Merck Milipore Cellicon Perfusion Solution for Process... User manual

The life science business of Merck KGaA, Darmstadt,

Germany operates as MilliporeSigma in the U.S. and Canada.

CelliconTM Perfusion Solution for Process

Development

User Guide

Contents

Introduction............................................2

System Components ................................2

Setting Up the System .............................3

Starting the System.................................4

User Interface.........................................4

Settings .................................................7

Running the Pump ...................................7

Alerts.....................................................9

Settings ............................................... 12

Shutdown............................................. 16

Planning for a Run ................................. 16

Preparation........................................... 16

Starting a Run....................................... 18

Run Maintenance................................... 19

Troubleshooting..................................... 21

Ending the Run ..................................... 22

CelliconTM Perfusion Solution for Process Development User Guide 2

Introduction

The CelliconTM Perfusion Solution for Process

Development includes scalable, single-

use filters and controllers that enable seed

train process intensification in upstream

biomanufacturing. The filtration technology

provides high throughput and membrane

efficiency in a closed assembly, while

maintaining a low shear environment to

support cell growth.

This guide describes the installation, setup

and use of the CelliconTM Perfusion Solution

for Process Development.

This system is for industrial use only and

cannot be used in a residential environment.

System Components

The CelliconTM Perfusion Solution for Process Development includes a single-use filter and

assembly, a holder for the assembly, a controller, a low-shear centrifugal pump, flowmeter and

feed pressure sensor.

Cellicon®Cell Retention Device

and Single-use Assembly

Assembly Holder Flowmeter

Pump

Controller

Retentate Pressure

Sensor

Perfusate (Permeate)

Pressure Sensor Feed Pressure Sensor

CelliconTM Perfusion Solution for Process Development

CelliconTM Perfusion Solution for Process Development User Guide 3

Installing the Filter

Refer to System Components image for

reference.

Prior to installation, there may be a slight

kink in the feed tubing line between the filter

and the pressure sensor. This is cosmetic and

does not impact the function of the system.

It should self-resolve by laying the tubing

inside the flow meter clamp.

1. Carefully remove the filter and tubing

assembly from the bags, and remove the

assembly from the backing card.

2. Slide the device into the slot on top of the

holder.

3. Open flowmeter clamp (located at the center of

the holder) and lay tubing inside.

4. Close the flowmeter, ensure the tubing is not

pinched or kinked, then clamp it.

5. Place the pump head into the pump drive by

aligning the outlet barb on the pump head

with green coloring on pump drive. Pull pin

out and push pump head in place. Rotate

pump head clockwise so barb is located over

the red coloring and release pin.

6. Connect the three pressure cables from

the control box to the sensors on the

assembly as follows:

Press. 1 to the feed line

Press. 2 to the retentate line

Press. 3 to the perfusate (permeate) line.

Connecting the

Bioreactor

Use a tubing welder to connect:

• The cell retention filter feed line to

the device inlet line of the bioreactor,

ensuring the line is submerged, and

below the sparger.

• The cell retention filter retentate line to

the device outlet line of the bioreactor.

Setting Up the System

The system should be set up close to the bioreactor, with cords behind the holder. The

controller screen should be easily accessible to the user.

Connecting the Component Cables

Carefully remove all the system components from the packaging.

Connect the components at the rear of the controller as shown below.

USB Flow Pres. 1 Temp. LAN Power Out

Press. 2 Remote

Analog In

24 V --- 0.5 A Out

Press. 3

RS485

24 V --- 0.5 A Out

Vent PLC

24 V --- 0.5 A In

USB Second

Flowmeter

(Optional)

Retentate

Pressure

Pump

Drive

Power In

Primary

Flowmeter

Feed Pressure

Sensor

Perfusate (Permeate)

Pressure Sensor

Once connected to the rear panel, connect the cables to the components as listed here:

Cable Color Connection

Gray Primary flowmeter

Black Power in (24 V)

When all cables have been connected, connect the power cord to the power source.

CelliconTM Perfusion Solution for Process Development User Guide 4

Starting the System

The system must be fully assembled prior to operation, as described

in Setting Up the System. The filter assembly must be installed and

the pump and sensors connected before starting a run.

Press the power button on the left side of the controller to turn it on.

The button should light up blue when the controller is on.

Powering up the system launches the perfusion control software. The

initial screen is the username selection screen.

After selecting the username, the password screen will appear.

Touch the white box on the screen to open the keyboard. Enter the

password and touch Login to log into the system.

User Interface

The main screen of the system has four regions:

• Menu

• Piping and instrumentation diagram (P&ID)

• Control

• Status

The menu region and the status region are always visible. The P&ID

and control regions are only visible when Control is selected on the

menu region.

Menu

P&ID

Data

Control

Main Menu Screen

CelliconTM Perfusion Solution for Process Development User Guide 5

Menu

M Logo Alert Button

Control

Button

Settings

Button

User Icon

Time & Date

Display

The menu region is always visible and has five main elements.

M Logo

Selecting the M logo starts a countdown of three seconds, then

generates a screenshot that is captured and saved to the USB drive

with the files name LCO_Screenshotxx.png, where xx represents a

consecutive number.

Control Button

Selecting the Control button returns the system to the main screen.

Alerts Button

Selecting the Alerts button displays a log of alarms and notifications.

The log may also be accessed when an active alert is selected on the

main screen. Each alarm or notification will display the time/date of

activation, the acknowledgement status, a description of the alert,

and tips for troubleshooting. See Alert Types section for explanation

of the alerts page.

Settings Button

Selecting the Settings button opens the settings screen.

User Icon and Time/Date Display

Selecting the user icon allows the user to lock the screen or switch

users. Lock screen will cause the controller to go into screensaver

mode.

Switch user allows the active user account to be changed.

The date and time settings can be changed in the Settings menu.

P&ID

The P&ID screen displays the components of the system connected

to the bioreactor and the CelliconTM Perfusion Solution for Process

Development.

Bioreactor

P2 Retentate

Pressure Sensor Filter

P3 Perfusate (Permeate)

Pressure Sensor

F2 Perfusate (Permeate)

Flow Sensor

Harvest Bag

P1 Feed Pressure Sensor

F1 Feed Flow

Sensor

Pump

Component status is indicated by color:

Item Color Meaning

Component light grey Disconnected from the system

dark grey Connected to the system

Fluid Path dark gray Pump OFF

light blue Pump ON

The animation indicates the direction of flow and acts as the

pump state indicator, showing that the pump is on. The perfusate

(permeate) line will only turn light blue if flowmeter 2 is connected

and measuring an active flow rate.

CelliconTM Perfusion Solution for Process Development User Guide 6

Tapping the icons listed in the following table displays the sensor

output:

Icon Display

Pump Speed in RPM

F1 Feed flow rate in mL/min

P1 Feed pressure in selected pressure units

P2 Retentate pressure in selected pressure units

P3 Perfusate (permeate) pressure in selected pressure units

F2 Perfusate (permeate) flow rate in mL/min

The icons change color to indicate the alert state of each component:

Color Alert Type

Red 1

Yellow 2

Blue 3

See Table of Alerts for details on the alert classifications.

Control

Change the pump state, setpoint, zero-adjust and access guidance for

priming from this screen.

Flow

Setpoint

Prime

System

Zero

Adjust

Flow Rate

Speed

Setpoint

Pump

Start

Decrease

Flow Rate

Increase

Flow Rate

Status

The current values, state of the system components and data logging

switch are displayed here.

TMP Indicator

Data Logging

Control

Component Indicators

Data Logging

Control

The TMP is a calculation based on P1, P2 and P3. It will only display a

value when all three pressure sensors are connected.

The data logging feature requires a USB drive. See Data Logging for

details about how to use data logging.

Each box within the status bar change color to indicate the status of

each component:

Color Component Status

Grey Not connected

White

Connected and ready to use (except pump, which

will display a type 1 alert until single-use pump

head is loaded)

Blue Connected with a Type 3 alert

Yellow Connected with a Type 2 alert

Red Connected with a Type 1 alert

CelliconTM Perfusion Solution for Process Development User Guide 7

Settings

Selecting an element in the settings menu

will open the screen for that element,

and will be indicated by a darker grey

background. The elements include System,

Sensors, Alerts, Controls, External Interfaces

and User Accounts. Refer to the example

below:

System Screen Selected

Running the

Pump

Start/Stop

Start and stop the pump from the control

region of the main screen. If the pump is

off, the button will read START PUMP. If the

pump is on, the button will read STOP PUMP.

Stopping the pump will cause a confimation

screen to appear.

Prime System

The pump needs to be primed to reduce

damage to cells because the design is not

positive displacement.

Prime system is accessed from the control

region of the main screen. Fill the flow

path with liquid prior to starting the prime

sequence.

The system will switch into speed setpoint

mode if Prime system is selected when the

pump is off. If Prime system is selected

when the pump is running, the priming

guidance will start with the pump in the

current setpoint mode.

Prime System Guidance Step 1

Prime System Guidance Step 2

CelliconTM Perfusion Solution for Process Development User Guide 8

Prime System Guidance Step 3

Prime System Guidance Step 4

The Next button will progress to the next

step in the manual priming procedure. The

Back button will revisit the previous step.

When all the steps are complete, select

Done. Select Exit priming to return to the

main screen at any point.

When Done or Exit priming is selected, the

system returns to flow setpoint mode.

Zero Adjust

Select Zero adjust from the control region of

the main screen. A popup containing options

for zero adjustment will appear.

If connected, the following sensors are

available for zero adjustment:

• Pressure 1

• Pressure 2

• Pressure 3

• Flowmeter 1

• Flowmeter 2

Select an icon to initiate a zero adjustment

of that sensor. Adjustment may take a few

minutes to complete.

When the adjustment is complete, the button

will return to its original state. The time and

date of the last zero adjustment for each

sensor will be displayed below the button. If

an adjustment fails, the button will turn red

and read Zero adjustment failed MM/DD/

YY HH:MM.

To initiate a zero adjustment for flowmeter 1, the

pump must be stopped. A pop-up will appear to

confirm that the pump is stopped. Flowmeter 2

does not require that the pump is stopped.

All sensors should be zero adjusted prior to

starting a run. Only one sensor can be zero

adjusted at a time.

Control Modes

The pump can be run in either Flow setpoint

or Speed setpoint. Choose the mode using

the toggle switch at the top of the control

region of the main screen.

When switching from flow control mode

to speed control mode while the pump is

running, the controller will default to the

current pump speed (RPM). Adjust the speed

using the +/-icons or enter a new speed in

the field.

When switching from speed control mode to

flow control mode while the pump is running,

the controller will default to the last flow

setpoint (mlpm) entered by the user. Adjust

the setpoint using the +/-icons or enter a

new flow target in the field.

Flow Setpoint

Select Flow setpoint when a perfusion run

is in progress. Enter the desired flow rate

and the system will maintain the flow rate

by adjusting the pump speed (RPM). Speed

adjustments are based on feedback from

Flowmeter 1.

Speed Setpoint

Speed setpoint should not be selected

when a perfusion run is in progress. When

switching to speed setpoint, a confirmation

popup will appear. Enter the desired RPM

and the system will maintain the speed. Use

speed setpoint for priming.

CelliconTM Perfusion Solution for Process Development User Guide 9

Alerts

When an alert is activated, it will appear in the alert bar on the main

screen and in the alert log.

Alert Log

Select the Alerts button to access the alert log. The left side lists past

alerts that were activated in the system. The right side displays the

details of the alert, including acknowledgement status, suggestions to

resolve the issue and when the alert was resolved.

Alert Log

Alert Bar

Selecting the alert bar will display the alert log, where details about

previous alerts can be viewed.

If there are multiple active alerts, expand the alert bar by selecting

the down arrow on the left side of the bar. All unacknowledged active

alerts will be displayed.

Alarm Acknowledgement

Alerts can be removed from the main screen by selecting

Acknowledge from the alert bar or in the alert log. The alert will

reappear on the alert bar if it remains active 10 minutes after being

acknowledged.

If any alert is unacknowledged, a red dot will appear on the

Alerts icon. Unacknowledged alerts will be listed in black font, and

acknowledged alerts will be listed in grey font in the alerts log. If

an alert is unacknowledged and unresolved, the icon will appear

in the color of the alert type (red, yellow, or blue). If an alert is

unacknowledged and resolved, the icon next to the listing will appear

black.

Alerts Status in P&ID and Data Region

The alert status of each sensor can be viewed from the P&ID and data

region of the main screen. An active alert on a sensor is indicated

when the sensor appears with the alert color. The sensor color will

return to dark grey once the alert is resolved.

CelliconTM Perfusion Solution for Process Development User Guide 10

Example of Alert on Main Menu Screen

Audible and Full-screen Alerts

Full-screen alerts can be enabled for a group of alerts under Settings > Alerts. If an alert

is enabled to be audible and full-screen, the system will make a loud beep when the alert is

activated. Select Dismiss to return to the main screen, then select Acknowledge on the alert

bar or within the alert log. The data region can still be viewed when a full-screen alert is active.

Example of Full-screen Alert Type 1

Alert Types

Alert types indicate the severity of an alert.

There are three alert types:

Type Color Alarm Type

1Red Critical

2 Yellow Warning

3 Blue Notification

Alerts

The list on the next page shows possible

alerts.

CelliconTM Perfusion Solution for Process Development User Guide 11

Table of Alerts

Alert

Category Alert Description Full-

screen

Alert

Type

Pump Error

Pump not connected

Always 1

No pump head detected

Pump impellor stabilization

failed

Pump supply voltage out of

range

Pump temperature too high

Pump motor type not detected

Internal pump error

Flowmeter

Error

Flow measurement error

Optional

1

Flow calibration parameter

error

Flow zero adjustment error

Internal flowmeter error

Flowmeter disconnected while

in flow control mode Always

Flow Alarms

Flow: Critical Alarm Low Optional 1

Flow: Warning Alarm Low Never 2

Flow: Warning Alarm High Never 2

Flow: Critical Alarm High Optional 1

Pressure

Alarms

Pressure: Critical Alarm Low Optional 1

Pressure: Warning Alarm Low Never 2

Pressure: Warning Alarm High Never 2

Pressure: Critical Alarm High Optional 1

Alert

Category Alert Description Full-

screen

Alert

Type

TMP Alarms

TMP: Critical Alarm Low Optional 1

TMP: Warning Alarm Low Never 2

TMP: Warning Alarm High Never 2

TMP: Critical Alarm High Optional 1

Pump Internal

Alerts

Pump impellor stabilizing issue

Optional 2

Pump supply voltage out of

range

Internal pump communication

issue

Application

Specific Alerts

Pump driver power limit

reached Optional 2

High pump temperature

Out of

Setpoint

Tolerance

Alerts

Speed out of tolerance

Optional 2

Flow out of tolerance

Other Alerts

Data logging aborted Optional

2

Auto-resume has recovered

previous system state Never

Bubble

Notification Bubble detected Never 3

CelliconTM Perfusion Solution for Process Development User Guide 12

Settings

System Settings

General

Auto-resume

Allows the system to store the current

system state and setpoint. If power is lost,

the system recovers automatically when this

feature is enabled. An alert shows the system

has recovered its last working point using the

auto-resume feature.

Date & Time

Adjust the values up or down. Select Done

when finished adjusting the values. The date

and time format is MM-DD-YYYY HH:MM.

Flip Display

Change the orientation of the display to

landscape, portrait or upside down.

Automatic Standby Mode

Locks the screen and displays a screensaver

after a defined period of inactivity (1 to 1000

minutes). Enable this feature by selecting

the checkmark next to Enable automatic

standby mode.

In standby mode, the screensaver shows the

following information:

Standby Mode with No Active Alerts

Standby Mode with Active Alerts

To unlock the screen, select UNLOCK and enter

user account credentials.

Data Logging

The beginning of the filename can be defined

by adding a log filename. The ending is fixed

and generated with the date followed by the

time when the logfile is created.

When data logging is switched On, a prompt

to enter a filename will appear. This filename

will replace the text in the log filename

region in the settings.

A USB drive must be inserted into the controller to

start the data logging. Data will be lost if the USB

drive is removed prior to ending the data logging.

The logfile is stored as a csv-file to the

subfolder/ logs on the USB drive.

The csv-file format allows a user to open the

logfiles with Microsoft Excel.

The data logging settings also define log

interval and the log file size.

Import/Export Settings

Settings can be imported via the USB drive.

By selecting IMPORT, if any settings file is

found it will be listed within the selection list

on the popup window and can be loaded onto

the controller. Existing controller settings will

be overwritten by the settings files imported

from the USB drive.

Import Settings Popup

Export Settings enables a user to store

all controller settings on a USB drive and

transfer them to another controller.

Factory Reset

By selecting RESTORE, all the settings will be

reset to the factory setting values.

Note All the existing controller settings will

be lost by restoring factory settings.

CelliconTM Perfusion Solution for Process Development User Guide 13

Software Update

Loading a software package (.levi-file)

via the USB drive allows the customer to

perform a software update on the controller.

Select REFRESH to search the USB drive for

a file, then select Update. Only one .levi file

should be on the USB drive. The flow meter

firmware can also be updated here.

Software/ Firmware Update Wizard

About System

This section contains information about the

controller and its connected peripherals,

like serial numbers, component names and

software/firmware versions.

Sensors Settings

Note Only single-use pump heads should

be used with this controller. The

controller does not support firmware

for the multi-use pump versions.

Flowmeters

Flowmeter settings contain all configuration

parameters for each flowmeter. If a clamp-

on sensor (LFSC-i06X) is connected, the

Tubing & System Temp setting will show

the calibration sets for this sensor. The user

can choose from a list of tubing types and

operating temperatures by selecting the box

displaying the current selection. When using

the CelliconTM filter, select Advantaflex, 370C.

The low cutoff setting can be specified by

the user. Every flow value below this cutoff is

shown as 0 mlpm.

When a less noisy flow signal is required this

signal can be smoothed by increasing the

damping time. Be aware by changing this

damping time the flow control performance

can be influenced negatively.

The flow error ignore time defines how long a

flow measurement error needs to be present

until any action is taken by the system. In

flow setpoint mode the defined pump behavior

is triggered (SettingsControlsFlow

ControlPump Behavior on Flow Error). In

speed setpoint mode, when the ignore time

has expired the flow value is set to 0 mL/min,

the flowmeter shows an error.

The resolution of the flow signal can be

improved by decreasing the full scale of the

flowmeter. The resolution of the flow signal is

always 1/10,000 of the full scale. Decreasing

the full scale below 1000 mlpm affects the

max flow setpoint.

Calibrate flowmeters every one to two years.

Pressure Sensors

An offset can be defined for each pressure

sensor. This value is automatically adjusted

when the zero adjustment is performed.

A quieter pressure signal can be achieved by

increasing the damping time.

The displayed pressure unit can be either psi

or mbar.

Alerts Settings

This section allows a user to configure how

different types of alerts are communicated.

If alerts are selected as Show, a message

will appear in the alert bar area of the main

screen. If alerts are selected as audible and

full-screen, a full screen alarm appears with

an audible beep sound. Each alert will be

added to the alert log, found by selecting

Alerts from the main screen.

If the controller is in standby mode when

the alert occurs, the alert will appear on

the screensaver. It will also be added to the

backlog of alerts on the main screen.

Audible alarms can be enabled or disabled, except:

• When pump errors are configured as

visible (Show pump errors), every

pump error that occurs when the pump

is enabled results in a full screen alert

together with an audible beep sound.

• When flowmeter errors are configured as

visible (Show Flowmeter errors) and the

flowmeter gets disconnected while in flow

control mode results in a full screen alert

together with an audible beep sound.

General Alerts

Application specific alerts, data logging

aborted alerts, and out-of-setpoint tolerance

alerts are alert type 2 and can be found on

the Table of Alerts.

Bubble alerts are alert type 3 and can be

found on the Table of Alerts.

Pump Alerts

Pump errors are alert type 1 alerts and will

stop the system. Pump errors can be found

on the Table of Alerts.

Pump internal alerts are alert type 2 alerts

and can be found on the Table of Alerts.

CelliconTM Perfusion Solution for Process Development User Guide 14

Flowmeter Alerts

When alerts for Flowmeter 1 are activated,

the system will take the selected pump

behavior on flow error (SettingsControls

Flow Control Pump Behavior on Flow

Error). Flow alerts can be found in the Table

of Alerts.

Flow alarms can be configured to provide an

alert when the actual value deviates outside

a specified range.

Flowmeter

Alarm Alarm Trigger Type

Critical Low

Level

Flow falls below the

critical low level 1

Warning

Low Level

Flow falls below the

warning low level 2

Critical High

Level

Flow rises above the

critical low level 1

Warning

High Level

Flow rises above the

warning low level 2

Refer to Table of Alerts for more information.

Critical alarms (type 1 alert) are shown in

red color, and warning alarms (type 2 alert)

are shown in yellow color. Neither critical nor

warning alarms will shut down the pump.

The Show flow alarms selection activates all

the flow alarms for that sensor. The Critical

flow alarms are audible and full screen

selection enables only the critical alarms to

be audible and full-screen.

Pressure and TMP Alerts

Pressure and TMP alarms can be configured

to provide an alert when the actual value

deviates outside a specified range. These

alarm levels define when a pressure or TMP

alarm notification goes active.

Pressure &

TMP Alarm Alarm Trigger Type

Critical Low

Level

Pressure or TMP falls

below critical low level 1

Warning Low

Level

Pressure or TMP falls

below the warning low

level

2

Critical High

Level

Pressure or TMP rises

above the critical low

level

1

Warning

High Level

Pressure or TMP rises

above the warning

low level

2

Refer to Table of Alerts for more information.

Critical alarms are shown in red color (type

1 alert). Warning alarms are shown in yellow

color (type 2 alert). Neither critical nor

warning alarms will shut down the pump.

The Show Pressure/TMP alarms selection

activates all the pressure alarms for that

sensor. The Critical Pressure/TMP alarms

are audible and full screen selection

enables only the critical alarms to be audible

and full-screen.

Controls Settings

Flow Control

The Flow Control Settings define the

parameters and take effect when the system

is running in flow setpoint mode. Flow

setpoint mode is activated by switching the

toggle on the main screen to show Flow

Setpoint highlighted by a white box.

P and I parameters can be adapted to

optimize the flow control behavior.

The minimum and maximum speed define

the range of pump RPM that the system will

allow. These settings only take effect when

running in flow setpoint mode. The setpoint

increment step defines which amount the

flow setpoint is increased/decreased when

selecting +or -on the main screen.

The setpoint tolerance parameter defines the

band around the setpoint which the actual

flow must reach.

Out of tolerance alert will be activated when

the actual flow does not reach the setpoint

tolerance band within the time defined in

out of tolerance alert delay. Activate the

alert to be notified when an out of tolerance

situation is present (Settings Alerts

General Out-of-Setpoint Tolerance Alerts).

A flowmeter error can be defined when the

number of seconds exceeds the setpoint in

Flow Error Ignore Time (Settings->Sensors-

>Flowmeter). The controller takes one of the

following actions, which can be defined under

Pump Behavior on Flow Error:

• Hold Current Speed: The pump

continuously holds the same speed.

• Choose Custom Speed: The pump

defaults to the defined speed.

• Stop Pump: The pump stops.

CelliconTM Perfusion Solution for Process Development User Guide 15

Choose Pump Behavior on Flow Error

Speed Control

These define the parameters which take

effect when the system is running in speed

setpoint mode. Speed setpoint mode is

activated by moving the toggle on the main

screen to show Speed Setpoint highlighted

by a dark grey box.

The minimum and maximum speed define

the range of pump RPM that the system

will allow. These settings take effect while

running in speed setpoint mode. The pump

speed ramp defines the rate of change when

a new setpoint is selected.

The out of tolerance alert will be activated when

the actual speed does not reach the setpoint

within the time defined in Out of tolerance alert

delay. The out of tolerance notification can be

activated under SettingsAlerts General

Out-of-Setpoint Tolerance Alerts.

External Interfaces

Settings

• LAN Accessibility

• Remote Control by PLC

• PLC Analog Input

• PLC Digital Input

• PLC Analog Output

User Accounts Settings

The administrator can generate, delete

and edit user accounts, including password

protection capabilities and rescrict access

permissions.

The administrator can define up to six

user accounts. After selecting the + Add

new user button, enter a username and

password, then press Set permissions. The

following permissions can be activated or

deactivated:

• Controller control – User can start/stop

the pump, change the setpoint, zero

adjust, and view priming instructions.

• Settings access – User can adjust all

settings.

• Data log access – User can turn on/off

data logging.

Create a New User

Set Permissions for New User

The active user can be changed by selecting

the user account icon in the top right region

of the screen and selecting Switch user.

When the screen is locked, any user account

can be selected to access the controller.

Only the administrator can change

permissions for each user, but users can

change their password when signed into their

account.

User Accounts Settings from a Non-

administrator Account

Access Denied Due to User Permissions

CelliconTM Perfusion Solution for Process Development User Guide 16

Shutdown

When the power button is pressed a

confirmation pop-up will appear. After

confirmation, the controller software initiates

the shutdown.

Shutdown Confirmation

When the main power button is pressed

for more than 4 seconds, the hardware

shutdown is triggered, the pump turns OFF

and the controller immediately shuts down.

Planning for a

Run

If possible, the CelliconTM Perfusion filter

should be attached to the bioreactor and

the recirculation pump should be turned

on during the media hold phase, before

cells have been added to the reactor. This

will eliminate the possible introduction of

cell shear when the system is primed (see

Priming).

Preparation

Equipment Needs

The following user supplied items may be

required to execute a perfusion process:

• Assembled and sterilized bioreactor, up to

3L working volume

• Control system for the bioreactor

•

(Advantaflex) tubing to attach the filter

• Peristaltic pump for the perfusate

(permeate)

• Peristaltic pump for priming

• Method to control the liquid level in the

bioreactor to maintain a constant volume

• Power outlet for plugging in the cell

retention system (100-240V, 1.7A max,

50/60hz)

• Sterile collection vessels to contain the

fresh media and collect the spent media

during the run.

• USB drive for data collection

CelliconTM Perfusion Solution for Process Development User Guide 17

P&ID for N-1 Perfusion Process.

Mobius 3L Bioreactor

Preparing the

Bioreactor

Connect the filter to the bioreactor by

welding Advantaflex tubing on the assembly.

To optimize process efficiency, reduce

the holdup of cell culture volume in the

recirculation loop outside of the bioreactor

by shortening the tubing length between the

bioreactor and the filter assembly. Tubing ID

in the recirculation loop. If using a diptube,

ensure that the ID of the diptube is between

Place the inlet to the cell retention filter

below the liquid level of the bioreactor, so it

will not pull in any bubbles that have been

released from the sparger.

Note Any air or gas in the pump head will

negatively affect pump performance

and decrease the recirculation flow rate.

MobiusTM 3L Single-use Bioreactor

When using the MobiusTM single-use 3L

reactor, the inlet to the cell retention

filter should be welded to the harvest line

(bottom) of the bioreactor. The retentate line

should be welded to one of the submerged

ports that does not contain a check value

(see image X). This is the ideal orientation

for the CelliconTM Perfusion filter because

sparger will be less likely to pull bubbles in,

and priming the system is easier.

Other Bioreactors

The CelliconTM Perfusion Solution for

Process Development can be used with any

bioreactor, single or multi use, with a working

volume of 3L or less. On single use reactors,

choose the harvest line as the inlet to the

filter. On most glass reactors, use a harvest

tube that extends below the sparger, or add

a length of tubing that extends to the bottom

of the diptube below the sparger.

CelliconTM

Filter

CelliconTM Perfusion Solution for Process Development User Guide 18

Operating Parameters

The bench scale N-1 perfusion filter was

designed for N-1 perfusion processes

targeting:

• 3-5 days of perfusion

• 2.7 L working volume

• 2 VVD

• 50 million cells/mL cell density

The performance of the filter is specific to

the cell line and media combination, as well

as the chosen operating parameters. The

most critical factors that impact performance

are perfusate (permeate) flux, which should

be less than 23 L/m/hr, cell density, and

crossflow rate.

Starting a Run

Priming

The recirculation pump for the cell retention

device is a magnetically coupled centrifugal

pump. It enables the assembly to be

single use and disposable while providing a

consistent and low shear flow rate. The pump

does not self-prime (will not successfully

pump unless it is filled with liquid).

When the bioreactor is in media hold and

the cell retention filter has been attached,

a priming procedure is performed to start

recirculation. Due to the harvest port location

on the MobiusTM 3L, it may prime after

unclamping the feed line. In this case, the

tubing will fill with liquid and recirculation

flow can start from the controller. If the

tubing does not self-prime, a secondary

peristaltic pump is required to start the

flow recirculation. Step-by-step priming

instructions can be found by clicking Prime

system on the main menu screen.

Priming Procedure

1. Select Prime system on the main menu

screen. This will switch the controller into

Speed setpoint mode and provide step-

by-step guidance on how to complete the

priming.

2. Ensure that the perfusate (permeate) line

is clamped.

3. Take an external peristaltic pump and

place the pump head on the feed line of

the cell retention device loop.

4. Turn on external peristaltic pump (<100

mL/min) and allow liquid to flow until

there are no bubbles left in the feed line

or pump head. If necissary, adjust the

angle to remove all bubbles.

5. Stop external peristaltic pump but leave it

clamped so bubbles do not return to the

feed line.

6. Select START PUMP on the controller

with the speed setpoint at 3000 RPM.

Quickly remove the external peristaltic

pump from the feed line, allowing flow to

recirculate through the device. Increase

the RPM to clear bubbles from the loop.

7. Select Exit Priming (returns to flow

setpoint mode). The flow will adjust

to the setpoint that was previously

entered in flow setpoint mode. Adjust

the flow setpoint according to the desired

recirculation rate for the run (100 mL/

min).

8. Select Zero adjust from the control

region of the main screen. Refer to Zero

Adjust for more information.

Turning the Pump On

The system is ready to begin recirculation

flow once the flow path has been primed and

the sensors have been zero adjusted.

There are two ways to operate the pump

between Flow setpoint and Speed setpoint,

indicated by the toggle on the main screen.

Ensure that Flow setpoint is selected for the

perfusion run. Speed setpoint is intended

to be used for priming only. See below for a

description of each setpoint:

CelliconTM Perfusion Solution for Process Development User Guide 19

Flow

setpoint

User inputs a desired flow rate

and system will maintain that

flow rate by adjusting pump RPM.

Speed

setpoint

User inputs a desired speed in

RPM and is held constant, but

actual flow rate may fluctuate.

For this reason, the speed

setpoint is recommended only

when priming the system.

In flow setpoint mode the user can define the

desired crossflow rate. The bench scale filter is

recommended to run at a crossflow of 100 mlpm.

Select START PUMP to begin and leave the

pump on for the duration of the run.

Starting Perfusion

Once the cell retention device and system

have been attached and primed, cells can be

added to the bioreactor. Typically there is a

delay between the inoculation and the start

of perfusion. The recirculation pump can

remain on during this time.

Before starting perfusion, a closed and sterile

perfusate (permeate) line must be welded to

a collection vessel (bag or bottle) to collect

the spent media. Attach a peristaltic pump

(not included with the cell retention system)

to the perfusate (permeate) tubing line to

pull spent media out of the cell retention

device. Continuously run the perfusate

(permeate) pump at a flow rate of 23 LMH

or less. If the flow rate of the perfusate

(permeate) pump is greater than 23 LMH it

might prematurely foul the filter. The flow

rates chosen (VVDs – vessel volumes per

day) are specific to each process.

Run Maintenance

Data Logging

Insert a USB flash drive into the USB port

in the back of the controller. The controller

can record process data while a run is in

progress. Data logging can be initiated by

selecting the toggle on the bottom, right-

hand corner of the main menu screen to On.

Select the toggle again to switch back to Off

and stop data logging. Removed the USB

drive from the controller.

To adjust data logging settings, select

Settings System Data Logging. Choose

the name of the file saved on the USB drive,

the log interval, and the log file size. Choose

a log interval of 60 seconds or greater and a

log file size of 65000 lines.

Insert the USB drive into a computer to view

data. Open Microsoft Excel and click the Data

tab on top, then download data From Text/

CSV. Choose the correct file from the flash

drive and follow prompts to open data in a

new sheet.

Sampling the

Perfusate (Permeate)

A sampling container should be used to take

samples from the perfusate (permeate) of

the device. The sampling container should

be placed between the perfusate (permeate)

pump and the perfusate (permeate)

collection bag.

Follow this procedure to take a sample:

1. Locate sample collection vessel.

2. Briefly stop perfusate (permeate) pump,

clamp line to collection vessel (Clamp 2) and

unclamp line to sampling container (Clamp 1).

3. Start the perfusate (permeate) pump

and fill sampling container until the

appropriate volume is collected.

4. Stop the perfusate (permeate) pump,

clamp sampling line (Clamp 1), unclamp

collection vessel line (Clamp 2).

5. Restart perfusate (permeate) pump.

6. Use a syringe to collect sample from

sampling container.

Changing the Filter

The CelliconTM Perfusion filter has been

designed to have a high throughput to

support N-1 perfusion applications. The

pressure profile of the pressure sensors and

the recorded TMP can describe fouling of

the membrane. If fouling occurs it will cause

the perfusate (permeate) pressure (P3) to

become negative, and will increase the TMP

reading (TMP = [(P1 + P2) / 2 ] – P3). Stop

the run when TMP > 5 psi.

If the run is not complete when TMP = 5

psi, replace the old filter with a new filter

and continue the run. Follow these steps to

replace the filter:

1. Pause the perfusate (permeate) pump.

2. Turn off the recirculation pump by

selecting STOP PUMP on the main menu.

3. Use a tube sealer to seal the lines

connecting to the old filter. Three

seals are needed on: the feed line,

the retentate line, and the perfusate

(permeate) line. Ensure there is enough

space on the bioreactor side to complete

another weld when the new device is

added.

4. Cut through the middle of all three tube

seals to disconnect the old filter.

CelliconTM Perfusion Solution for Process Development User Guide 20

5. Locate a new filter and place it in the

holder.

6. Use a tubing welder to connect the

new filter to the tubing lines that were

designated for feed, retentate, and

permeate.

7. Unclamp the feed and retentate lines, but

ensure that the perfusate (permeate) is

clamped.

8. Prime the system again. If using a

peristaltic pump, run at a low flow rate to

avoid causing shear damage to the cells

in the line.

9. Restart the recirculation pump by

selecting START PUMP on the main

menu. Ensure that the flow rate has

reached the desired setpoint.

10. Restart the perfusate (permeate) pump.

Troubleshooting

System Troubleshooting

The following chart can be used to help identify issues related to system operation.

Symptom Corrective Action

No power Plug in system and press power button

System

component

appears light grey

and does not read

values

Connect cables from component to controller

Install correct software

Component is in

an alarm state,

appears red or

yellow

Plug in component cables

Pump alert: Place pump head into motor

Flow alert: Place tubing into flowmeter and

prime tubing

Adjust flow alarm ranges

Follow instructions provided for specific alert

Assembly does

not fit into holder

Follow order of operations for installation found

in user guide

Pump head does

not fit into motor

Pull out locking pin during installation and move

barb from covering green area to covering red

area

Place pump head facing upwards

System does not

allow changes

Check login credentials and user permissions

Disable “When LAN Accessibility is enabled,

console control is disabled” setting under

Settings->External Interfaces->LAN Accessibility

System will not

prime

Use external peristaltic pump to start flow

Choose peristaltic pump appropriate for the

tubing size

Ensure dip-tube is open and submerged in liquid

No pinching or kinking of tubing lines, welds are

open

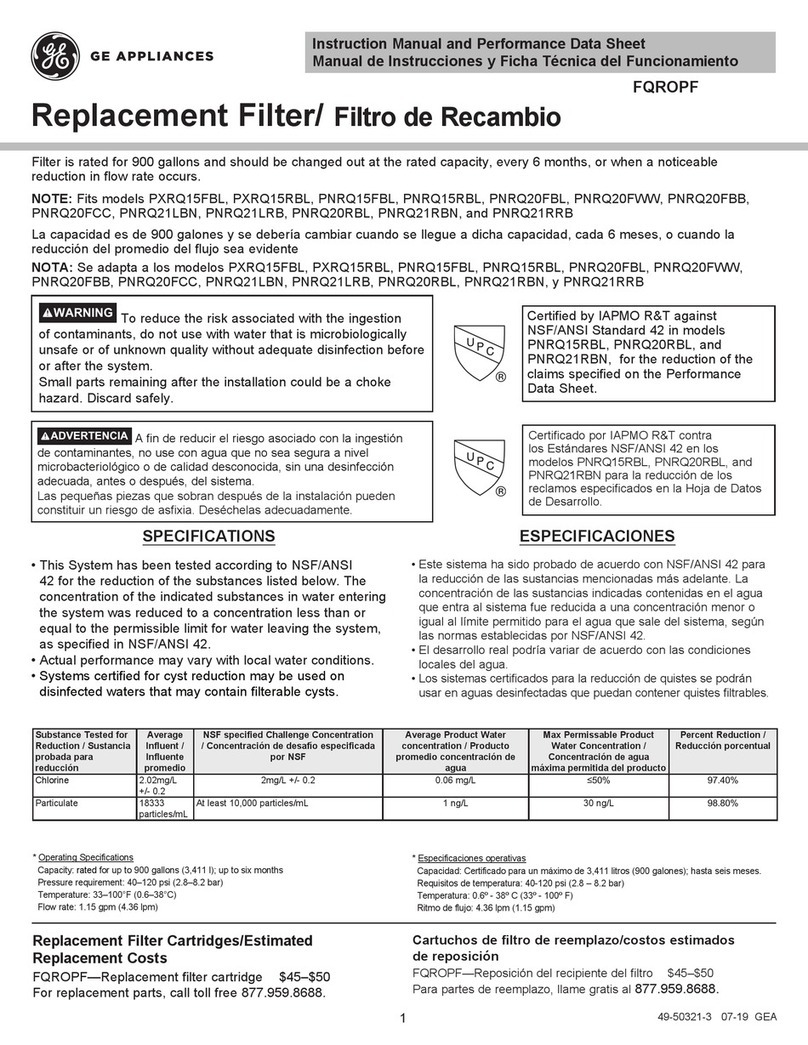

Table of contents

Other Merck Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Environmental Water Systems

Environmental Water Systems Spectrum CS-EWS-1354-7000 installation guide

First Sales

First Sales IBW10-1 Installation instructions and owner's manual

Watts

Watts PWRO4 Installation, operation and maintenance manual

Rockford Fosgate

Rockford Fosgate RLS-1815 Owner's maintenance guide/INSTALLATION INSTRUCTIONS

Hydrotec

Hydrotec HYDROION VAS-CS Series Operating and maintenance manual

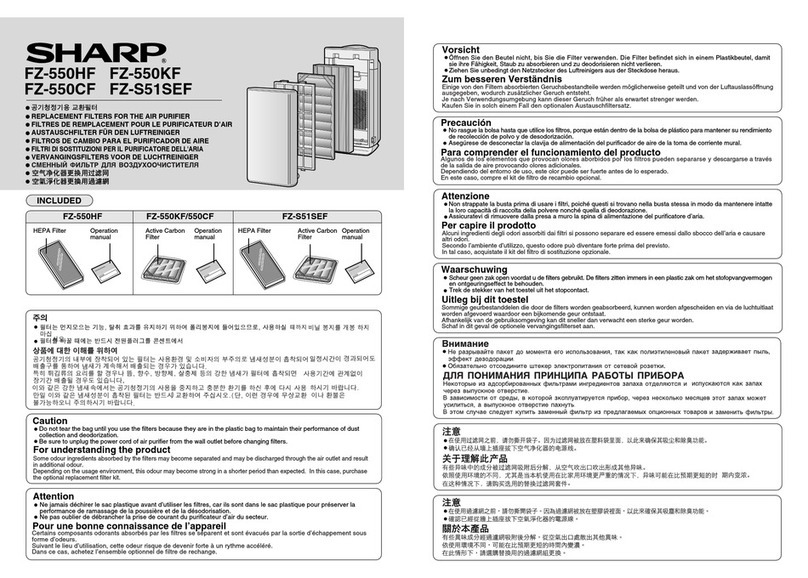

Sharp

Sharp FZ-550HF Replacement parts