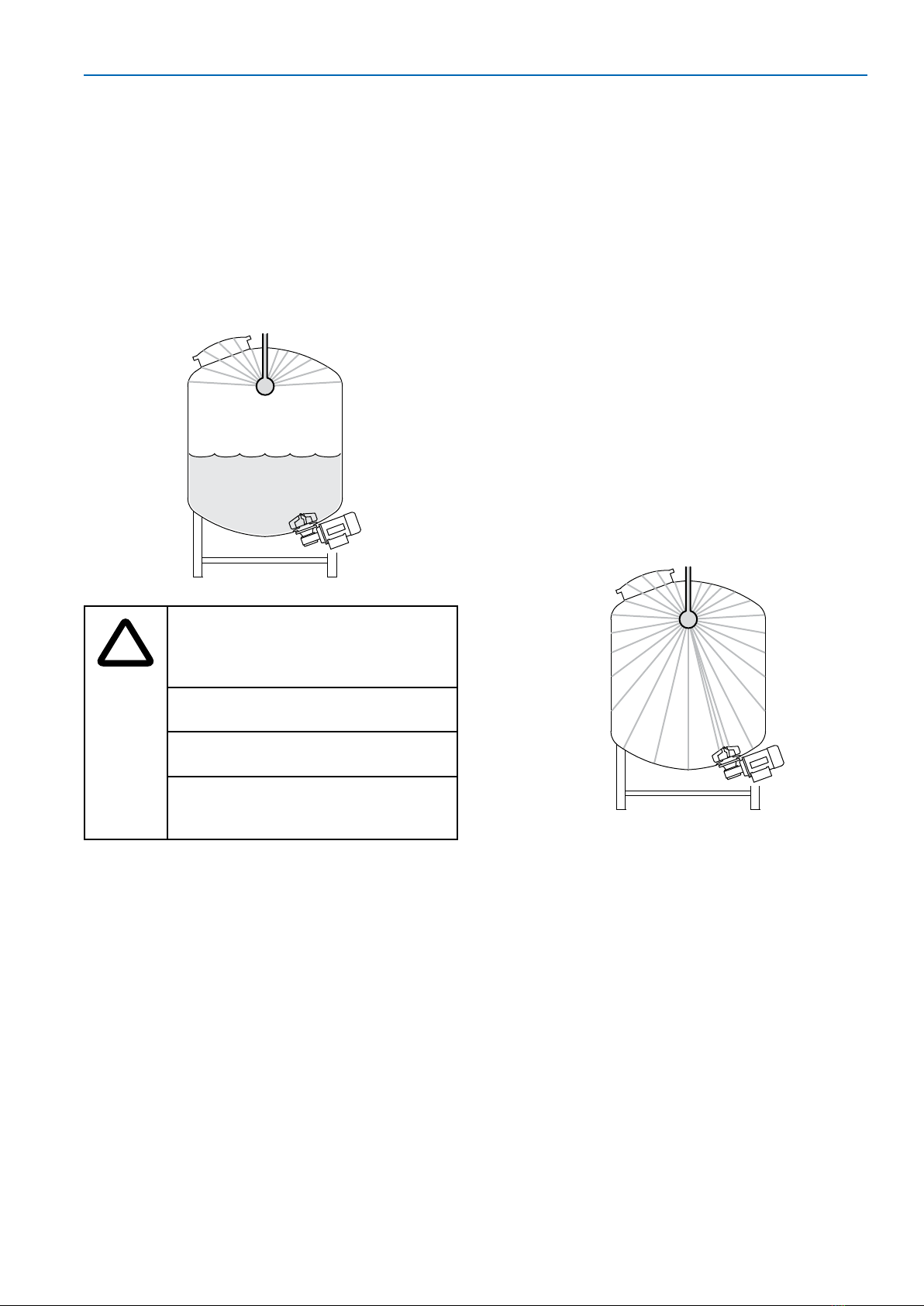

Starting the Mixer

1. Fill the vessel to a minimum level that

completely covers the mixing head and

the male bearing to provide sufficient

lubrication of the bearing.

2. Start the mixer and slowly increase to

a minimum speed (50 rpm). (Note: the

first time the mixer is started, run it for a

few seconds at this speed and check that

the motor fan is turning in the correct

direction.)

3. Increase the speed slowly to working

speed. If the mixer makes a rumbling

noise, stop the mixer immediately and

consult the troubleshooting section in this

user guide.

NovAseptic® GMP ATEX Mixer 15

Operating Notes

• Fill the vessel with liquid before adding solid

material.

• Always ensure that the mixing head is

always completely covered with liquid

during all ATEX operation.

• For ATEX operation during draining, stop

the mixer before the liquid level reaches

below the top of the mixer. This will ensure

the mixer is not run dry. If the mixer has

been run dry, turn off the mixer and inspect

the bearings. Consult the troubleshooting

section.

• Avoid buildup of large quantities of solids on

the bottom of the vessel.

Disassembly

!

Before dismounting the drive unit:

• Ensure that the power supply

is turned off.

• Ensure that the vessel is empty

and ventilated.

• Ensure that the vessel is at

atmospheric pressure.

• Ensure that the vessel is

cooled to below 25 °C (77 °F).

• Ensure that all connected

media is shut off.

Before entering the vessel, follow

the local safety precautions.

The drive unit may be heavy. Use

appropriate equipment to avoid

injury.

Dismount the mixer in the following order to

prevent personal injuries and damage to the

equipment:

1. Drive Unit

2. Mixing Head

3. Male Bearing

Storage

• Do not store in areas exposed to weather or

humidity.

• Always place wood or other non-magnetic

material between floor and product, to

avoid direct contact with the floor.

• For storage periods exceeding 60 days,

protect all coupling surfaces (such as

flanges and shafts on the drive unit) with a

suitable anti-oxidation product (Mobilarma

248 or equivalent).

• For storage periods exceeding 6 months,

turn the rotor outer driving head on the

drive unit every 1–2 months.

Recycle and Disposal

Recycle and dispose of equipment according to

local laws and regulations.

16 Installation and User Guide

Cleaning and Sterilizing

Procedures

Cleaning in Place (CIP)

GMP mixers are designed for CIP using any

of the following processes: sprayball, rotary

jethead, or submerged.

Sprayball and Rotary Jethead Cleaning

!

Start the liquid circulation through

the sprayball or jethead before

starting the mixer to ensure

lubrication of the bearing.

Ensure that the bearings are

continuously lubricated.

Stop the mixer before turning off

the sprayball/jethead function.

Add liquid before running the

mixer after cleaning to ensure

lubrication of the bearings.

NOTE

Recommended maximum speed of

the mixing head is 100 rpm.

Submerged Cleaning

Introduce enough cleaning or rinsing liquid into

the vessel to cover the mixing head and the

male bearing.

NOTE:

Avoid vortex.

Add liquid before running the mixer

after cleaning to ensure lubrication of

the bearings.

Magnetic Particles:

If presence of magnetic particles is

suspected, remove the mixing head.

Remove the particles and reinstall the

mixing head. (Refer to Male Bearing

Installation, Mixing Head Installation,

and Drive Unit Installation in this

manual.)

Magnetic particles are not removed

from the mixing head during CIP;

they must be removed manually or by

alternative cleaning. Magnetic particles

can cause corrosion and damage. They

can also cause a higher torque, which

may cause the mixing head to decouple

and severely damage the vessel.

Sterilizing in Place (SIP)

GMP mixers are designed for SIP.

Sterilization by Pressurized Steam

The mixer can be intermittently operated

during the initial condensate phase of the

sterilization sequence up to 100 °C (212 °F).

Recommended maximum speed of the mixing

head is 50 rpm for no longer than 30 seconds.

NOTE

Ensure that condensate lubricates the

bearing surfaces.

Recommended maximum speed of the

mixing head during sterilization is 50 rpm.

Turn the mixer off when the

temperature reaches 100 °C (212 °F).

Add liquid before restarting the mixer

after sterilization to secure lubrication

of the bearings.

Magnetic Particles

If presence of magnetic particles is

suspected, remove the mixing head.

Remove the particles and reinstall the

mixing head. (Refer to Male Bearing

Installation, Mixing Head Installation,

and Drive Head Installation in this

manual.)

Magnetic particles are not removed

NovAseptic® GMP ATEX Mixer 17

from the mixing head during CIP;

they must be removed manually or by

alternative cleaning. Magnetic particles

can cause corrosion and damage. They

can also cause a higher torque, which

may cause the mixing head to decouple

and severely damage the vessel.

Other Sterilization Methods

For information on using other sterilization

methods, please contact your EMD Millipore

representative for NovAseptic®GMP ATEX Mixer

product information.

18 Installation and User Guide

Installation ATEX Checklist

To ensure correct installation, before using the mixer make sure to complete each step in this

checklist, and check the applicable box.

Note:

Follow all installation recommendations, cautions and warnings in this manual.

Install the Male Bearing

Complete

1Ensure the proper position of the O-ring on the male bearing. qyes qno

2Lubricate the O-ring with purified water. qyes qno

3Ensure that the thread connection in the tank plate is clean, dry, and free from

foreign material. qyes qno

4Position the male bearing in the appropriate tightening tool or

multi-tool. qyes qno

5Tighten the male bearing clockwise. qyes qno

6Tighten the bearing to metal-to-metal contact; use table to determine correct

torque. qyes qno

Install the Mixing Head

Complete

1Inspect and remove any foreign magnetic particles from the mixing head. qyes qno

2Remove the drive unit. Install the mixing head. qyes qno

3Position the mixing head and align it with the tank plate. qyes qno

4Ensure that the mixing head rotates smoothly. qyes qno

Before Installing the Drive Unit

Complete

1Verify that the drive unit classification noted on the product label (G or D or

GD) is matches the installation. qyes qno

2Turn on the motor. Verify that the drive head rotates clockwise and that the fan

rotates counterclockwise. qyes qno

Install the Drive Unit – GMP 50 ATEX, GMP 100 ATEX, GMP 500

ATEX

Complete

1Install the drive unit into the tank plate; put the two studs on the tank plate

into the slots on the drive unit. qyes qno

2Turn the drive unit clockwise (view from below) to the stop position. qyes qno

3Tighten the two nuts with a wrench. qyes qno

NovAseptic® GMP ATEX Mixer 19

Install the Drive Unit – GMP 1000 ATEX and GMP 2000 ATEX

Complete

1Fit screws and tighten clockwise (view from below). qyes qno

2Install the drive unit into the tank plate. Install locking screws into the two oval

holes in the tank plate. qyes qno

3Turn the drive unit clockwise (view from below) to the stop position. qyes qno

4Tighten the two screws clockwise (view from below). qyes qno

Install the Drive Unit – GMP 5000 ATEX, GMP 10000 ATEX, GMP

20000 ATEX

Complete

1Install the drive unit into the tank plate. Align the four holes in the drive unit to

the threaded holes in the tank plate. qyes qno

2Screw the four bolts into the tank plate and tighten. qyes qno

Before Installing the Electrical Components

Complete

1Ensure all incoming power is equipped with an emergency stop and an on/off

switch. qyes qno

2Shield motor cables. qyes qno

3Ensure the drive unit is grounded. qyes qno

4Ensure electrical cables are long enough to enable the drive unit to be

disassembled and removed from the vessel. qyes qno

Install the AC Motor

Complete

1Connect the drive unit. qyes qno

2

Ensure that the supply voltage and overload protection are set. Ensure that the

electrical cover and conduit entries are in place. Ensure that the outer drive

head rotates clockwise (view from above).

qyes qno

Install the Revolution Counter

Complete

1Connect the wiring from the tachometer into the appropriate apparatus

according to the proof of intrinsic safety. qyes qno

20 Installation and User Guide

Table of contents

Popular Mixer manuals by other brands

AUSTRALIAN MONITOR

AUSTRALIAN MONITOR AMIS PM4 introduction

ALFA LAMDA

ALFA LAMDA Primo MK-36 User instructions

Brabantia

Brabantia D3 instruction manual

HOMEKRAFT

HOMEKRAFT HKMIXPLROTARY1 user manual

Northern Industrial Tools

Northern Industrial Tools 998255 owner's manual

InoTec

InoTec inoMIX S16 Original operating manual